Converter slag forming process for rapid slagging

A converter and slagging technology, which is applied to the improvement of process efficiency, manufacturing converters, lime production, etc., can solve the problems of affecting the dust removal effect of fans, waste of lime, affecting the speed of slag making, etc., so as to reduce lime consumption and production. cost, the effect of improving the speed of slag formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

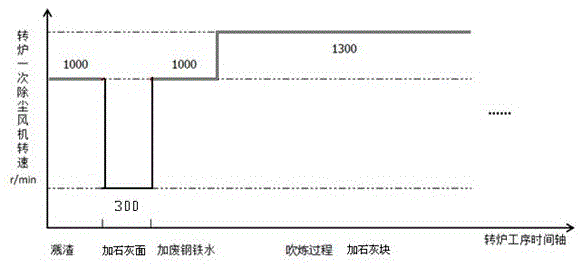

[0040] When the molten iron silicon is 0.41%, the primary fan speed changes:

[0041] When the converter is slag splashing, keep the primary fan speed at 1000r / min. After the slag splashing is over, the fan speed will drop to 300r / min. After watering, increase the fan speed to 1300r / min until the end of blowing.

[0042] Lime material addition amount:

[0043] The amount of lime surface added is 1500kg. When loading molten iron, the impact of molten iron is used to make slag initially, so that the lime is distributed in a dispersed manner. The first batch of lime blocks of 1500kg can be added in the early stage of blowing for 1 minute to form a smelting stage with the ash surface before iron loading. converter slag.

Embodiment 2

[0045] When the molten iron silicon is 0.45%, the primary fan speed changes:

[0046] When the converter is slag splashing, keep the primary fan speed at 1000r / min. After the slag splashing is over, the fan speed will drop to 300r / min. After watering, increase the fan speed to 1300r / min until the end of blowing.

[0047] Lime material addition amount:

[0048] The amount of lime surface added is 1700kg. When the molten iron is loaded, the impact of the molten iron is used to make slag initially, so that the lime is distributed in a dispersed manner. The first batch of lime blocks of about 1700kg can be added in the first 75 seconds of blowing to form a smelting process with the ash surface before iron loading. Early converter slag.

Embodiment 3

[0050] When the molten iron silicon is 0.50%, the primary fan speed changes:

[0051] When the converter is slag splashing, keep the primary fan speed at 1000r / min. After the slag splashing is over, the fan speed will drop to 300r / min. After watering, increase the fan speed to 1300r / min until the end of blowing.

[0052] Lime material addition amount:

[0053] The amount of lime surface added is 2000kg. When the molten iron is loaded, the impact of the molten iron is used to make slag initially, so that the lime is distributed in a dispersed manner. The first batch of lime blocks of about 2000kg can be added in the first 90 seconds of blowing to form a smelting process with the ash surface before loading the iron. Early converter slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com