Hard calcium ferrite and manufacturing method thereof

A technology of permanent ferrite and soft ferrite, applied in the field of permanent ferrite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] The preparation process of material A and material B is carried out as follows: (1) batching and mixing, according to the composition formula M x B y Si z o (x+2z+3y / 2) with W n Fe m o (n+3m / 2) , M is Sr, and x=1, y=2, z=0.67; W is Co, m=2, n=0.95, m:n=2.1, calculate the compound SrCO containing each metal element 3 , H 3 BO 3 , SiO 2 ,Co 3 o 4 , Fe 2 o 3The addition ratio of each component is accurately weighed, and the wet method is used to mix them evenly; (2)M x B y Si z o (x+2z+3y / 2) heat treatment, the M x B y Si z o (x+2z+3y / 2) In the air, carry out heat treatment at 810 ℃ for 2 hours; (3) W n Fe m o (n+3m / 2) pre-burning treatment. Will W n Fe m o (n+3m / 2) Pre-calcined in air at 850°C for 3 hours to obtain soft magnetic ferrite pre-sintered material; (4) Crushed, finely pulverized to powders with an average particle size of 1.0 μm, ready for use.

[0081] According to the composition formula Ca δ A σ R τ Fe 12 o 19 , A is Sr, R is ...

Embodiment 2

[0083] According to the composition formula Ca δ A σ R τ Fe 12 o 19 , A is Sr, R is La, and δ=0.218, σ=0.430, τ=0.432, σ+δ+τ=1.08, calculate the compound SrCO containing each metal element 3 , CaCO 3 , La 2 o 3 , Fe 2 o 3 The addition ratio of each component is accurately weighed, and after mixing them uniformly by wet method, in O 2 Under the condition that the volume fraction of the calcium permanent magnet ferrite is greater than 9%, the pre-calcination is carried out at 1300 ° C for 1 hour, and then the blocky reactant is broken into 2 μm calcium permanent magnet ferrite pre-sintered powder with a vibrating crusher. Add CaSiO with a mass fraction of 0.9% 3 , is 0.8% sorbitol, meanwhile, add A material and B material prepared by embodiment 1, wherein, A material is 0.5%, is 7.8% B material, grinds 14 hours, all the other process control and embodiment 1, the typical data of the magnetic properties of the obtained magnets are shown in Table 1.

Embodiment 3

[0085] The preparation process of B material is carried out as follows: batching and mixing, according to the composition formula W n Fe m o (n+3m / 2) , W is Co, m=2, n=1, m:n=2, and the rest are prepared in the manner of Example 1 as material B for use.

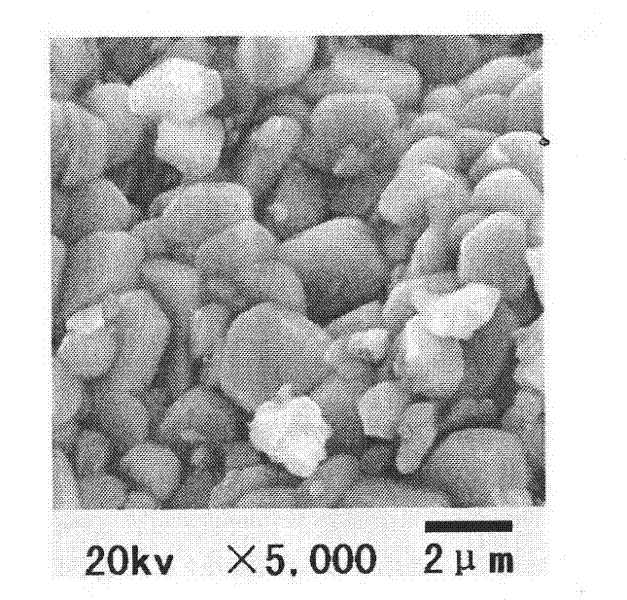

[0086] According to the composition formula Ca δ A σ R τ Fe 12 o 19 , A is Sr, R is La, and δ=0.548, σ=0.120, τ=0.542, σ+δ+τ=1.21, and the rest are prepared in the manner of Example 2 to prepare calcium permanent magnet ferrite calcined material. In this calcined powder, by mass fraction, add 7.81% B material, 0.9% CaSiO 3 , 0.8% sorbitol, at the same time, add the material A prepared by Example 1 with a mass fraction of 0.5%, and the rest of the process control is the same as in Example 2. The typical data of the magnetic properties of the obtained magnet are shown in Table 1 As shown, the microstructure of the magnet is as figure 2 shown. The SEM analysis of the magnet cross-section shows that the crystals have a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain diameter | aaaaa | aaaaa |

| Average grain diameter | aaaaa | aaaaa |

| Average grain diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com