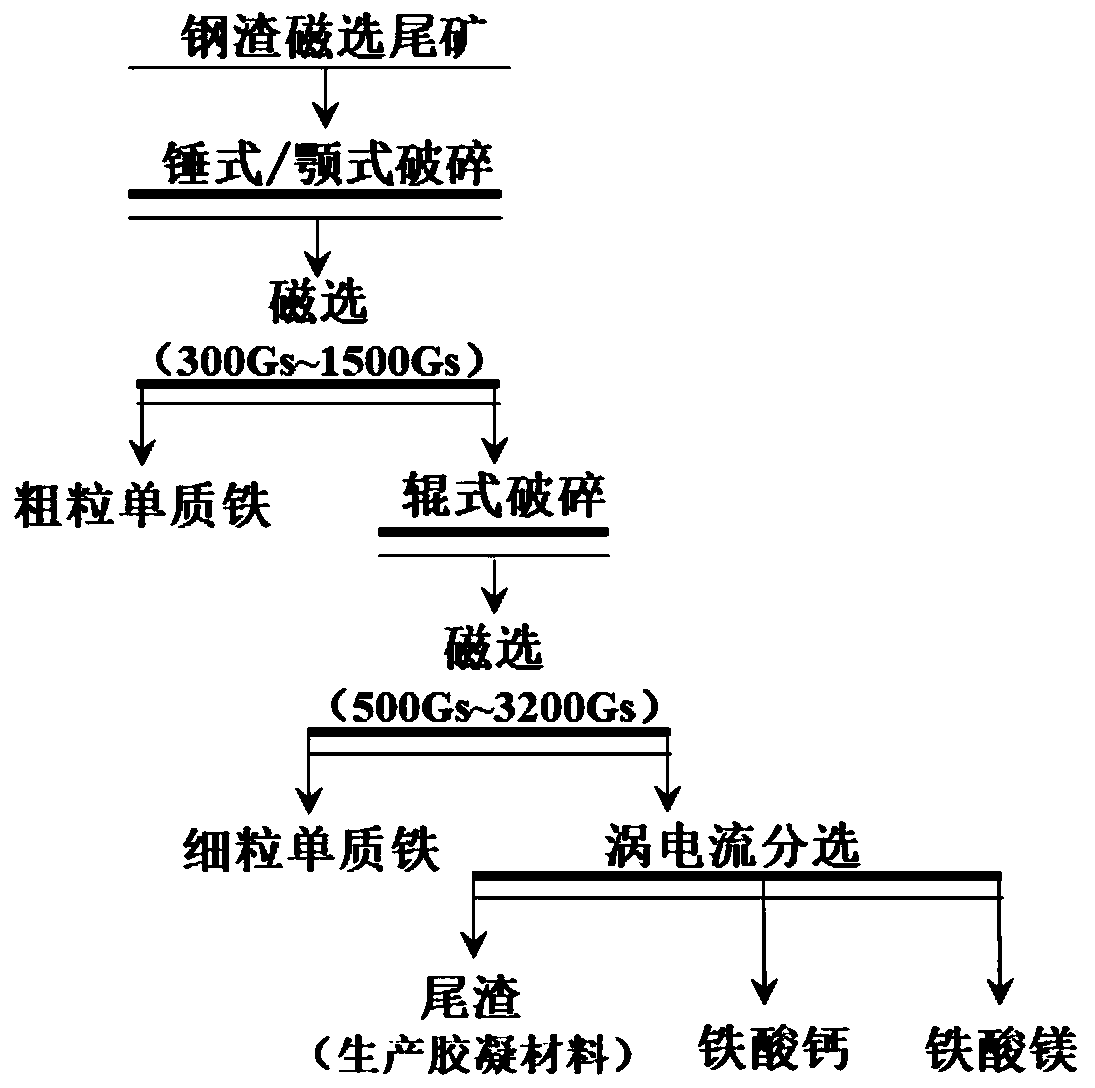

Method for separating calcium ferrite and magnesium ferrite from steel slag magnetic separation tailings

A technology for magnetic separation of steel slag and calcium ferrite, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve problems such as inability to further produce and separate calcium ferrite and magnesium ferrite products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Comprehensive steel slag magnetic separation tailings of a steel plant in Hubei Province, the main components (multiple test range values) are: TFe26.22% ~ 27.61%, CaO 37.10% ~ 38.98%, MgO 7.50% ~ 8.22%, Al 2 o 3 4.23%~5.24%, SiO 2 11.59%~14.20%, SO 3 0.16% to 0.27%.

[0026] Use process:

[0027] (1) Selective dissociation of coarse elemental iron. Take 5kg of raw material steel slag magnetic separation tailings, first use a jaw crusher to crush the raw steel slag magnetic separation tailings to 9.8mm-11.2mm (the average value of multiple measurements, the same below), and selectively dissociate coarse-grained elemental iron particles .

[0028] (2) Separation of coarse grained elemental iron. Under the field strength of 795Gs~810Gs (the average value of multiple measurements, the same below), the dry powder magnetic separator is used for magnetic separation, and the coarse-grained elemental iron is removed in the form of magnetic separation concentrate, which ...

example 2

[0033] Comprehensive steel slag magnetic separation tailings of a steel plant in Hebei Province, the main components are: TFe 22.14% ~ 22.37%, CaO 36.15% ~ 37.03%, MgO 8.77% ~ 9.09%, Al 2 o 3 2.22%~2.38%, SiO 2 16.35%~16.41%, SO 3 0.21% to 0.32%.

[0034] Use process:

[0035] (1) Selective dissociation of coarse elemental iron. Take 20kg of raw material steel slag magnetic separation tailings, first use a jaw crusher to crush the raw steel slag magnetic separation tailings to 12.82mm-12.96mm, and selectively dissociate coarse-grained elemental iron particles.

[0036] (2) Separation of coarse grained elemental iron. Under the field strength of 540Gs ~ 552Gs, the dry powder magnetic separator is used for magnetic separation, and the coarse elemental iron is removed in the form of magnetic separation concentrate. The latter contains 68.27% ~ 68.76% iron and is used as a raw material for steelmaking.

[0037] (3) Selective dissociation of calcium ferrite and magnesium f...

example 3

[0041] Comprehensive steel slag magnetic separation tailings from a steel plant in Liaoning Province, the main components are: TFe 27.31%-27.93%, CaO 31.35%-31.08%, MgO 9.77%-9.89%, Al 2 o 3 1.93%~2.16%, SiO 2 16.82%~16.97%, SO 3 0.30% to 0.31%.

[0042] Use process:

[0043] (1) Selective dissociation of coarse elemental iron. Take 10kg of raw material steel slag magnetic separation tailings, first use a jaw crusher to crush the raw steel slag magnetic separation tailings to 12.91mm-13.77mm, and selectively dissociate coarse-grained elemental iron particles.

[0044] (2) Separation of coarse grained elemental iron. Under the field strength of 1139Gs ~ 1157Gs, the dry powder magnetic separator is used for magnetic separation, and the coarse elemental iron is removed in the form of magnetic separation concentrate. The latter contains 70.05% to 70.23% iron and is used as a raw material for steelmaking.

[0045] (3) Selective dissociation of calcium ferrite and magnesium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com