Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

189 results about "Calcium ferrite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintering method for high-chromic vanadium-titanium ferroferrite

The invention discloses a sintering method of high-chromine typed V-Ti-bearing iron ore, which comprises the following steps: 1) allocating limestone and fined ferric ore to make grain; 2) adding water to wet; 3) putting wet and grained materials into sintering material in the mixer to ball; adding B2O3 in the composite material; 4) adding MgO in the composite material; 5) loading the composite material into sintering cup or sintering machine to sinter over 50 deg.c; increasing the content of calcium ferrite in the sintering ore by 5% and production by 4.2-5.0%.

Owner:PANZHIHUA IRON AND STEEL

Stripping method for diasporite type bauxite

ActiveCN101054626ASolid waste managementProcess efficiency improvementResource utilizationPre treatment

A releasing method of monohydrate hard bauxite ore belongs to alumina production technical field, especially a pretreatment of pulp additive calcium ferrite and calcareousness and regeneration method of pretreated lye. The releasing process comprises: pretreating the bauxite by lye, calcium ferrite 2CaO.Fe2O3, calcareousness CaO, then performing centrifugal separation, releasing the separated solid under the common Bayer process releasing condition; adding calcareousness in the used pretreated lye, removing the alumina in solution, regenerating the pretreated lye. The method can economically treat monohydrate hard bauxite ore containing silicon by Bayer process, improves the resource utilization factor and provides a technical support to the aluminium industry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Steel-making dephosphorization agent and preparation method thereof

InactiveCN102787212AReduce manufacturing costImprove product qualityChemical indexToxic industrial waste

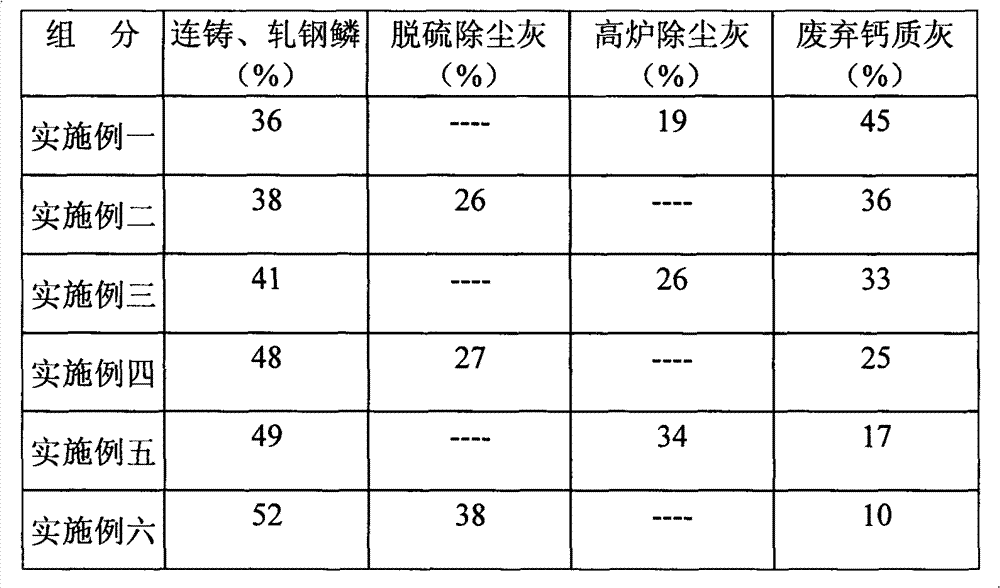

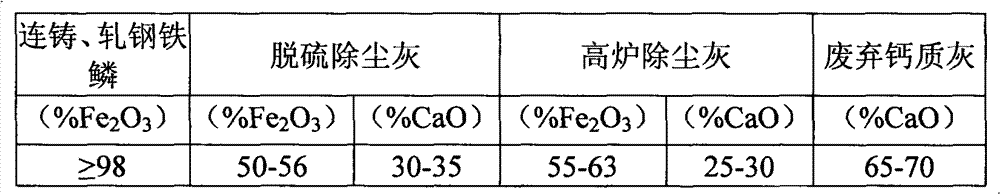

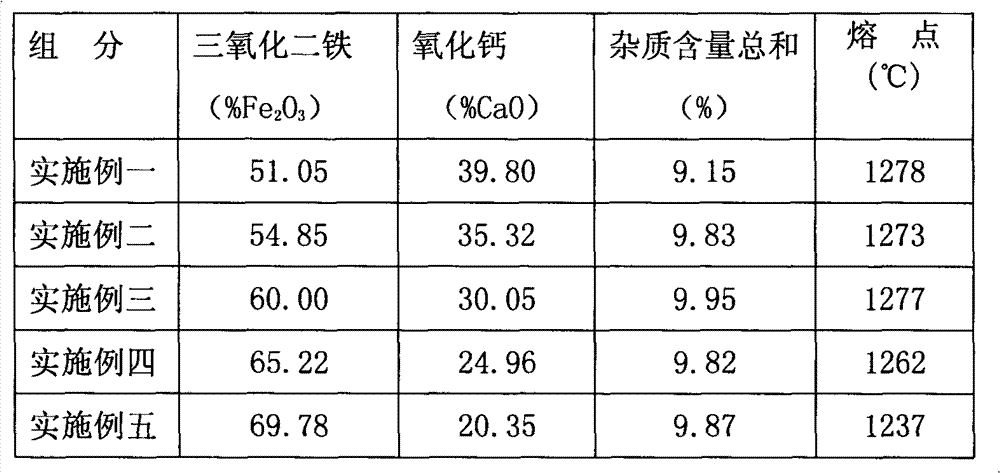

The invention puts forward a steel-making dephosphorization agent and a preparation method thereof. Raw materials of the dephosphorization agent mainly comprise industrial waste rich in calcium oxide and iron oxide. The preparation method thereof comprises preparing the raw materials, crushing, mixing, stirring, smelting at a high temperature of 1500 to 1550 DEG C, cooling crystallization after melting and tapping, breaking to mold, and obtaining the calcium ferrite dephosphorization agent rich in CaO and Fe2O3 and having a particle size of 5 to 40 mm, wherein the prepared steel-making dephosphorization agent has a main phase of 2Cao.Fe2O3, a melting point of not more than 1280 DEG C, the melting point having a small fluctuation range, stable components, and a variety of equivalent physical and chemical indexes to steel-making dephosphorization agents prepared from high-purity materials. According to the invention, the method is low in production cost, and the product is stable in quality, pollution-free and easy to store. The method is beneficial to popularization and development of a dephosphorization technology.

Owner:辽宁中汇环保科技有限公司

Preparation method of calcium ferrite

The invention relates to a preparation methodof calcium ferrite, which belongs to the technical field of metallurgy. The method comprises the following steps of: (a) mixing gypsum, pyrite and iron supplements to obtain a mixed material, wherein the molar ratio of calcium sulphate in gypsum to ferrous disulfide in pyrite to iron element in the iron supplements is 1: (0.1-2.5): (0-2), the molar ratio of calcium element to the iron element in the mixed material is 1: (1-2.5), the water content of the gypsum is less than 10wt%, and the water content of the pyrite is 0.1-15wt%; and (b) roasting the mixed material for 0.1-4 hours at a roasting temperature of 900-1500 DEG C under a protective atmosphere, and after the roasting is finished, cooling to obtain calcium ferrite, wherein the protective atmosphere is an inert atmosphere or a reductive atmosphere or an oxidative atmosphere with an oxygen content of less than 5 wt%.

Owner:SICHUAN UNIV +1

High-hardness waterproof wallpaper

InactiveCN106867372AImprove waterproof performanceWell mixedCoatings with pigmentsCovering/liningsEpoxyPolyvinyl chloride

The invention discloses high-hardness waterproof wallpaper. The high-hardness waterproof wallpaper comprises a base material layer, a waterproof layer and a high-hardness protective layer, wherein the periphery of the base material layer is coated with the waterproof layer; the periphery, away from the base material layer, of the waterproof layer is coated with the high-hardness protective layer; raw materials of the high-hardness protective layer comprise rosin phenolic resin, modified polyurethane, styrene-acrylic emulsion, polyvinyl chloride resin, nano inorganic antibacterial powder, rosin resin, epoxy resin, alkyd resin, n-butyl acetate, aluminum hydroxide, calcium ferrite, nitro-cotton, mica powder, zinc oxide, chlorinated paraffin, calcium ferrite, modified aids, a silane coupling agent KH-570, hexamethylcellulose, citric acid and a curing agent. The high-hardness waterproof wallpaper is excellent in hardness and waterproof performance.

Owner:安徽易有墙纸有限公司

Method for sintering taihe vanadium and titanium magnet concentrates

The invention discloses a method for sintering taihe vanadium and titanium magnet concentrates. The mineral composition and the structure of sintered ores can be effectively improved by adopting the method so as to improve the quality and the yield of sintered ores. The method comprises the following steps of: 1) sieving coke breeze to be sintered to ensure that the grain size of all the coke breeze are less than 3 millimeters; 2) crushing the common coke breeze with a grain size of more than 5 millimeters in the sintering raw materials; 3) removing the returned mine with a grain size of more than 3 mm by sieving; 4) adding 5 to 8 percent of slaked lime into the sintering raw material; 5) adding the taihe vanadium and titanium magnet concentrates, common ore fines, the slaked lime, limestone, coke powder and the returned mine into a mixing cabin, adding water into the mixing cabin and blending the mixture; and 6) filling the mixed material into a sintering cup and performing ignition and air draft to sinter the concentrates. When the method of the invention is used, the calcium ferrite content of the sintered ore is increased by over 5 to 10 percent, the strength of a sintered ore drum is increased by 1.2 to 15 percent, the rate of finished products is increased by 1.2 to 3.0 percent and the yield is increased by 2.3 to 4.0 percent.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

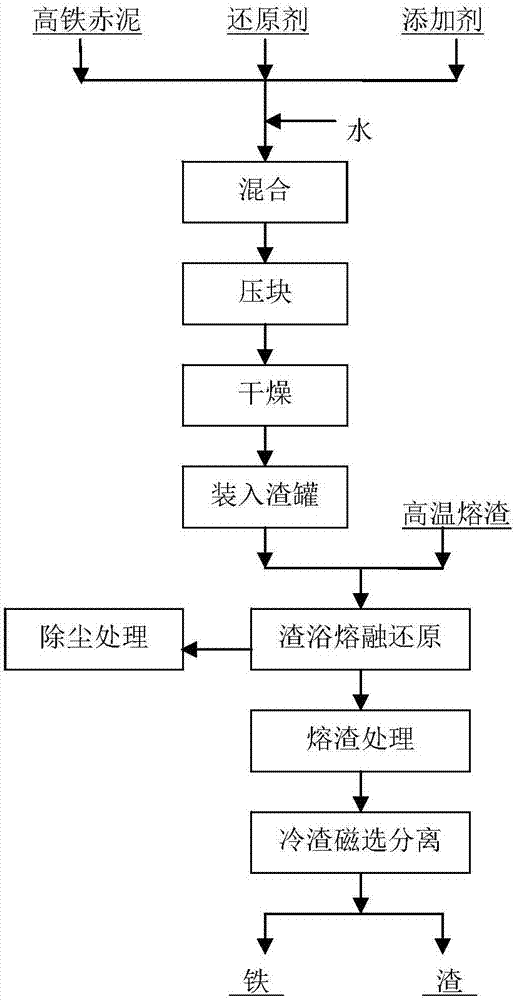

Method for recycling iron by utilizing high-iron-content red mud

The invention discloses a method for recycling iron by utilizing high-iron-content red mud. The method for recycling the iron by utilizing the high-iron-content red mud comprises the steps that a 10-30 mm of red mud mass block is made from the even mixture of the high-iron-content red mud, reducing agent and additives; mass percent of the additives in ingredient composition is 3-10 wt%, the ratio of the high-iron-content red mud and the reducing agent is reasonably matched, so that molar ratio C / O of carbon and iron oxide in the red mud mass block is 1.2-1.5; the reducing agent is one of pulverized coal, coke powder and coking dust-removal ash; the additives are calcium ferrite powder; and the red mud mass block is added into an empty slag pot in advance, high temperature molten slag is injected during slag tapping, after-treatment is conducted by adopting a general slag disposal process after reaction for 10-30 minutes, and magnetic separation treatment is conducted on the cooling slag to separate the slag and the iron.

Owner:ANGANG STEEL CO LTD

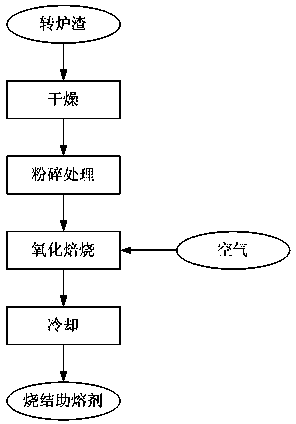

Preparation method of sintering flux for iron ore sintering

The invention provides a preparation method of a sintering flux for iron ore sintering, which can solve the problem of waste recycling of converter slags, also can produce a low-cost sintering flux, and reduces the damages of converter slags on the environment. According to the invention, converter slags and air are fully reacted at a high temperature of 800-1100 DEG C, a main ingredient SFCA (complex calcium ferrite) in an obtained sintering flux product can reduce the melting point of the flux, so that the formation of a liquid phase in the process of sintering is facilitated, therefore, the energy consumption is reduced, conditions are provided for the improvement of the efficiency of a blast furnace, the maximum value of converter slags is utilized as much as possible, the recycling of metallurgical slags is implemented, and the energy conservation and emissions reduction of enterprises are facilitated. The preparation method of a sintering flux for iron ore sintering disclosed by the invention provides products and technical supports for the reduction of ironmaking and steelmaking production costs and the implementation of energy conservation and emission reduction.

Owner:CHONGQING UNIV

Preparation method of converter steelmaking dephosphorizing agent

InactiveCN102453788ADephosphorization effect is stableReduce consumptionSteelmakingMaterials science

The invention relates to a converter steelmaking dephosphorizing agent and a preparation method thereof. The converter steelmaking dephosphorizing agent is characterized by comprising the following raw materials in percentage by weight: 40-45% of Fe2O3, 45-50% of CaO, 1-4.0% of Al2O3, less than 5.0% of SiO2 and 0-1.5% of CaF2, and the melting point is lower than 1150 DEG C. The preparation method comprises the following steps of: crushing and uniformly mixing the raw materials, smelting the mixture at high temperature of 1200-1550 DEG C, and producing calcium ferrite through a melting reaction; after the calcium ferrite is cooled, processing the produced calcium ferrite into 3-40 mm granules as a practical converter dephosphorizing agent. The converter steelmaking dephosphorizing agent provided by the invention has the advantages of stable dephosphorization effect and low energy consumption, and the content of phosphorus element in steel can be controlled below 0.003%. What's more important, the converter steelmaking dephosphorizing agent does not contain fluorine or contains micro fluorine and has small environmental pollution, long storage life and the like.

Owner:金素玉

Metallurgical auxiliary material fluxing agent and preparation method thereof

InactiveCN101748235APlay a role in fluxingFlux benefitsBlast furnace detailsManufacturing convertersMaterials scienceCalcium ferrite

The invention relates to the field of metallurgical technology, in particular to a metallurgical auxiliary material fluxing agent which is characterized in that the melting point of the fluxing agent is 1100 DEG C-1150 DEG C, and the fluxing agent contains, by weight percent, 40-50 Fe2O3, 45-50 CaO, 2.0-6.0 AL2O3, 0-5.0 SiO2 and 0-1.5CaF2. The preparation method is as follows: crushing the compositions to 0-20mm grains, mixing, melting at high temperature of 1200 DEG C -1550 DEG C so as to get calcium ferrite after the melting reaction, cooling and then grinding the calcium ferrite to 200-mesh powder. The fluxing effect can be best when the amount of the fluxing agent added is 4-6% by weight percent of the agglomerate or pellets reduced in a rotary kiln, and after being added, the fluxing agent is mixed with the agglomerate or pellets. The invention has the advantages that: firstly, the fluxing agent not only has fluxing function but also participates in the metallurgical reaction, and secondly, the melting point of the fluxing agent is 1150 EDG C which is lower than that of the fluxing agent of fluorite, so the fluxing agent has better fluxing action to the auxiliary material and is stable in fluxing effect, low in unit and environment-friendly.

Owner:LIAONING TIANHE TECH

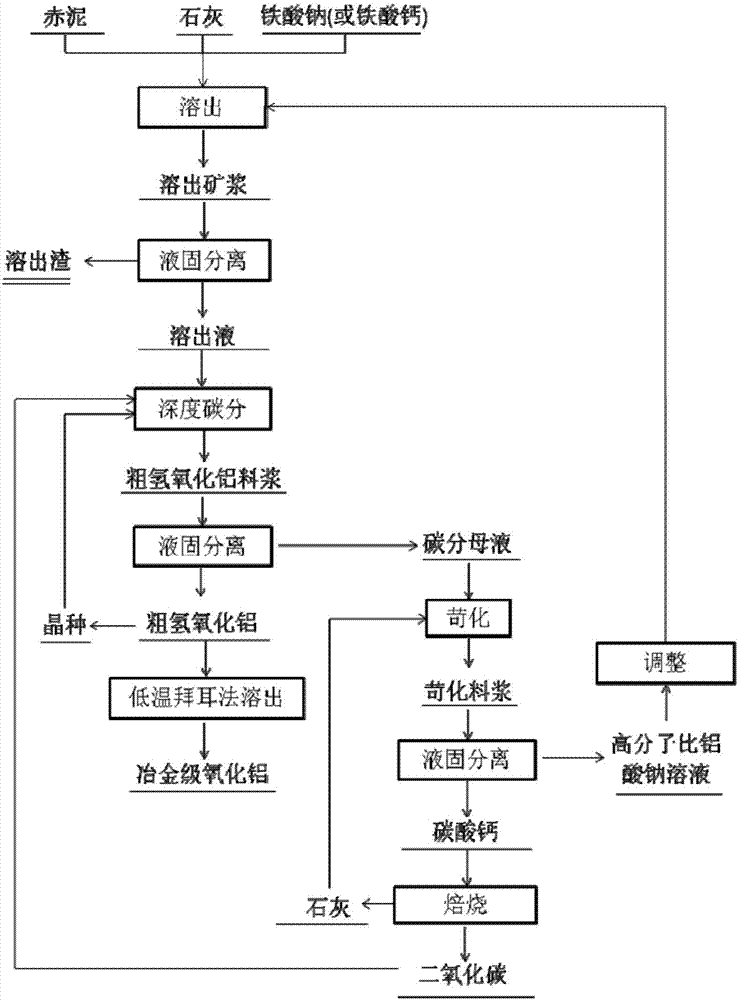

Method by using andradite one-step alkaline heat process to treat Bayer process red mud to produce metallurgical aluminum oxide

InactiveCN107298452AAchieve recyclingLow alkali contentAlkali metal oxidesAluminium oxides/hydroxidesAndraditeAluminium hydroxide

Owner:NORTHEASTERN UNIV

Method for producing ultra-low phosphorus steel through applying pre-melting calcium ferrite to refine outside LF (Ladle Furnace) molten steel furnace

InactiveCN102876845AReduce smelting intensityExtend your lifeLime productionUltimate tensile strengthMaterials science

The invention provides a method for producing ultra-low phosphorus steel through applying pre-melting calcium ferrite to refine outside an LF (ladle furnace) molten steel furnace. The method mainly the following steps: tapping through a converter, deeply removing phosphorus through an LF refining furnace (carrying out argon stirring on molten steel in the whole refining and phosphorus removal process), drossing, adjusting temperature and stirring, deoxidizing, refining, alloying and continuously casting. Deep phosphorus removal is carried out through the method, so that the phosphorus removal rate is more than 80%, the phosphorus content in the molten steel is lower than 0.003%, the phosphorus removal efficiency is high and stable, the smelting intensity of the converter is reduced, the service life of the converter is increased, and meanwhile, the lime consumption and the oxygen consumption are reduced, the electric energy is saved, the consumption of a steel material is reduced, and the metal yield is improved.

Owner:LIAONING TIANHE TECH

Prepn process of Bayer process leaching additive

ActiveCN1888096AHigh recovery rateEasy to manufactureProcess efficiency improvementRed mudPhase change

The preparation process of Bayer process leaching additive of hydrated calcium ferrite, 3CaO .Fe2O3 .6H2O, includes the following steps: 1. baking iron ore and limestone to produce dicalcium ferrite, 2CaO .Fe2O3; and 2. adding lime for phase change according to the equal material ratio between CaO and calcium ferrite at the conditions of alkali concentration Nk of 100-300 g / L, solid content of 50-300 g / L, temperature of 80-160 deg.c and reaction time of 0.5-16 hr, to obtain the additive. The Bayer process leaching additive has lowered Al / Si ratio and Na / Si ration of the leached red mud.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Method for utilizing pyrite to simultaneously reduce phosphogypsum and titanium white waste residue green vitriol for producing sulfuric acid

InactiveCN108383089AHigh recovery rateSimple ingredientsSulfur compoundsIron compoundsSteelmakingDecomposition

The invention discloses a method for utilizing pyrite to simultaneously reduce phosphogypsum and titanium white waste residue green vitriol for producing sulfuric acid. The technological process comprises the following steps: evenly mixing the pyrite, the phosphogypsum and the titanium white waste residue green vitriol, which are finely ground into a certain particle size, according to a certain proportion; (2) after the mixture is tabletted, directly enabling the mixture to react for a certain period of time at certain temperature to obtain a solid reduced product and SO2-containing tail gas,wherein the obtained solid reduced product is used as a pre-melt type steelmaking slagging agent; (3) carrying out dust removal and purification on the SO2-containing tail gas obtained in the step (2), and then sending the purified product to a sulfuric acid system to prepare the finished product sulfuric acid. The process utilizes the pyrite to simultaneously reduce the phosphogypsum and the titanium white waste residue green vitriol producing sulfuric acid, thus realizing the treatment and recycling of the phosphogypsum and the titanium white waste residue green vitriol, and obtaining sulfuric acid and the steelmaking slagging agent-calcium ferrite product. The phosphogypsum decomposition rate of the method can reach 98wt% or above, the SO2 concentration of the kiln gas can reach 15 vol% or above, and the purity of the solid phase product calcium ferrite can reach 90wt% or above. The method is simple in process, free from discharge of three wastes, and remarkable in environmental and economic benefit advantages.

Owner:SICHUAN UNIV

Hard calcium ferrite and manufacturing method thereof

The invention which discloses a hard calcium ferrite and a manufacturing method thereof belongs to the field of hard ferrites. The hard calcium ferrite comprises a main component of CadeltaAsigmaRtauFe12O19, wherein A is at least one element of Sr and Ba, and R is at least one element which is selected from La, Nd, and Pr and must contains La; a soft ferrite component with the composition formulaof WnFemO(n+3m / 2), wherein W is one or more of Mn, Co, Zn, and Ni; and a composite additive, wherein the composite additive contains at least an additive with the composition formula of MxBySizO(x+2z+3y / 2), and in the composition formula, M is one or more divalent metal elements, such as Sr, Ba, and Ca. The hard ferrite magnet obtained in the invention has a Br of 4200-4700 Gs, a HCJ of 4900-5700Oe, and a squareness ratio (Hk / HCJ) of above 90%, and especially has the Br of 4400-4700 Gs, the HCJ of 5000-5700 Oe, and the squareness ratio of above 95%, and simultaneously the production cost is substantially reduced.

Owner:自贡市江阳磁材有限责任公司

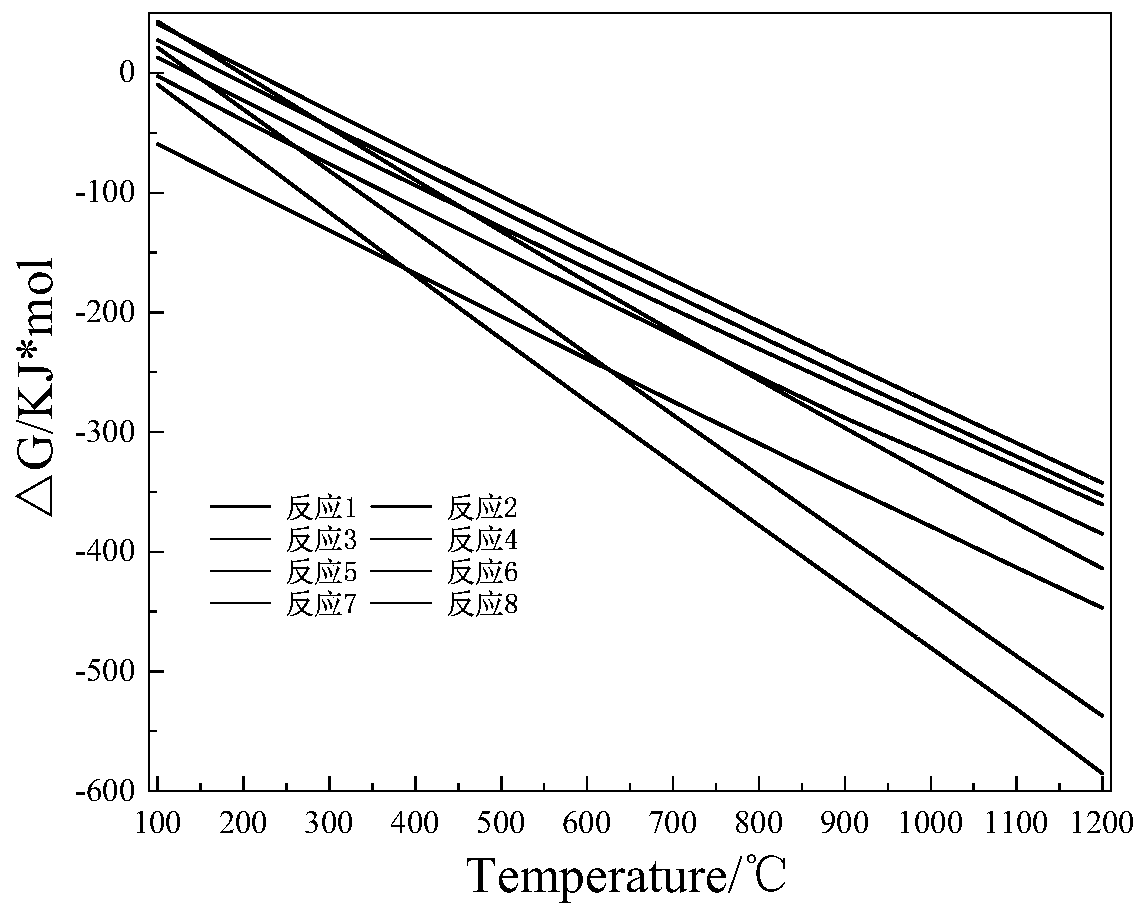

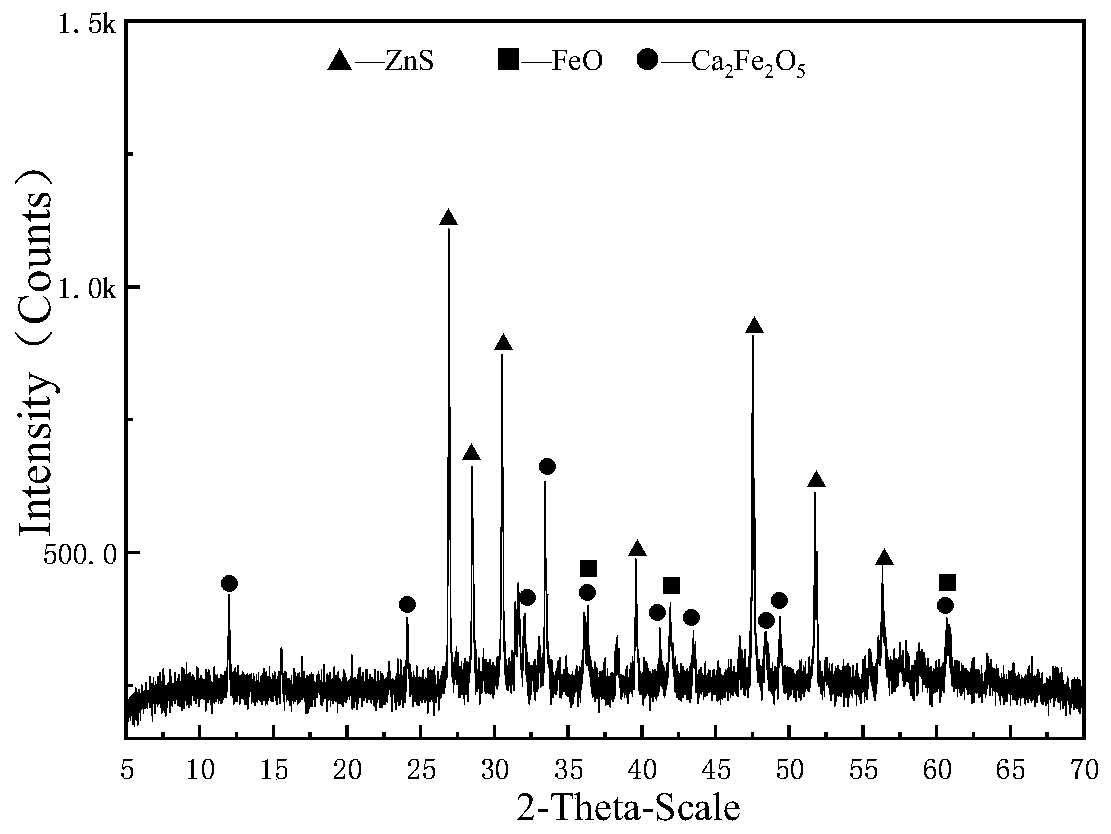

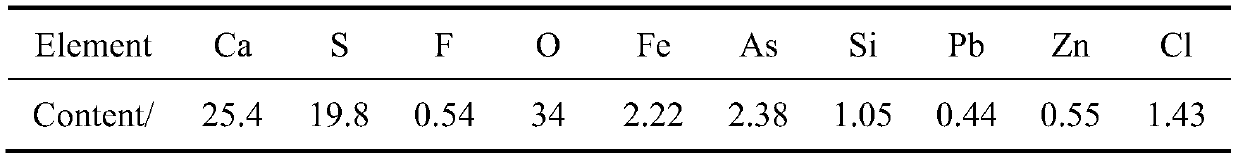

Method of synergistically vulcanizing and roasting lead-zinc smelting slag and gypsum slag

ActiveCN110983029AAchieving clean co-processingAchieve recyclingFlotationCalcium silicateSulfidation

The invention discloses a method of synergistically vulcanizing and roasting lead-zinc smelting slag and gypsum slag. The method comprises the following steps of: mixing lead-zinc smelting slag, gypsum slag and a carbonaceous reducing agent for reducing sulfurization roasting, using the gypsum slag as a vulcanizing agent to directionally convert lead, zinc and other heavy metals in the lead-zinc smelting slag into metal sulfides easy for flotation separation, enabling calcium in the gypsum slag to react with iron and silicon compounds in the lead-zinc smelting slag to generate calcium ferriteand calcium silicate compounds which can be used for manufacturing building materials and cement, and enabling arsenic in the gypsum slag to be volatilized and enriched in smoke dust to be recycled. The method has the advantages of being low in energy consumption and environmentally friendly, can solve the problem of environmental pollution caused by existing gypsum slag and lead-zinc smelting slag treatment, and has good application and popularization prospects.

Owner:CENT SOUTH UNIV

Indoor air purifying material using shell powder and calcium ferrite complex as main components and preparation method and application of indoor air purifying material

The invention relates to an indoor air purifying new material using shell powder and calcium ferrite complex as main components. The indoor air purifying new material has the advantages that the functions of adsorbing and decomposing harmful gas and foreign odor, inhibiting bacteria, sterilizing and resisting static electricity are realized; the defects of high cost, high energy consumption and self pollution in the existing indoor air purifying material are overcome. The indoor air purifying new material using the shell powder as one main component is characterized in that the natural or artificially cultured shell powder is used as a basic material, and a certain amount of calcium ferrite and graphene complex, nanometer zinc oxide powder and an adhesive are added. The indoor air purifying new material is prepared from the following components in percentage by weight: 30 to 60% of the shell powder, 1 to 5% of the calcium ferrite and graphene complex, 10 to 20% of calcined montmorillonoid, 10 to 20% of nanometer calcium carbonate, 10 to 20% of nanometer silicon dioxide, 1 to 5% of nanometer zinc oxide powder, and 5 to 20% of the adhesive, wherein the particle size of the shell powder is 700 to 1200 meshes.

Owner:玛蒂耐特建筑材料有限公司 +1

Calcium-iron-silicon-based composite material for restoring heavy metal polluted acid soil and application thereof

ActiveCN105199736ANo change in structureNo change in compositionAgriculture tools and machinesOther chemical processesCalcium silicateALUMINUM PHOSPHATE

The invention discloses a calcium-iron-silicon-based composite material for restoring heavy metal polluted acid soil and application thereof. The mass ratio of component elements of the composite material is calcium:iron:silicon:manganese:magnesium:phosphorus:aluminum= 30-40:19-25:8-12:1-3:5-6:1-3:2-5, the composite material is particularly prepared from, by volume, 55-70% of calcium silicate, 20-30% of calcium ferrite and 5-15% of compound mixture, and the compound mixture is a mixture of calcium-iron-aluminum oxides, calcium iron silicate, calcium aluminate, calcium-aluminum oxides, calcium-manganese-iron oxides, hydroxyl aluminium phosphate and hydroxyl manganese phosphate. The composite material is used for improving and restoring the heavy metal polluted acid soil, the pH value of the soil can be increased by 0.5-2.5 units, the content of effective state heavy metal in the soil is reduced by 64-98%, the content of heavy metal in agricultural products is reduced by 33-94% compared with a control group, and the yield of the agricultural products is increased by 16-1412% compared with the control group.

Owner:SUN YAT SEN UNIV

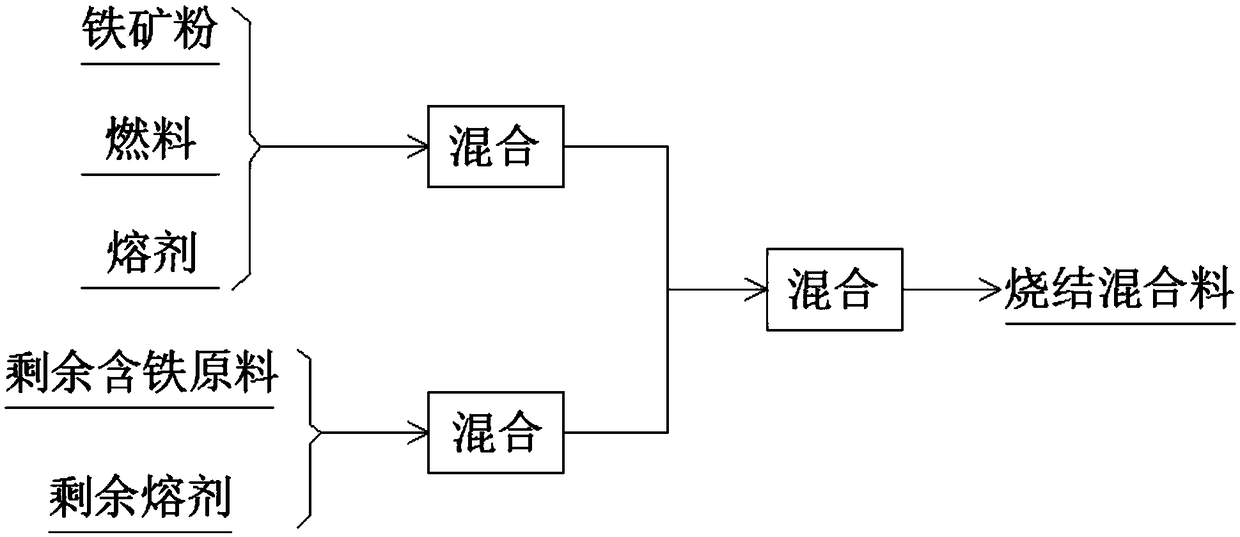

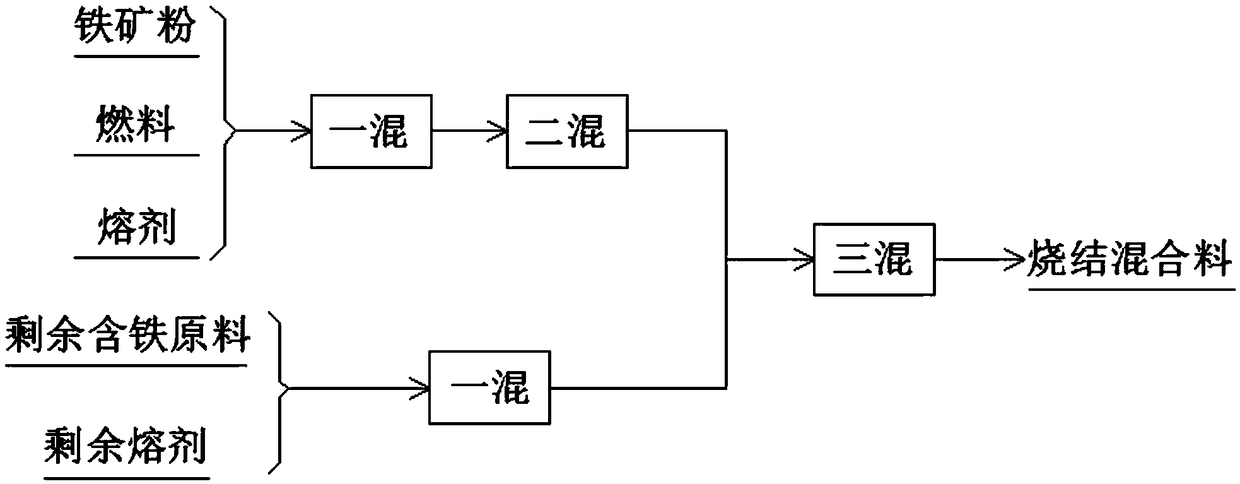

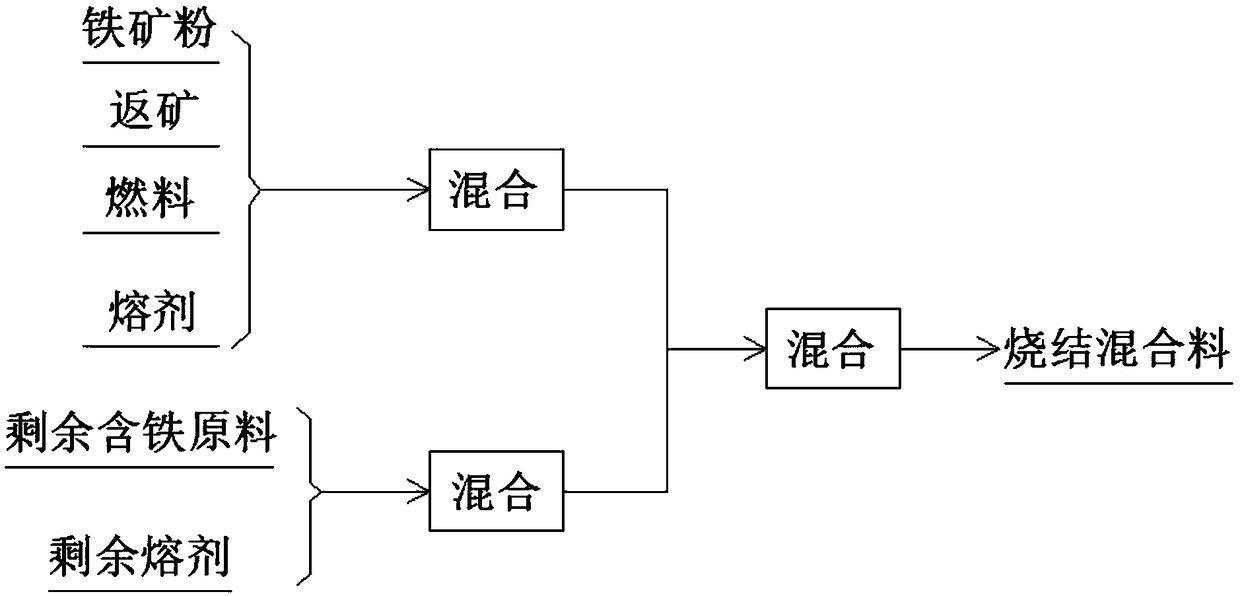

Mixing method for reducing emission of NOX in sintering process

The invention discloses a mixing method for reducing emission of NOX in a sintering process, and belongs to the technical field of reduction of pollutant emission in the sintering process. Iron ore powder with the calcium ferrite generation mass percentage of more than 60% is selected; the iron ore powder is mixed with fuels and fluxes to obtain fuel-contained mixtures; and the fuel-contained mixtures are mixed with remained iron-contained raw materials and the fluxes to obtain sintering mixtures. NO released by combustion of the fuels in the sintering process is wrapped by calcium ferrite; the calcium ferrite achieves a catalysis effect on reduction of NO as N2, so that the generation of sintering NOx is reduced; and on the other hand, the fuels are wrapped by iron ores and quick lime toinhibit generation of NOX during sintering. The generation of NOX in the sintering and mixing process can be reduced, so that the emission reducing pressure in sintering smoke denitration is greatly reduced.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for oxidizing treatment of steel plant slag to obtain cement-based materials

InactiveUS6946014B2Improve propertiesImprove hydration kineticsManufacturing convertersCement productionSlagPortland cement

A method for treating a raw steel plant slag to transform it into a hydraulic binder at least equivalent to a Portland cement clinker, comprises the following steps: oxidizing treatment with input of oxygen, air or a mixture thereof at a pressure ranging between 1 to 15 bars, at a temperature ranging between 1650 and 1400° C., of raw steel slag containing, relative to the raw slag total weight, at least 45 wt. % of CaO and less than 30 wt. % of Fe2O3; and adding to the slag a lime source optionally with silica and / or alumina, so that the slag, after tranformation and at room temperature, has a propotion of Fe2O3 of less than 13 wt. % and a mineralogical composition comprising at least 40 wt. % in C3S mineralogical phase and more than 10 wt. %, of calcium ferrite, relative to the final slag total weight.

Owner:SA CIMENTS LAFARGE

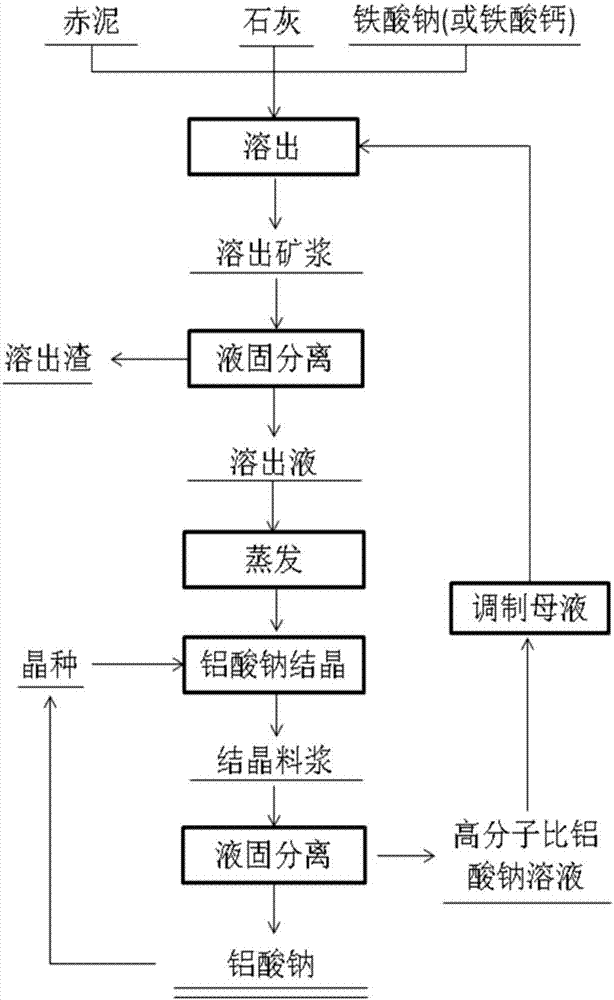

Method for producing sodium aluminate by treating Bayer-process red mud through andradite one-step alkali thermal method

InactiveCN107244683AAchieve recyclingLow alkali contentSilicon compoundsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationAndraditeAdhesive

The invention relates to a method for producing sodium aluminate by treating Bayer-process red mud through an andradite one-step alkali thermal method. The method comprises the following steps: S1: mixing the red mud, sodium ferrite or calcium ferrite, active lime and a circulating mother solution to prepare raw material ore pulp; S2: carrying out alkali thermal dissolution reaction on the raw material ore pulp; after reacting, obtaining dissolved-out ore pulp; S3: diluting the dissolved-out ore pulp to obtain a diluting solution; carrying out liquid-solid separation on the diluting solution to obtain dissolved-out dreg and a dissolved-out solution; S4: after evaporating the dissolved-out solution, adding a crystal seed, crystallizing and carrying out solid-liquid separation to obtain a sodium aluminate solid and a high-molecular-ratio sodium aluminate solution; S5: blending the high-molecular-ratio sodium aluminate solution to prepare the circulating mother solution used in step S1. According to the method provided by the invention, aluminum oxide and sodium oxide in the red mud are recycled so that the alkali content in the dissolved-out dreg is reduced to be 0.5 percent or below and the red mud can be used as raw materials including cement, concrete, an iron-melting adhesive and the like; the method provided by the invention can be used for consuming a lot of the red mud so that the recycling of the red mud is realized and the green utilization effect of resources is realized.

Owner:NORTHEASTERN UNIV

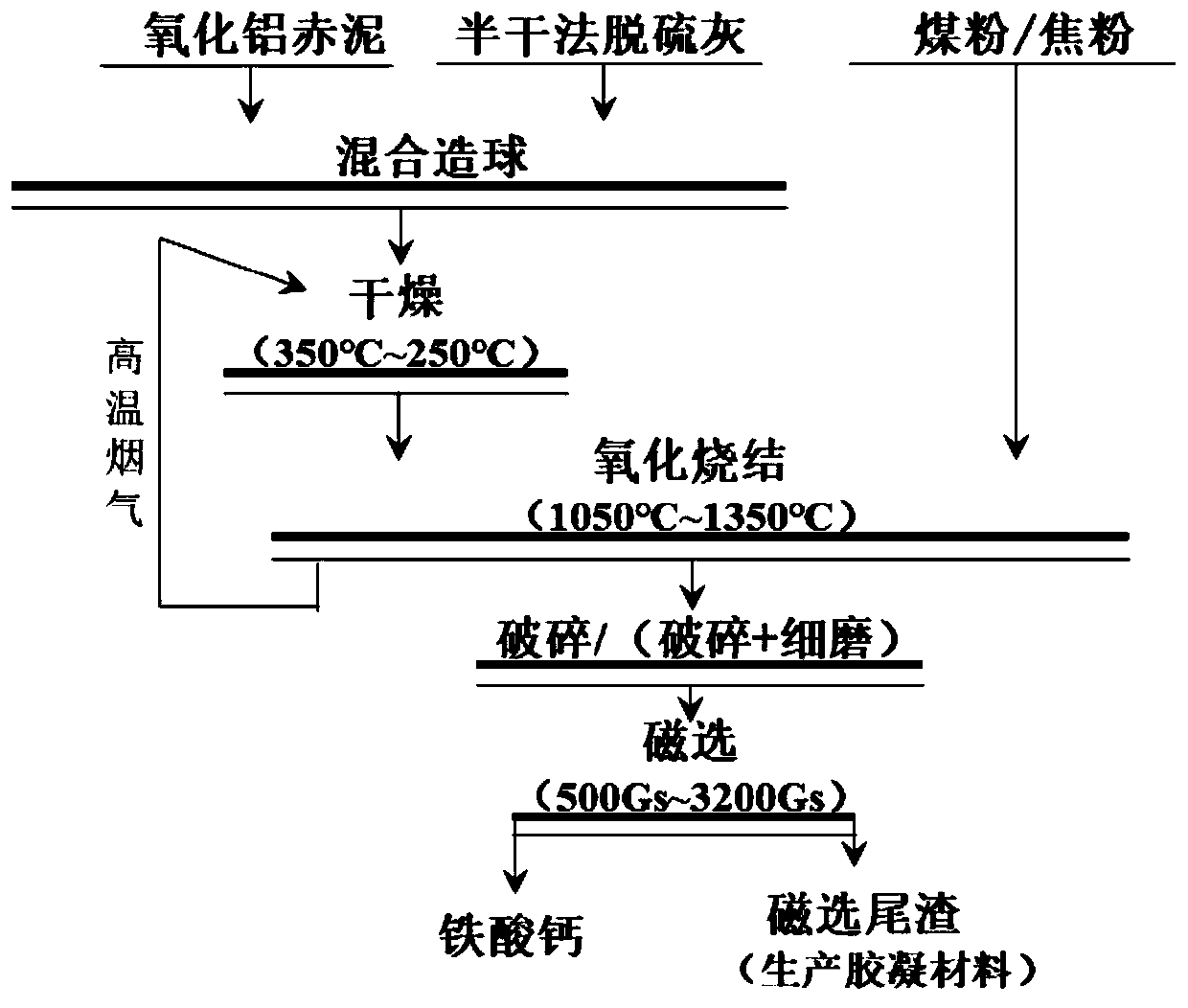

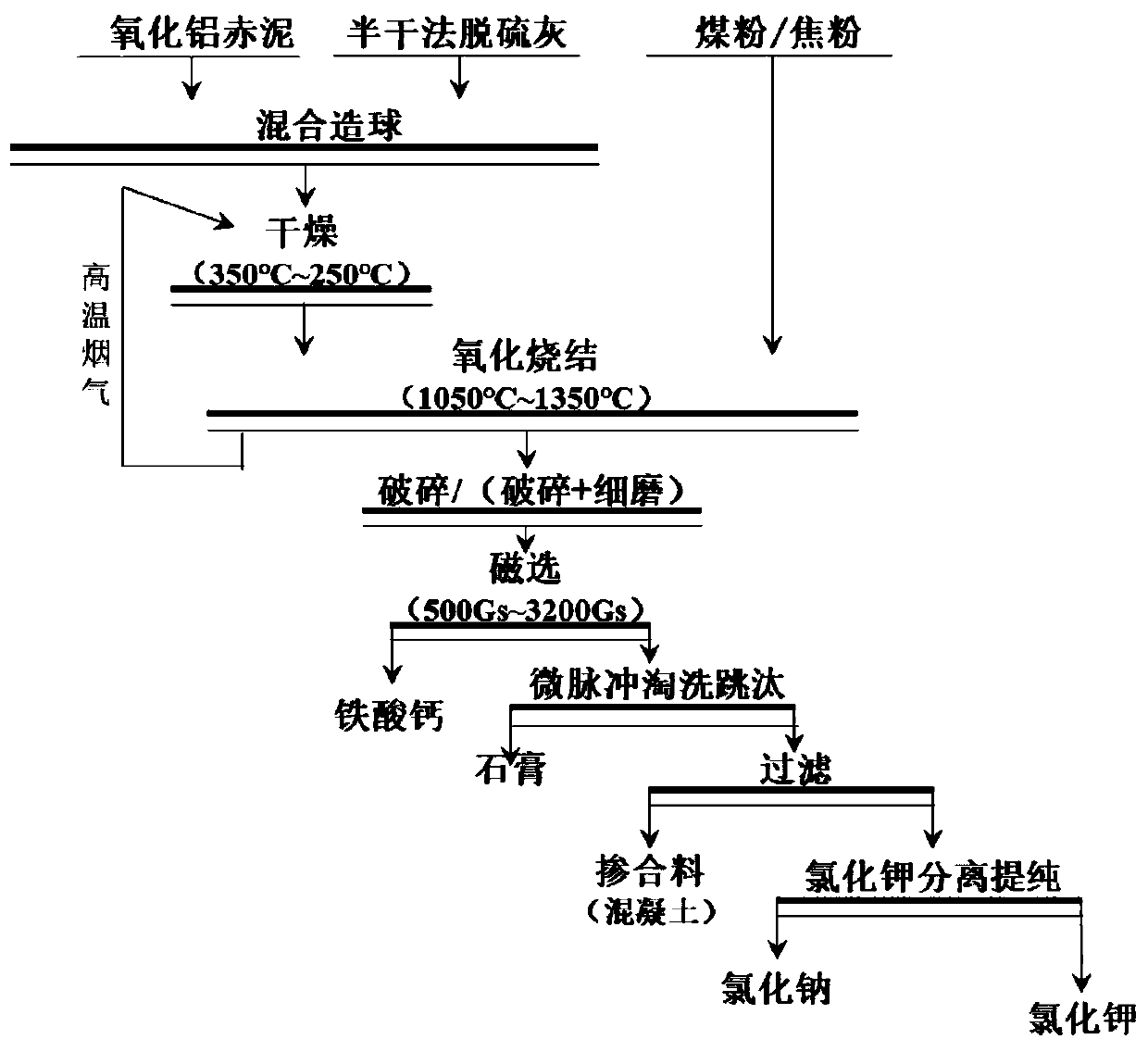

Co-recycling method of aluminum oxide red mud and semi-dry desulfurized fly ash

PendingCN111285406AEfficient separation methodSolid waste managementCalcium/strontium/barium sulfatesRed mudEngineering

The invention belongs to the field of resource regeneration, and particularly relates to a co-recycling method for aluminum oxide red mud and semi-dry desulfurization ash. Compared with desulfurized gypsum, the semi-dry desulfurized fly ash has a high free alkali content, more complex components and unstable properties. First, aluminum oxide red mud and semi-dry desulfurized fly ash are mixed according to a mass ratio of 1: (0.03-1.95), the mixture is pelletized, pellets are dried, the pellets and pulverized coal (or coke powder) are mixed according to a mass ratio of 1: (0.03-0.95), and oxidation sintering is carried out. After cooling, the sintered ore is crushed and finely ground to 0.028mm-13.5mm through roller type crushing equipment and rod milling equipment, and calcium ferrite andgypsum are selectively dissociated. Firstly, magnetic separation is carried out under the conditions that the magnetic separation field intensity is 500 Gs-2100 Gs and the ore pulp concentration is 15%-99.99% to separate out calcium ferrite. The tailings are used for producing a cementing material to replace cement; or a gypsum product is separated from the tailings by using a micro-pulse elutriation jigger, and jigging tailings are filtered. The filter residue is used as a concrete admixture, filtrate is returned to a micro-pulse elutriation jigging process, soluble salt is circularly enriched, and then sodium chloride and potassium chloride are produced by processes such as a cold crystallization direct flotation method.

Owner:UNIV OF SCI & TECH BEIJING

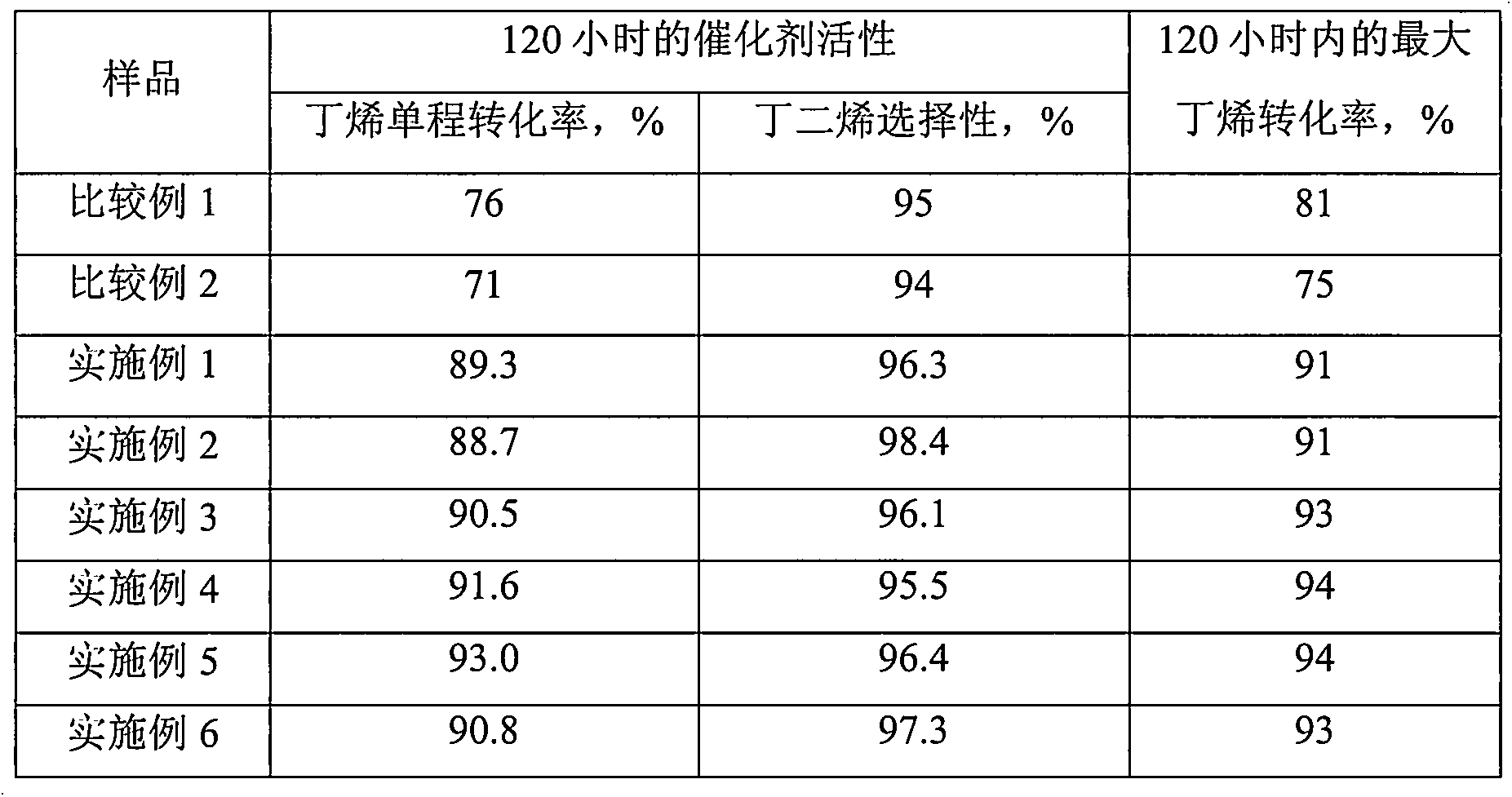

Catalyst for preparing butadiene from mixed C4 and preparation method thereof

InactiveCN103316688AHigh activityImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsIron saltsAdhesive

The invention discloses a catalyst for preparing butadiene from mixed C4 and a preparation method thereof. According to the catalyst, zinc ferrite serves as an active main body, and manganese ferrite and calcium ferrite serve as auxiliary active ingredients. The method comprises the following steps: mixing an iron salt solution, a zinc salt solution, a manganese salt solution and a calcium salt solution according to a certain ratio, so as to obtain a coprecipitation solution under the action of an alkaline solution; filtering and washing to obtain a catalyst sol, molding, drying and roasting the sol to obtain an axial fixed bed or constant-temperature fixed bed catalyst used for a fixed bed reaction process; preparing slurry from the sol and an adhesive with a certain ratio, and performing spray drying forming, drying and roasting to obtain a fluidized bed catalyst used for a fluidized bed reaction process. The catalyst has high activity and stability on dehydrogenation production of butadiene through the mixed C4 under the condition of the presence of oxygen, the conversion per pass of the butane in the mixed C4 is 88-93 percent, the selectivity on the butadiene is over 95 percent, and the catalyst can be applied to the field of industrial production of the butadiene.

Owner:王伟跃

Shell powder indoor air purification wall material and preparation method thereof

InactiveCN107224867AHigh reactivityImprove clearanceBiocideDispersed particle separationChemical reactionPowder mixture

The invention discloses a shell powder indoor air purification wall material and a preparation method thereof and belongs to the technical field of polymer composite materials. The shell powder indoor air purification wall material is composed of 30% to 60% by mass of a shell powder mixture, 5% to 20% by mass of chitosan, 10% to 40% by mass of ash-calcium, 5% to 20% by mass of microporous calcium metasilicate, 5% to 15% by mass of calcium ferrite, 5% to 20% by mass of washed kaolin and 10% to 25% by mass of a copolymer binder. The material can highly efficiently adsorb and decompose harmful substances and odor and has functions of bacteriostasis, sterilization and electric resistance. The used chitosan can be used for decomposing to remove harmful substances such as formaldehyde in air, has a removal rate of 99% and effectively reduces the formaldehyde content to 0.05%. The amine group (-NH2) having high reaction activity in the chitosan can react with many gaseous harmful substances to be decomposed into water and oxime.

Owner:苏州贝涂新材料科技有限公司

High-hardness, oil-resistant, antibacterial and heat-resisting paint

ActiveCN105713458AHigh hardnessImprove heat resistanceFireproof paintsRubber derivative coatingsEpoxyCellulose

The invention discloses high-hardness, oil-resistant, antibacterial and heat-resisting paint. Raw materials of the paint comprise fluorination modified nitrile rubber, nano inorganic antibacterial powder, a styrene-acrylic emulsion, alkyd resin, ethyl acetate, epoxy resin, polyvinyl chloride resin, aluminum hydroxide, bentonite, barite powder, nitrocotton, zinc oxide, mica powder, zeolite powder, chlorinated paraffin, calcium ferrite, hexamethyl cellulose, citric acid, propanol, xylene and a curing agent. The paint has high hardness, good oil resistance and antibacterial property and excellent heat resistance.

Owner:宁波长发涂料有限公司

Method for preparing sintered ore

InactiveCN101177731AReduce particle fraction contentReasonable particle size compositionAdhesiveMaterials science

The invention pertains to the metallurgy technical field, in particular to a method of a sintered ore, which aims at solving the technical problem that sintered coke powder is easy to be over crushed, resulting in the proportion of -0.5mm granule being over high and then influencing the sintered effect. The method comprises the steps of crushing the coke powder, making balls with burden and mixture, burden distribution sinter, etc. The invention is characterized in that the coke powder after being crushed is added with adhesive to make the granule and then make the balls with the burden and the mixture. Since the method of the invention is adopted, the coke powder -0.5 mm granule proportion is decreased by 10 percent -21 percent, thus improving the sintered process; the calcium ferrite content in the sintered ore is increased by over 2 percent, the drum strength in the sintered ore is improved by 1.0 percent-1.62 percent, the rate of finished products is improved by 1.35 percent-3.26 percent, the yield is increased by 2.7 percent-5.4 percent, and the metallurgical property of the sintered ore is also promoted. The technology is simple and practicable, and the on-site technology process can be conveniently modified with strong feasibility.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +1

Method for producing ultra-low phosphorus steel in argon blowing station by using premelted calcium ferrite to refine molten steel outdoors

The invention provides a method for producing ultra-low phosphorus steel in an argon blowing station by using the premelted calcium ferrite to refine the molten steel outdoors, mainly comprising the following steps: tapping steel from a converter, refining in the argon blowing station to dephosphorize deeply, slagging, adjusting temperature, stirring, deoxidizing, refining, alloying and casting continuously. By using the method to dephosphorize deeply, the dephosphorization rate can be more than 80%, the content of phosphorus in the molten steel is controlled below 0.003% stably, the dephosphorization efficiency is high and stable, the smelting intensity of the converter is reduced, the service life of the converter is prolonged, the consumption of lime, oxygen and iron and steel materials is reduced, the electric energy is saved, and the metal yield is improved.

Owner:LIAONING TIANHE TECH

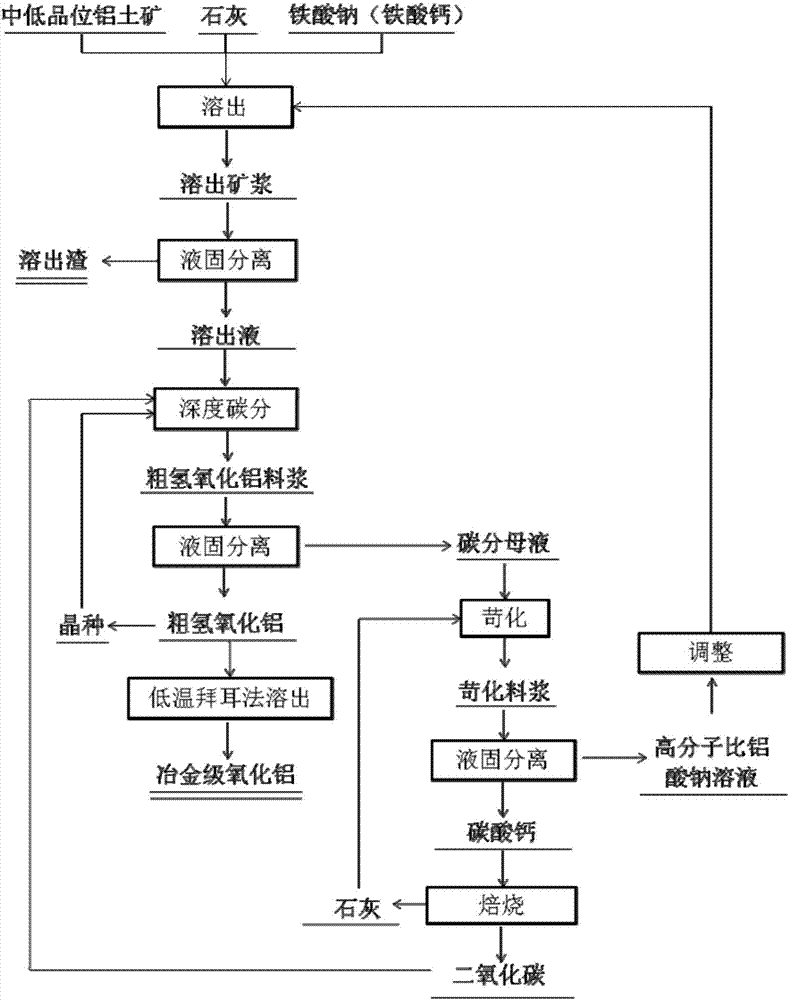

Method for treating medium- and low-grade bauxite to produce metallurgical-level aluminum oxide by one-step andradite alkali heat method

InactiveCN107188209AHigh dissolution rateShort process and high efficiencyAluminium compoundsAndraditeAluminium hydroxide

The invention relates to a method for treating medium- and low-grade bauxite to produce metallurgical-level aluminum oxide by a one-step andradite alkali heat method. The method comprises the following steps of S1, crushing and finely grinding the medium- and low-grade bauxite into mineral powder; S2, mixing and preparing the mineral powder, sodium ferrite or calcium ferrite, activated lime and circulating mother liquor into raw-material mineral pulp; S3, subjecting the raw-material mineral pulp to an alkali heat dissolving-out reaction; S4, diluting dissolved-out mineral pulp, and subjecting diluted liquor to liquid-solid separation; S5, introducing a carbon dioxide gas into a low-molecular-ratio sodium aluminate solution to carry out carbonation decomposition, so as to obtain crude aluminum hydroxide and carbonation-decomposed mother liquor; S6, subjecting the crude aluminum hydroxide to bayer-process treatment, so as to obtain the metallurgical-level aluminum oxide. According to the method provided by the invention, through adding the lime and the sodium ferrite or the calcium ferrite in a dissolving-out procedure, andradite-type slag instead of conventional dissolved-out slag is generated in the dissolving-out procedure; the dissolving-out rate of the aluminum oxide can be improved greatly; meanwhile, the metallurgical-level aluminum oxide is prepared; the method has the characteristics of being short in flow path and high in efficiency; the zero release of a material is realized.

Owner:NORTHEASTERN UNIV

Desulfurizing agent for blast furnace gas and preparation method thereof

InactiveCN111841296ASolve the emission problemLow priceDispersed particle separationGas contaminants removalSlagRed mud

The invention provides a desulfurizing agent for blast furnace gas and a preparation method thereof, belonging to the technical field of air pollution treatment. The desulfurizing agent comprises blast furnace slag, steel slag, red mud from a steel mill, red mud from an aluminum mill, an organic binder, a pore-forming agent, a peptizing agent and water. The method comprises the following steps: mixing the blast furnace slag or the steel slag with the red mud, the organic binder and the pore-forming agent, adding the peptizing agent and the water into the mixed materials, carrying out kneadingand molding, and finally drying and roasting the molded material to obtain the desulfurizing agent with calcium ferrite as an active component. According to the method, the desulfurizing agent which is low in price, high in sulfur capacity and high in desulfurizing precision is produced by utilizing solid wastes of iron and steel enterprises and adopting a simple preparation process, so the cost of dry desulfurization of blast furnace gas at present is reduced, and discharging problems of solid wastes in iron and steel enterprises are solved.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

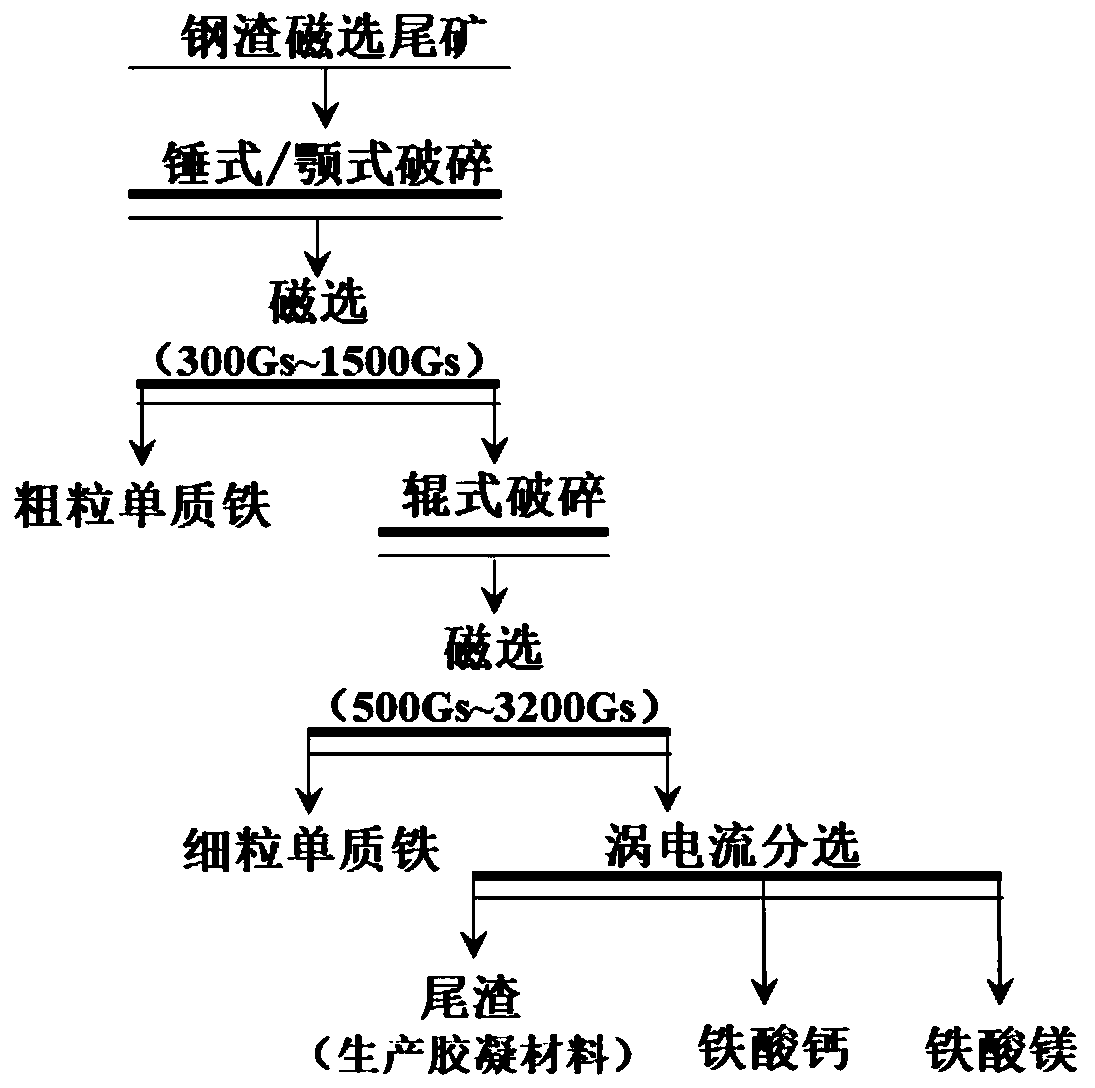

Method for separating calcium ferrite and magnesium ferrite from steel slag magnetic separation tailings

The invention belongs to the field of resource regeneration, and particularly relates to a method for separating calcium ferrite and magnesium ferrite from steel slag magnetic separation tailings. Themethod comprises the following steps: firstly, crushing the steel slag magnetic separation tailings containing 20%-30% of iron to 10mm-13mm by using selective crushing equipment, and selectively dissociating coarse-grained elemental iron particles; secondly, conducting magnetic separation under the field intensity of 300 Gs-1500 Gs, removing coarse-grained elemental iron in the form of magnetic concentrate and using the coarse-grained elemental iron as a steelmaking raw material; thirdly, finely crushing the magnetic separation tailings to 0.5mm-3.5mm by using roller type crushing equipment,and selectively dissociating calcium ferrite and magnesium ferrite by using hardness difference; and fourthly, carrying out magnetic separation under the field intensity of 500 Gs-3200 Gs, separatingout fine-grained elemental iron and merging the fine-grained elemental iron into the steelmaking raw material, and purifying residual calcium ferrite and magnesium ferrite crude products through a vibration bed eddy current sorting machine, thus obtaining a final product. The tailings without specific purposes generated in the process are merged for producing a cementing material, and finally all-component resource utilization of the steel slag is achieved.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com