Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

123results about How to "Short process flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for combined water treatment of chemical oxidizing-biological biological filtering tank

ActiveCN1724420ASmall volumeSmall footprintTreatment using aerobic processesMultistage water/sewage treatmentWater sourceCompound (substance)

A process for treating the polluted water source or sewage by combination of chemical oxidizing and aerating-bio-filtering pool includes such steps as chemical oxidizing, regulating pool and aerating bio-filter pool. If the Fendun agent is used as the chemical oxidant, a depositing pool is additionally used. Its advantages are high effect and low cost.

Owner:SOUTH CHINA UNIV OF TECH

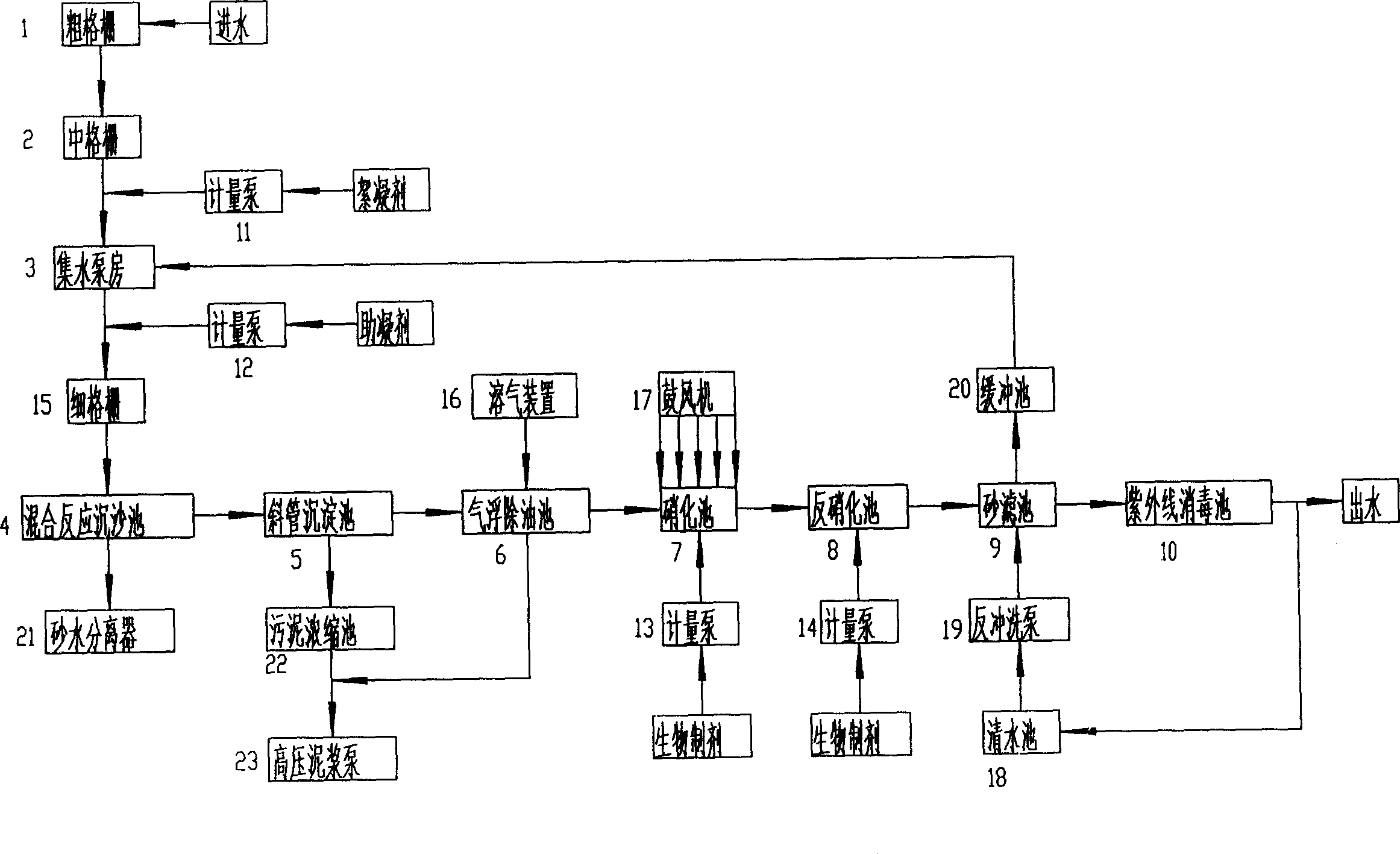

City sewage treating process and system

InactiveCN1706760AReduce loadImprove securityMultistage water/sewage treatmentIndustrial effluentNitrogen

The present invention discloses city sewage treating process and system. The city sewage treating process includes interception with coarse and middle grating to eliminate large suspended matter and the following steps: throwing flocculent before sewage flows into collecting pump house; throwing coagulant aid after sewage flows out of collecting pump house; treating in mixing and reacting silt basin; solid-liquid separation in settling pond; treating in nitrifying pond and denitrifying pond and filtering in sand filter. The process can treat mixed city sewage of industry waste water and domestic sewage and with BOD / COD in 0.15-0.3, can eliminate phosphate and nitrogen simultaneously. The present invention has short retention period, short technological process, small covered area and convenient management.

Owner:高斌 +2

Biological solidification and stabilization method of bottom mud in riverways and lakes

InactiveCN102092916ASolve the way outReduce curing costsSludge treatment by de-watering/drying/thickeningBiological sludge treatmentAmylaseActive agent

The invention relates to improvement of a biological solidification and stabilization method of dredge bottom mud. The biological solidification and stabilization method is characterized by comprising the following steps: primarily dehydrating clay particles which have less possibility of being dehydrated, and mixing and stirring the dehydrated clay particles with dry soil to form mixed soil; and spraying a compound biological enzyme liquid at least consisting of reductase, amylase, cellulase, esterase, lipase, ligninase, prolease, urease, xylanase and a detergent surface active agent to be mixed with the mixed soil, then compacting and solidifying. The biological solidification and stabilization method has the advantages of short process flow and simplicity; by utilizing the method, the volume of the bottom mud to be solidified and stabilized is greatly reduced, the volume of the bottom mud to be solidified after classification and dehydration is 10%-15% of that of the bottom mud to be conventionally solidified, the processing flow is reduced compared with the existing biological enzyme solidification, the solidification cost is reduced, the solidification strength is high, the solidification filling shear strength can reach the Mpa grade, thus the method can be used for road construction, parking lots, slope solidification, reservoir surface solidification, refuse landfill bottom solidification and seepage prevention and public road building. By using the method, the outlet problem of the dredge bottom mud is effectively solved, and a novel decrement and solidification process for the bottom mud in the lakes is created.

Owner:GUANGZHOU ZHUSHUI ENVIRONMENT TECH

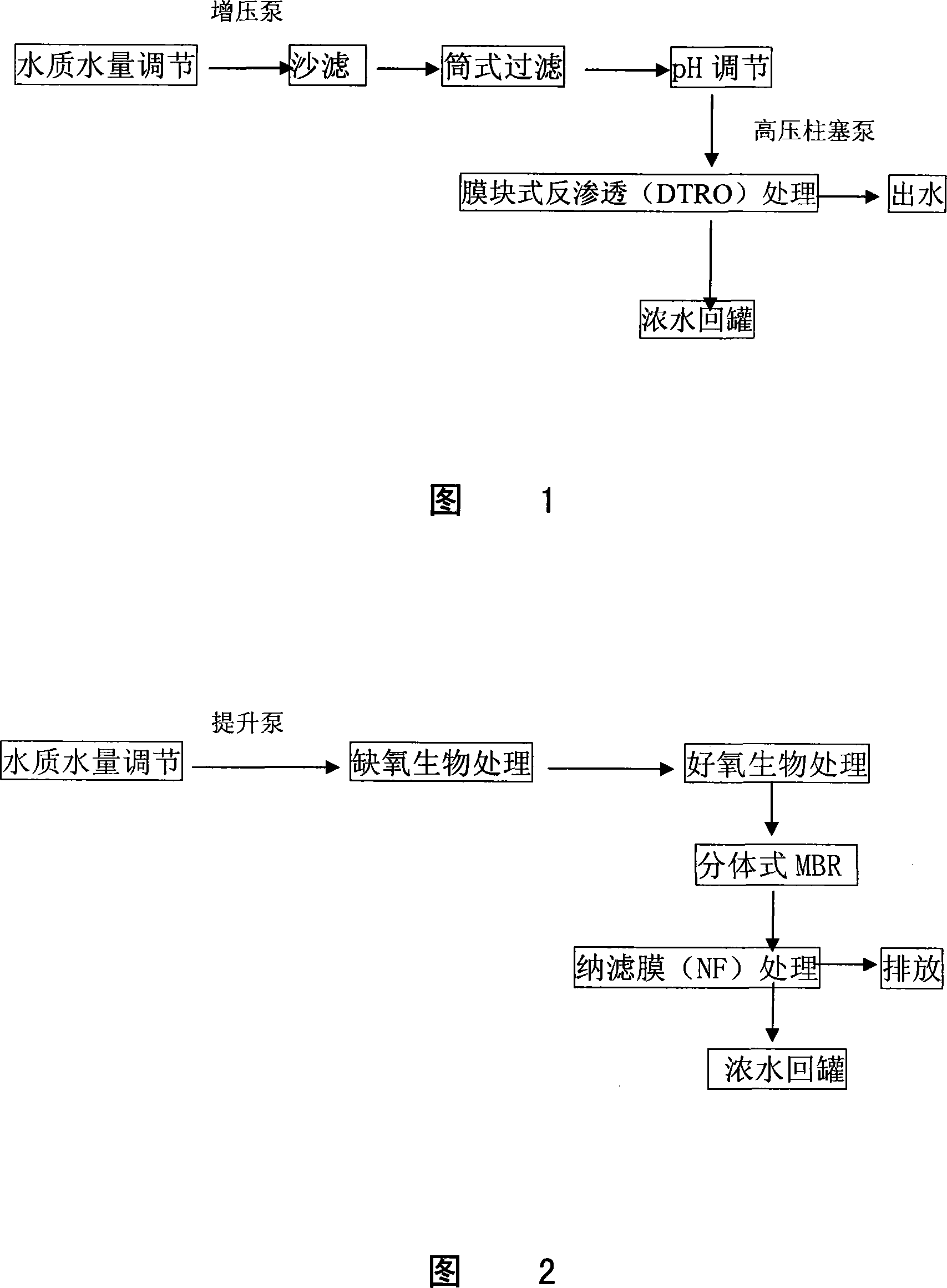

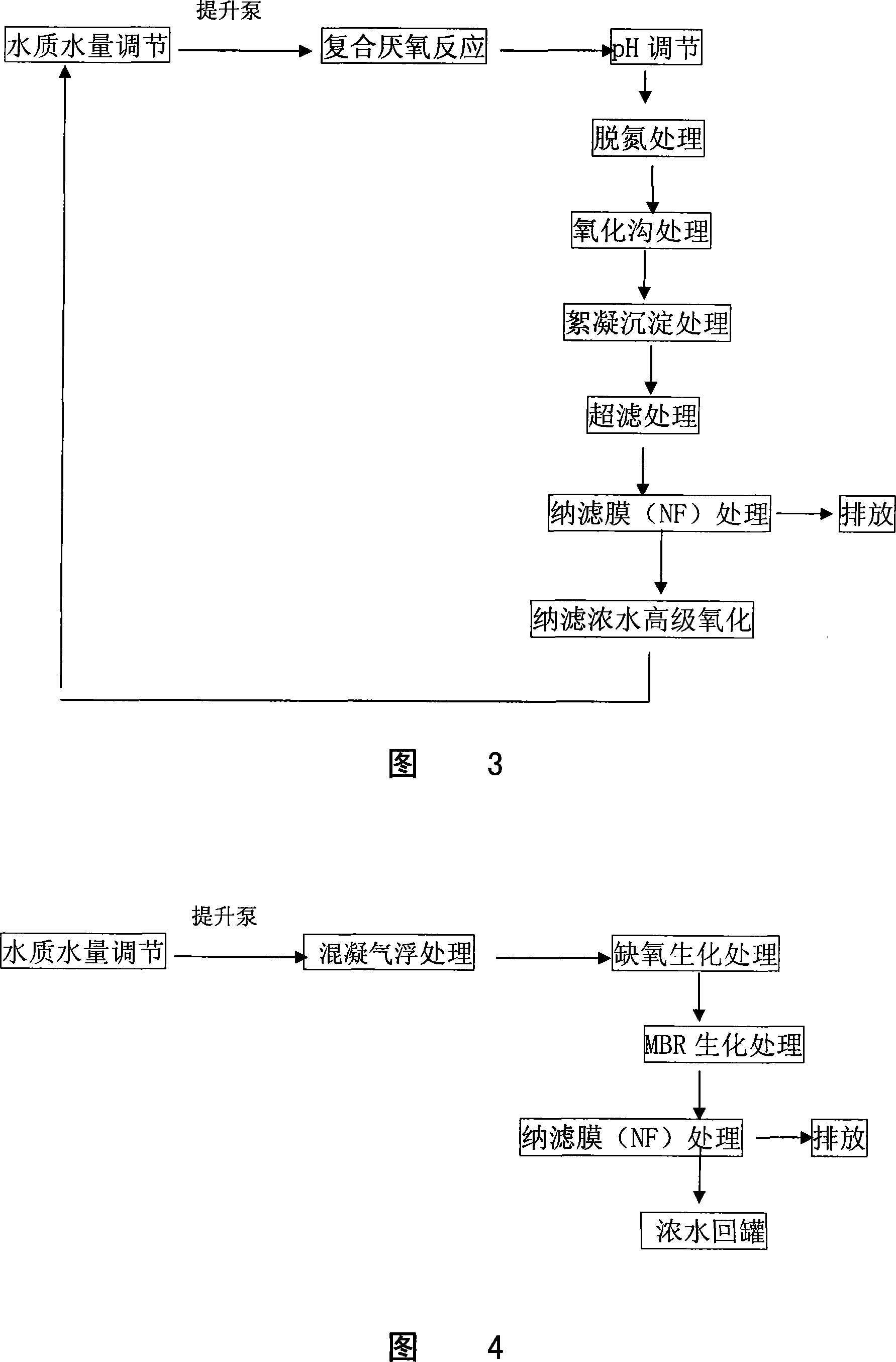

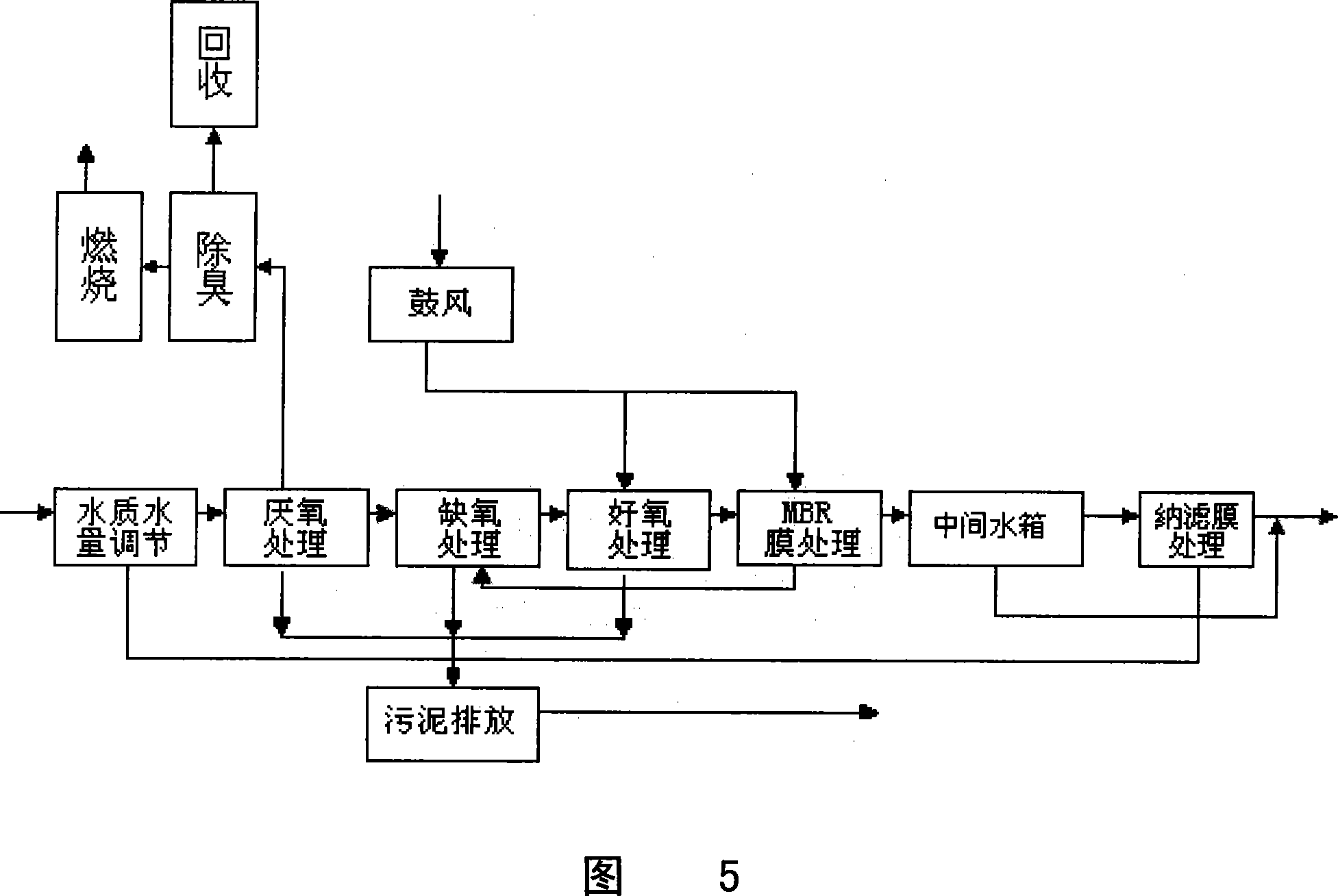

Technique for processing garbage leachate

ActiveCN101219845AShort process flowEasy to controlUltrafiltrationTreatment with aerobic and anaerobic processesRefluxBioprocessor

The invention relates to a process for treating waste leachate, which comprises the steps: (1) water quality and water quantity of the waste leachate is regulated in a regulating tank; (2) the leachate after water quality and quantity regulation is an anaerobic tank and treated by the anaerobic process under 25 DEG C-45DEG C and the anaerobic process time is 50-100 hours; (3) the biogas produced in the anaerobic process is treated and the sludge produced in the anaerobic process is discharged; (4)the leachate after anaerobic process is sent into a hypoxia tank to carry out a hypoxia process and the sludge produced in the hypoxia process is discharged; (5) the leachate after hypoxia process is sent into an aerobic tank to carry out an aerobic process and the sludge produced in the aerobic process is discharged; (6) the leachate after the aerobic process is sent into a membrane biological processor to carry out solid-liquid separation and the reflux is carried out for the sludge produced after the process based on reflux rate 3:1; (7) the leachate after being processed by the membrane biological processor is sent into a middle water tank; (8) the leachate is processed by nanofiltration and the water after being processed is directly metered and discharged or first mixed with the water in the water tank according to certain proportion and then metered and discharged; (9) the concentrated water after nanofiltration is returned back to the regulating tank.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

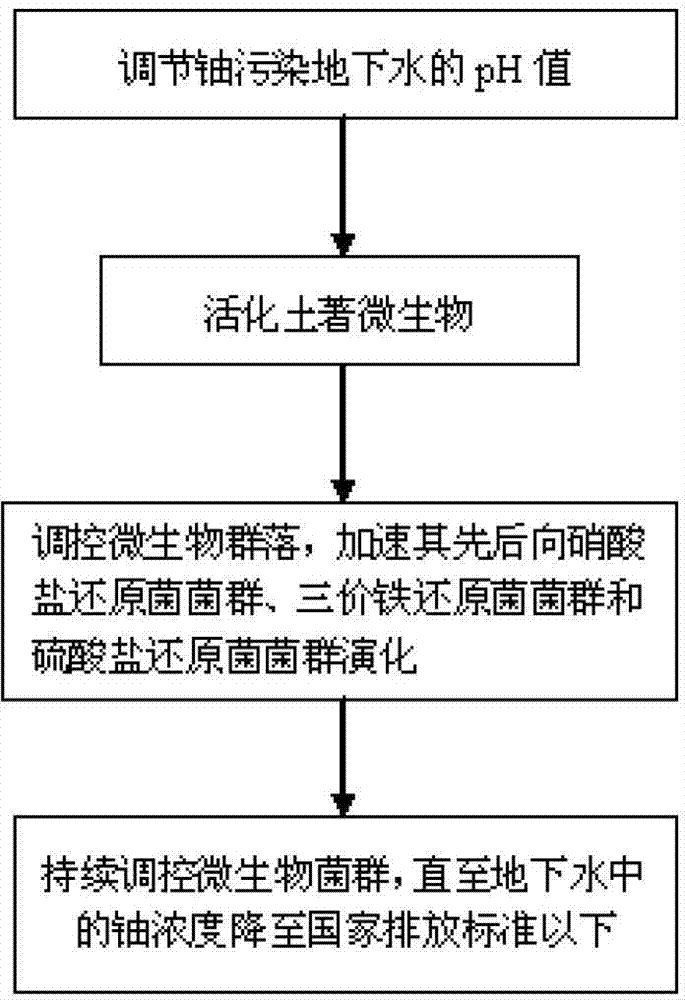

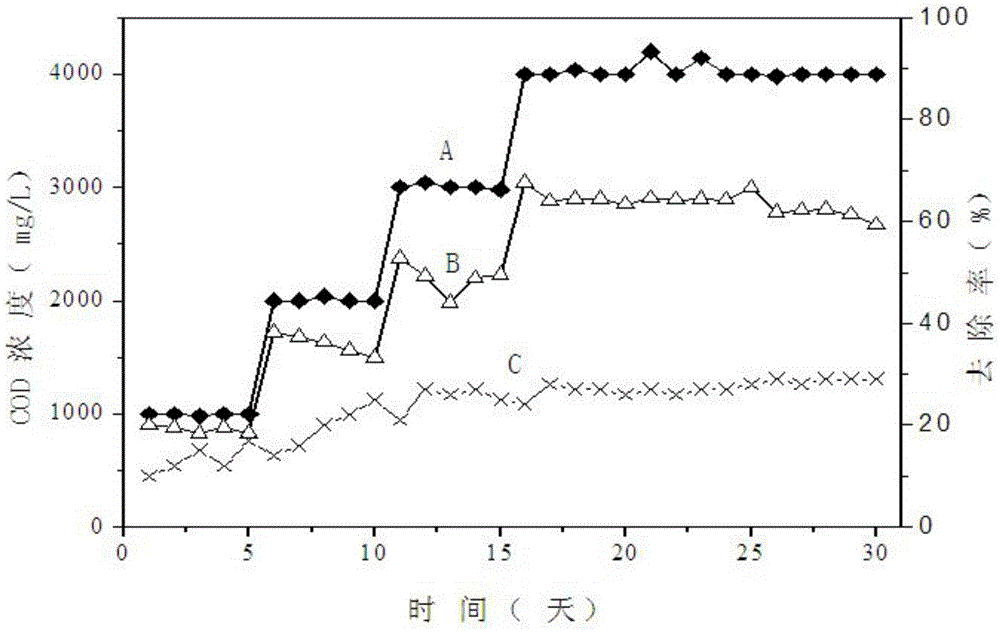

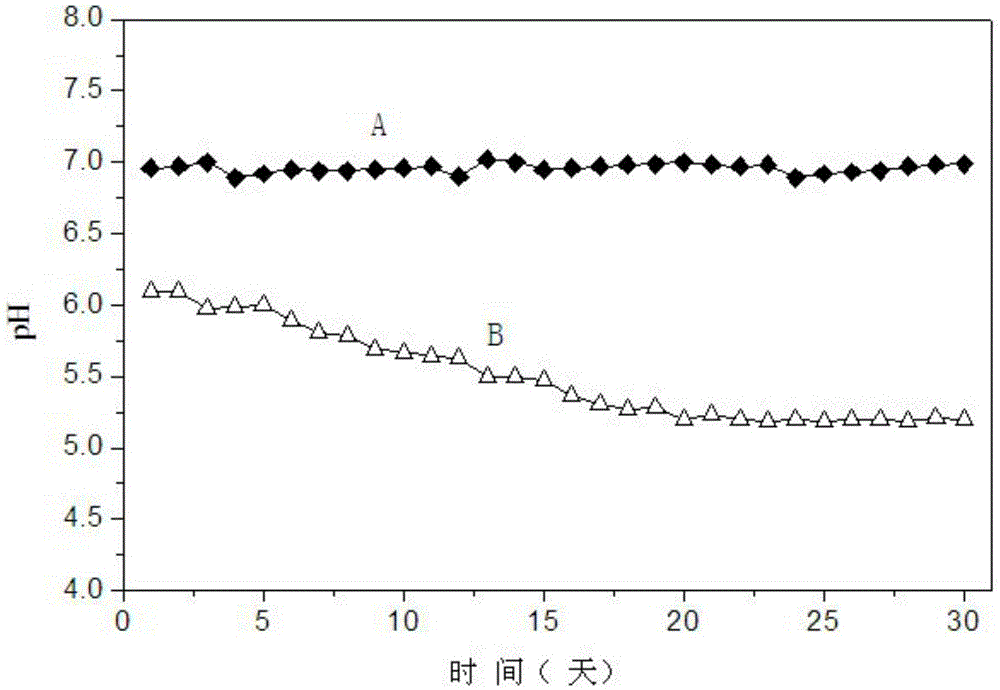

Method of using native function microflora to in-situ purify ground water polluted by uranium

ActiveCN103093847AEasy to operateIn situ repairRadioactive decontaminationSulfate-reducing bacteriaEmission standard

The invention relates to a method of using native function microflora to in-situ purify ground water polluted by uranium. The method translates transferable hexavalent uranium into nontransferable uranous uranium in the ground water through nitrate reducing bacteria flora, ferric iron reducing bacteria flora and sulfate reducing bacteria flora which are formed under the anaerobic condition by microorganism, and therefore the purpose of purifying the ground water polluted by the uranium is achieved. The specific implementation method comprises: (1) adjusting a potential of hydrogen (Ph) value of the ground water polluted by the uranium; (2) activating the microorganism in sediments; (3) regulating and controlling variation of the microflora, accelerating evolution of the nitrate reducing bacteria flora, the ferric iron reducing bacteria flora and the sulfate reducing bacteria flora by means of adding a carbon source, regulating oxidation reduction potential of the water polluted by the uranium and the like; (4) continuously regulating and controlling the microbial flora until uranium concentration in the ground water polluted by the uranium is reduced below the national emission standard and the purpose of purifying the groundwater polluted by the uranium is achieved. The method of using the native function microflora to in-situ purify the ground water polluted by the uranium solves in-situ purifying problem of the ground water polluted by the uranium, and has the advantages of being high in purifying efficient, short in period, simple in equipment, short in process procedure, low in purifying cost, strong in operability, free of secondary pollution, good in purifying effect and the like.

Owner:NANHUA UNIV

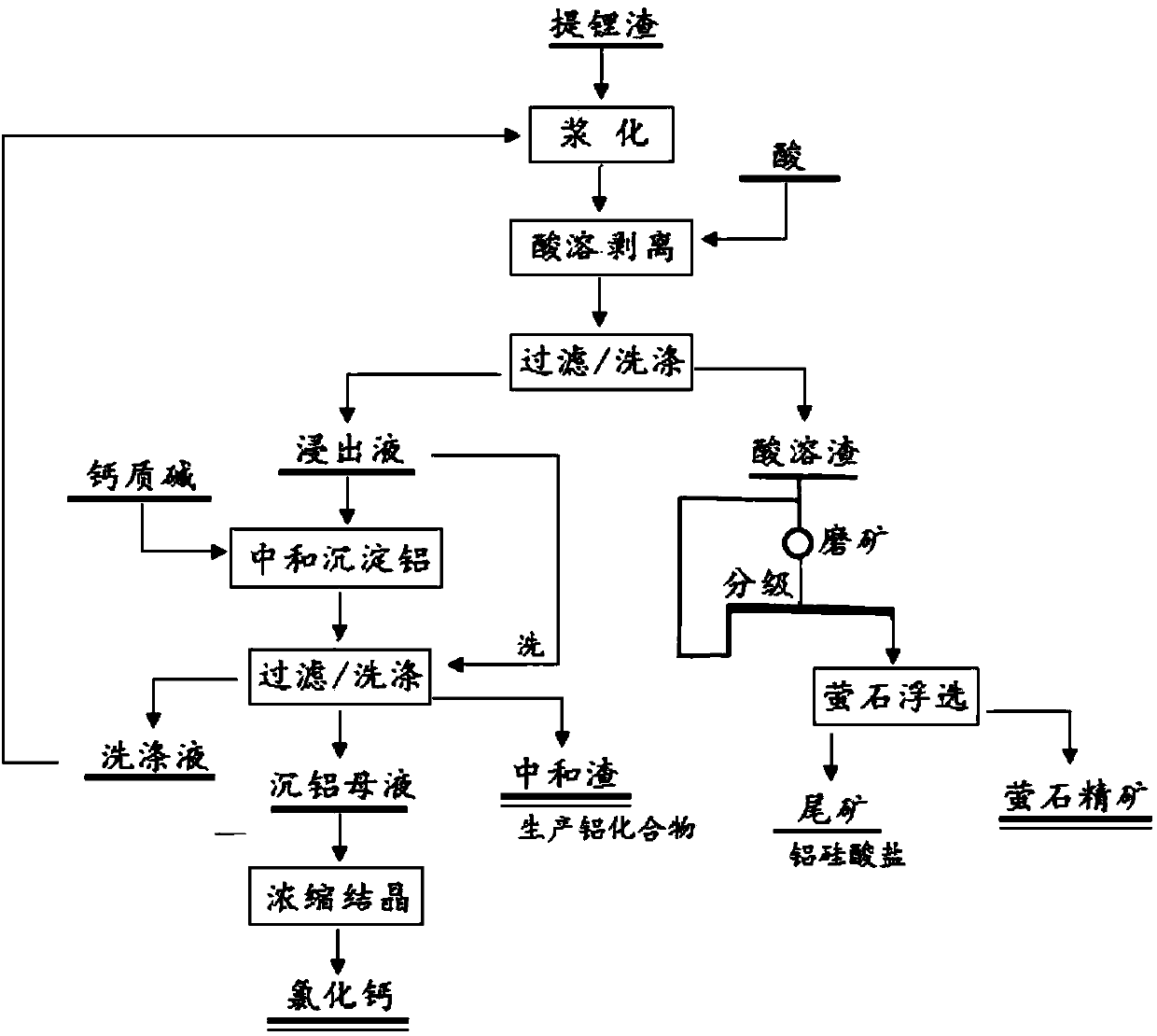

Method for comprehensively utilizing lepidolite mineralogical reconstruction lithium-extraction slags

ActiveCN103789553AShort process flowLess chemical material and energy consumptionProcess efficiency improvementSlagLithium carbonate

The invention provides a method for comprehensively utilizing lepidolite mineralogical reconstruction lithium-extraction slags, wherein the technique of extracting battery-grade lithium carbonate by treating lepidolite by a mineralogical reconstruction method is set as the background of the method, and the lepidolite mineralogical reconstruction lithium-extraction leaching slags are utilized comprehensively. The lithium-extraction leaching slags are subjected to the process steps of stripping, precipitating aluminum hydroxide by a conversion method, concentrating and crystallizing calcium chloride, selecting fluorite out of acid leaching slags, and all the steps cooperate with one another to realizing economic and efficient utilization of the lithium slags together.

Owner:CENT SOUTH UNIV

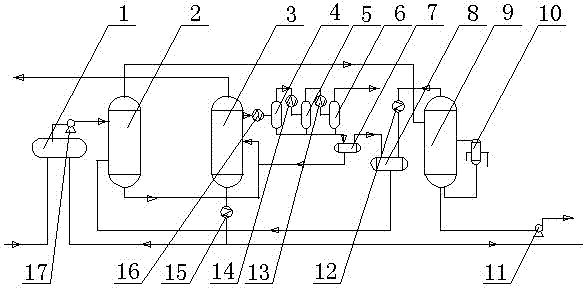

Method for treating high-concentration phenol-ammonia wastewater

InactiveCN103496812AShort process flowImprove processing efficiencyWater contaminantsMultistage water/sewage treatmentCoal gasification wastewaterButyl acetate

The invention relates to a method for treating high-concentration phenol-ammonia coal gasification wastewater. The method takes butyl acetate as an extraction agent and comprises the steps of firstly extracting by use of a phenol extraction tower to remove phenols contained in the wastewater, removing the acid gas and ammonia in the wastewater by use of an acid and ammonia removal tower, and recovering the extraction agent in the extraction phase by use of a solvent stripping tower so as to obtain a crude phenol product from the bottom of the tower. The method provided by the invention realizes high-purity removal of the phenols, acid gas, free ammonia and solid ammonia in the coal gasification wastewater so as to meet the requirement of biochemical treatment on the inflow water quality, and obtains the crude phenol product and high-concentration ammonia gas. Compared with the prior art, the method provided by the invention has the advantages of good extraction effect, high phenol removal efficiency, short process flow and low treatment cost; the method is simple and convenient to operate, and the treatment quality is reliable.

Owner:HENAN DRAGON INTO COAL TECH CO LTD

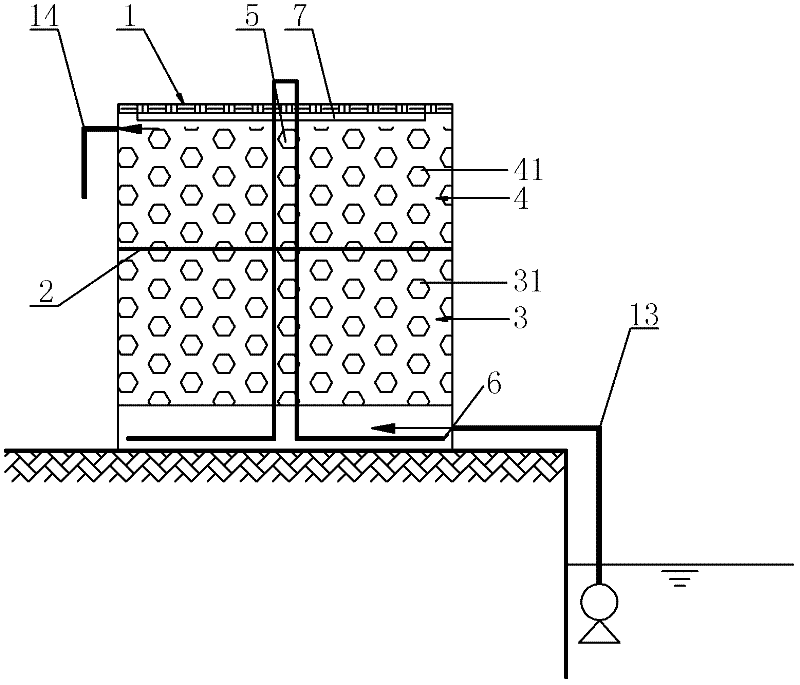

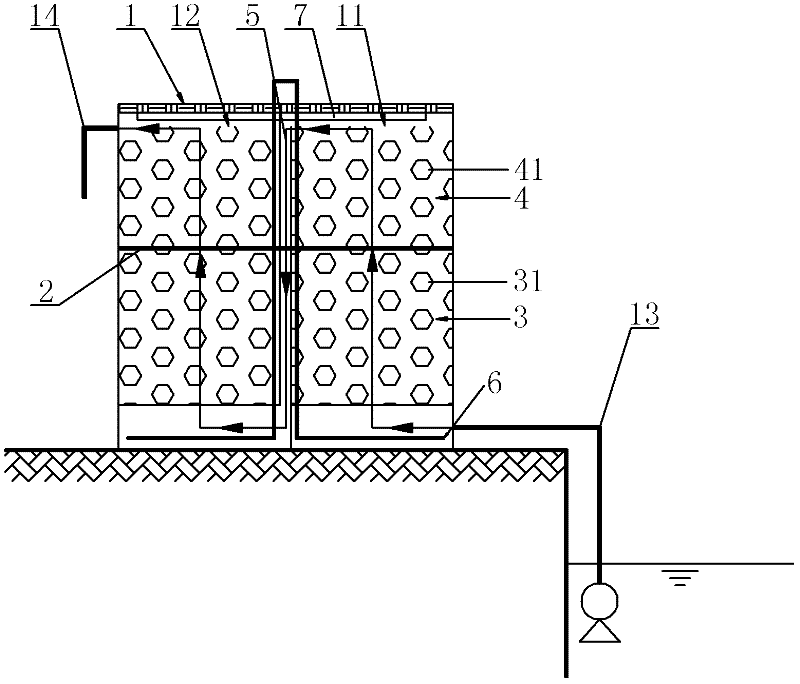

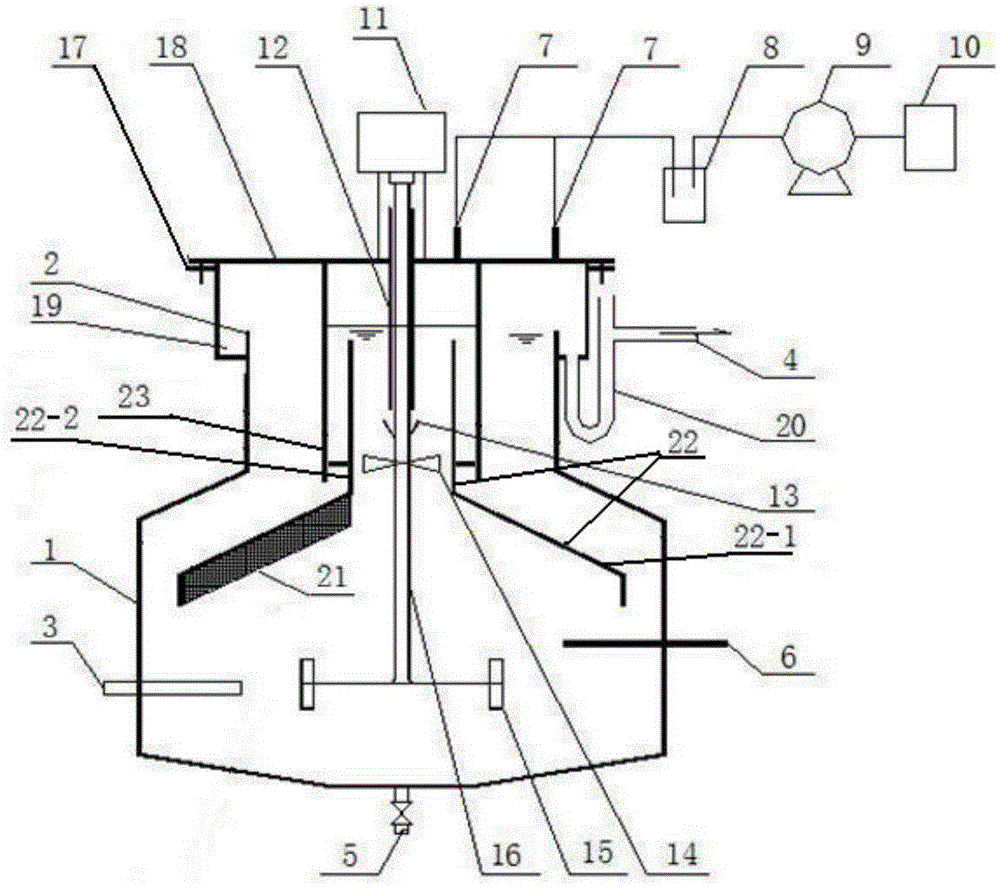

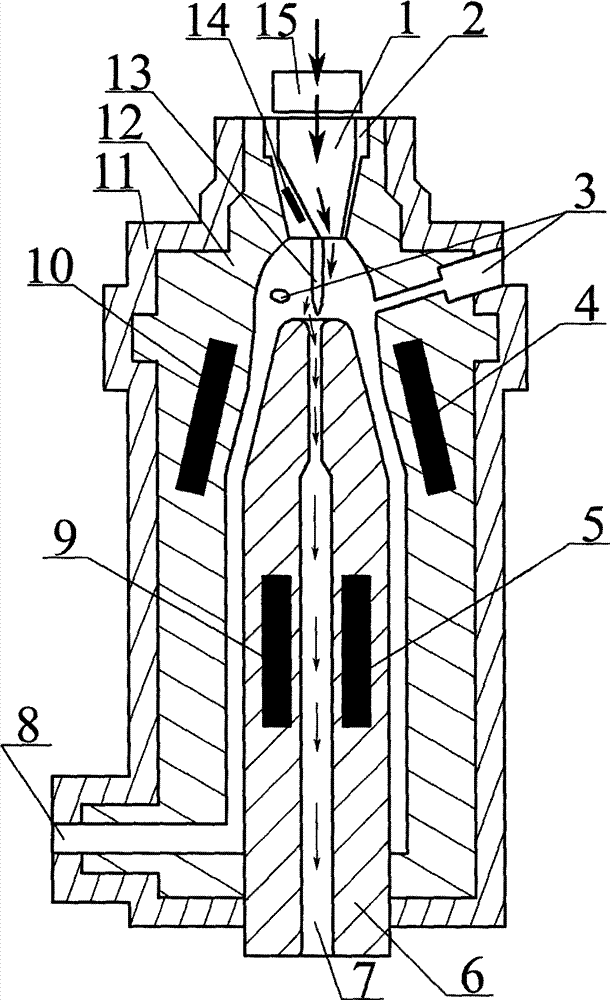

Biological membrane-photocatalytic integration reaction device for micro pollution raw water pretreatment

InactiveCN102336503AImprove the overall degradation efficiencyShort process flowWater/sewage treatment by irradiationMultistage water/sewage treatmentPhotocatalytic reactionFilling materials

The invention relates to a biological membrane-photocatalytic integration reaction device for micro pollution raw water pretreatment, which comprises a device body, a water inlet pipeline and a water outlet pipeline, wherein the water inlet pipeline and the water outlet pipeline are communicated with the device body, the device body is separated into a biological membrane biochemical reaction region positioned at the lower part and a photocatalytic reaction region positioned at the upper part through a transverse perforated separation plate, biological filling materials are filled in the biological membrane biochemical reaction region, photocatalytic suspension filling materials are filled in the photocatalytic reaction region, the bottom of the biological membrane biochemical reaction region is provided with the water inlet pipeline, the water inlet pipeline is communicated with raw water through a water pump, and the top of the photocatalytic reaction region is provided with the water outlet pipeline. The biological membrane biochemical reaction and the photocatalytic reaction are integrated into one reaction device, the transverse separation is realized through a middle perforated plate, the flow direction conversion of the water flow is realized through a middle vertical water pass passage, the total degradation efficiency of the reaction device on organic matters can be improved after the two-stage treatment of biological-photocatalytic treatment, simultaneously, the treatment process flow is shortened, and the occupied area is saved.

Owner:CHANGZHOU UNIV +1

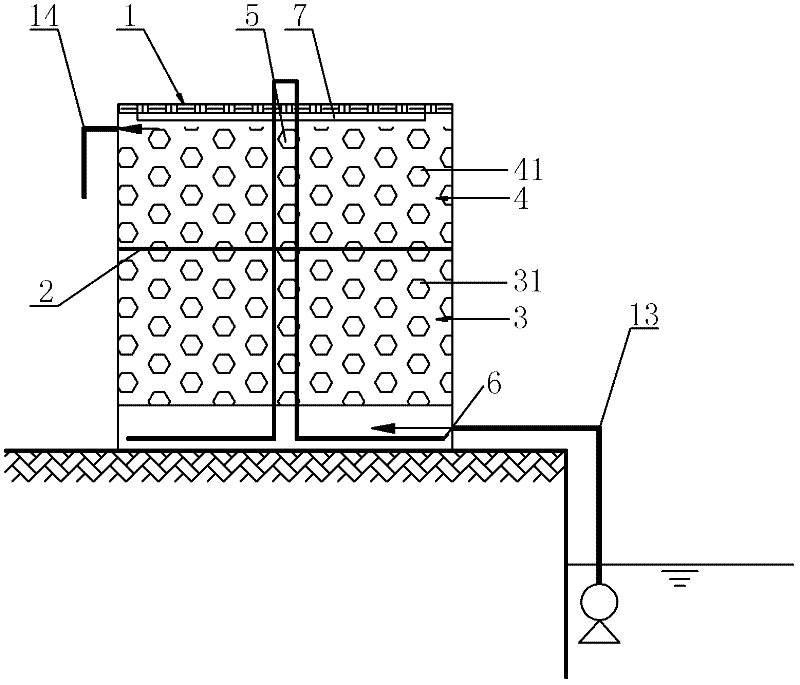

Production technology of finish-rolled ribbed bars

ActiveCN102363832AShort process flowReduce manufacturing costHeat treatment process controlCarbon steelRebar

The invention belongs to the technical field of ferrous metallurgy technology, and especially provides a production technology of finish-rolled ribbed bars. The technological line provided by the invention comprises steps of billet heating, rolling, on-line controlled cooling, cold bed natural cooling, scaling, and stack cooling. Medium-carbon steel is adopted in square billets with a dimension of 150mm*150mm. A three-stage heating method comprising preheating, heating, and soaking is adopted in the heating process. An initial rolling temperature is controlled at 1000 DEG C to 1100 DEG C in the rolling process. In the on-ling controlled cooling process, the temperature is controlled at 920 to 1000 DEG C when the billets are delivered into a water tank; a one-step cooling method is adopted; self-tempering temperatures of PSB785 and PSB830 are controlled at 480 to 550 DEG C; and a self-tempering temperature of PSB930 is controlled at 430 to 480 DEG C. The cooling speed is controlled at 1-5 DEG C / s in the cold bed natural cooling process. Off-line stack cooling under a temperature of 150 to 350 DEG C is carried out in the stack cooling process, wherein a stack cooling time is lower than 48 hours. Various properties of the finish-rolled ribbed bars provided by the invention can completely satisfy the requirements of users.

Owner:TIANJIN IRON & STEEL GRP

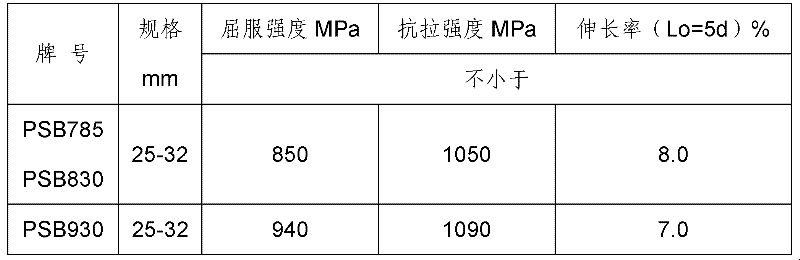

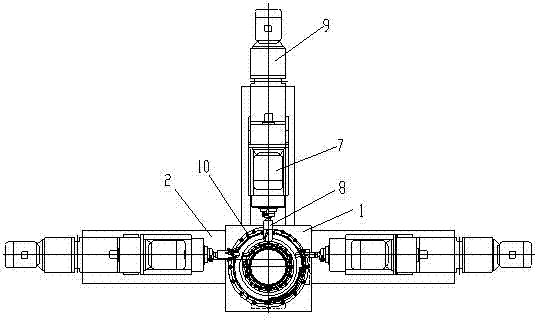

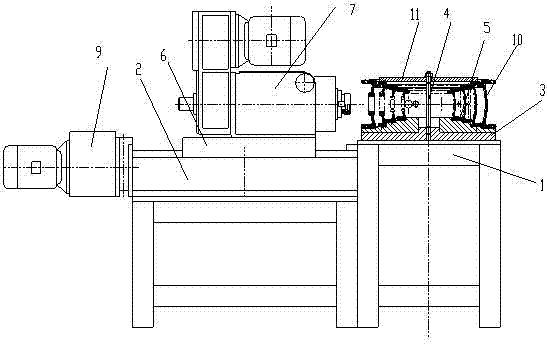

SMF20-50 multi-station drill boring machine

InactiveCN102773712AImprove interchangeabilityReduce clampingOther manufacturing equipments/toolsPositioning apparatusMachining timeMachine tool

The invention discloses an SMF20-50 multi-station drill boring machine, comprising a pagoda disc seat and bases. The bases are all distributed on the left side, the right side, and the middle of the plane around the pagoda disc seat. The pagoda disc seat is provided with a pagoda disc. The pagoda disc comprises a locating shaft arranged in the center of the pagoda disc. At least four layers of step clamping surfaces are arranged by using the locating shaft as a center. Each base is moveably provided with a sliding table. The sliding table is provided with a power head. The power head is provided with a drill head. The direction of the drill head points to the pagoda disc. Through the SMF20-50 multi-station drill boring machine disclosed by the invention, three holes can be drilled while one-time clamping positioning is carried out, and the machining precision is guaranteed by the self precision of a machine tool without repeated clamping and repeated adjusting, so that the clamping and adjusting time is greatly shortened. The three holes are simultaneously machined so as to largely shorten the machining time. The SMF20-50 multi-station drill boring machine disclosed by the invention has the advantages of high precision, short process flow, and small cumulative error, lightened labor intensity and improved machining efficiency; in addition, the assembly interchangeability of parts is very good.

Owner:常州华东人防设备有限公司

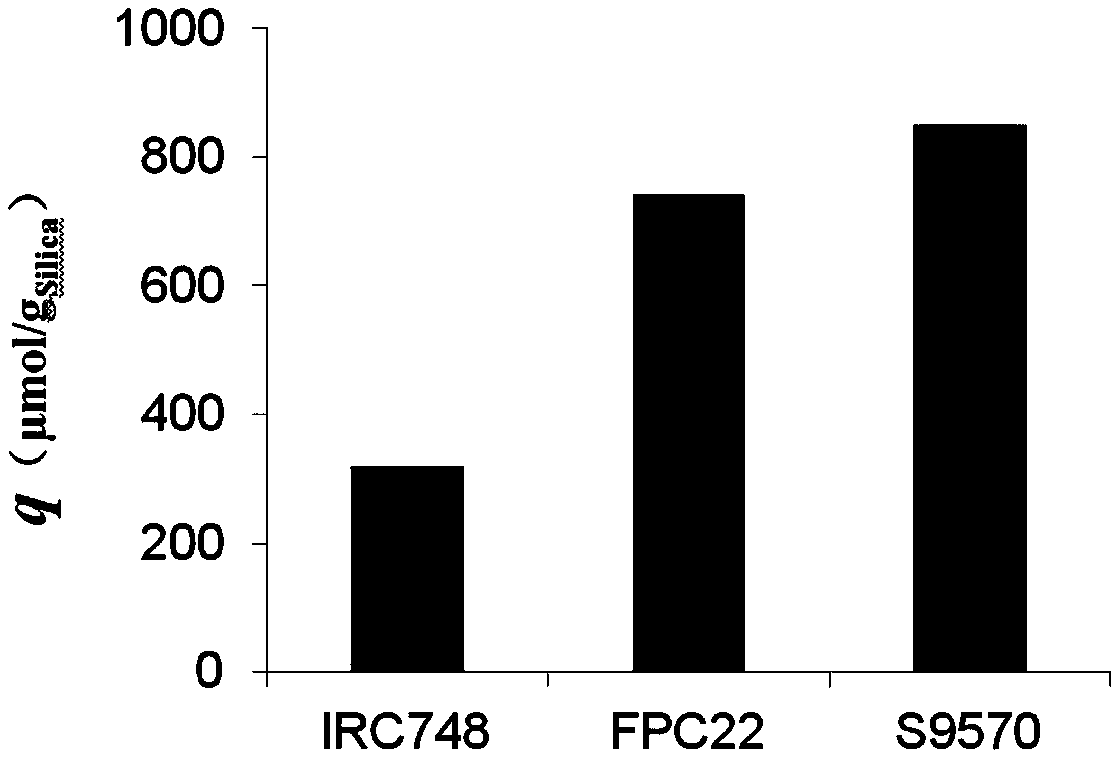

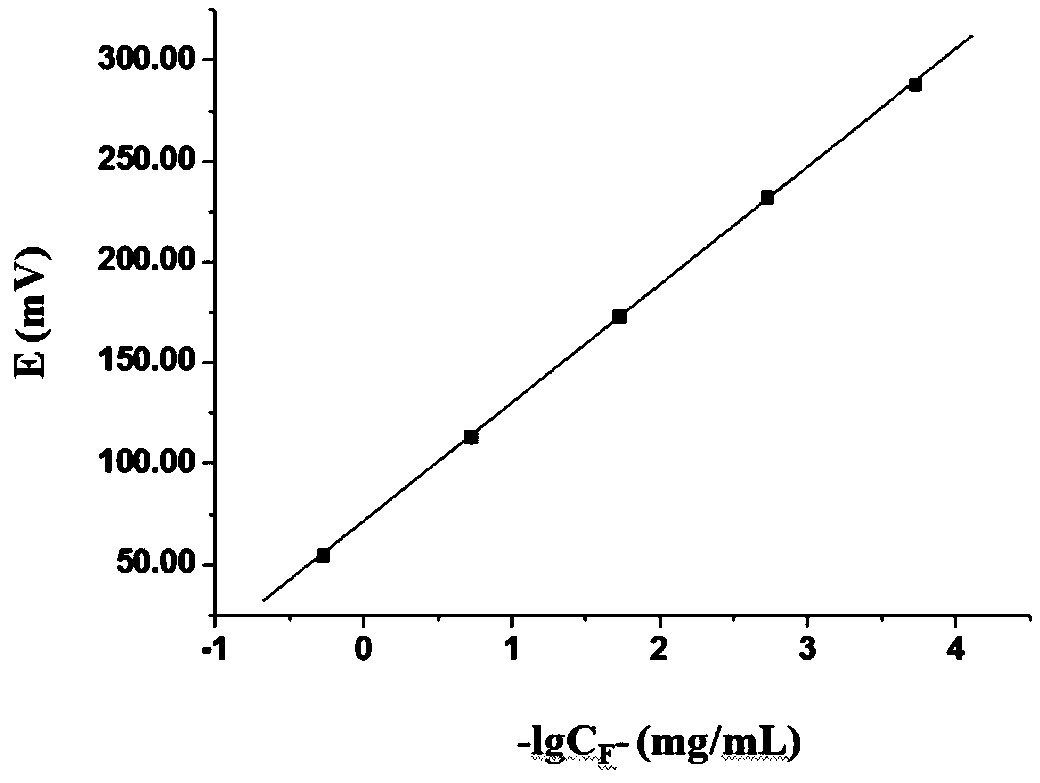

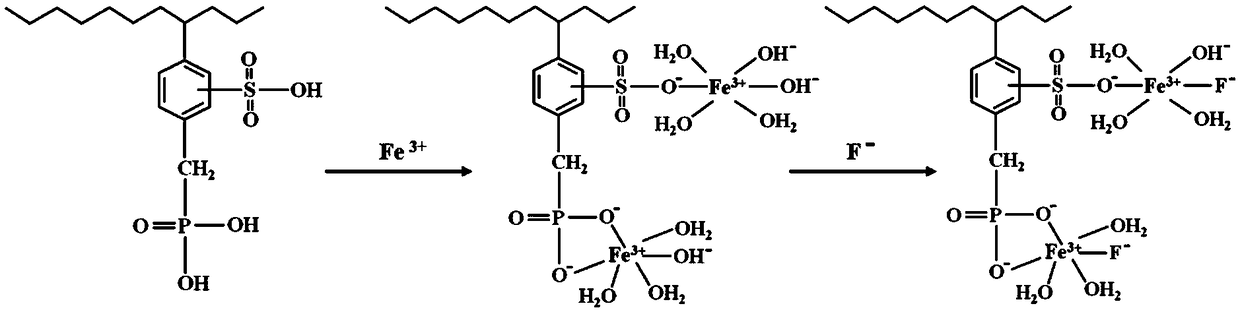

Use of bifunctional metal chelate resin adsorbent in fluoride removal from wastewater

ActiveCN108996598AStrong chelating abilityTo achieve the effect of defluorinationOther chemical processesWater contaminantsSorbentMetal chelate

The present invention discloses a use of a bifunctional metal chelate resin adsorbent in fluoride removal from wastewater. A bifunctional chelate resin is used for the first time, which is firstly converted into a metal chelate resin through full adsorption with metal ions. Then, fluoride containing waste water to be treated is fully contacted with the chelate resin, and fluoride-free purified water is obtained by means of coordination interaction between metal ions and fluoride ions. This method achieves the effect of removing fluoride from wastewater with the advantage of double bifunctionalgroups. Compared with a traditional method of removing fluoride with a chelate resin, the method adopted in the present invention is fluoride removal with double functional groups, which overcomes the defects of fluoride removal with a single functional group and is significant in fluoride removal effect.

Owner:NORTHWEST UNIV

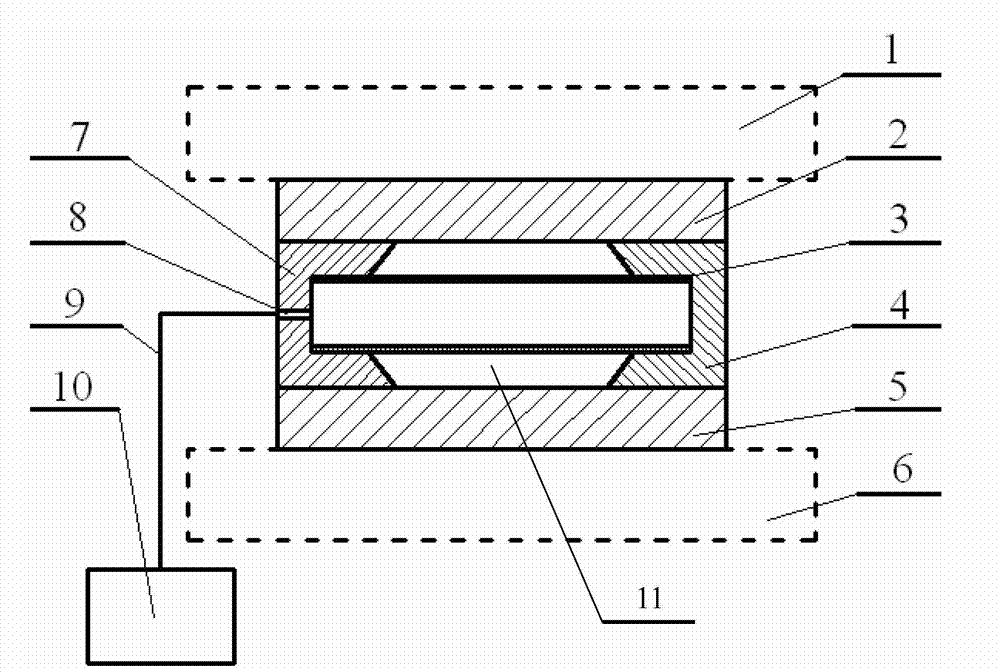

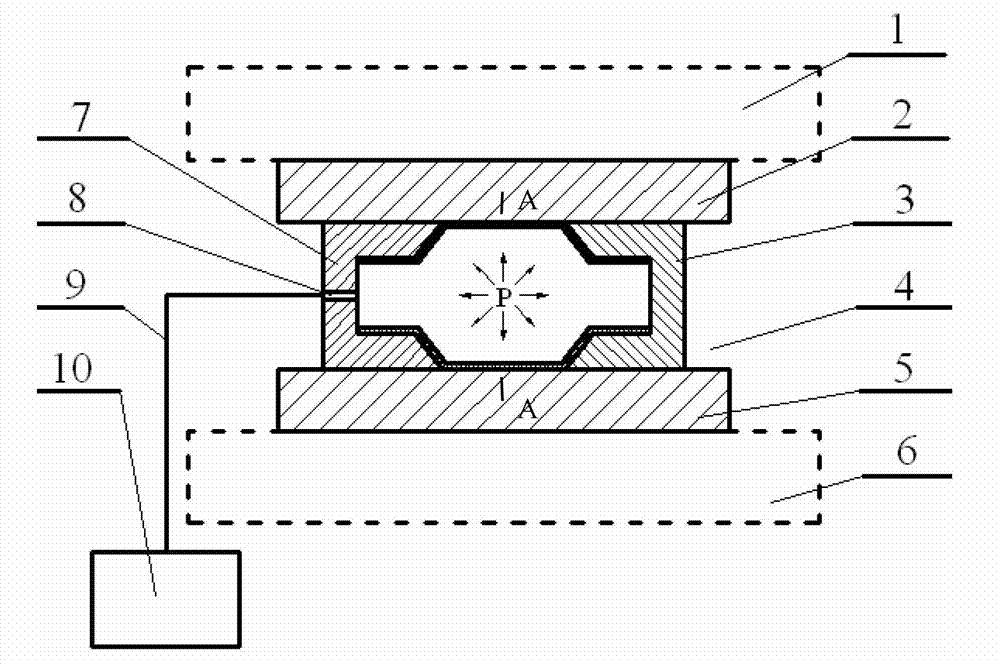

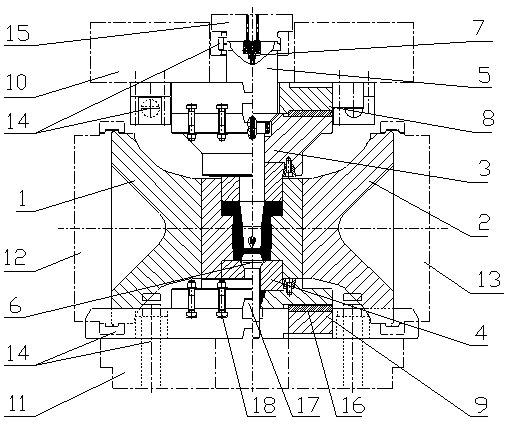

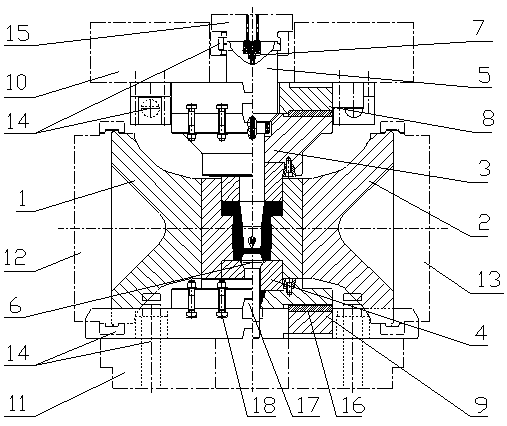

Section-variable hollow component forming device and method

InactiveCN102921791AAvoid technical problems with high sealing requirementsImprove uniformitySize differenceLiquid medium

The invention provides a section-variable hollow component forming device and a section-variable hollow component forming method, belongs to the technical field of hydraulic formation, and solves the problems that when a hollow component with a large hydraulic formation section size difference of a traditional tubular product is formed, axial feeding is difficult, the deformation uniformity is poor and the like. A closed cavity is formed by an upper die base, a left puncher pin, a right puncher pin and a lower die base; a puncher pin liquid injection hole is formed on the left puncher pin or the right puncher pin; a pressurizing device is communicated with the puncher pin liquid injection hole through a liquid channel; and the puncher pin liquid injection hole is used for injecting a liquid medium into a pipe blank. A pipe blank is placed into a die cavity and the puncher pins at the two ends are used for fixing the pipe blank; the upper die base is moved downwards to form a sealed hollow cavity with the lower die base; a force transfer medium is injected into the tubular product from the puncher pin injection hole at one side to pressurize; and the formation of a diameter-changing tube piece is realized under the matching effect of moving the left and right puncher pins to the inner side. After the formation, pressure in the die cavity can be removed after the formation, the upper die base is removed to separate the left and right puncher pins, and the formed piece is taken out. The section-variable hollow component forming device and the section-variable hollow component forming method are suitable for forming the hollow component with the great change of the section size and the circular-section or non-circular-section diameter-changing part.

Owner:哈尔滨松花江汽车座椅有限责任公司

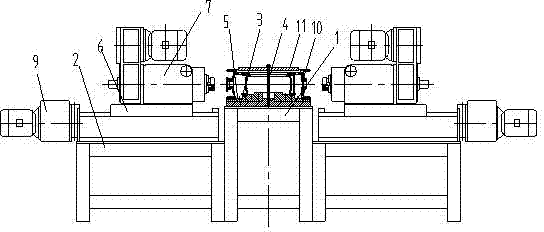

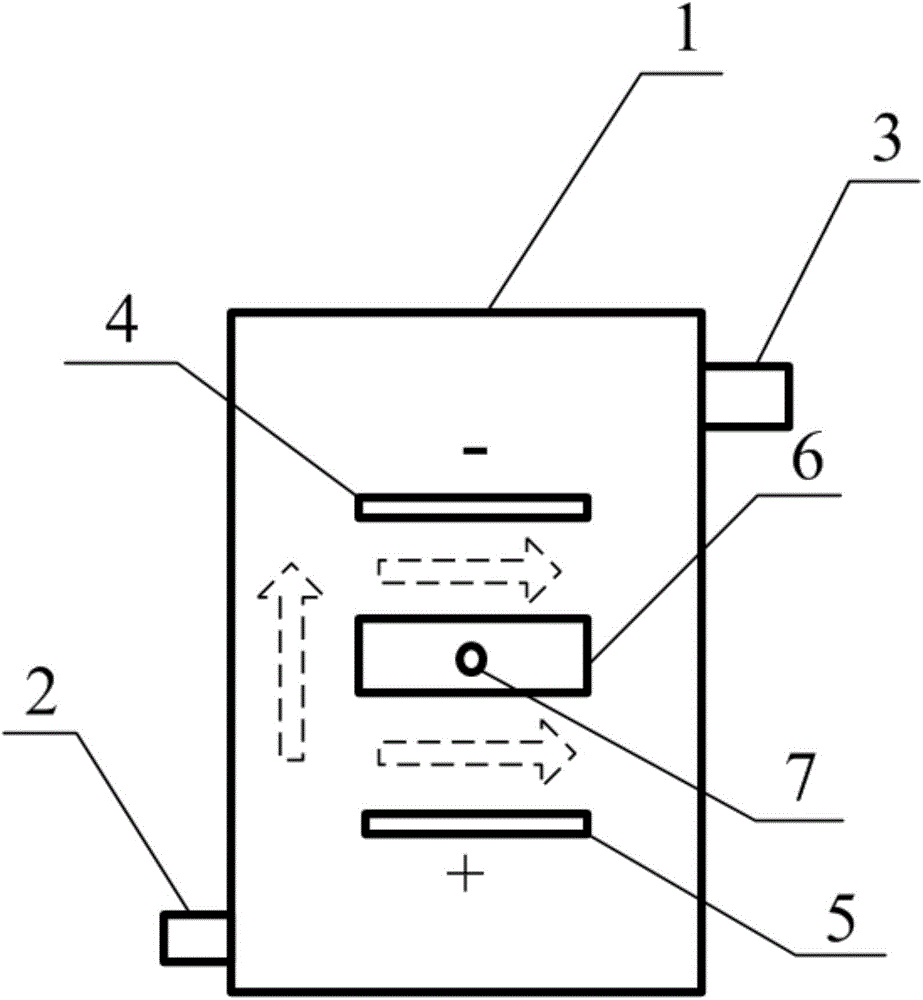

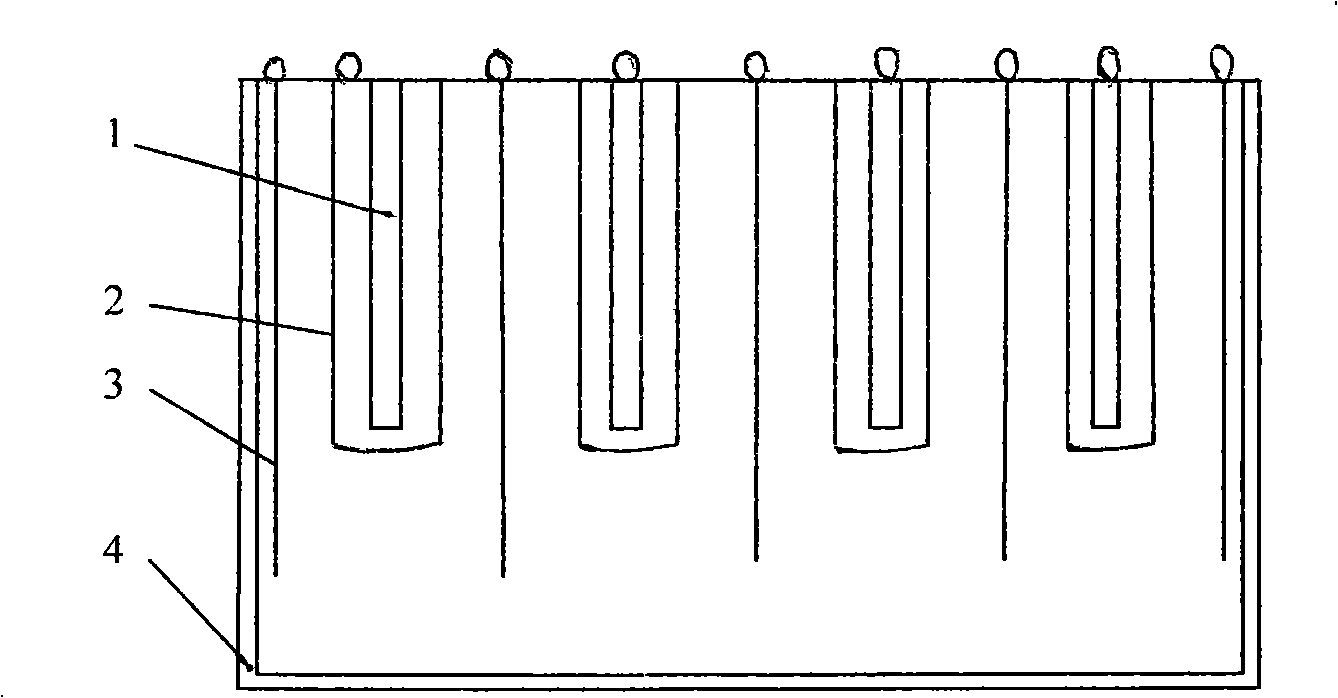

Electric flocculation and membrane separation water treatment device, treatment method and application of device

InactiveCN104787940AImprove filtering effectImprove surface propertiesMultistage water/sewage treatmentFlocculationFiltration

The invention provides an electric flocculation and membrane separation water treatment device, a treatment method and an application of the device. The device comprises a device body (1), wherein a water inlet (2) is arranged on one side of the bottom of the device body (1), a water outlet (3) is arranged on one side, opposite to the side where the water inlet (2) is located, of the top of the device body (1), a cathode plate (4), an anode plate (5) and a membrane assembly (6) are arranged in the device body (1), and a collector pipe water outlet (7) is formed in one side surface of the device body (1). An electric flocculation and membrane technology is organically integrated to the same reaction unit to form an electric flocculation and membrane separation short-process technology; the flocculation form and a floccule structure are controlled under the electrochemical action, the membrane filtration performance is optimized, meanwhile, the membrane surface characteristics are optimized through actions of an electric field effect, electrochemical oxidation and electroflotation, so that electric flocculation effluent quality is improved, the membrane pollution is relieved, and pollutants are removed through the synergistic effect of electric flocculation and membrane separation.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Silver micro powder as well as preparation method and application thereof

InactiveCN107052326AReduce contentShort process flowTransportation and packagingMetal-working apparatusChemical reactionSlurry

The invention relates to a method for preparing silver substances through a chemical reaction, in particular to silver micro powder as well as a preparation method and application thereof. The silver micro powder consists of silver particles of which the average particle size is 0.8-1.6 [mu]m, and the particle size distribution of the silver particles is that D50 is lower than or equal to 0.5 [mu]m, D10 is lower than or equal to 0.2 [mu]m, and D90 is lower than or equal to 1.2 [mu]m; the apparent density is 1.2-2.1 g / cm<3>; and the tap density is 2.8-4.5g / cm<3>. The preparation method of the silver micro powder comprises the following steps of adding a silver nitrate solution and a reducing agent solution to a reaction kettle together; using nitric acid and an ammonia solution as an acid-base adjusting agent, and performing a reaction under the condition of pH value being 1-7 and the temperature being 20-50 DEG C; performing filtering and performing washing; and after grinding for 1-3h, performing drying and performing screening so as to obtain the silver micro powder. According to the silver micro powder as well as the preparation method and the application thereof disclosed by the invention, sheet-form silver powder is directly prepared from silver nitrate, so that the process flow is short, the technology is simple, and the production efficiency is high; the prepared silver micro powder in irregular shape can be applied to products including solar battery conductor slurry, a conductive coating, conductive ink, conductive adhesive and the like; and under the premise that the same performance is achieved, the silver powder content can be effectively reduced, and the cost is saved.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Self-heat-supply type sludge dewatering and drying method and system

PendingCN107867790AImprove the coagulation effectReduce dosageSludge treatment by de-watering/drying/thickeningGas treatmentFlocculationCombustion

The invention relates to a self-heat-supply type sludge dewatering and drying method and system. The dewatering and drying method comprises the following steps: firstly, adding a flocculation chemicalto to-be-treated sludge, and performing concentration and dewatering to obtain concentrated sludge; adding a sludge conditioner to the concentrated sludge, and stirring the sludge uniformly to obtainconditioned sludge; performing press filtration dewatering on the conditioned sludge to obtain a sludge filter cake; crushing and drying the sludge filter cake in high-temperature flue gas to obtaina dust and sludge mixture; conveying the dust and sludge mixture to a gas-solid separation device, and separating the sludge from the flue gas to obtain powdery sludge with water content being 15wt.%-20wt.%; feeding the sludge into a combustion heat supply mechanism after granulation, performing combustion to obtain high-temperature flue gas, cooling the high-temperature flue gas and conveying thehigh-temperature flue gas to a crushing and drying device. The method and the system are high in continuity and dewatering degree, the sludge treatment process is short, the operation cost is low, anexternally added heat source is not needed, so that energy cost is reduced greatly, and the sludge mass is further reduced by combustion.

Owner:HUNAN BAILIN BIOLOGICAL TECH

Anodic oxidation coloring technology for titanium and titanium alloy

InactiveCN107236982AShort processImprove surface qualitySurface reaction electrolytic coatingAnodic oxidationTitanium

The invention discloses an anodic oxidation coloring technology for titanium and titanium alloy. According to the technological process, the machined and cleaned titanium or titanium alloy is subjected to the following steps that (1) pretreatment is conducted, specifically, light grinding treatment is conducted on the surface of the titanium or the titanium alloy, so that a sample A of the titanium or the titanium alloy is obtained; (2) pickling activation is conducted, specifically, the sample A of the titanium or the titanium alloy is subjected to pickling activation treatment through a pickling solution, and a sample B of the titanium or the titanium alloy is obtained; and (3) anodic oxidation is conducted, specifically, the sample B of the titanium or the titanium alloy is subjected to anodic oxidation treatment through electrolyte, and a product C of the titanium or the titanium alloy is obtained and has a high-brightness oxidation film with different colors. According to the anodic oxidation coloring technology, the treatment procedure is short, the surface of the titanium or the titanium alloy is high in quality and glossy, and on the basis that the basic performance of an original colorful oxidation film is maintained, the product is made to be more beautiful.

Owner:TIANJIN ZHENGTIAN MEDICAL INSTR CO LTD

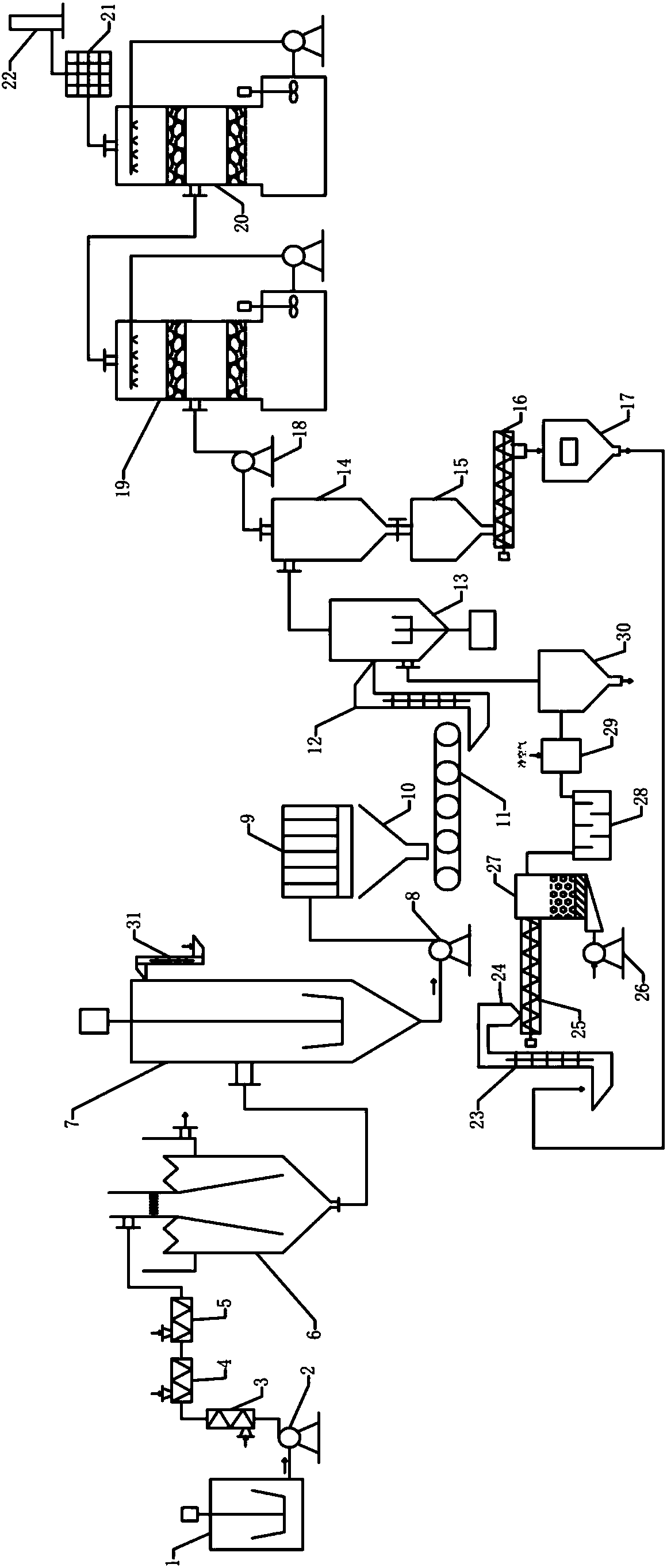

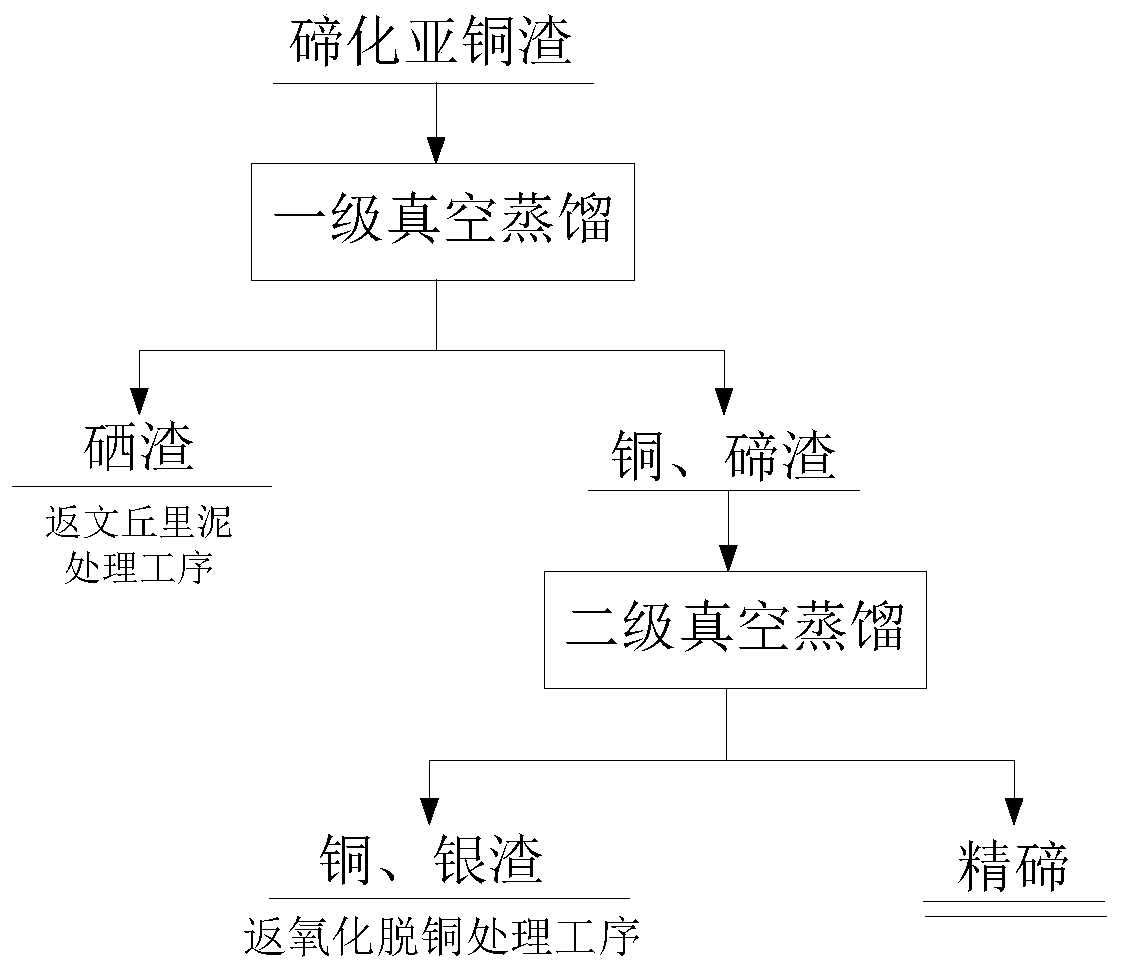

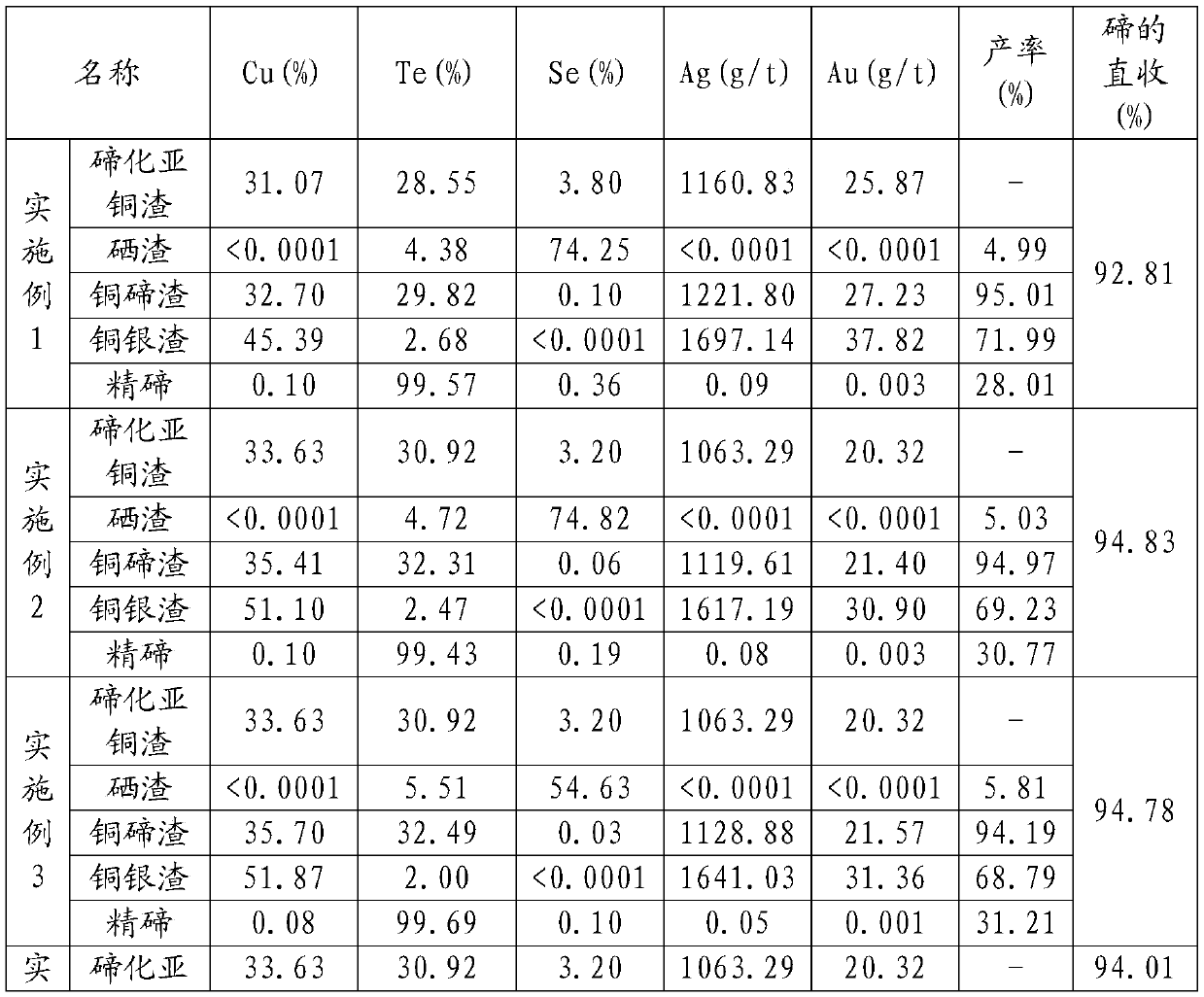

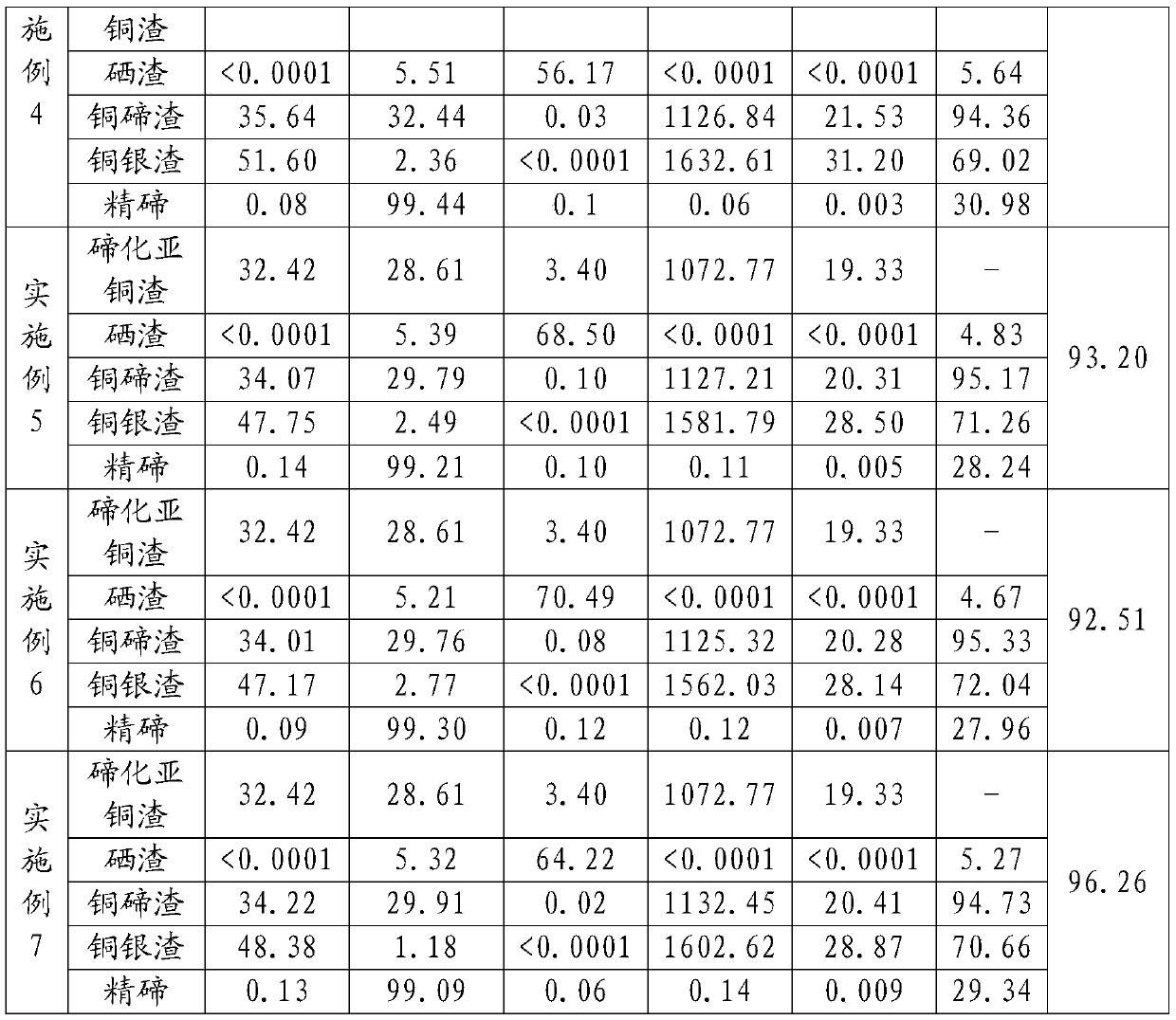

Method for separating and purifying tellurium from cuprous telluride slag through vacuum distillation

InactiveCN110144458AAchieve leachingStable in natureRotary drum furnacesProcess efficiency improvementSlagTe element

The invention discloses a method for separating and purifying tellurium from cuprous telluride slag through vacuum distillation. The method comprises the following steps of S1, placing the cuprous telluride slag in a vacuum distillation furnace, and performing vacuum distillation at the vacuum degree of 10-150 Pa to obtain selenium slag and copper-tellurium slag, wherein the vacuum distillation temperature is 390 DEG C-470 DEG C, and the time is 1-4 h; and S2, placing the copper-tellurium slag obtained in the S1 in the vacuum distillation furnace, and performing vacuum distillation at the vacuum degree of 10-150 Pa again to obtain refined tellurium products and copper-silver slag, where the secondary vacuum distillation temperature is 890 DEG C-950 DEG C, and the time is 1-4 h. According to the method, the problems of low direct recovery, long process flow and the like in the current cuprous telluride slag treatment process can be solved, and the short-process and high-value recovery of valuable elements in the cuprous telluride slag is achieved.

Owner:ZIJIN MINING GROUP +2

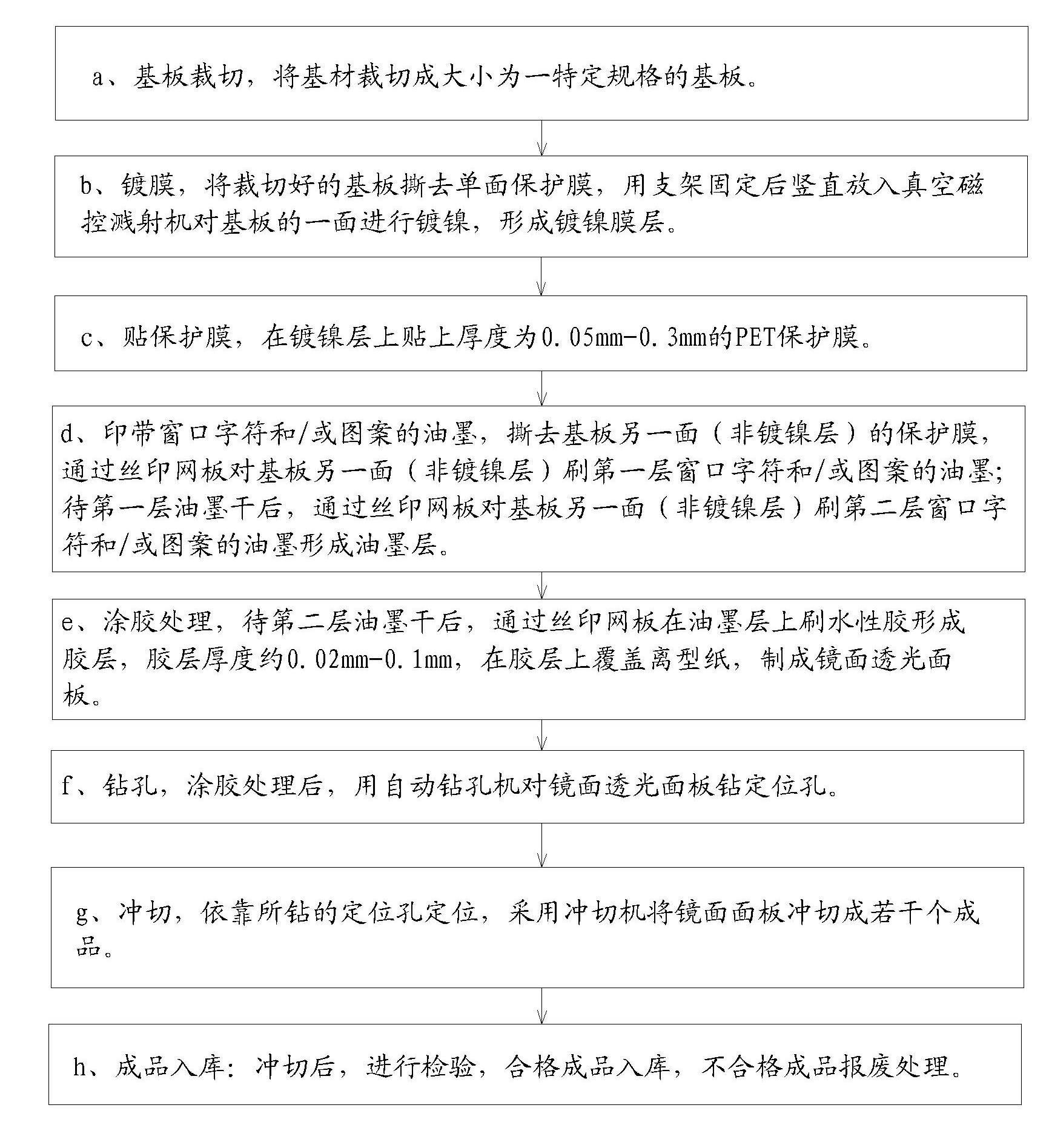

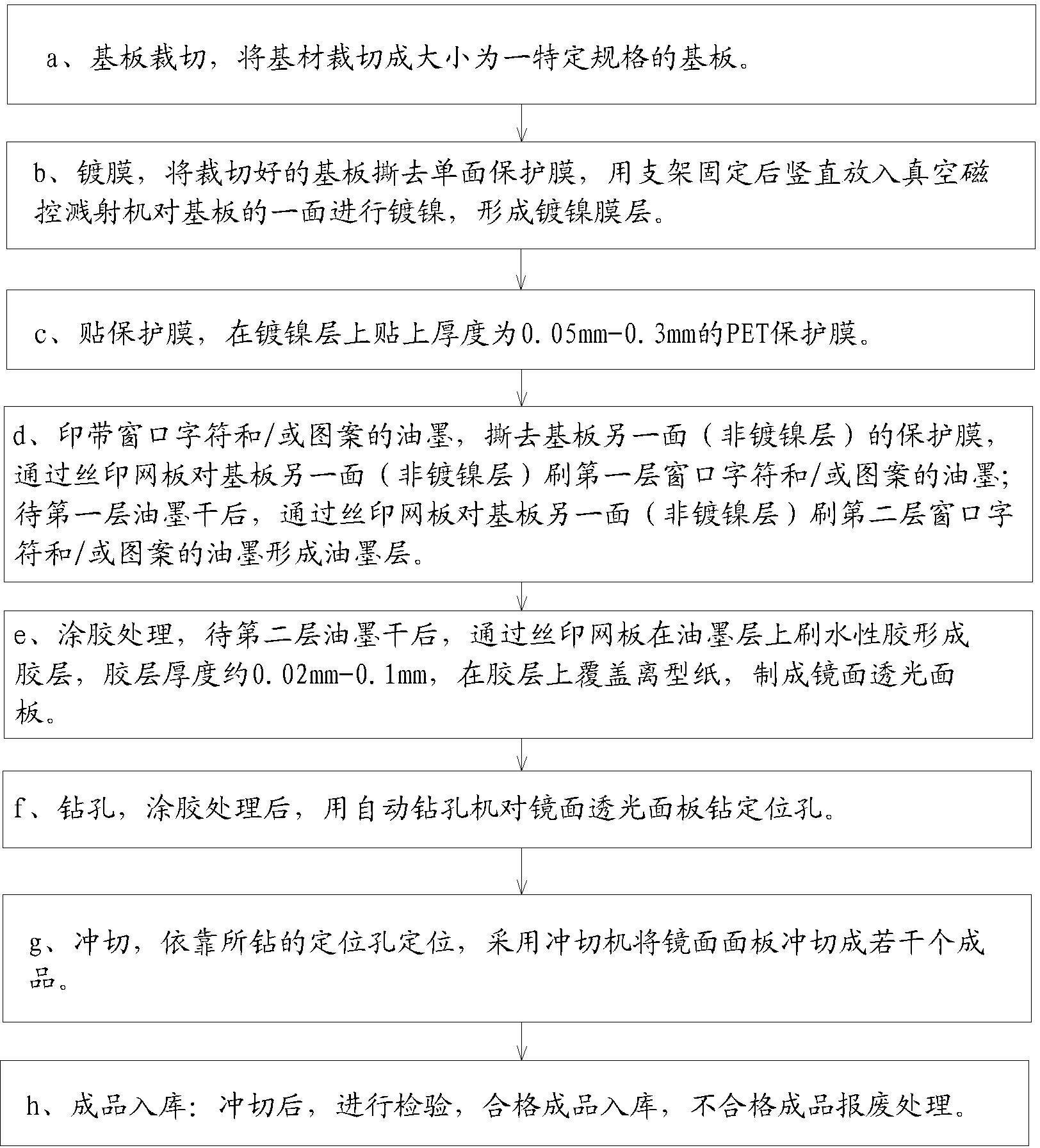

Production process of single-layer mirror-surface light transmitting panel

ActiveCN102416726AImprove aestheticsSimple preparation processLamination ancillary operationsLaminationWater basedTectorial membrane

The invention provides a production process of a single-layer mirror-surface light transmitting panel. The process comprises the following steps of: substrate cutting, wherein a base material is cut into a substrate with size of a particular specification; film coating, wherein nickel is plated on one surface of the cut substrate; sticking of a protection film, wherein a PET (polyethylene terephthalate) protection film with thickness of 0.05-0.3 mm is adhered to the nickel plating layer; printing of ink with a window character and / or pattern, wherein two layers of ink with a window character and / or pattern are brushed on the other surface of the substrate; gluing treatment, wherein after the second layer of ink is dried, brushing water-based glue on the ink layer to form a glue layer with thickness of 0.02-0.1 mm, and covering release paper to obtain a mirror-surface light transmitting panel; drilling, wherein an automatic drilling machine drills a positioning hole on the mirror-surface light transmitting panel; punching, wherein after the positioning, the mirror-surface panel is punched into multiple finished products by a punching machine; and storage of the finished products, wherein after the punching, the finished products are inspected, and the qualified products are stored. Through the process provided by the invention, the produced single-layer mirror-surface light transmitting panel has a good light transmission and mirror surface effect, and is beautiful and easy to produce; and moreover, the technique is simple, the cost is low, and the process has a short flow.

Owner:XIAMEN HUALIAN ELECTRONICS CO LTD

Heavy oil sewage demulsifier

ActiveCN101397160AShort process flowLow running costWater/sewage treatment by flocculation/precipitationTherapeutic effectToxic industrial waste

The invention relates to a thick-oil sewage demulsifier. The main raw materials of the thick-oil sewage demulsifier are industrial waste acid and polyaluminium chloride polyacrylamide, the weight percentage of the both is 70% and 30% respectively, industrial waste acid and polyaluminium chloride polyacrylamide are added in the thick oil sewage, and pH value is adjusted at about 7.0, after polyacrylamide is added in for rapid mixing, slow reaction and sedimentation, emulsion breaking of thick oil sewage and separation of oil and water are realized. The thick-oil sewage treatment agent provided by the invention is characterized by low cost and good treatment effect, by utilizing the thick oil sewage treatment agent, the process flow of sewage treatment can be shortened greatly, and good economic benefit can be obtained.

Owner:PETROCHINA CO LTD

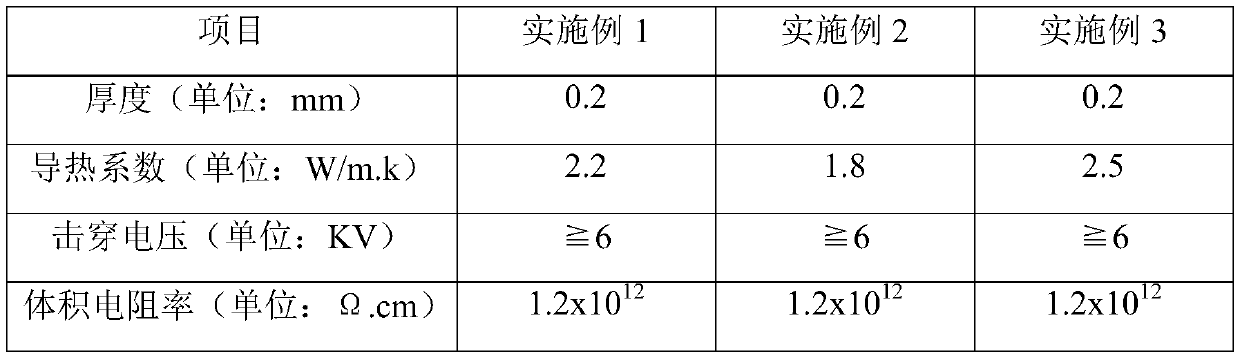

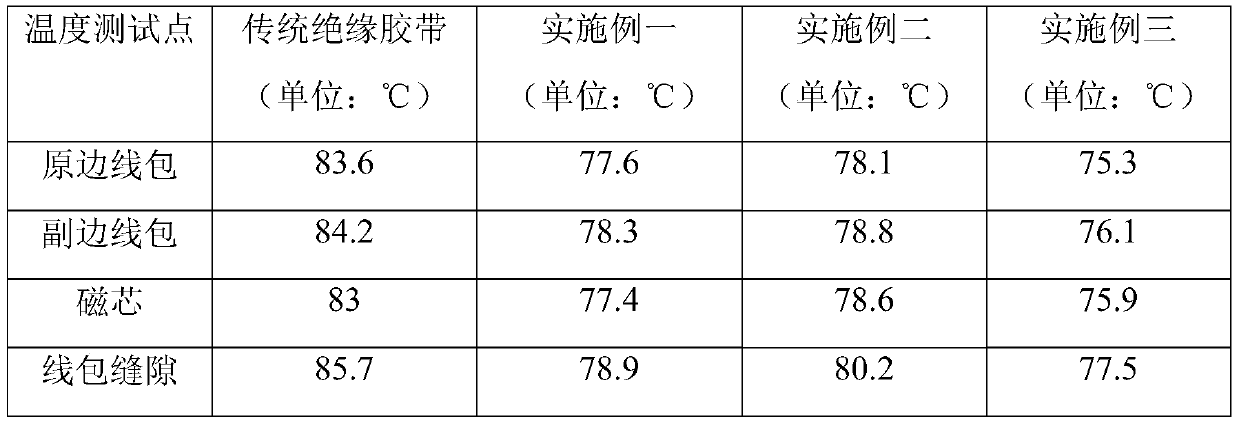

Heat conduction insulating adhesive tape and preparation method thereof

InactiveCN110698994ASolve the cooling problemSolve insulation problemsNon-macromolecular adhesive additivesFilm/foil adhesivesAdhesive cementPolymer science

The invention relates to a heat conduction insulating adhesive tape and a preparation method thereof. The heat conduction insulating adhesive tape comprises a substrate layer, a heat conduction adhesive layer and a release film layer which are arranged successively from bottom to top, wherein the substrate layer is a non-woven fabric substrate or a composite fiber fabric substrate; and the heat conduction adhesive layer comprises an adhesive, a nanometer heat conduction filler, a heat stabilizer, an antioxidant, a plasticizer, a coupling agent and a solvent. As the non-woven cloth or compositefiber cloth is preferred as the material of the substrate layer, and together with the nanometer heat conduction filler used in the heat conduction adhesive layer, high insulation and high thermal conductivity of the adhesive tape are comprehensively realized; when a conventional insulating adhesive tape is replaced by the heat conduction insulating adhesive tape provided by the invention, both the insulation can be ensured and the problem of temperature rise of a device can be solved, the operation stability of a product can be improved, and the service life of the product can be prolonged;and meanwhile, the adhesive tape is simple in preparation method process, short in process procedure, common in use equipment, low in raw material price and applicable to on-batch production and use.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Novel sole making process

InactiveCN106108259AAvoid crackingImprove adhesionDomestic footwearShoe gluingEngineeringPhysical property

The invention discloses novel sole making process. The process comprises following steps: cleaning an abrasion resistant attachment; gluing a to-be-bonded surface of an abrasion resistant attachment and upwardly putting the processed to-be-bonded surface of the abrasion resistant attachment to a die; putting a telescopic film to the die to cover abrasion resistant attachment and a sole, wherein a frame-combining die is used for fixing the telescopic film and heating the die; carrying out vacuum processing in the die such that the telescopic film and a film bottom are closely and smoothly attached, and pouring foaming material to the die and finishing die-combining. The novel sole making process has following beneficial effects: abrasion resistant sheet material and the telescopic film are integrated into an overall sole structure when foams form; operation flow is short; a production cycle is short; flow line production is achieved; working efficiency is high; the sole is not easy to crack; the abrasion resistant sheet material and foaming material are firmly bonded; during the process of making the sole, no foams appear and a glue layer is not exposed without foams; the surface is smooth and attractive in external appearance and uniform in color; a physical property of a product is stable and easy control is achieved.

Owner:中山杰伟鞋业有限公司

Spinning and dyeing pretreatment auxiliary agent and preparation method and application thereof

The invention relates to a spinning and dyeing pretreatment auxiliary agent, which is prepared by adopting the following raw material components: 30 to 50 parts by weight of desizing agent, 5 to 20 parts by weight of alkali-resisting penetrant, and 4 to 10 parts by weight of complexing agent; the desizing agent is multi-alkyl amine salt; the alkali-resisting penetrant is an alkali-resisting nonionic surfactant; the complexing agent is hydroxy carboxylate. Further, the adopted raw material components also include 1 to 10 parts by weight of hydrogen peroxide stabilizer; the hydrogen peroxide stabilizer is organic phosphonate. The spinning and dyeing pretreatment auxiliary agent can be obtained through the preparation of successively mixing the raw material components, and the spinning and dyeing pretreatment auxiliary agent can be applied to a cold-batch method or open-width scouring-bleaching method spinning and dyeing pretreatment process. The spinning and dyeing pretreatment auxiliary agent can shorten the flow of the conventional spinning and dyeing pretreatment process, can reduce the energy consumption and material consumption in the pretreatment process, and can reduce the effluent volume; an obtained intermediate product of textile fabrics has good whiteness, capillary effect and desizing percentage.

Owner:青岛先达精细化工有限公司

Iron and steel product surface treating agent and preparation method thereof

InactiveCN105256321AShort processLess waste waterMetallic material coating processesActive agentSurface-active agents

The invention provides an iron and steel product surface treating agent and a preparation method thereof, and relates to the technical field of metal surface treating agents. The surface treating agent comprises, by weight, 12%-17% of phosphoric acid with the concentration of 85%, 3%-8% of composite phosphate, 7%-12% of nitric acid with the concentration of 65%, 5%-10% of corrosion inhibitor(s), 1%-3% of aqueous surface active agent(s), 3%-6% of zinc chrome, 4%-7% of polyol ester, and the balance water. The iron and steel product surface treating agent can be used for carrying out derusting, deoiling and phosphating on iron and steel products at the same time, and the generation amount of industrial waste water in the production process can be greatly reduced; the iron and steel product surface treating agent can be stored for a long time without lowering of the effectiveness, and uniform and compact phosphating films still can be formed on the surfaces of the iron and steel products even if the iron and steel product surface treating agent is stored for a long time; in addition, when the iron and steel product surface treating agent is used for carrying out comprehensive surface treating on the iron and steel products, the replacement frequency of bath solutions is low, the utilization rate of acid liquor is high, and the production cost of enterprises is low.

Owner:NANHUA UNIV +1

Sludge circulation efficient hydrolytic reactor

ActiveCN105565489AIncrease mass transfer rateHigh activityBiological treatment apparatusTreatment with anaerobic digestion processesInterior spaceSludge

A sludge circulation efficient hydrolytic reactor comprises a reaction zone, mud lifting zone, a guide zone, a sludge reflow zone and a precipitation zone. The top of the reaction zone is in an umbrella shape, and the inner wall of the umbrella shape is provided with guide plates; the reaction zone is provided with a rectangular stirring paddle, the mud lifting zone is provided with a screw propeller, the rectangular stirring paddle and the screw propeller are fixed to a coaxial stirring link; wastewater flows in the reactor in a circulatory manner; the reactor enables internal circulation of sludge, requires no precipitation tank, makes efficient use of its interior space and has the advantages of high mass transfer capacity, biomass quantity, high hydrolytic efficiency, low cost, small size and the like.

Owner:HARBIN INST OF TECH

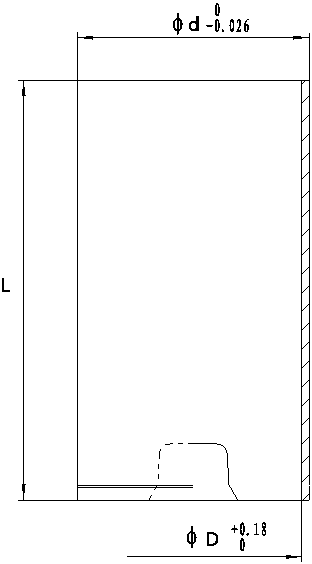

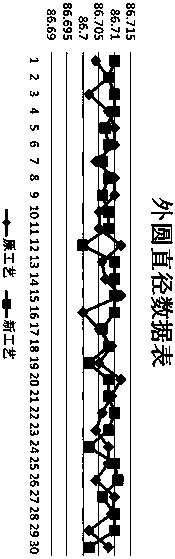

Dry cylinder liner preparation technology

The invention discloses a dry cylinder liner preparation technology, and belongs to the technical field of cylinder liner production. The dry cylinder liner preparation technology comprises casting and machining, and specifically comprises the following preparation steps that (1) a cylinder liner casting piece is prepared through a steel pipe or metal mold wet coating centrifugal casting technology, then, the cylinder liner casting piece is sawn into cylinder liner casting piece blanks, and heat treatment is conducted on the blanks; and (2) the cylinder liner casting piece obtained in the step(1) is subjected to inner hole cutting and outer circle cutting and then follow-up outer circle grinding and milling through a high-precision machine tool, and specifically, inner hole boring, outercircle finish turning, outer circle finish grinding and opening milling are conducted. According to equipment adopted in the technological method, sawing is conducted through a high-precision sawing machine, inner hole boring and outer circle finish turning are conducted through a full-featured numerically-controlled machine tool, outer circle finish grinding is conducted through a high-precisiongrinding machine, and opening milling is conducted through a numerically-controlled machining center. The technological method is suitable for cast iron cylinder liner machining and steel cylinder liner machining. The dry cylinder liner preparation technology has the beneficial effects that the process flow is short, layout is reasonable, the production efficiency is high, the quality is stable, and the comprehensive cost is low.

Owner:ZYNP GRP

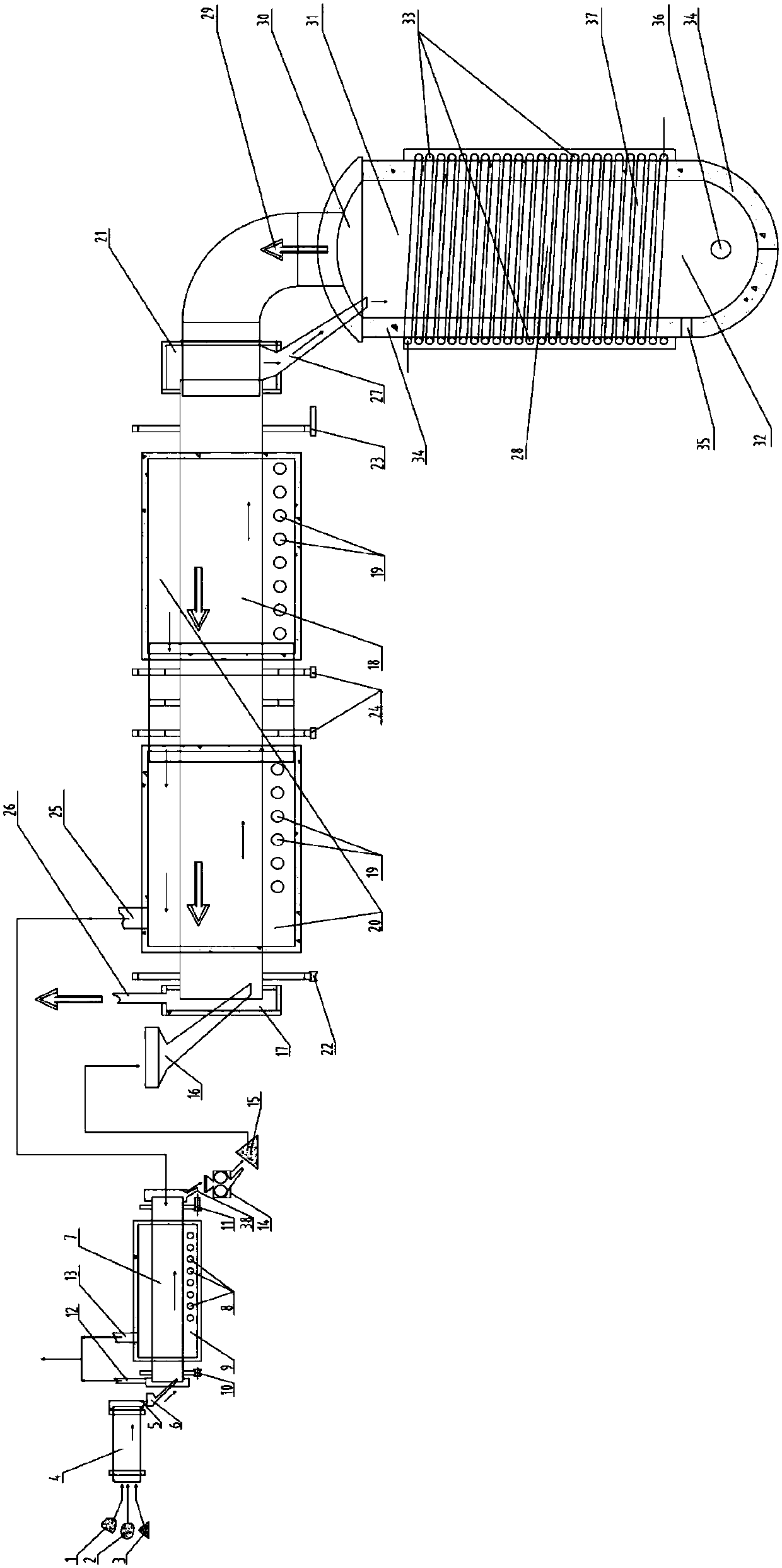

Short process iron-making device and coke-free saltpeter-free energy-saving environmental short process iron-making method thereof

InactiveCN107904398AEmission reductionLarge NOx contentRotary drum furnacesShaft furnacePelletizingCoal

The invention belongs to the technical field of metallurgy, and particularly relates to a short process iron-making device and a coke-free saltpeter-free energy-saving environmental short process iron-making method thereof. Iron mine powder is directly matched with carbon hot-pressing ball, pelletizing does not need to be sintered, coal is not subjected to coking, and the coal is not needed in thesmelting process; the inner-matched carbon pelletizing has a function of auto-restoring, does not produce NOx, the process flow is short, coal gas and high temperature flue gas produced in the smelting process are all recycled and fully used to greatly reduce the smelt cost, and melted iron is semisteel component which highly suits and meets converter steelmaking requirement. The coke-free saltpeter-free energy-saving environmental short process iron-making method is a green melted-iron-smelting new method which has the advantages of short process, high fuel adaptation, energy conservation, environment protection and emission reduction, is a best method which can replace blast furnace iron-making, and is a milestone in the technological development of the world iron-making industry.

Owner:唐竹胜

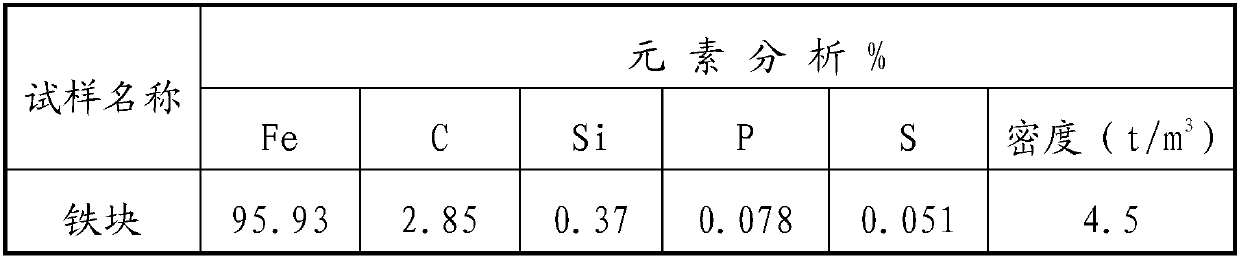

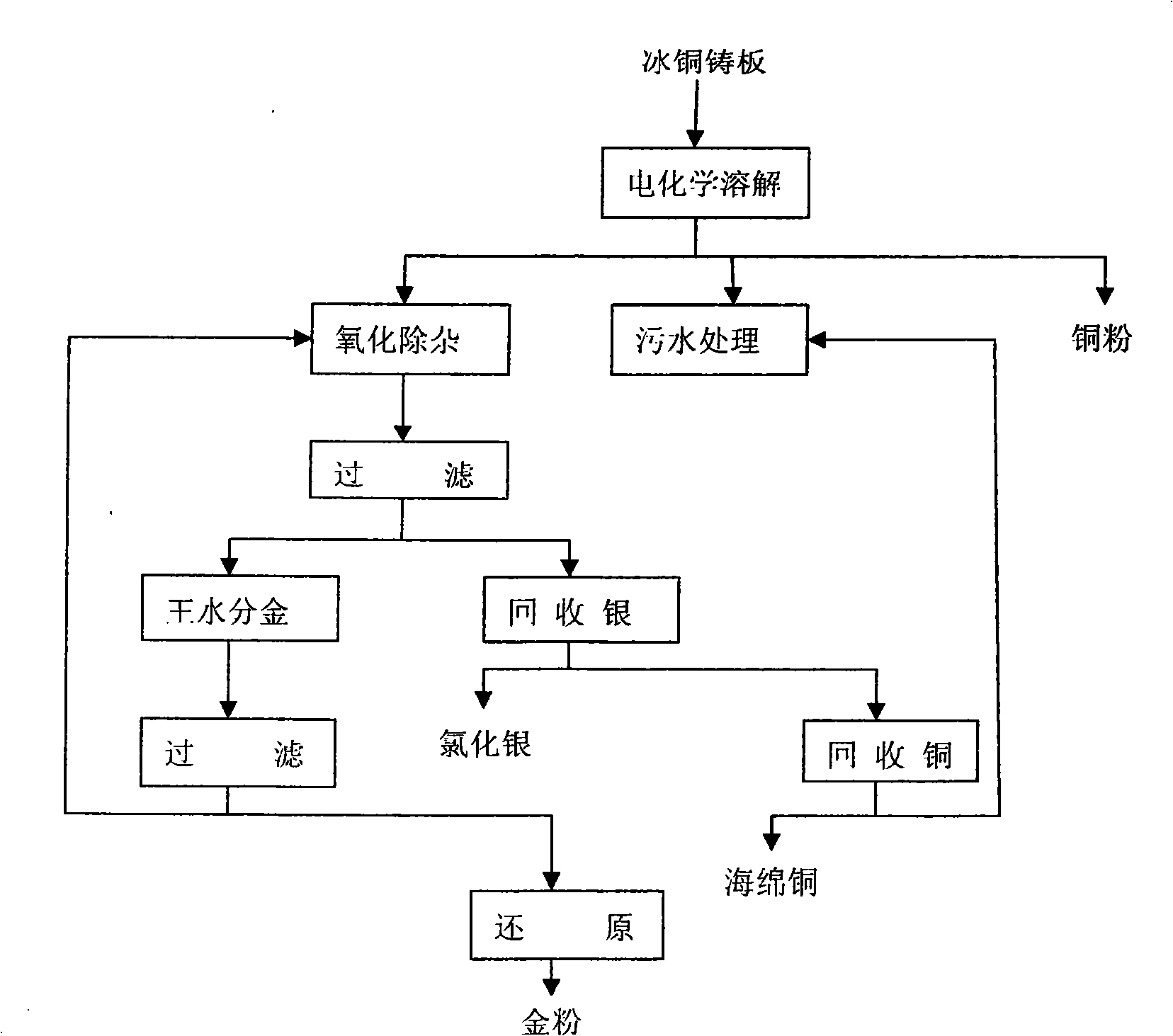

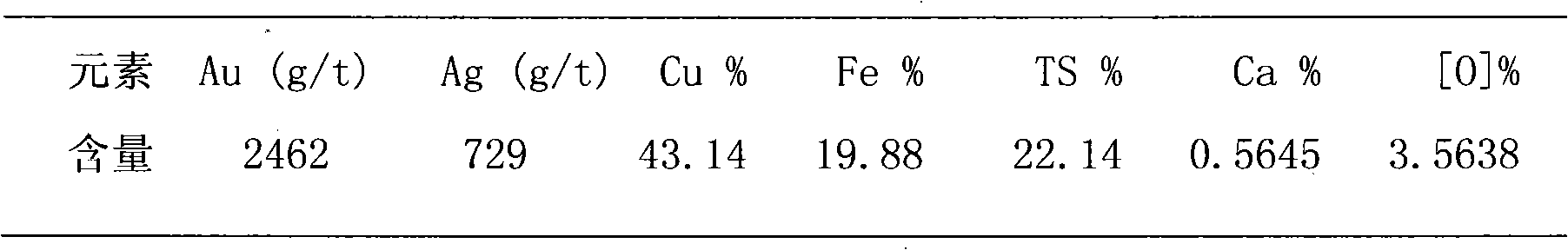

Electrochemical separation and recovery method for gold and silver in copper matte

ActiveCN101338439ASolve the Kinetics of LeachingReduce dosagePhotography auxillary processesProcess efficiency improvementRecovery methodFiltration

The invention relates to an electrochemistry parting method of bullion in matte, which comprises procedures as follows: (1) electrochemistry dissolving: the matte anode plate and the copper negative plate of an outer housing anode bag are arranged at intervals in an electrochemistry dissolving tank containing sulphuric acid for the electrochemistry dissolving, and the byproduct of copper powder is produced; (2) oxidation and impurity removal: nitric acid is added into matte anode mud dissolved by the electrochemistry for oxidation and impurity removal; (3) filtration: after being oxidized and edulcorated , the matte anode mud is filtered; and sodium chloride is added into filtered liquor to generate depositional silver chloride; (4) aqua regia parting: filtered filter mass is put into the aqua regia for the aqua regia parting; (5) filtration: after the aqua regia parting, the filter mass is filtered; and (6) deoxidization: sodium sulfite is added into the filtered liquor containing gold and the filtered liquor is deoxidized into gold powder. The electrochemistry parting method solves the dynamic problem of matte extraction and has the characteristics of rapid extraction speed, little treating solution, short process, low investment, high comprehensive rate, good product purity, etc.

Owner:ZIJIN MINING GROUP

Combined split mold once extrusion forming method with large flange middle through body

ActiveCN109848236AShort process flowReduce energy consumptionShaping toolsPerforating toolsEngineeringEnergy consumption

The invention discloses a combined split mold once extrusion forming method with a large flange middle through body, and meanwhile, discloses a vertical double-acting extrusion combination mold of combined split molds. Left / right horizontal concave molds are closed to form a peripheral mold cavity; upper / lower vertical extrusion molds and the closed left / right horizontal concave molds form an axial mold cavity of a flange; upper / lower vertical perforating tools are arranged in the upper / lower vertical extrusion molds; and water cooling devices are arranged in perforating needles. The forming method comprises the steps of preheating of the combination mold, returning of the molds to a given initial position, placement and positioning of heated blanks, horizontal mold closing, vertical double-acting extrusion and demolding after extrusion shaping; the once extrusion forming of the vertical double-acting extrusion combination mold is realized; each mold can be independently operated to move; the reasonable flowing of metal can be flexibly controlled to prevent folding defects; the flange part is fully filled with metal, so that products only need one-fire heating and once extrusion forming; and the method is short in procedure flow, low in energy consumption, high in efficiency and precise in size of the products.

Owner:NANJING DEV ADVANCED MFG

Separation and purification method of 2,3-dimethylpyridine

The invention discloses a separation and purification method of 2,3-dimethylpyridine. According to the separation and purification method, BS-80-5 macroporous resin is adopted for separation and purification of 2,3-dimethylpyridine crude products; the BS-80-5 macroporous resin is taken as an adsorbent, selective adsorption performance and screening effect of the BS-80-5 macroporous resin on different ingredients are used, and appropriate adsorption and desorption conditions are selected, so that separation and purification of one or a certain kind of organic compounds are realized.

Owner:ANHUI COSTAR BIOCHEM CO LTD

Method for improving performances of yarns formed by vortex spinning

InactiveCN102691143BImprove yarn tightnessLow modulusContinuous wound-up machinesOpen-end spinning machinesEngineeringYarn strength

The invention relates to a method for improving performances of yarns formed by vortex spinning by reducing the modulus and the rigidity of fibers on line and belongs to the field of textile processing. According to the method disclosed by the invention, a sectional softening treatment method is applied for carrying out progressive softening treatment on fibers subjected to vortex spinning on a vortex spinning machine, and thus the fiber modulus and the bending rigidity are quickly reduced on line and the performances of the resultant yarns prepared from fibers by vortex are improved. For a vortex yarn structure, the structure compactness is improved, the yarn strength is enhanced and residual torque of the yarns is small; in addition, the non-spinning fibers can be subjected to vortex spinning on the vortex spinning machine; the fibers with poorer quality for the resultant yarns formed by the vortex spinning are subjected to high-quality spinning on the vortex spinning machine; and particularly, the improvement on the spun count of the fibers on the vortex spinning machine is facilitated and the smooth production of high grade cotton yarns formed by vortex spinning is realized. The method disclosed by the invention has the advantages of short work procedure flow, strong pertinence, high efficiency, lower cost, reasonable structure, convenience in operation and easiness in large-area popularization and use.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com