Catalyst for preparing butadiene from mixed C4 and preparation method thereof

A technology for mixing C4 and catalysts, which is applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of high energy consumption and production costs, and the selectivity of target products It is not high, the catalyst reactivity is not high, etc., to achieve the effect of strong anti-coking ability, good technical effect, good activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

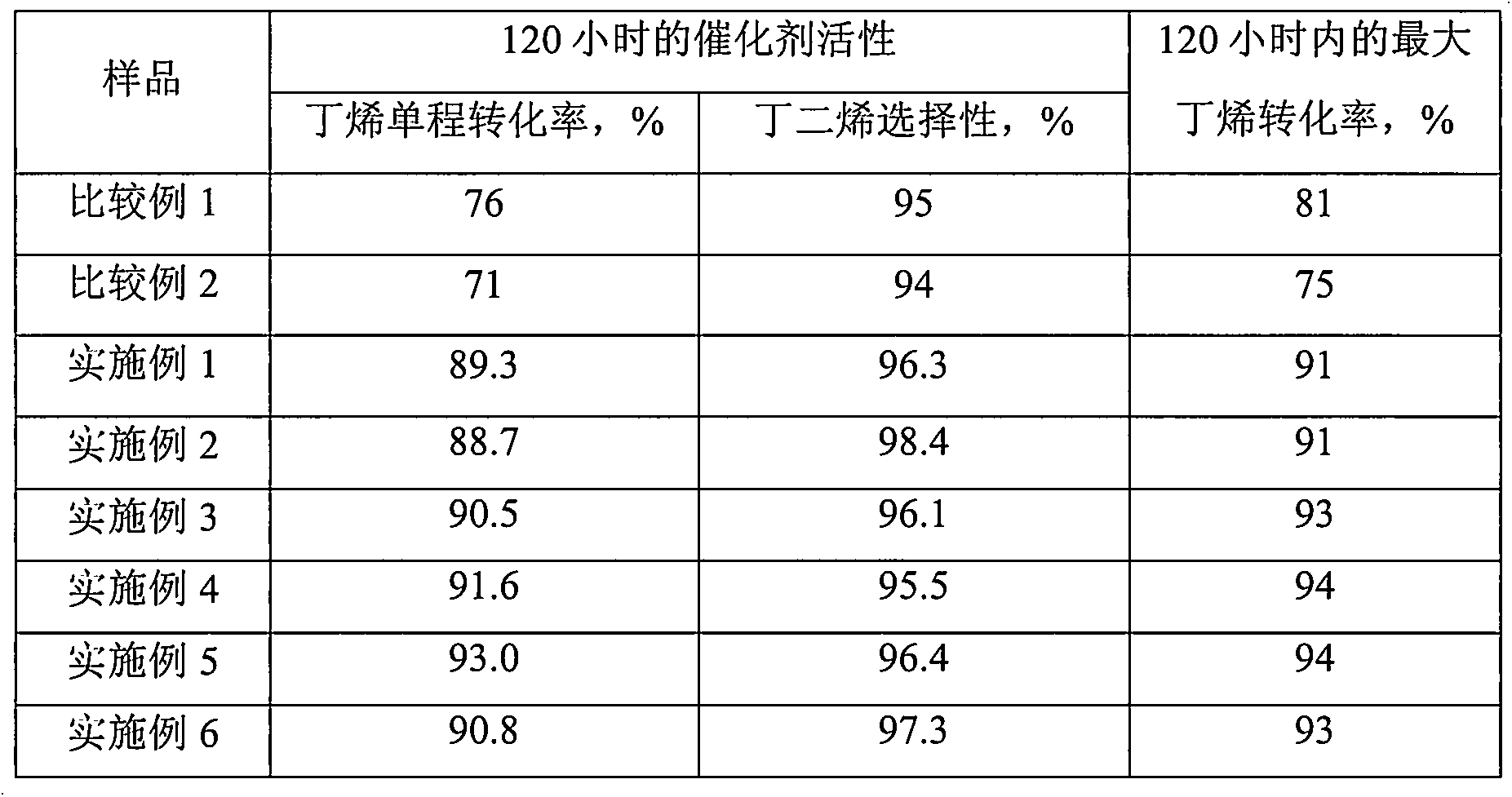

Examples

Embodiment 1

[0038] Ferric nitrate, zinc nitrate, manganese nitrate, and calcium nitrate solution are mixed according to the ratio of 1: 0.3: 0.2: 0.3 (molar ratio), while stirring while dripping ammonia water, stop dripping ammonia water after the pH value of the mixed solution is 9.0; Then the temperature of the mixed solution was raised to 80°C, stirred for 30 minutes and left to stand to obtain a coprecipitated mixed solution; the coprecipitated mixed solution was washed with deionized water until the pH value of the filtrate was 7.5 to obtain a catalyst sol; the catalyst The sol was directly extruded into a cylindrical bar-shaped catalyst, then dried at 100°C for 18 hours, and then calcined at 550°C for 8 hours to obtain fixed-bed catalyst sample 1.

[0039] Apply this catalyst sample to a 2-stage axial fixed-bed reactor with a volumetric space velocity of butene of 400 hours -1 The inlet temperature of the first stage reactor is 340°C, the inlet pressure of the first stage reactor is...

Embodiment 2

[0041] Mix ferric chloride, zinc chloride, manganese chloride, and calcium chloride solutions in a ratio of 1:0.8:0.3:0.5 (molar ratio), and stir while dripping ammonia water until the pH value of the mixed solution is 9.5, then stop Add ammonia water dropwise; then raise the temperature of the mixed solution to 80°C, stir for 23 minutes and let it stand to obtain a co-precipitation mixed solution; wash the coprecipitated mixed solution with deionized water until the pH value of the filtrate is 7.8 to obtain a catalyst sol The catalyst sol was directly extruded into a clover-shaped catalyst, then dried at 120°C for 13 hours, and then calcined at 650°C for 6 hours to obtain fixed bed catalyst sample 2.

[0042] Apply this catalyst sample to a 3-stage axial fixed-bed reactor with a volumetric space velocity of butene of 350 hours -1 , the inlet temperature of the first-stage reactor is 340° C., the inlet pressure of the first-stage reactor is 0.28 MPaG, and the ratio (molar rati...

Embodiment 3

[0044] Mix ferric chloride, zinc chloride, manganese chloride, and calcium chloride solutions in a ratio of 1:0.5:0.1:0.1 (molar ratio), and stir while dripping ammonia water until the pH value of the mixed solution is 8.3, then stop Add ammonia water dropwise; then raise the temperature of the mixed solution to 86°C, stir for 31 minutes and let it stand to obtain the co-precipitation mixed solution; wash the coprecipitated mixed solution with deionized water until the pH value of the filtrate is 7.1 to obtain the catalyst sol ; The catalyst sol was directly extruded into a cylindrical bar-shaped catalyst, then dried at 120°C for 15 hours, and then calcined at 600°C for 8 hours to obtain a fixed-bed catalyst sample 3.

[0045] The catalyst sample is applied to a first-stage tubular isothermal fixed-bed reactor. The catalyst is packed in the tubular, and desalinated water is used outside the tubular to exchange heat and generate low-pressure steam; the volume space velocity of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com