Calcium aluminate for desulfurization of ultralow titanium and carbon steel and preparation method thereof

A calcium aluminate and ultra-low titanium technology, which is applied in the field of steelmaking and refining, can solve the problems of titanium increase and molten steel carbon increase, and achieve the effects of fast slag formation, control of carbon increase amount, and reduction of production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

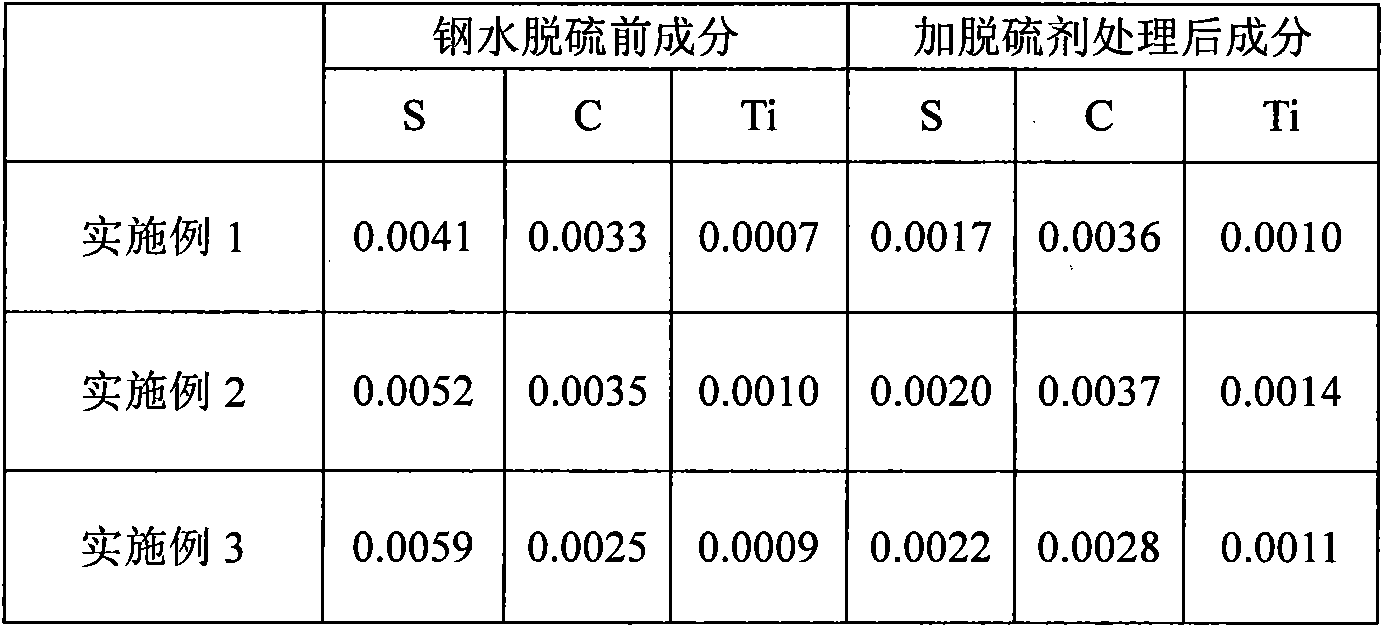

Examples

Embodiment 1

[0019] (1) Add raw materials according to the following weight percentages: CaO: 61%, Al: 39%. The particle size of CaO is 0-10mm, and the particle size of Al is 0-10mm.

[0020] (2) The raw material granules are mechanically mixed in a mixer, and the mixing time is 2 hours.

[0021] (3) Put the mixture into the melting furnace, and then inject fuel oil for heating. The calorific value of the fuel oil is 41900 kJ, the weight percentage of the sulfur content is less than 1.2%, and the temperature of the furnace is raised to 980°C.

[0022] (4) Inject oxygen into the furnace for smelting. The melt was warmed to 1470°C.

[0023] (5) Take it out of the oven, cool it down, and crush it for use. When the temperature is above 1400°C, control the cooling rate to 4°C / min. The finished product specification is 5-10mm.

[0024] Through the above operations, the calcium aluminate composition of the gained is (% by weight): Ca 12 Al 14 o 33 : 95.11%, Ca 3 Al 2 o 6 : 1.82%, Ca ...

Embodiment 2

[0026] (1) Add the following raw materials according to the following weight percentages: CaO: 63%, Al: 37%. The particle size of CaO is 0-7mm, and the particle size of Al is 0-7mm.

[0027] (2) The raw material granules are mechanically mixed in a mixer, and the mixing time is 2.5 hours.

[0028] (3) Put the mixture into the melting furnace and then inject fuel oil for heating. The calorific value of the fuel oil is 42200 kJ, the weight percentage of the sulfur content is less than 1.2%, and the furnace temperature is raised to 1005°C.

[0029] (4) Inject oxygen into the furnace for smelting. The temperature of the melt was raised to 1480°C.

[0030](5) Take it out of the oven, cool it down, and crush it for use. When the temperature is above 1400°C, control the cooling rate to 3°C / min. The finished product specification is 5-15mm.

[0031] Through the above operations, the calcium aluminate composition of the gained is (% by weight): Ca 12 Al 14 o 33 : 95.39%, Ca 3...

Embodiment 3

[0033] (1) Add the following raw materials according to the following weight percentages: CaO: 64%, Al: 36%. The particle size of CaO is 0-5mm, and the particle size of Al is 0-5mm.

[0034] (2) The raw material granules were mechanically mixed in a mixer, and the mixing time was 3.5 hours.

[0035] (3) Put the mixture into the melting furnace and then inject fuel oil for heating. The calorific value of the fuel oil is 43210 kJ, the weight percentage of the sulfur content is less than 1.1%, and the temperature of the furnace is raised to 1010°C.

[0036] (4) Inject oxygen into the furnace for smelting. The melt was warmed to 1490°C.

[0037] (5) Take it out of the oven, cool it down, and crush it for use. When the temperature is above 1400°C, control the cooling rate to 3°C / min. The finished product specification is 5-25mm.

[0038] Through the above operations, the calcium aluminate composition of the gained is (% by weight): Ca 12 Al 14 o 33 : 96.67%, Ca 3 Al 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com