Recycling method of refining white slag

A technology of white slag and slagging agent, which is applied in the direction of recycling technology and improvement of process efficiency, etc., can solve problems such as waste of resources, achieve the effects of reducing solid waste emissions, reducing refining power consumption, and reducing the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

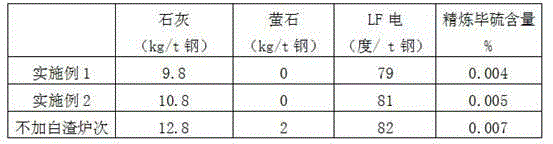

Embodiment 1

[0020] Embodiment 1: The recycling method of this refined white slag (steel type Q345B 120 tons of molten steel / steel), the specific steps are as follows:

[0021] (1) The ladle temperature is 1558°C when the primary furnace is tapped, the ladle is well blown with argon, and the free space is 600mm. It is directly poured into the upper furnace and poured into the liquid refining white slag of 720kg. Sampling before pouring the refining slag C: 0.063%, S: 0.037%;

[0022] (2) LF refining: 700kg of lime, 1800kg of silicon-manganese alloy, 300kg of calcium carbide, 50kg of silicon carbide, yellow and white slag are added within 10 minutes after the refining seat is powered on, and the temperature is measured at 1547°C by power cut. Minute sampling: C: 0.085%, S: 0.029%; continue power supply for 15 minutes, add 400kg of lime, 550kg of silicon-manganese alloy, 100kg of ferrosilicon powder, cut off power and measure temperature at 1608°C, blow argon for 2 minutes. Sampling: C: 0.13...

Embodiment 2

[0023] Embodiment 2: The recycling method of this refined white slag (steel type Q345B 120 tons of molten steel / steel), the specific steps are as follows:

[0024] (1) The ladle temperature at the end of the primary smelting furnace is 1549°C, the ladle is well blown with argon, the free space is 500mm, and the sampling C: 0.067%, S: 0.042%;

[0025] (2) After the LF refining seat bag is powered on, first add 480kg of solid refining white slag, then add 600kg of lime, 1800kg of silicon-manganese alloy, 300kg of calcium carbide, 50kg of silicon carbide, and yellow and white slag. Aluminum wire 600m, argon blowing for 1 minute sampling: C: 0.078%, S: 0.031%; continue to power on for 15 minutes, add lime 500kg, silicomanganese alloy 600kg, ferrosilicon powder 80kg, cut off power and measure temperature at 1602℃, blow argon Sampling in 2 minutes: C: 0.147%, S: 0.009%; continue power supply for 8 minutes, add 200kg of lime, cut off power and measure temperature at 1639°C, sampling:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com