Fluoride-free refining slag for 20 Cr structural alloy steel and preparation method thereof

A technology for alloying structural steel and refining slag, applied in the field of steelmaking, can solve the problems of increased equipment maintenance cost, slow melting speed of slag, chronic poisoning of livestock, etc., and achieves significant fluxing effect, light corrosion of furnace lining, and elimination of fluorine pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

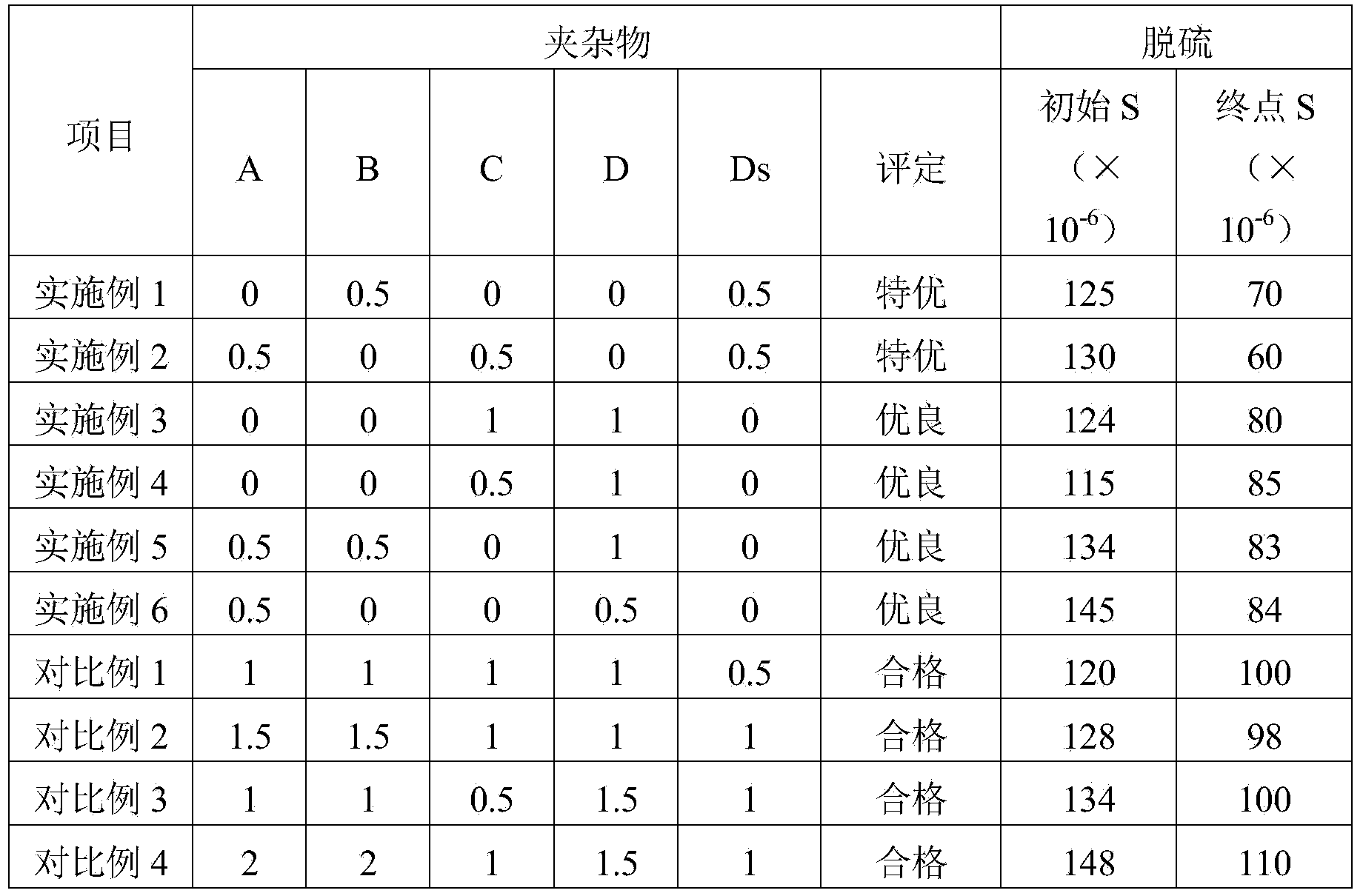

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with specific embodiments.

[0028] The preparation method of the fluorine-free refining slag of the present invention is: will have CaO, SiO 2 、Al 2 o 3 , MgO and B 2 o 3 Raw materials of ingredients: active lime, calcium aluminate, wollastonite, dolomite and boric anhydride are crushed → batched → formed into refining slag with a particle size of 15-35mm, and the components in the refining slag are as follows by weight percentage: 55~60%CaO, 10~16%SiO 2 , 15~20%Al 2 o 3 , 4~6%MgO, 5~10%B 2 o 3 , TFe≤1%, the balance is impurities, and the particle size of refining slag is 15-35mm. Those skilled in the art can know, when adopting other have CaO, SiO 2 、Al 2 o 3 , MgO and B 2 o 3 During the raw material of composition, as: limestone, quartz stone, bauxite, light burnt dolomite and boric anhydride, can solve technical problem of the present invention equally, reach technical effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com