Continuous casting method for increasing equal thickness continuous casting plate billet equal axial crystal rate in non-oriented silicon steel

A technology of oriented silicon steel and equiaxed crystallinity, applied in the field of steel-making slab continuous casting, can solve the problems of unable to produce high-grade non-oriented silicon steel, unable to install electromagnetic stirring device, small space of continuous casting machine, etc. Corrugation defects, effects of improved thermodynamic and kinetic conditions, improved interior and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

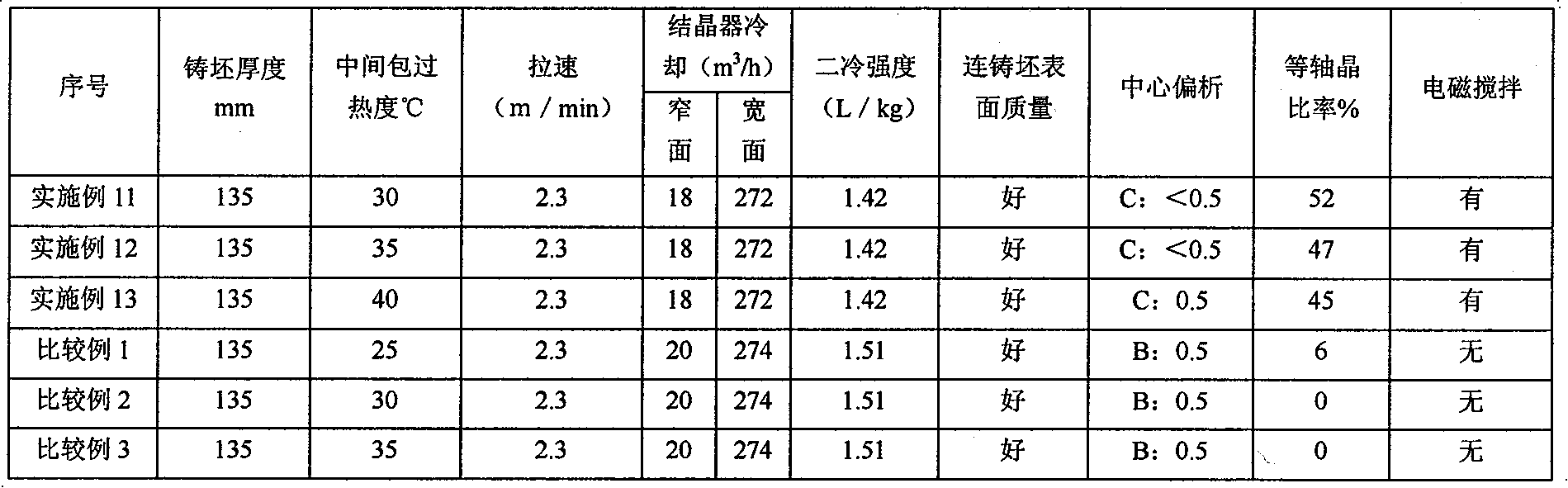

[0014] Converter smelting, RH-TB vacuum treatment to obtain C: 0.003%, Si: 2.0%, Mn: 0.25%, P: 0.08%, S: 0.005%, Al: 0.25%, N: 0.0035%, O: 0.012%, Ti , V, Nb, Zr, Gr, Cu and other trace alloys are all 3 / h, the flow rate of cooling water on the wide side of the crystallizer is 272m 3 / h; Two-hole submerged nozzle, nozzle angle 15°. Compared with the proportion of equiaxed grains of continuous casting slab produced without electromagnetic stirring, see Table 1.

[0015] Table 1 Effect of electromagnetic stirring and continuous casting process system on the internal quality of 135mm thick slab

[0016]

Embodiment 2

[0018] Converter smelting, RH-TB vacuum treatment to obtain C: 0.0040%, Si: 2.0%, Mn: 0.3%, P: 0.08%, S: 0.004%, Al: 0.27%, N: 0.0040%, O: 0.012%, Ti , V, Nb, Zr, Gr, Cu and other trace alloys are all less than 0.005%, and the rest is Fe. It is continuously cast into slabs and hot rolled at a casting speed of 2.0m / min, and then pickled and cold rolled into 0.5mm thick slabs. Cold-rolled sheet, finished silicon steel sheet after final annealing. Continuous casting machine crystallizer cooling system: the flow rate of cooling water on the narrow side of the crystallizer is 19m 3 / h, the flow rate of cooling water on the wide side of the crystallizer is 274m 3 / h; Two-hole submerged nozzle, nozzle angle 15°. Compared with the proportion of equiaxed grains of continuous casting slab produced without electromagnetic stirring, see Table 2.

[0019] Table 2 Effect of electromagnetic stirring and continuous casting process system on the internal quality of 150mm thick slab

[0020...

Embodiment 3

[0022] Converter smelting, RH-TB vacuum treatment to obtain C: 0.003%, Si: 2.0%, Mn: 0.25%, P: 0.08%, S: 0.004%, Al: 0.28%, N: 0.0035%, O: 0.011%, Ti , V, Nb, Zr, Gr, Cu and other trace alloys are all less than 0.005%, and the rest is Fe. It is continuously cast into slabs and hot rolled at a casting speed of 2.5m / min, and then pickled and cold rolled into 0.5mm thick slabs. Cold-rolled sheet, finished silicon steel sheet after final annealing. Mold cooling system of continuous casting machine: the cooling water flow rate of the narrow side of the mold is 18m 3 / h, the flow rate of cooling water on the wide side of the crystallizer is 270m 3 / h; Two-hole submerged nozzle, nozzle angle 15°. Compared with the equiaxed grain ratio of continuous casting slab produced without electromagnetic stirring, see Table 3.

[0023] Table 3 Effect of electromagnetic stirring and continuous casting process system on the internal quality of 100mm thick slab

[0024]

[0025]Tables 1 to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com