No-fluorine composite slag melting agent for converter steelmaking and its production process

A converter steelmaking and production method technology, applied in the manufacture of converters, etc., can solve problems such as blockage of hoppers, prolonging the smelting cycle, and splashing, and achieve the effects of prolonging service life, shortening smelting time, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

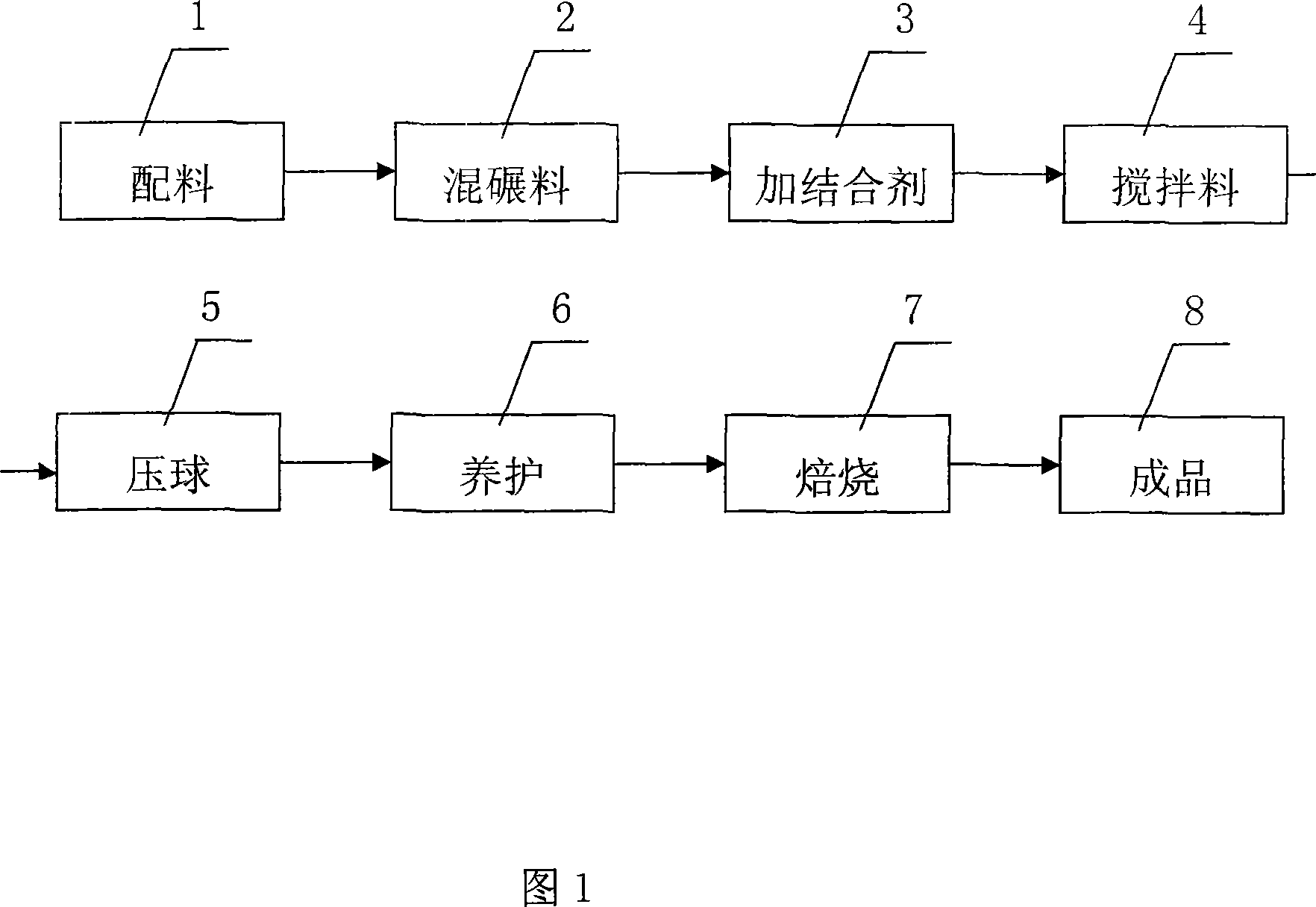

Method used

Image

Examples

Embodiment

[0023] This slag-removing agent is used in the No. 4 converter of a steel plant: a combined blowing converter with a nominal capacity of 30 tons. Its components and contents are iron oxide FeO: 43.70%; calcium oxide CaO: 12.40%; manganese oxide MnO: 12.02% ; Magnesium oxide MgO: 2.08%; Aluminum oxide Al 2 o 3 : 2.54%, and the units used for the remaining components have not been tested. The total test volume is 8 tons. The specific test data are shown in Table 1 and Table 2.

[0024]

[0025] furnace number

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com