Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Strong anti-coking ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heavy arenes lightening catalyst and preparing method thereof

InactiveCN1472181AImprove activity stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsMordeniteCarbon deposit

Owner:CHINA PETROLEUM & CHEM CORP +1

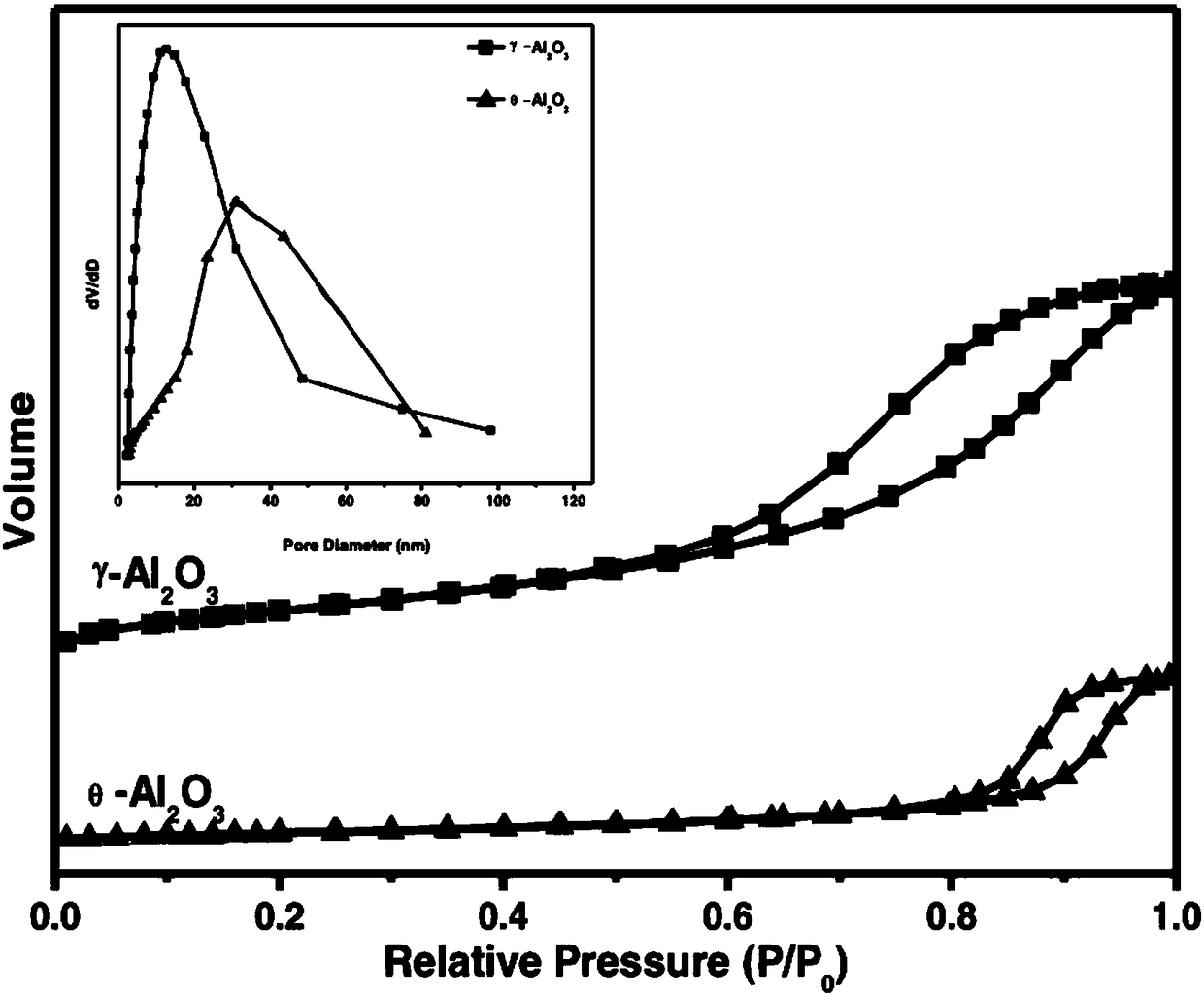

Aluminium oxide carrier containing magnesium and phosphor and preparing method

InactiveCN101069853AStrong anti-coking abilityHigh activityMetal/metal-oxides/metal-hydroxide catalystsLarge poreChemistry

The present invention discloses an aluminium oxide carrier which contains magnesium and phosphorus, also can contain potassium and its preparation method. The magnesium, phosphorus and potassium can be added in the process of preparation. Said carrier is low in acidity and has large pore volume and large specific surface area. The catalyst prepared by using said carrier has the features of strong anti-coking property and good stability.

Owner:林方 +3

Catalyst for synthesizing para diethyl benzene by ethanol and ethyl benzene combination reaction and its preparation method

InactiveCN1605390AHigh yieldGood choiceOrganic chemistryMolecular sieve catalystsMolecular sievePtru catalyst

The present invention relates to catalyst for alkylating ethanol and ethyl benzene into p-diethylbenzene and its preparation process. The industrial catalyst for efficient synthesis of p-diethylbenzene is prepared with the H-ZSM-5 molecular sieve with Si / Al ratio of 50 as basic matter and through surface acidity and tunnel regulation with B, Mg and Co, and has ideal pore size distribution and in-tunnel acidity distribution and strong coking resisting capacity. The precursor of B is boric acid, that of Mg is magnesium nitrate and that of Co is cobalt nitrate. The mass ratio between B and H-ZSM-5 molecular sieve is 1-3 %, that between Mg and H-ZSM-5 molecular sieve is 0.1-1 % and that between Co and H-ZSM-5 molecular sieve is 1-3 %. Compared with available similar catalyst, the present invention has the features one simple preparation process, low cost, high selectivity and yield of p-diethylbenzene, etc.

Owner:NANKAI UNIV

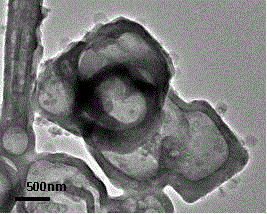

Superfine granular zeolite aromatizing catalyst and its preparation and use

InactiveCN1552821AStrong anti-coking abilityImprove stabilityTreatment with hydrotreatment processesLanthanideRare earth

Preparation of micro-size particle zeolite catalyst for aromatization and its application in complete fractional FCC gasoline hydrogenation-aromatization composite process are disclosed. The catalyst consists of: transition metal oxide and lanthanide metal oxide is 1.0wt% - 10.0wt%, micro-size particle zeolite of 20nm-800nm 50.0wt% - 90.0wt%, and balanced inorganic oxide binder. Its advantages include low total and L acidity, unblocked pore canal, good stability and strong anticoking ability, low antiknock index ((R+M) / 2) loss of gasoline product with reduced S and olefin contents of FCC gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

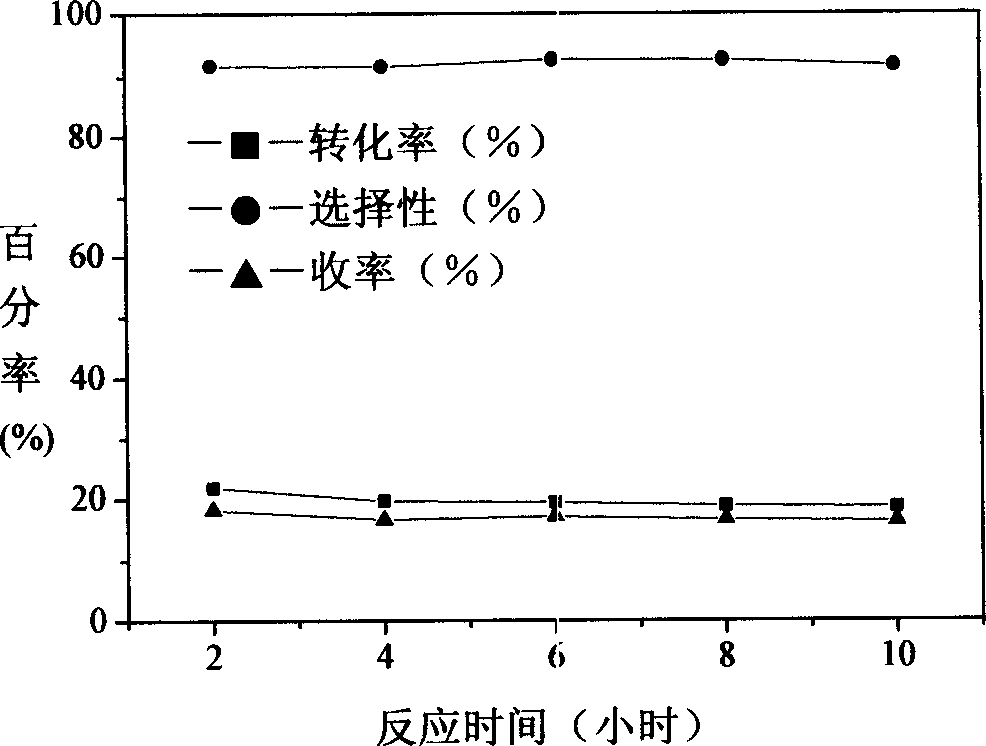

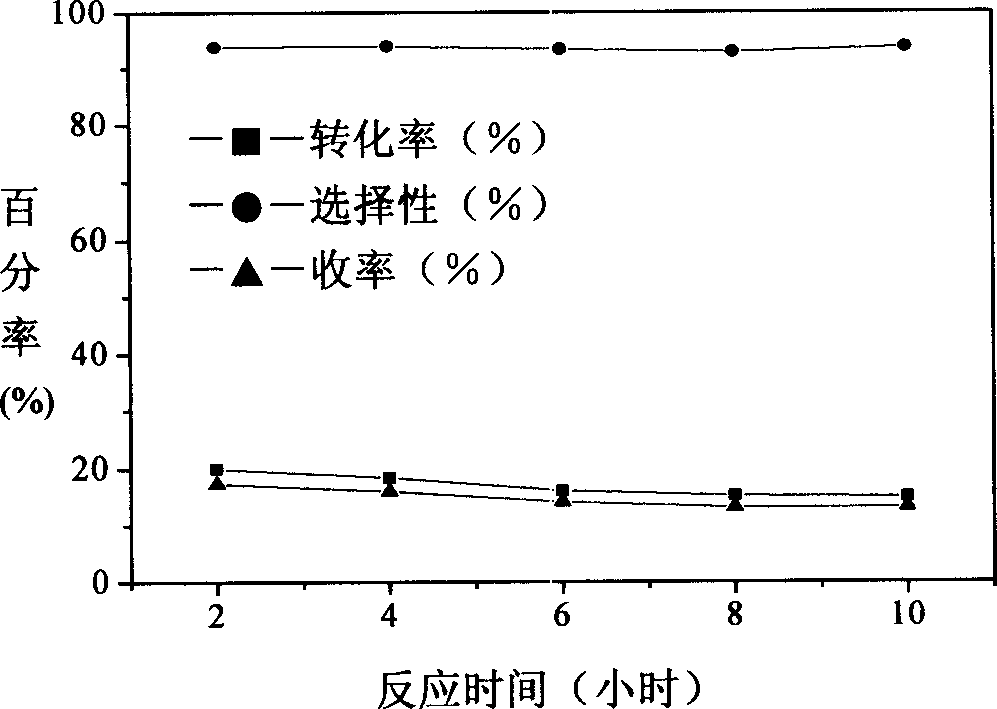

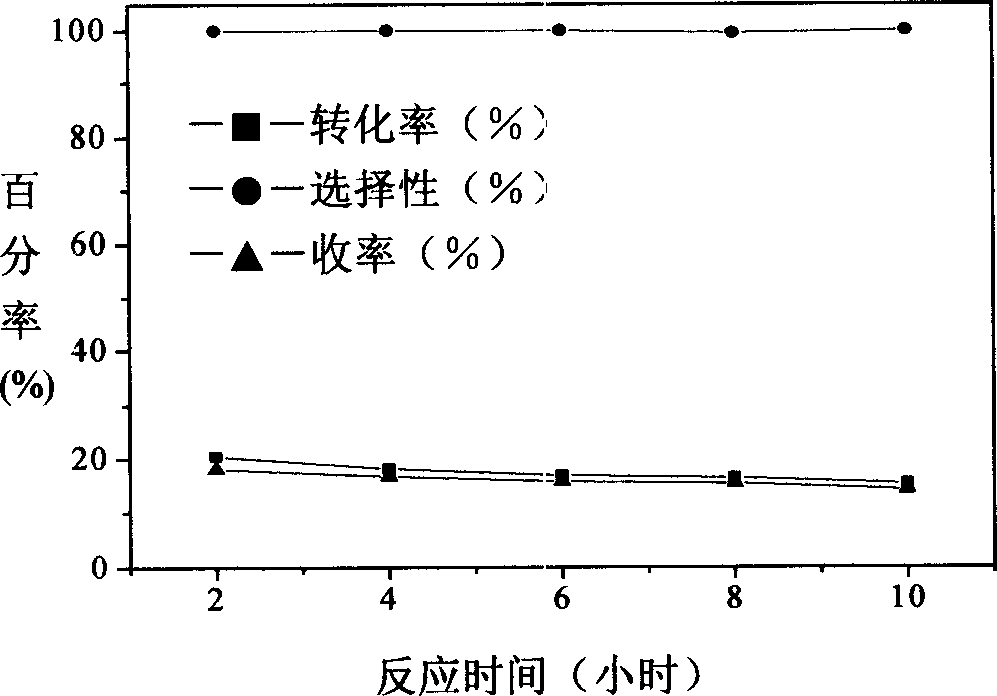

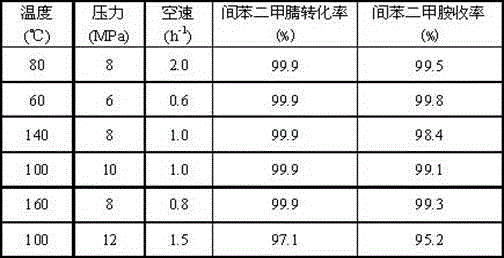

Catalyst and method for preparing m-xylylenediamine by hydrogen isophthalonitrile

ActiveCN104148080ALarge apertureExtend your lifeOrganic compound preparationAmino compound preparationChemistryFixed bed

The invention relates to a catalyst and a method for preparing m-xylylenediamine by hydrogen isophthalonitrile and mainly solves the problem that in the prior art, a catalyst easily cokes and loses activity. The catalyst is composed of the follow components in parts by weight: (a) 5.0-40.0 parts of metallic nickel or nickel oxide, (b) 0.01-25.0 parts of at least one element or oxide of the element selected from the IIA column in the Periodic Table, (c) 0.01-10.0 parts of at least one of Mo, Zr, and Ti or oxide of Mo, Zr and Ti, (d) 0.01-10.0 parts of at least one of Sn, Fe, and Cu or oxide of Sn, Fe and Cu, (e) 0.01-10.0 parts of at least one element or oxide of the element selected from rare earth and (f) 9-95 parts of silicon dioxide carrier. By adopting the technical scheme, the problem is well solved and the catalyst can be used in the technical scheme for fixed bed continuous hydrogenation production of m-xylylenediamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalyst for hydrogen production from catalytic pyrolysis of natural gas and preparation method thereof

InactiveCN101439287AReduce manufacturing costInert surfaceHydrogenMetal/metal-oxides/metal-hydroxide catalystsCatalytic pyrolysisActive component

The invention discloses a natural gas catalytic pyrolysis hydrogen production catalyst and a preparation method thereof. The natural gas catalytic pyrolysis hydrogen production catalyst takes MOyCNFs as a carrier to load an active component Ni; wherein, the weight portions of each component are as follows: 10 to 50 portions of Ni element, 5 to 70 portions of MOy and 2 to 45 portions of CNFs; the preparation method is as follows: the MOy and pretreated CNFs are added into water solution of nickel salt, then a soda lye is added to adjust the pH value between 6 and 8; then the mixture is stirred and stood; the obtained deposit is filtered, washed and dried, thus obtaining the catalyst. The catalyst has the advantages of high methane conversion rate, high carbon deposit resistance and good stability. The invention belongs to the field of natural gas hydrogen production.

Owner:HANERGY TECH

Superfine granular zeolite aromatizing catalyst and its preparation and use

InactiveCN1227334CStrong anti-coking abilityImprove stabilityTreatment with hydrotreatment processesPtru catalystLanthanide

Preparation of micro-size particle zeolite catalyst for aromatization and its application in complete fractional FCC gasoline hydrogenation-aromatization composite process are disclosed. The catalyst consists of: transition metal oxide and lanthanide metal oxide is 1.0wt% - 10.0wt%, micro-size particle zeolite of 20nm-800nm 50.0wt% - 90.0wt%, and balanced inorganic oxide binder. Its advantages include low total and L acidity, unblocked pore canal, good stability and strong anticoking ability, low antiknock index ((R+M) / 2) loss of gasoline product with reduced S and olefin contents of FCC gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing good quality diesel oil

InactiveCN1415705AImprove acid resistanceImprove matchTreatment with hydrotreatment processesEngineeringProcess conditions

A process for preparing high quality diesel oil from poor-qualiry fraction oil includes such steps as hydrorefining, hydro-pour-depressing and arylhydrocarbon saturation. Its advantages are high hexadecame value, low pour point, and low contents of S and arylhydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP +1

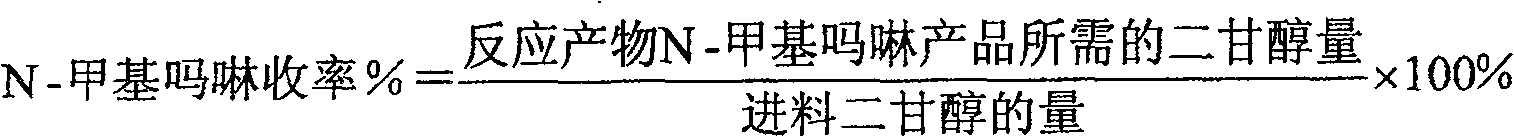

Catalyst required for coproducing N-methyl morpholine and morpholine

ActiveCN1911505AEasy to useExtended service lifeOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsNitrateMorpholine

The catalyst for co-producing N-methyl morpholine and morpholine with materials including diglycol, liquid ammonia and monomethyl amine consists of carrier of (delta + theta)Al2O3, MgO, CaO or BaO and supported active components of Ni and Cu. Specifically, the catalyst consists of carrier in 78 wt% and active components including Ni 12 wt% and Cu 10 wt%. The preparation process of the catalyst includes soaking cloverleaf formed gamma-Al2O3 in water solution of nitrate of Mg, Ca or Ba, drying and calcining to obtain the carrier, soaking the carrier in mixed solution of nitrate of Cu and Ni, drying, drying and calcining to obtain the catalyst.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

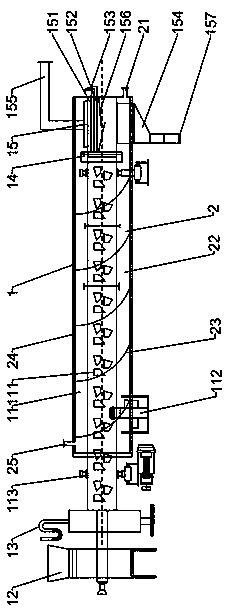

Pyrolysis, carbonization and catalysis integrated method

ActiveCN111218291ALow costHigh activityCatalyst activation/preparationIndirect heating destructive distillationPtru catalystFlue gas

The invention discloses a pyrolysis, carbonization and catalysis integrated method, and belongs to the field of biomass pyrolysis. The invention aims to solve the problems of high energy consumption,high cost and low energy utilization rate of an existing method. The pyrolysis, carbonization and catalysis integrated method comprises five processes of sealed feeding, uniform distribution, continuous pyrolysis, tar catalysis and flue gas recycling. Biomass is used as a raw material, feeding and uniform distribution of the processed raw material are realized under a sealed condition, a pyrolyticreaction is carried out, and a pyrolytic oil-gas mixture and biochar are obtained after two main processes of pyrolytic carbonization and carbon-gas separation in sequence; a pyrolysis oil-gas mixture is subjected to a tar catalytic process in a catalytic chamber integrated with a pyrolysis furnace, part of cured biochar is prepared into a new catalyst for being continuously used, and the processes are subjected to stepped heat supply by utilizing waste heat of reflux flue gas. The nickel-based biochar catalyst is high in activity, good in stability, low in preparation cost, environmentally friendly and efficient.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

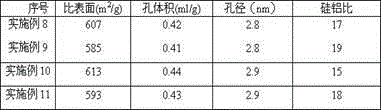

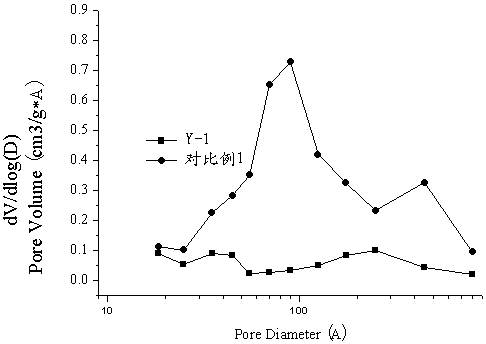

USY molecular sieve with double meso-structures and preparation method thereof

ActiveCN105712370AReduce the ratio of silicon to aluminumIncrease acidityFaujasite aluminosilicate zeoliteMolecular sieveSilicon oxide

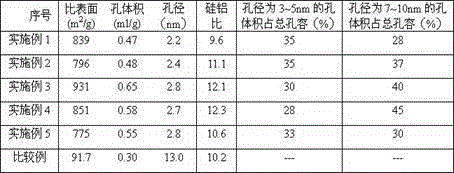

The invention discloses a USY molecular sieve with double meso-structures. The volume of pores with pore sizes of 3 to 5 nm in the USY molecular sieve accounts for 15 to 40% of the total pore volume of the USY molecular sieve; the volume of pores with pore sizes of 7 to 10 nm accounts for 25 to 50% of the total pore volume of the USY molecular sieve; a mol ratio of silicon oxide to alumina in the molecular sieve is in a range of 7 to 15; and the USY molecular sieve has a specific surface area of 680 to 980 m<2> / g, a pore volume of 0.42 to 0.75 ml / g and an average pore size of 1.9 to 3.1 nm. The USY molecular sieve prepared in the invention has meso pores of two pore sizes, can provide more reaction space for large molecules and has improved catalysis performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

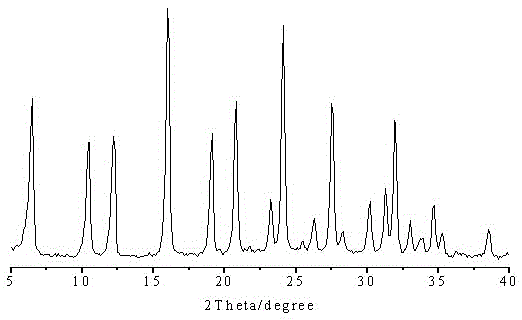

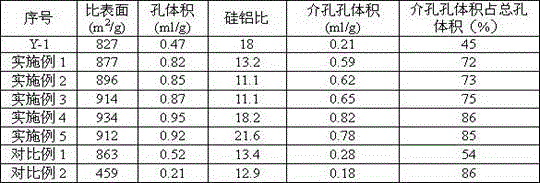

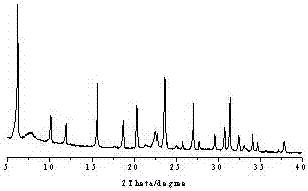

Modified Y type molecular sieve and preparation method thereof

ActiveCN106672997ALarge mesostructure distributionReduce the ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveFiltration

The invention discloses a modified Y type molecular sieve and a preparation method thereof. The molecular sieve has the following properties: the total pore volume is 0.76-1.25ml / g, wherein the mesoporous volume is 0.55-1.05ml / g and the mesoporous volume is 65-90% of the total pore volume; the mole ratio of silicon oxide to aluminum oxide is 10-35; and the specific surface area is 680-1050m<2> / g. The preparation method comprises the following steps: under a stirring condition, adding the Y type molecular sieve into a pressure container filled with organic aqueous alkali; closing the system; increasing the pressure to 0.2-1.0MPa, and then increasing temperature to 50-90 DEG C and treating for 0.5-3 hours under constant temperature; and relieving pressure, performing suction filtration, drying and roasting, thereby acquiring the modified Y type molecular sieve. The molecular sieve has larger-size mesoporous distribution and can supply much more reaction space for macromolecules; the catalytic performance of the molecular sieve is promoted; and the preparation method is simple and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

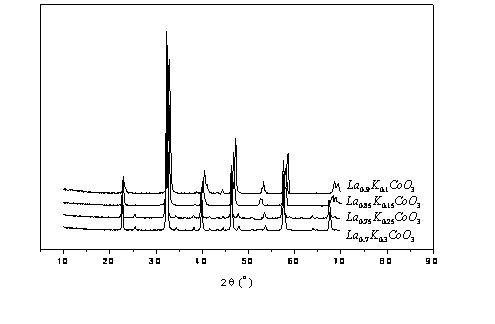

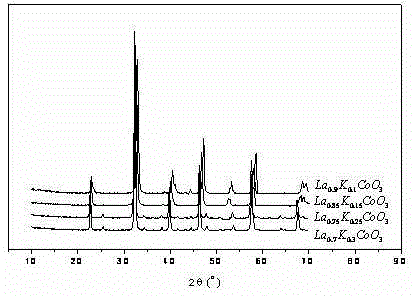

Composite oxide oxygen carrier and preparation method and application thereof

ActiveCN102864008AEasy to prepareLow costFuel additivesMetal/metal-oxides/metal-hydroxide catalystsEvaporationRare earth

The invention discloses a composite oxide oxygen carrier and a preparation method and application thereof. The oxygen carrier is a composite metal oxide AxA'l-xBO3 with a perovskite structure, wherein A is rare earth metal lanthanum, A' is transition metallic potassium, B is transition metallic cobalt, and 0.7<x<1. The application of the oxygen carrier in chemical looping combustion technology is that the temperature of combustion in an air reactor is 450-850 DEG C, and the temperature of reduction in a fuel reactor is 450-850 DEG C. The preparation method of the oxygen carrier is that cobalt nitrate, lanthanum nitrate and potassium nitrate are used as a precursor, citric acid or ethylene glycol is used as a complexing agent, a solution is prepared and mixed and stirred evenly, then evaporation of water is conducted, the solution is converted into thick gel from transparent sol, finally drying and baking are conducted, and a sample after baking is the composite metal oxide with the perovskite structure. The oxygen carrier is high in oxygen carrying rate and catalytic activity, strong in carbon deposit resistance and good in stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

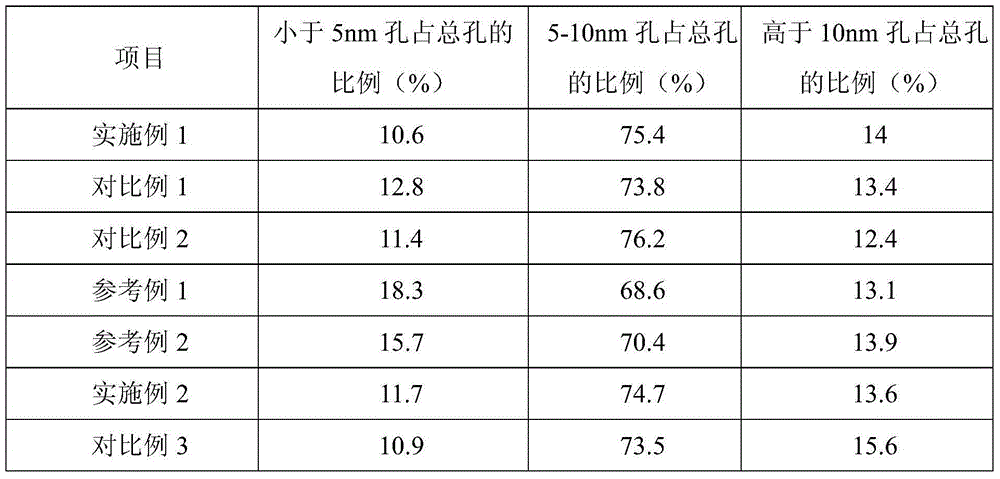

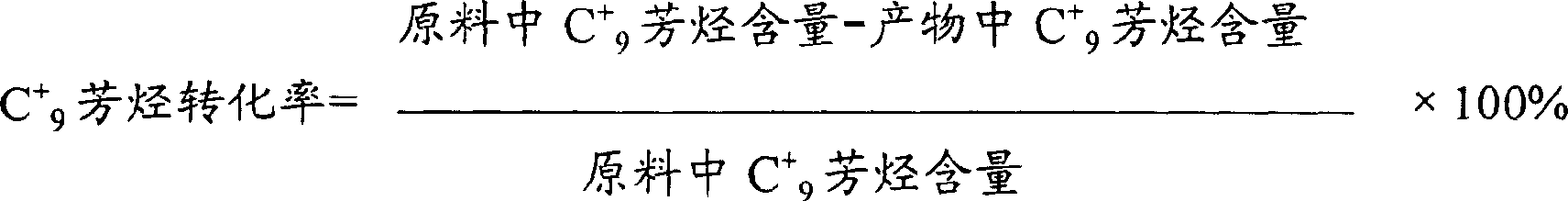

Acrylic acid catalyst regeneration method

InactiveCN103551161AStrong anti-coking abilityExtended service lifeOrganic compound preparationCarboxylic compound preparationPore distributionNitrogen atmosphere

The invention relates to an acrylic acid catalyst regeneration method. An acrylic acid catalyst has a concentrated pore distribution and a moderate total pore volume, the amount of medium-sized pores of about 5-10nm accounts for above 70% of the amount of total pores, and the medium-sized pores of about 5-10nm form short and thick tunnel structures, so the catalyst has the characteristics of strong carbon deposit resistance, difficult agglomeration and long service life. The two-step calcining regeneration method for regenerating an inactivated acrylic acid catalyst comprises the following steps: heating the inactivated acrylic acid catalyst to 280-320DEG C at a speed of 1-2DEG C / h, and carrying out constant temperature calcining for 1-10h; and heating to 330-370DEG C at a speed of 1-2DEG C / h, calcining in an oxidizing gas for 1-3d, heating to 380-410DEG C, and calcining in nitrogen atmosphere for 1-3d to obtain a regenerated acrylic acid catalyst having an equivalent activity with the fresh catalyst.

Owner:CHINA NAT OFFSHORE OIL CORP +1

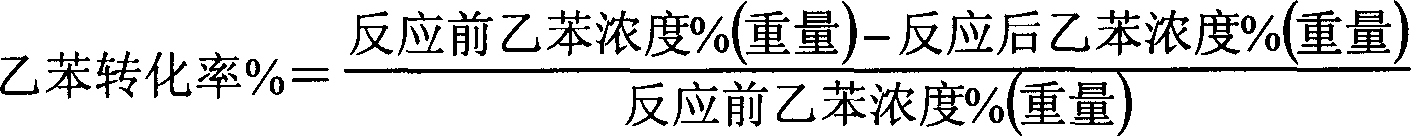

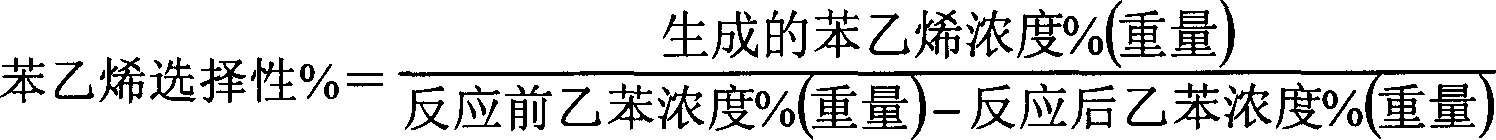

Dehydrogenating catalyst for preparing alkyl alkenyl arene

ActiveCN1810369AControl release speedImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsCarbon depositPotash

The present invention relates to one kind of alkyl arene preparing dehydrogenating catalyst and aims at avoiding potassium loss of catalyst during reaction, raising the carbon deposit resistance of catalyst and increasing catalyst life. The technological scheme of the present invention includes replacing partial soluble potassium compound in the Fe-K-Ce-Mo catalyst system with potash feldspar, and adding carbon separation resisting assistant to inhibit carbon separation reaction to the Fe-K-Ce-Mo catalyst system. The dehydrogenating catalyst system may be used in industrial alkyl arene preparing production.

Owner:CHINA PETROLEUM & CHEM CORP +1

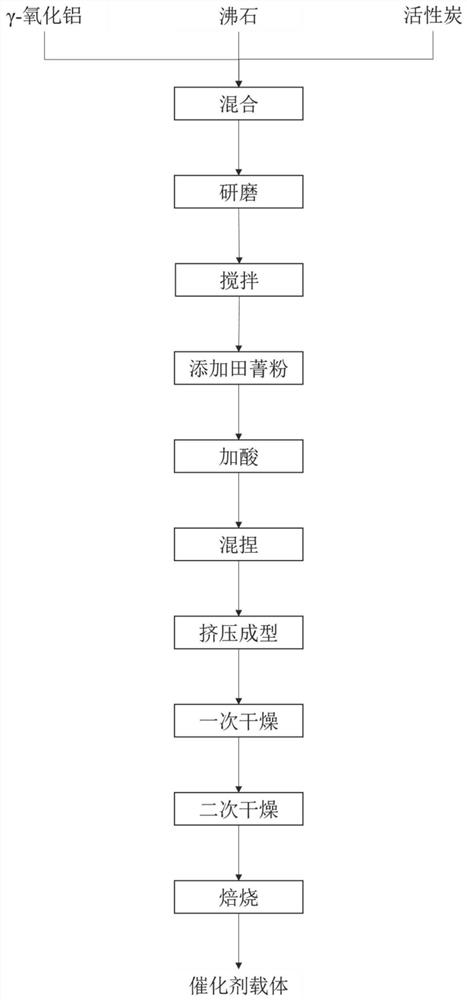

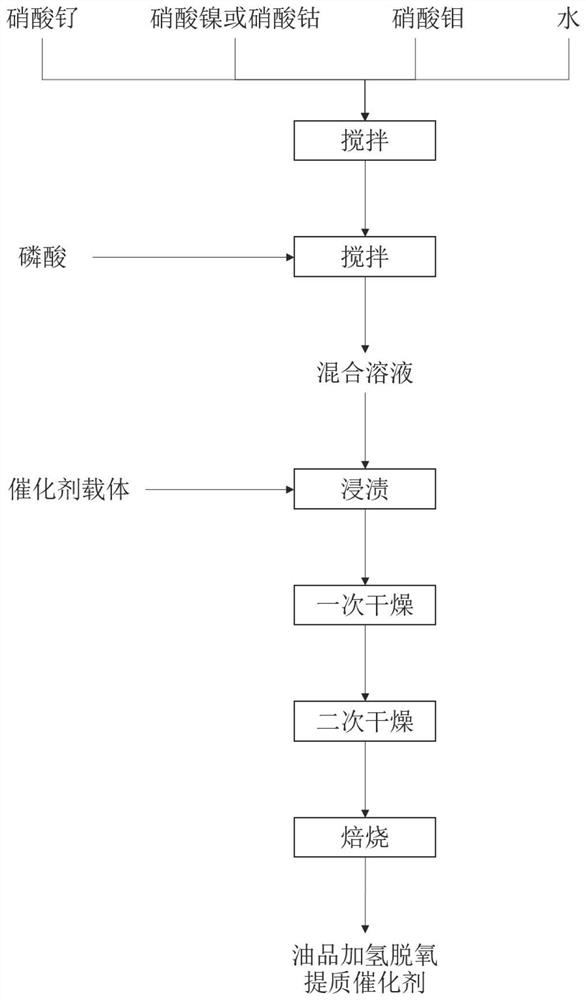

Oil product hydrodeoxygenation upgrading catalyst and preparation method and application thereof

ActiveCN112044465APrevent sinteringInhibitory activityMolecular sieve catalystsCatalyst activation/preparationPtru catalystHigh activity

The invention discloses an oil product hydrodeoxygenation upgrading catalyst and a preparation method and application thereof. The oil product hydrodeoxygenation upgrading catalyst comprises a catalyst carrier, and an active component and an auxiliary agent which are loaded on the catalyst carrier, wherein the active component comprises ruthenium oxide, molybdenum oxide, nickel oxide and / or cobaltoxide; the catalyst carrier comprises gamma aluminum oxide, zeolite and activated carbon; the auxiliary agent comprises phosphorus oxide; in the active component, the molar ratio of ruthenium oxide to molybdenum oxide to nickel oxide and / or cobalt oxide is (0.2-1): (10-28): (2-10). The oil product hydrodeoxygenation upgrading catalyst has the characteristics of high activity and conversion rate of low-temperature hydrodeoxygenation, good selectivity, repeated long-term recycling, good stability, strong coking resistance, good hydrothermal stability and good acid and water resistance, and thepreparation method is simple and wide in application prospect.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

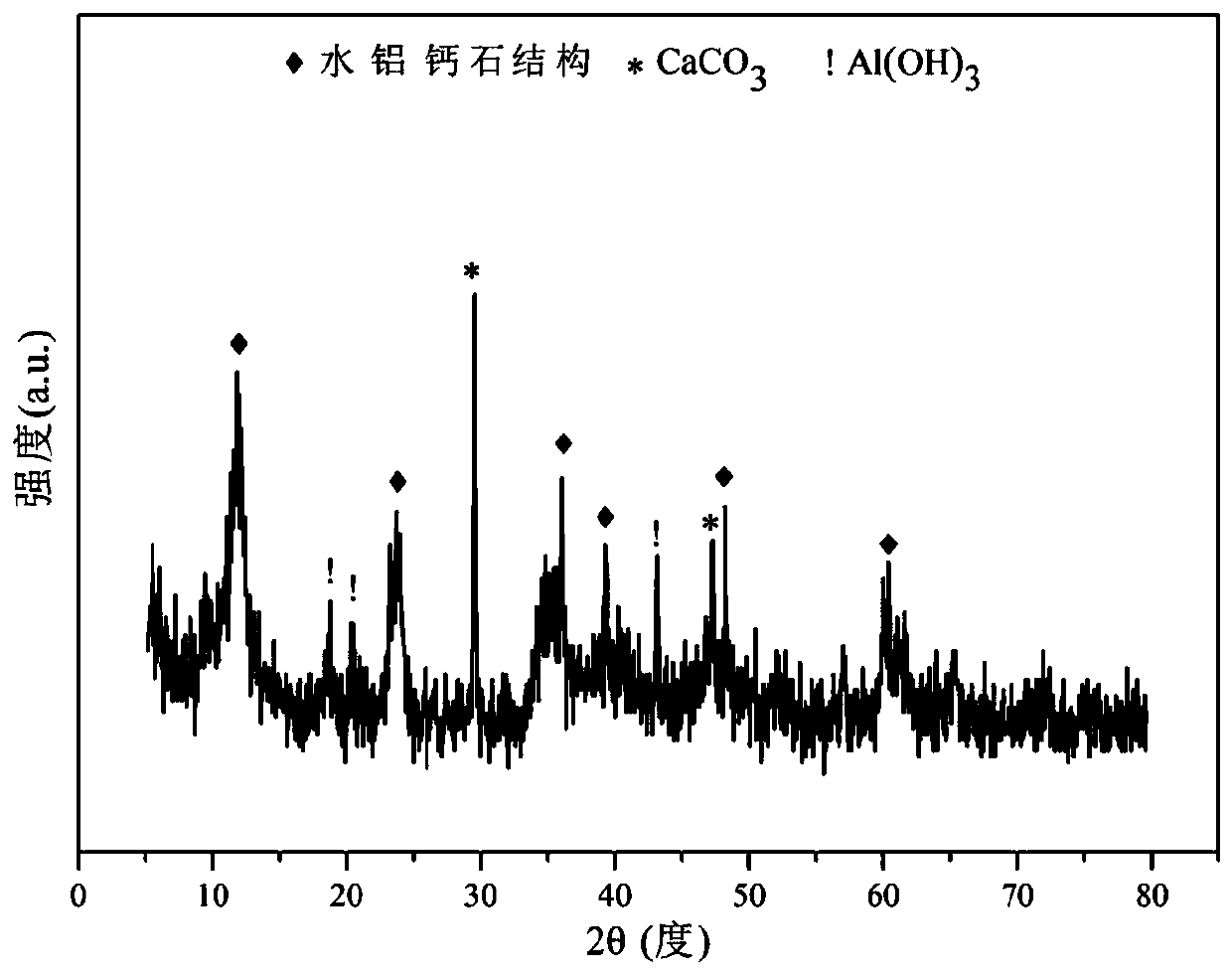

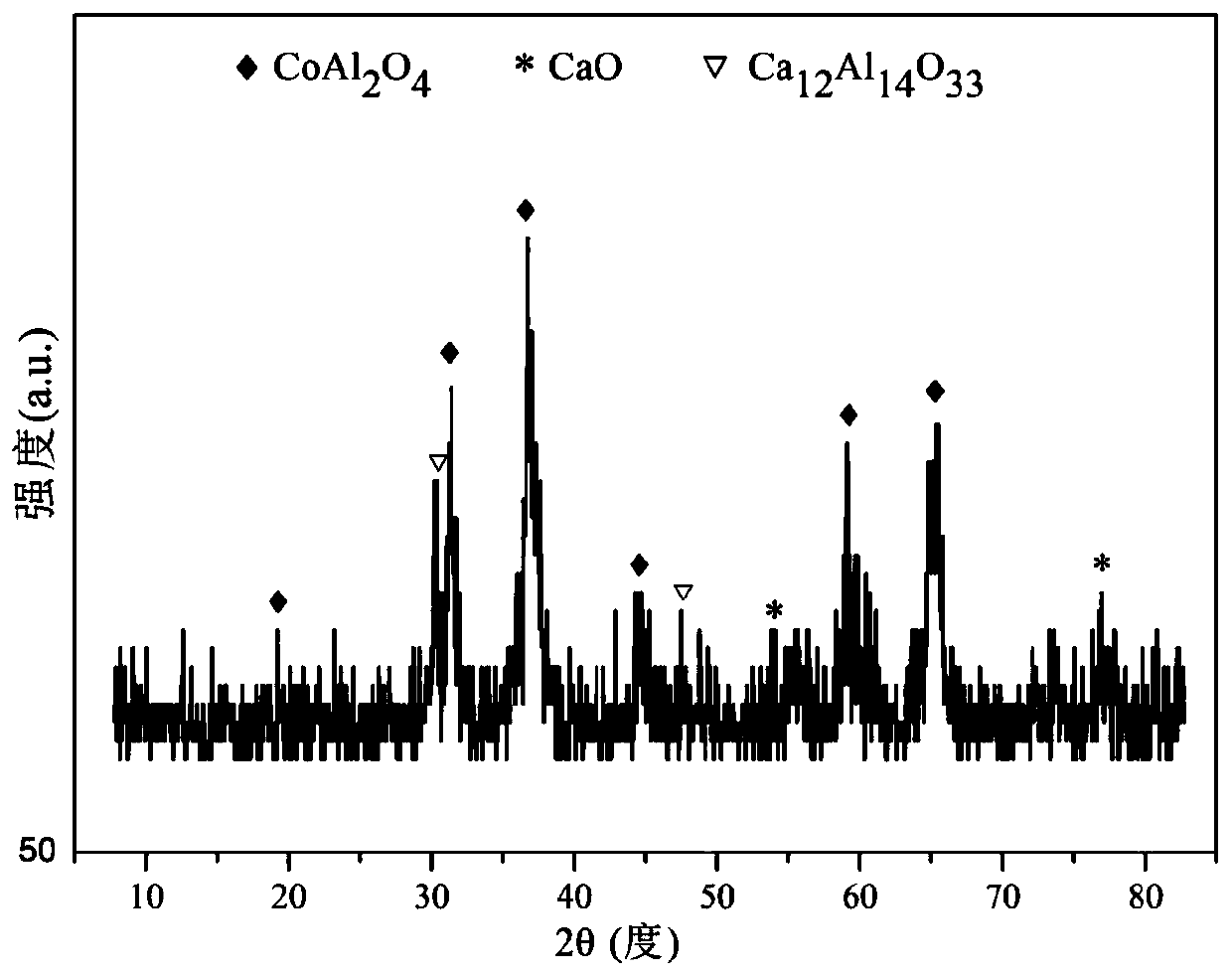

Hydrocalumite derived cobalt-based catalyst for hydrogen production by autothermal reforming of acetic acid

ActiveCN109718785AImprove anti-sintering performanceImprove thermal stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsAcetic acidActive component

The invention relates to a hydrocalumite derived cobalt-based catalyst for hydrogen production by autothermal reforming of acetic acid. Directed at the problem that catalyst structure change and the oxidation and sintering of active components can cause catalyst deactivation in existing catalysts during the autothermal reforming reaction of acetic acid, the invention provides a new catalyst characterized by stable structure, sintering resistance, oxidation resistance, carbon deposition resistance, and high activity. The molar composition of the catalyst is (CaO)a(CoO)b(AlO1.5) c, wherein a is1.66-5.19, b is 0.34-0.81 and c is 1.0. The invention adopts coprecipitation method to prepare a catalyst precursor, and then roasting is carried out to obtain the Ca-Co-Al-O mesoporous composite oxide. The catalyst takes calcium oxide as the framework, contains cobalt-alumina spinel phase and a small amount of Ca12Al14O33, inhibits the acidity of the catalyst, improves the carbon deposition resistance and sintering resistance of the catalyst, and improves the activity of hydrogen production by autothermal reforming of acetic acid.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Catalyst for C12-C12 fat carboxylic acid ketonization and its application

ActiveCN100363098CSolution to short lifeInhibit cokingPreparation by hydrogenolysisCatalyst activation/preparationKetonic acidsCerium

The invention provides a C2-C12 aliphatic carboxylic acid ketone activator. The invention uses gamma-aluminum oxide as carrier and the single, double elements, and ternary elements of lanthanum, cerium, praseodymium and neodymium of light lanthanide series rare earth as active components. While the activating carrier method comprises (1) the heat treatment process while the treatment temperature is 480-800 Deg. C; (2) azotic acid aqueous solution method while the concentration of azotic acid aqueous solution is 5-45%; (3) evacuation method. In addition, the activator is prepared via the immersion method while it can be used to C2-C12 aliphatic carboxylic acid ketone.

Owner:PETROCHINA CO LTD

Catalyst required for coproducing N-methyl morpholine and morpholine

ActiveCN100548477CEasy to useExtended service lifeOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsPtru catalystMorpholine

The present invention relates to a kind of catalyst that takes diethylene glycol, liquefied ammonia and monomethylamine as raw materials to co-produce N-methylmorpholine and morpholine, which is based on (δ+θ)Al2O3 and MgO, CaO and BaO Any one is a carrier, on which Ni and Cu are supported as two active components to form; in percent by weight, the catalyst is 100 parts, and the carrier is 78%, wherein (δ+θ) Al O375%, MgO, CaO or BaO is 3%; the active component is 22%, of which Ni is 12% and Cu is 10%. The preparation method of the catalyst is as follows: the clover-shaped γ-Al2O3 carrier is impregnated with magnesium, calcium or barium nitrate aqueous solution, dried and calcined to obtain the above carrier, and then impregnated with copper and nickel nitrate mixed solution, dried and calcined. The above catalyst was obtained.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

USY molecular sieve and preparation method thereof

ActiveCN105712375AAchieve the purpose of modificationHigh catalytic activityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveSilicon oxide

The invention discloses a USY molecular sieve. The USY molecular sieve has a hollow structure. The USY molecular sieve has a silicon oxide-alumina mole ratio of 4.5-25, the grain size of 0.5-1.2 microns, a specific surface area of 420-800m<2> / g, a pore volume of 0.33-0.82ml / g and an average aperture size of 1.5-4.0nm. The USY molecular sieve has more exposed reaction active sites, greatly shortens a diffusion distance of reactants and improves molecular sieve catalysis performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of spherical alumina

PendingCN111151232AHigh strengthWear-resistantMaterial nanotechnologyCatalyst carriersPtru catalystPolyethylene glycol

The invention discloses a preparation method of spherical alumina. The preparation method of spherical alumina comprises the following steps: (1) mixing raw materials containing an aluminum source, anacid I solution and an acid II solution, and heating to obtain aluminum sol, wherein the acid II solution is an organic polybasic acid solution; and (2) adding polyethylene glycol and a gelatinizingagent into the aluminum sol to obtain a solution I, dropwise adding the solution I into an oil column to form gel beads, and aging, washing, drying and roasting the gel beads to obtain the spherical alumina. The spherical alumina prepared by the method has the characteristics of high strength, wear resistance and large pore diameter and pore volume, and a propane dehydrogenation catalyst preparedfrom the spherical alumina is strong in carbon deposition resistance, good in stability and high in propylene selectivity.

Owner:YINGKOU XIANGYANG CATALYST

Preparation method of hollow USY molecular sieve

ActiveCN105712374AAchieve the purpose of modificationHigh catalytic activityMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveEngineering

The invention discloses a preparation method of a hollow USY molecular sieve. The preparation method comprises 1, preparing a guiding agent, 2, preparing a mixed solution from an aluminum source, water and sodium hydroxide, adding a low silica-alumina ratio NaY molecular sieve and the guiding agent obtained through the step 1 into the mixed solution, carrying out uniform stirring, carrying out constant temperature crystallization on the gel at a temperature of 90-120 DEG C for 12-72h and carrying out cooling, washing, pumping filtration and drying to obtain a Y-Y composite molecular sieve, 3, carrying out ammonium exchange on the Y-Y composite molecular sieve prepared through the step 2, 4, treating the Y-Y composite molecular sieve subjected to ammonium exchange under hydro-thermal conditions and 5, washing the composite molecular sieve subjected to hydro-thermal treatment in the step 4 to obtain the hollow USY molecular sieve. The USY molecular sieve has more exposed reaction active sites, greatly shortens a reactant diffusion distance and improves molecular sieve catalysis performances.

Owner:CHINA PETROLEUM & CHEM CORP +1

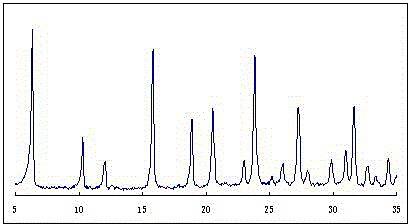

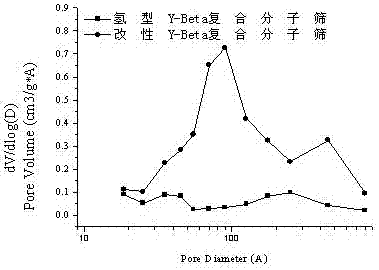

Modified Y-Beta composite molecular sieve as well as preparation method and application thereof

ActiveCN107344115ALarge mesostructure distributionReduce the ratio of silicon to aluminumMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveOrganic base

The invention discloses a modified Y-Beta composite molecular sieve as well as a preparation method and application thereof. The preparation method comprises the following steps of under a stirring condition, adding a Y-Beta composite molecular sieve into a pressure container full of an organic base solution, sealing a system, pressurizing to 0.2 to 1.0MPa, then heating to 50 to 90 DEG C, treating for 0.5 to 3 hours at constant temperature, depressurizing, carrying out suction filtration, drying, and roasting to obtain the modified Y-Beta composite molecular sieve. The modified Y-Beta composite molecular sieve prepared through the method has mesopore pore size distribution with a larger size, can provide more reaction spaces for macromolecules, and is beneficial to improving a catalytic performance of the molecular sieve, simple in the preparation method, and applicable to industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

A catalyst for pretreatment of inferior reforming raw materials, a preparing method thereof and a pretreatment method for inferior reforming raw materials

InactiveCN109420513ALarge specific surface areaHigh mechanical strengthHeterogenous catalyst chemical elementsCatalyst activation/preparationElemental compositionPretreatment method

A catalyst for pretreatment of inferior reforming raw materials, and a preparing method thereof are disclosed. The catalyst is composed of an active component, an auxiliary agent and a carrier, wherein the active component is composed of a Group VIB element and a Group VIII element; the auxiliary agent is phosphorus; the catalyst comprises, based on oxides, 10-30 wt% of the Group VIB element, and2-10 wt% of the Group VIII element; the weight ratio of the Group VIB element to the P is 0.05 to 0.20; and the weight ratio of the Group VIII element to the P is 0.8 to 2.0. The invention also discloses a pretreatment method for inferior reforming raw materials. The catalyst can remove the sulfur and nitrogen in the inferior reforming raw materials to 0.5 [mu]g / g or below in the pretreatment method, the ultra-deep hydrodesulfurization and denitrification of the inferior reforming raw materials are achieved, and oil formed after hydrogenation can meet material feeding requirements of a reformer.

Owner:PETROCHINA CO LTD

Composite oxide oxygen carrier and preparation method and application thereof

ActiveCN102864008BEasy to prepareLow costFuel additivesMetal/metal-oxides/metal-hydroxide catalystsEvaporationRare earth

Owner:CHINA PETROLEUM & CHEM CORP +1

Heavy arenes lightening catalyst and preparing method thereof

InactiveCN1227192CImprove activity stabilityImprove conversion rateMolecular sieve catalystsHydrocarbonsMordeniteCarbon deposit

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of modified Y-type molecular sieve and preparation method thereof

ActiveCN106672997BLarge mesostructure distributionReduce the ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveOrganic base

The invention discloses a modified Y type molecular sieve and a preparation method thereof. The molecular sieve has the following properties: the total pore volume is 0.76-1.25ml / g, wherein the mesoporous volume is 0.55-1.05ml / g and the mesoporous volume is 65-90% of the total pore volume; the mole ratio of silicon oxide to aluminum oxide is 10-35; and the specific surface area is 680-1050m<2> / g. The preparation method comprises the following steps: under a stirring condition, adding the Y type molecular sieve into a pressure container filled with organic aqueous alkali; closing the system; increasing the pressure to 0.2-1.0MPa, and then increasing temperature to 50-90 DEG C and treating for 0.5-3 hours under constant temperature; and relieving pressure, performing suction filtration, drying and roasting, thereby acquiring the modified Y type molecular sieve. The molecular sieve has larger-size mesoporous distribution and can supply much more reaction space for macromolecules; the catalytic performance of the molecular sieve is promoted; and the preparation method is simple and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Molecular sieve catalyst for medium and low temperature denitration and production method of molecular sieve catalyst

InactiveCN109675612AGood catalytic activity and diffusion propertiesStrong anti-coking abilityGas treatmentMolecular sieve catalystsContinuous flowMolecular sieve

The invention provides a molecular sieve catalyst for medium and low temperature denitration. The molecular sieve catalyst is a loaded manganese base medium and low temperature Mn / USY catalyst and comprises a USY molecular sieve carrier and an active component manganese, wherein the loading capacity of the active component manganese is 5 to 15 percent; the USY molecular sieve carrier has a hollowstructure; in addition, a certain amount of amorphous silica is reserved at a hollow part of the hollow structure, so that the molecular sieve catalyst has good catalytic activity and diffusion capability and high coke formation resistance; besides, the invention further provides a production method of the molecular sieve catalyst for the medium and low temperature denitration; the Mn / USY catalystis obtained by impregnating a manganese acetate solution and a USY molecular sieve, drying, calcining and sieving. The production method of the molecular sieve catalyst is simple and convenient; Mn / USY catalysts with different manganese loading capacities can be produced by adjusting different manganese loading capacities of active components; by measurement of a continuous flow fixed reactor, the Mn / USY catalyst with 10 percent of manganese loading capacity has highest catalytic efficiency.

Owner:PINGXIANG HUAXING ENVIRONMENTAL PROTECTION ENG TECH CO LTD

A kind of modified y-beta composite molecular sieve and its preparation method and application

ActiveCN107344115BLarge mesostructure distributionReduce the ratio of silicon to aluminumMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveOrganic base

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocalumite-derived cobalt-based catalysts for autothermal reforming of acetic acid to produce hydrogen

ActiveCN109718785BImprove anti-sintering performanceImprove thermal stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsHigh activityCobalt

The invention relates to a hydrocalumite derived cobalt-based catalyst for hydrogen production by autothermal reforming of acetic acid. Directed at the problem that catalyst structure change and the oxidation and sintering of active components can cause catalyst deactivation in existing catalysts during the autothermal reforming reaction of acetic acid, the invention provides a new catalyst characterized by stable structure, sintering resistance, oxidation resistance, carbon deposition resistance, and high activity. The molar composition of the catalyst is (CaO)a(CoO)b(AlO1.5) c, wherein a is1.66-5.19, b is 0.34-0.81 and c is 1.0. The invention adopts coprecipitation method to prepare a catalyst precursor, and then roasting is carried out to obtain the Ca-Co-Al-O mesoporous composite oxide. The catalyst takes calcium oxide as the framework, contains cobalt-alumina spinel phase and a small amount of Ca12Al14O33, inhibits the acidity of the catalyst, improves the carbon deposition resistance and sintering resistance of the catalyst, and improves the activity of hydrogen production by autothermal reforming of acetic acid.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com