Metallurgy lime powder utilization system and technology method

A process method, lime powder technology, applied in the direction of process efficiency improvement, etc., can solve the problems of increased steelmaking production costs, low lime activity, increased lime consumption, etc., to reduce the lime consumption index per ton of steel and fast slagging speed , the effect of increasing the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The high-efficiency utilization system of metallurgical lime powder in this embodiment, the system includes a vibrating screen arranged on the lime raw material supply section for screening lime powder with a particle size below 5mm, and a lime powder briquetting ball for briquetting the lime powder Machine and the lime powder conveying unit connecting the vibrating screen and the lime briquette machine, wherein the lime powder conveying unit transports the lime powder screened out by the vibrating sieve to the lime powder briquette machine, and the lime powder The briquetting machine performs the briquetting operation on the lime powder to obtain a particle size of 20mm-40mm and a specific gravity of 1.9-2.2t / m 3 lime balls. The vibrating screen is arranged at the operation station of the bulk material feeding system of the steelmaking furnace.

Embodiment 2

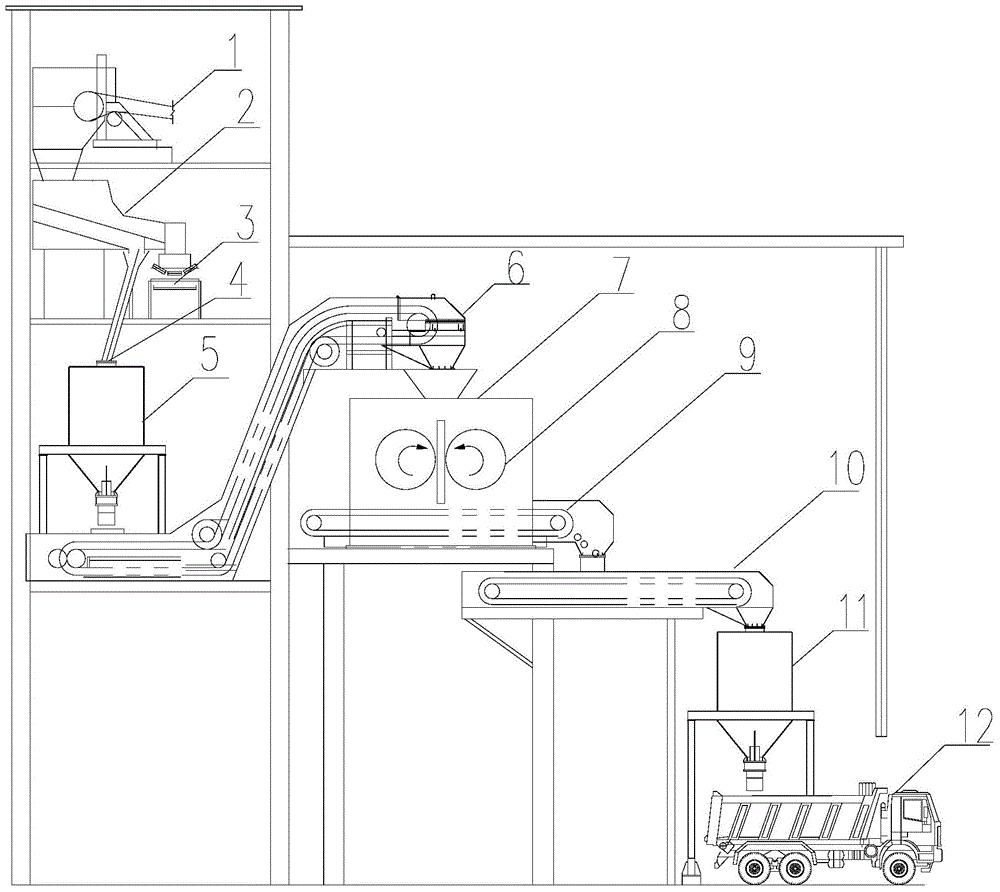

[0037] Such as figure 1 As shown, the high-efficiency utilization system of metallurgical lime powder in this embodiment includes a vibrating screen arranged on the lime raw material supply section for screening lime powder with a particle size below 5 mm, and a lime powder briquetting ball for briquetting the lime powder. Machine and the lime powder conveying unit connecting the vibrating screen and the lime briquette machine, wherein the lime powder conveying unit transports the lime powder screened out by the vibrating sieve to the lime powder briquette machine, and the lime powder The briquetting machine performs the briquetting operation on the lime powder to obtain a particle size of 20mm-40mm and a specific gravity of 1.9-2.2t / m 3 lime balls. The vibrating screen is arranged at the tail of the lime kiln product belt conveyor.

[0038]The lime powder conveying unit includes a discharge chute connected to the sieve opening of the vibrating screen, and a lime powder stor...

Embodiment 3

[0044] The high-efficiency utilization process method of metallurgical lime powder in this embodiment is realized by adopting the above-mentioned high-efficiency utilization process method of metallurgical lime powder. The process method includes: separating and transporting the lime powder with a particle size below 5mm on the lime raw material supply section to the lime powder briquetting machine. Described lime powder is carried out pressure ball operation to described lime powder, obtains particle size as Specific gravity is lime balls.

[0045] Process flow of this embodiment

[0046] Lime kiln finished product belt conveyor tail or bulk material feeding system - vibrating screen (lime powder below 5mm screening) - discharge chute - lime powder intermediate storage bin - third belt conveyor - lime powder briquetting machine - first Four-belt conveyor—lime ball finished product warehouse—dump truck.

[0047] Explanation of the embodiment: the metallurgical lime passes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com