Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Reduce the ratio of silicon to aluminum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

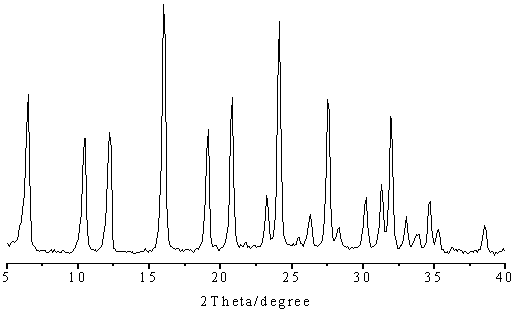

ZSM-48 molecular sieve with low silica-alumina ratio and preparation method thereof

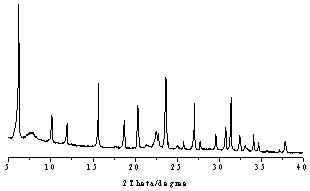

ActiveCN103803576AIncrease acidityReduce the ratio of silicon to aluminumCrystalline aluminosilicate zeolitesMolecular sieveMass ratio

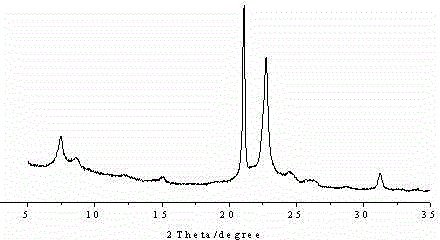

The invention discloses a ZSM-48 molecular sieve with a low silica-alumina ratio and a preparation method thereof. The molecular sieve has the following properties: the molar ratio of silica to alumina is 25-50; the specific surface is 250-400 m2 / g; the pore volume is 0.25-0.35 cm3 / g; the average pore size is 3-5 nm. The preparation method comprises the following steps: (1) well mixing a seed crystal S, a template R, a silicon source, an aluminium source, sodium hydroxide and water to prepare a reaction mixture, wherein the composition of the reaction mixture is as follows: on a basis of oxide, the molar ratio of R to SiO2 is 0.05-0.2, the molar ratio of SiO2 to Al2O3 is 30-50, the molar ratio of Na2O to SiO2 is 0.06-0.1, the molar ratio of H2O to SiO2 is 15-23, the mass ratio of S to SiO2 is 0.05-0.5, S is the ZSM-48 molecular sieve, and R is 12-crown ether-4; (2) performing hydrothermal crystallization of the reaction mixture prepared in step (1) at 150-170 DEG C for 4-8 days, performing filtration, washing, drying, and roasting of the crystallization product to obtain the ZSM-48 molecular sieve with a low silica-alumina ratio. The ZSM-48 molecular sieve prepared by the method of the invention has a low silica-alumina ratio, and has good application prospects in technical fields of isodewaxing and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

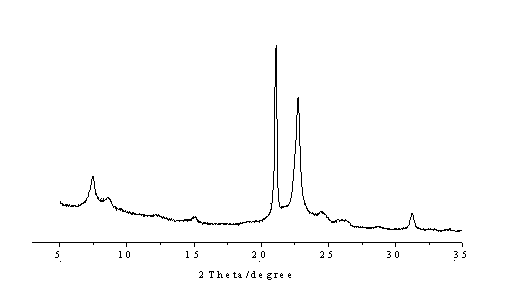

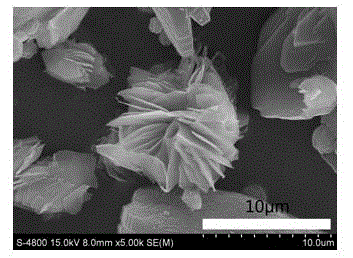

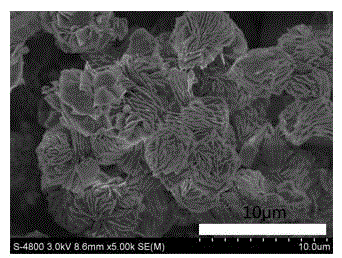

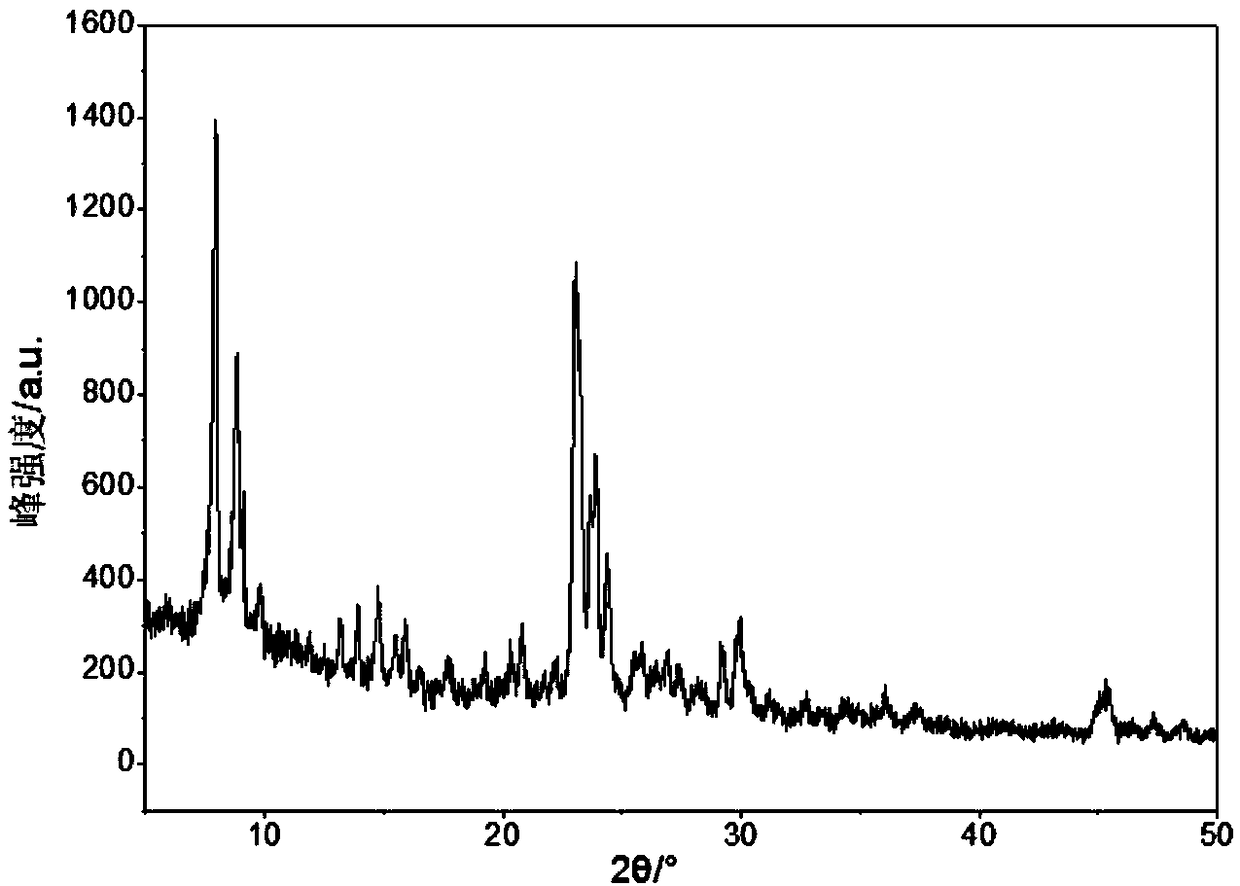

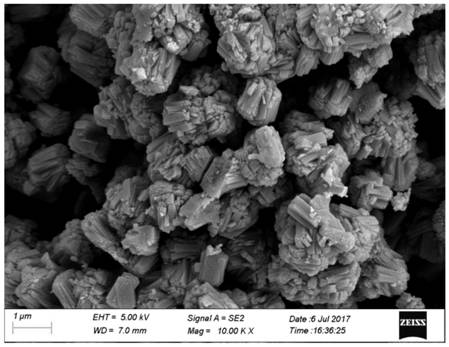

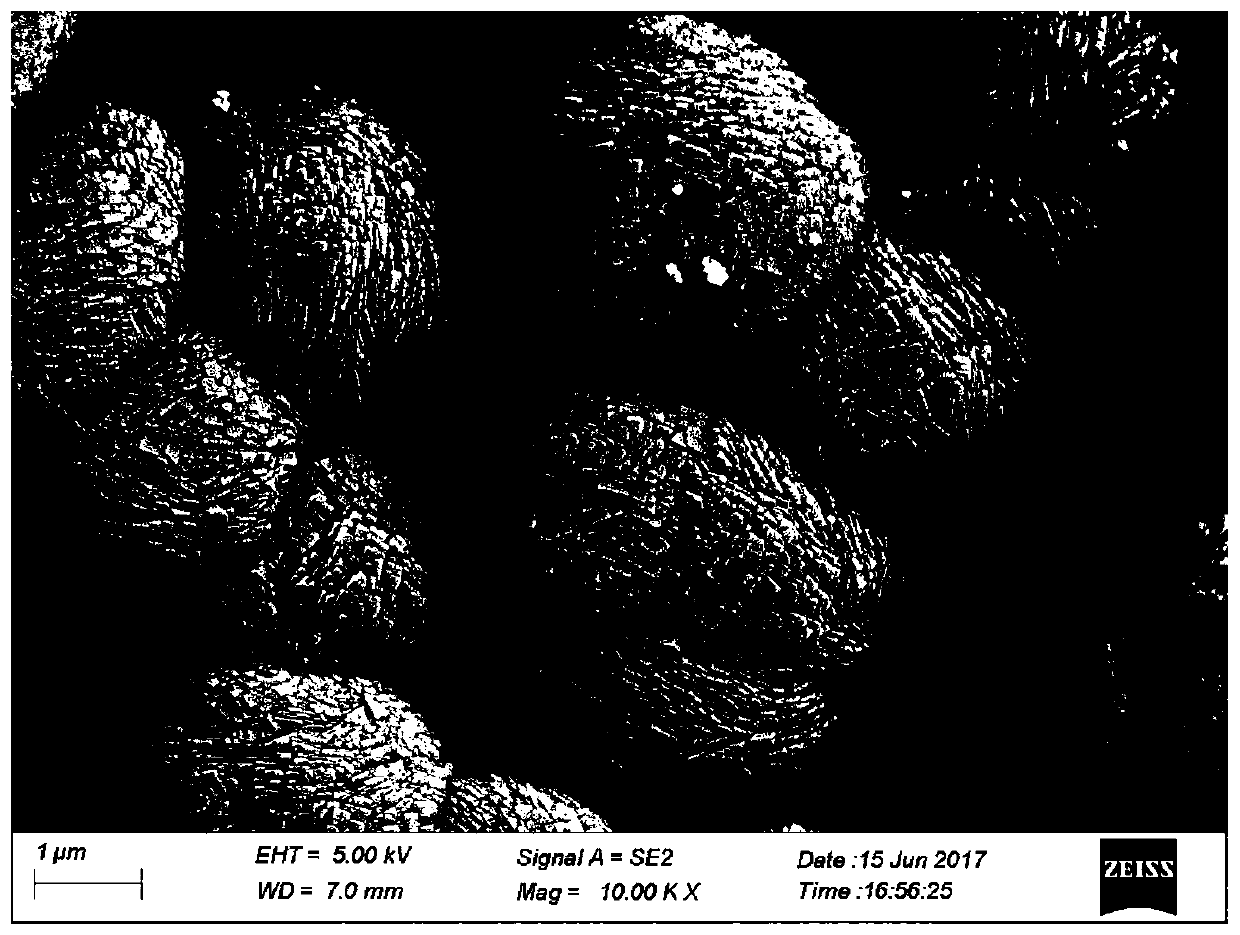

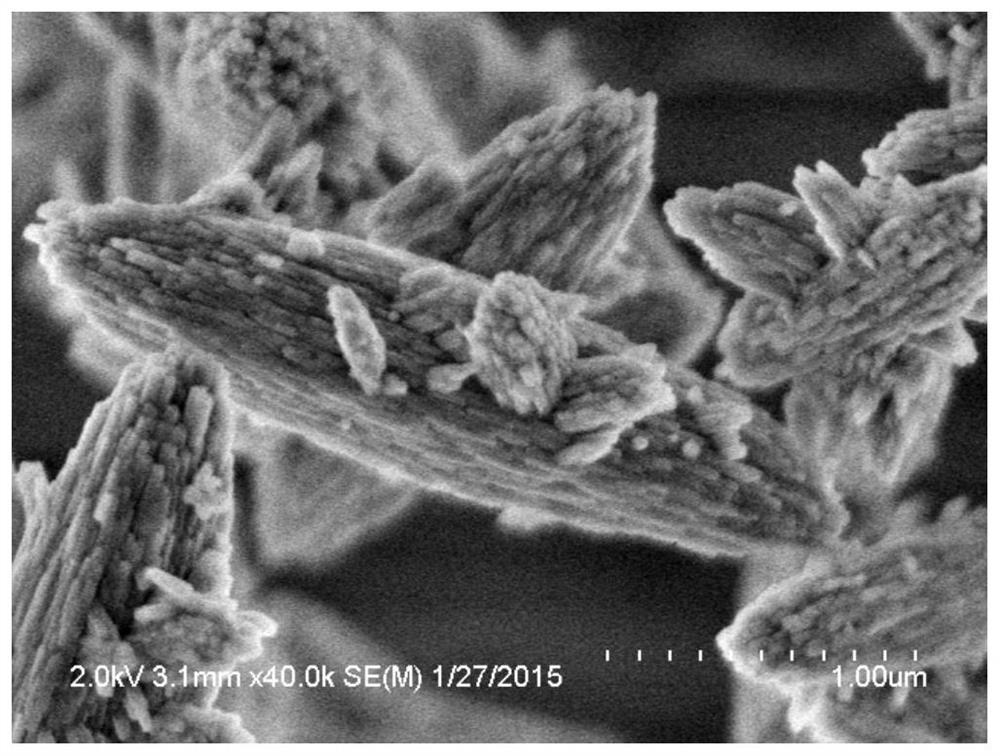

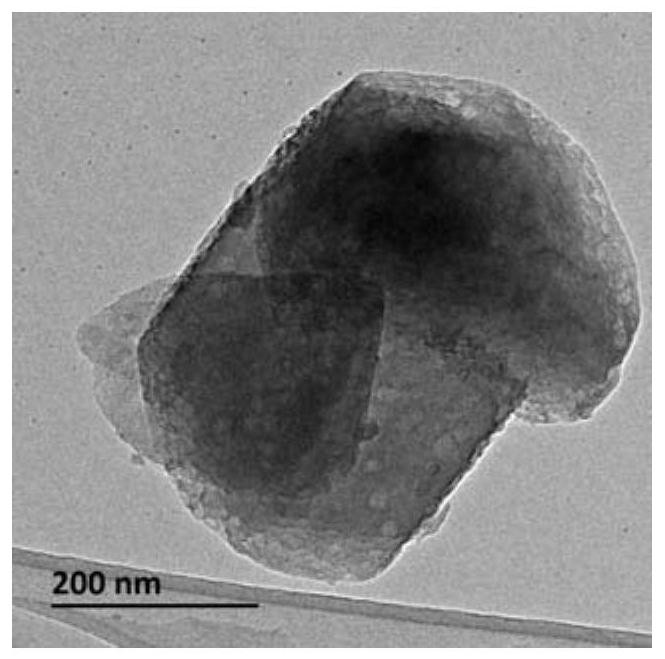

Preparation method for low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve

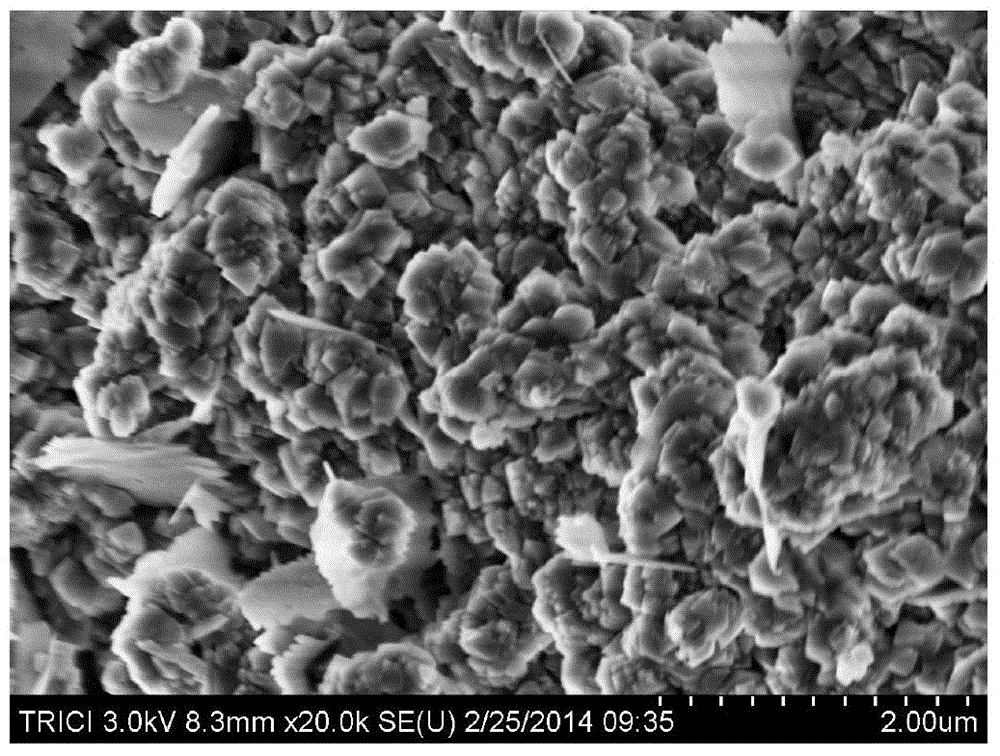

InactiveCN103601213AWide variety of sourcesReduce the ratio of silicon to aluminumMaterial nanotechnologyMordenite aluminosilicate zeoliteIsomerizationReaction rate

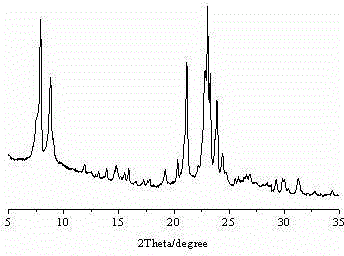

The invention discloses a preparation method for a low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve. The preparation process of the mordenite molecular sieve includes: dissolving an aluminum source and an alkali source in deionized water, adding silica sol into the obtained clarified solution to obtain a uniform white colloid, transferring the white colloid into a reaction kettle to undergo hydrothermal reaction, thus obtaining the low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve. The mordenite molecular sieve prepared by the invention has the advantages of wide silicon source and aluminum source, low silicon-aluminum ratio, multiple active centers, no adding of any surfactant, low preparation cost, less environmental pollution and large specific surface area, and is conducive to spread of the reactants and product and acceleration of the reaction rate, thus being widely applicable in adsorption, separation, catalytic cracking, isomerization and other fields.

Owner:TIANJIN UNIV

Copper-based microporous composite molecular sieve-based catalyst for FCC (fluid catalytic cracking) regenerated flue gas denitration, and preparation method and application thereof

InactiveCN104028299AGood chemical stabilityReduce the ratio of silicon to aluminumMolecular sieve catalystsDispersed particle separationPhosphoric acidReaction temperature

The invention relates to a copper-based microporous composite molecular sieve-based catalyst for FCC (fluid catalytic cracking) regenerated flue gas denitration, and a preparation method and application thereof. A nano-level ZSM-5 molecular sieve is prepared by performing solution stirring mixing, crystallization, washing separation, drying baking and the like on tetraethyl orthosilicate serving as a silicon source, aluminium isopropoxide serving as an aluminum source and organic amino and deionized water which serve as raw materials. A ZSM-5 / SAPO-34 microporous composite molecular sieve is prepared by performing solution stirring mixing, crystallization, washing separation, drying baking and the like on silica sol serving as a silicon source, pseudo-boehmite serving as an aluminum source, phosphoric acid serving as a phosphorous source and the organic amino and the deionized water which serve as the raw materials, and adding nano-level ZSM-5 crystal seeds; then a final product is obtained by loading an active component on the molecular sieve by an isometric steeping method. The catalyst is high in reaction activity, wide in reaction temperature window and good in application prospect in SCR (silicon controlled rectification) reaction for the FCC regenerated flue gas denitration.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

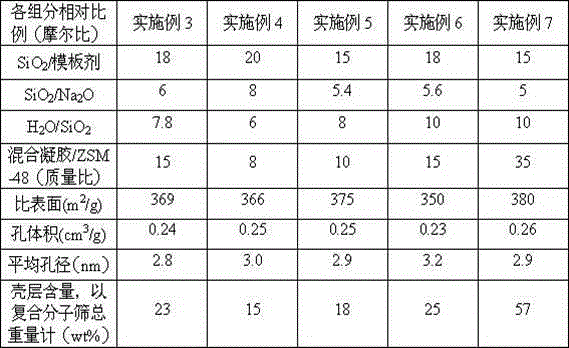

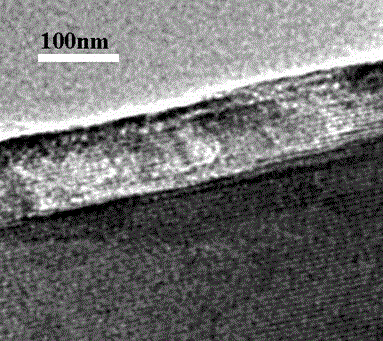

ZSM-48/Silicalite-1 composite molecular sieve and preparation method thereof

ActiveCN104418341AReduce the ratio of silicon to aluminumIncrease acidityCrystalline aluminosilicate zeolitesMolecular sieveChemistry

The invention discloses a ZSM-48 / Silicalite-1 composite molecular sieve and a preparation method thereof, the composite molecular sieve takes the ZSM-48 molecular sieve with low silica-alumina ratio as a shell phase, and takes Silicalite-1 as a core layer, total specific surface area of the composite molecular sieve is 330-400m<2> / g, the total pore volume is 0.22-0.28ml / g, average aperture is 2.5-3.5nm, by measuring gross weight of the composite molecular sieve, the shell layer content is 10-70%; wherein, mol ratio of silicon oxide of the ZSM-48 molecular sieve with low silica-alumina ratio to alumina is 25-50. The preparation method comprises the following steps: uniformly mixing the ZSM-48 molecular sieve with low silica-alumina ratio, sodium hydroxide, a template and water, adding silicon source to prepare a reaction mixture gel system, crystallizing the reaction mixture gel, separating the crystallization products, drying, and roasting to obtain the ZSM-48 / Silicalite-1 composite molecular sieve. The composite molecular sieve has good shape-selecting performance and anti-carbon deposition capability, and has latent industrial application value in alkylation and isomerization reactions.

Owner:CHINA PETROLEUM & CHEM CORP +1

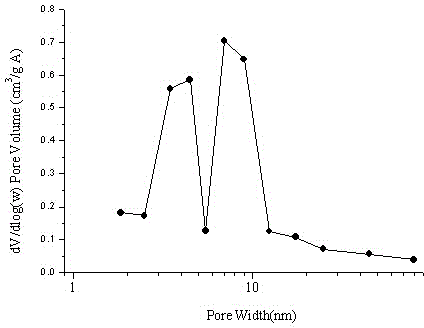

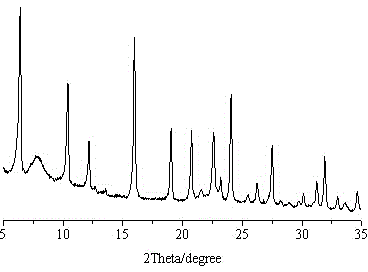

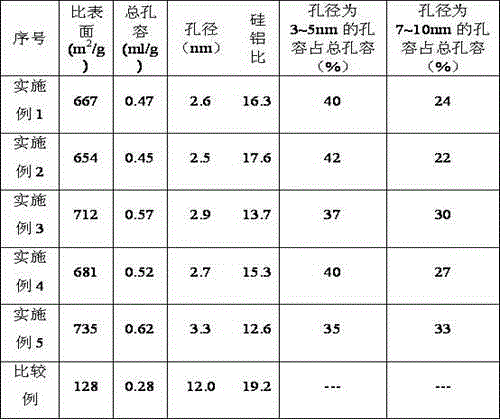

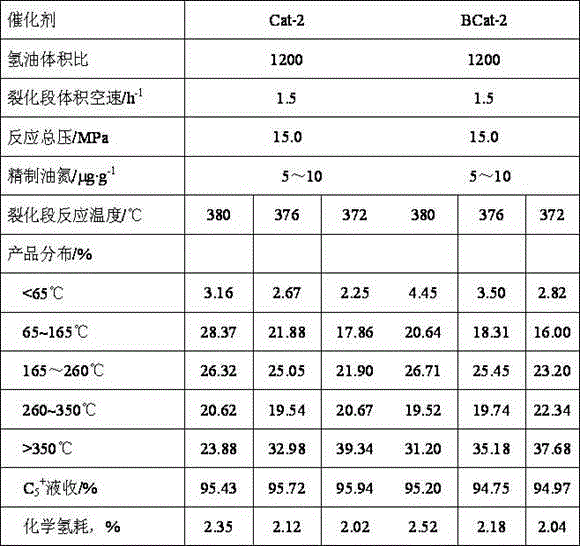

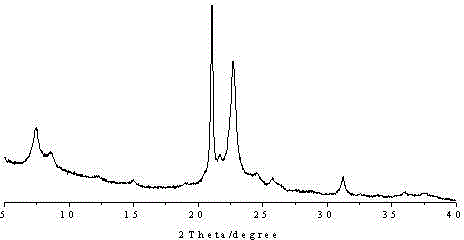

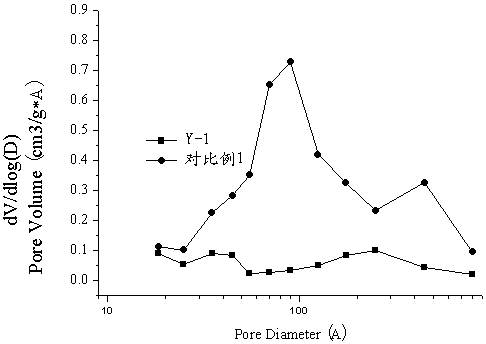

Y-Beta composite molecular sieve having double mesoporous structure, and preparation method thereof

ActiveCN105540608AReduce the ratio of silicon to aluminumIncrease acidityFaujasite aluminosilicate zeoliteMolecular sieveHydrogen

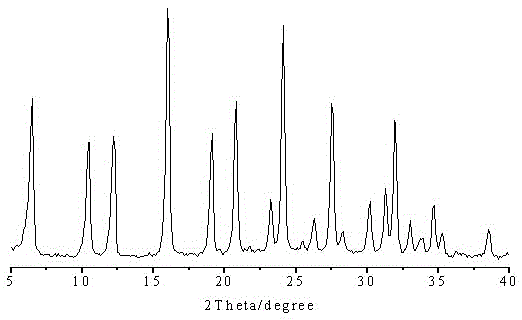

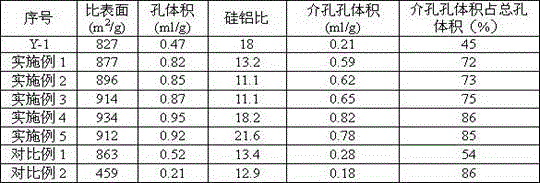

The present invention discloses a Y-Beta composite molecular sieve having a double mesoporous structure, and a preparation method thereof. The Y-Beta composite molecular sieve has two mesoporous structures such as 3-5 nm mesopores and 7-10 nm mesopores, wherein the pore volume of the mesopores with the pore size of 3-5 nm accounts for 20-50% of the total pore volume, the pore volume of the mesopores with the pore size of 7-10 nm accounts for 15-40% of the total pore volume, a molar ratio of silica to alumina is 7-25, a specific surface area is 480-780 m<2> / g, the total pore volume is 0.39-0.70 ml / g, and the average pore size is 1.7-3.8 nm. The preparation method comprises: (1) dissolving an inorganic alkali and an organic alkali in water to form a mixed solution; and (2) adding a hydrogen type Y-Beta composite molecular sieve to the mixed solution, carrying out a constant temperature treatment, filtering, washing, drying, calcining, and carrying out ammonium exchange on the calcined product to obtain the Y-Beta composite molecular sieve having the double mesoporous structure. The Y-Beta composite molecular sieve of the present invention can provide more reaction spaces for macromolecules so as to improve the catalytic performance of the composite molecular sieve.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of ZSM-48 molecular sieve with low silicon-aluminum ratio and preparation method thereof

ActiveCN103803576BIncrease acidityReduce the ratio of silicon to aluminumCrystalline aluminosilicate zeolitesMolecular sieveMass ratio

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing large-grain and highly-dispersed 4A zeolite

InactiveCN102502693AIncrease water to sodium ratioReduce the ratio of silicon to aluminumAluminosilicate zeolite type-AIonRaw material

The invention discloses a method for synthesizing large-grain and highly-dispersed 4A zeolite. The method comprises the following steps of: preparing materials, gelatinizing, crystallizing, washing, and drying. In order to synthesize the large-grain and highly-dispersed 4A zeolite, a certain silicon-to-aluminum ratio is kept, a water-to-sodium ratio is properly increased, and a relatively low sodium-to-silicon ratio is controlled in the aspect of a raw material ratio; in order to ensure that grains are large and uniform, N-atom-containing organic alkali or an anionic surfactant is properly added into ingredients; in order to synthesize a 4A molecular sieve with large grains and high dispersibility, two-section crystallization is adopted, the first section is dynamic crystallization, the temperature is controlled to be between 70 and 85 DEG C to control the number of grain seeds and achieve a high dispersion degree among the seeds, and the second section is static crystallization to create conditions for grain growth only; and a certain amount of builder is added at the late stage of washing, so that the pH value of raw powder of the molecular sieve can be reduced, and bonded ions can be neutralized due to weak acidity and enter a solution to meet the requirement of dispersibility.

Owner:江苏洁欧康科技有限公司

USY molecular sieve with double meso-structures and preparation method thereof

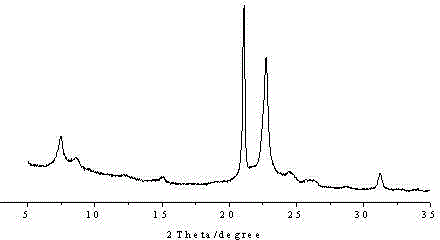

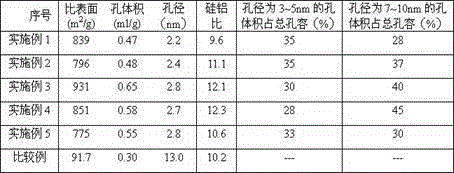

ActiveCN105712370AReduce the ratio of silicon to aluminumIncrease acidityFaujasite aluminosilicate zeoliteMolecular sieveSilicon oxide

The invention discloses a USY molecular sieve with double meso-structures. The volume of pores with pore sizes of 3 to 5 nm in the USY molecular sieve accounts for 15 to 40% of the total pore volume of the USY molecular sieve; the volume of pores with pore sizes of 7 to 10 nm accounts for 25 to 50% of the total pore volume of the USY molecular sieve; a mol ratio of silicon oxide to alumina in the molecular sieve is in a range of 7 to 15; and the USY molecular sieve has a specific surface area of 680 to 980 m<2> / g, a pore volume of 0.42 to 0.75 ml / g and an average pore size of 1.9 to 3.1 nm. The USY molecular sieve prepared in the invention has meso pores of two pore sizes, can provide more reaction space for large molecules and has improved catalysis performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y type molecular sieve and preparation method thereof

ActiveCN106672997ALarge mesostructure distributionReduce the ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveFiltration

The invention discloses a modified Y type molecular sieve and a preparation method thereof. The molecular sieve has the following properties: the total pore volume is 0.76-1.25ml / g, wherein the mesoporous volume is 0.55-1.05ml / g and the mesoporous volume is 65-90% of the total pore volume; the mole ratio of silicon oxide to aluminum oxide is 10-35; and the specific surface area is 680-1050m<2> / g. The preparation method comprises the following steps: under a stirring condition, adding the Y type molecular sieve into a pressure container filled with organic aqueous alkali; closing the system; increasing the pressure to 0.2-1.0MPa, and then increasing temperature to 50-90 DEG C and treating for 0.5-3 hours under constant temperature; and relieving pressure, performing suction filtration, drying and roasting, thereby acquiring the modified Y type molecular sieve. The molecular sieve has larger-size mesoporous distribution and can supply much more reaction space for macromolecules; the catalytic performance of the molecular sieve is promoted; and the preparation method is simple and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

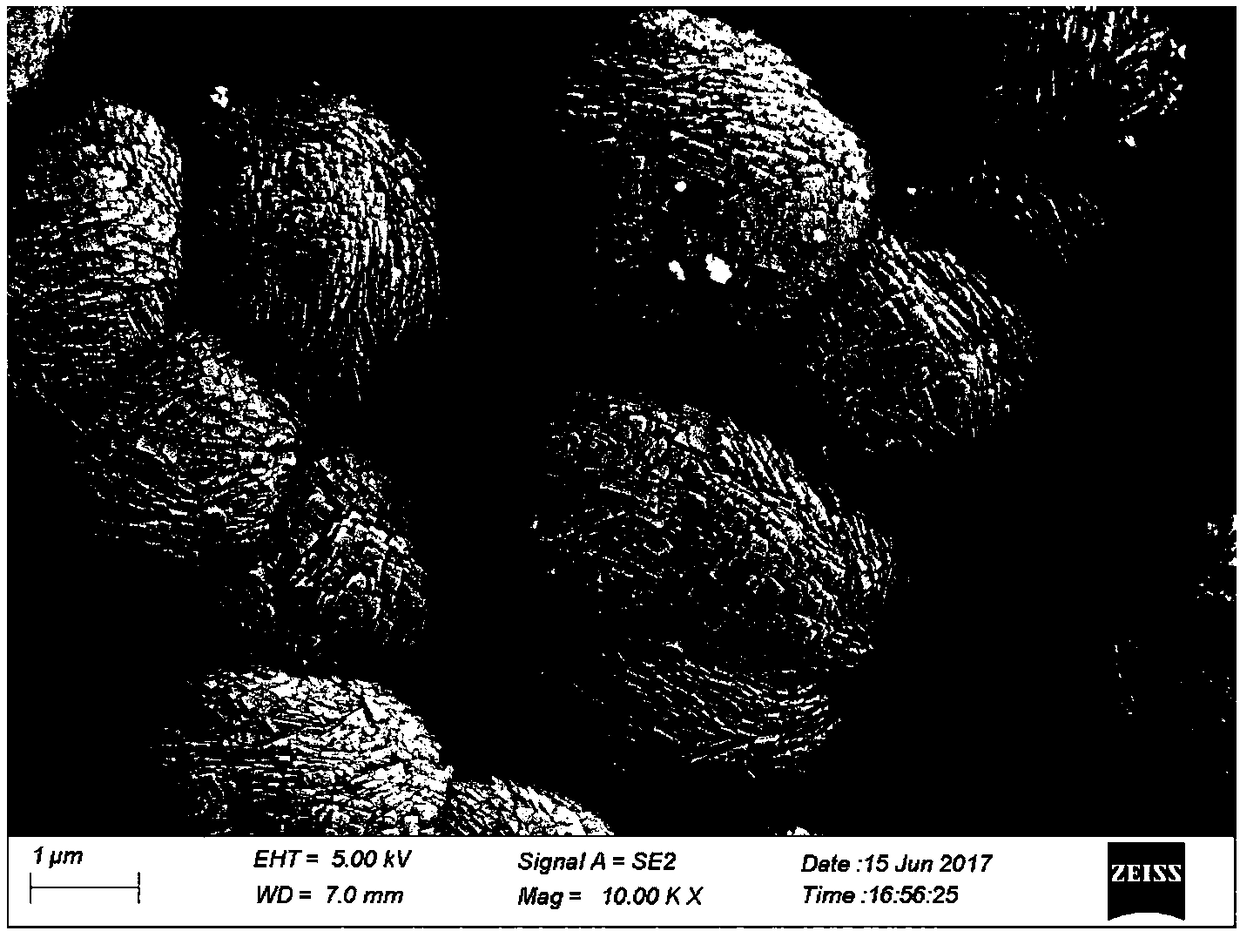

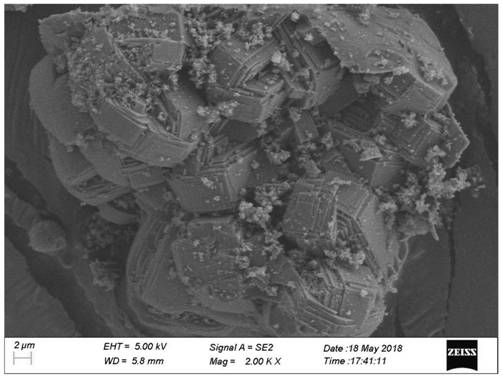

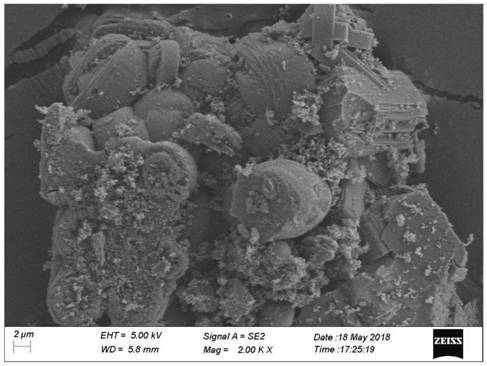

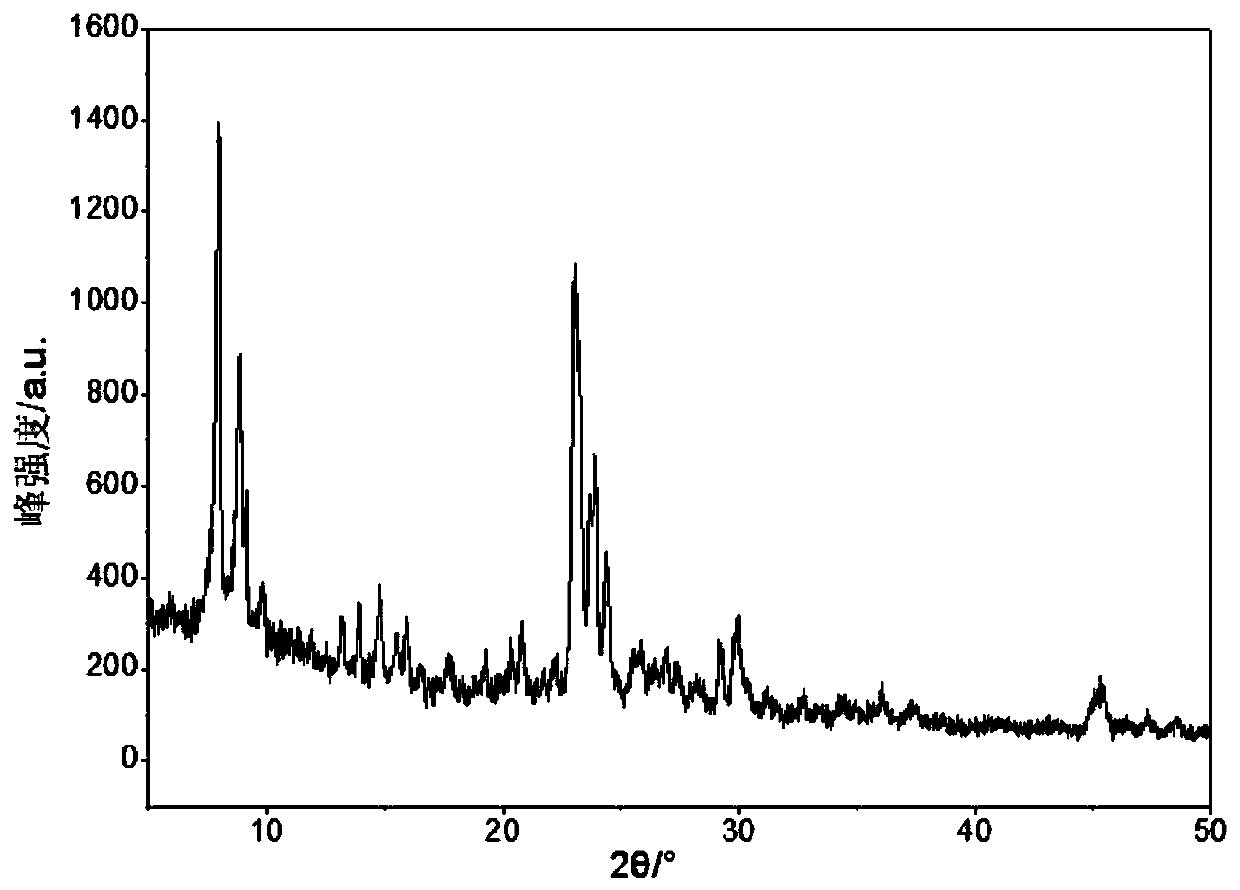

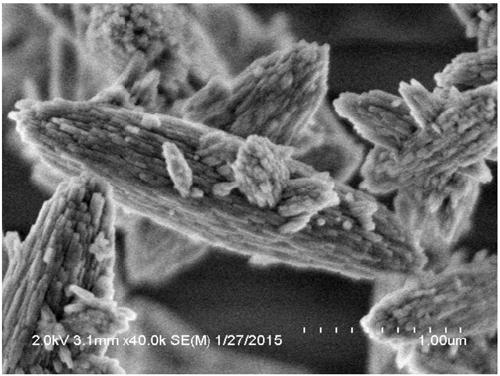

Low-silicon multistage structure ZSM-5 zeolite molecular sieve, and preparation method and application thereof

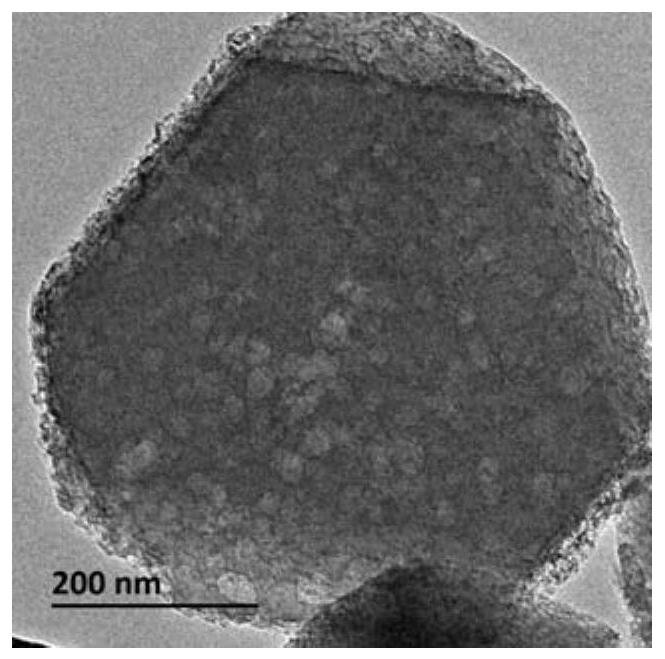

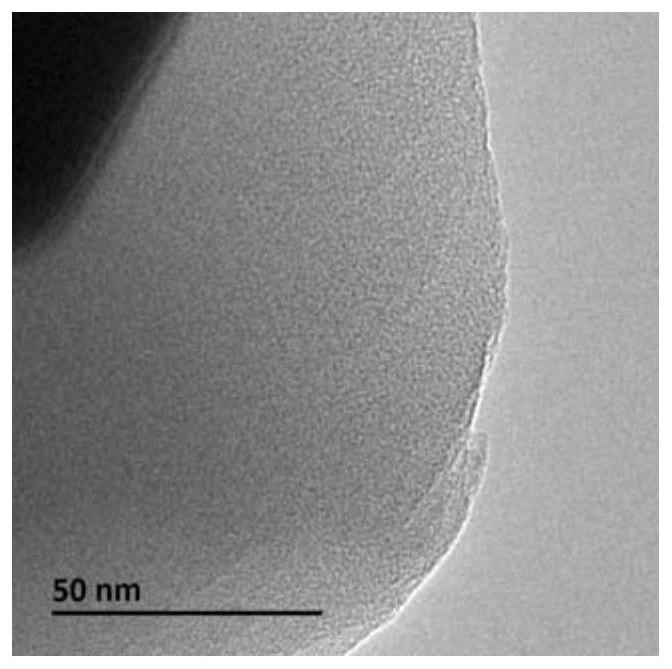

ActiveCN108178163AIncrease acidityExcellent mass transfer and diffusion propertiesMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveZSM-5 zeolite

The invention relates to a low-silicon multistage structure ZSM-5 zeolite molecular sieve, and a preparation method and application thereof. The low-silicon multistage structure ZSM-5 zeolite molecular sieve is provided with a micropore-mesoporous multistage structure, wherein a one-time particle size is smaller than 300nm, and a secondary accumulation particle size is 300nm-4mu m; the silica-alumina ratio of the ZSM-5 zeolite molecular sieve is 10-80, the outer superficial area is greater than 100m<2> / g, mesoporous volume is not smaller than 0.1cm<3> / g, and total acid content is greater than1.5mmol / g. The low-silicon multistage structure ZSM-5 zeolite molecular sieve is high in acid content and reaction activity, more mesoporouses enable a reactant or products to be quickly diffused, side reaction and carbon deposition generation can be reduced, the carbon containing ability of the molecular sieve is increased, and the service life of the molecular sieve is prolonged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

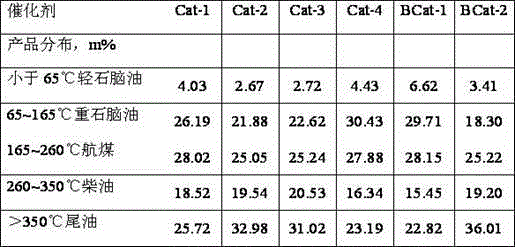

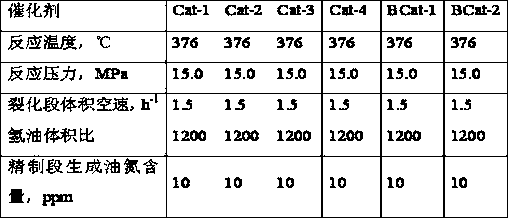

Method for preparing hydro-cracking catalyst composition

ActiveCN105618113AReduce the ratio of silicon to aluminumImprove heat sensitivityMolecular sieve catalystsHydrocarbon oil crackingPtru catalystOrganosolv

The invention discloses a method for preparing a hydro-cracking catalyst composition. The method comprises the following steps: 1, modified Y type molecular sieve, amorphous silica-alumina and / or aluminum oxide are well mixed according to a certain ratio; dilute nitric acid is added, such that a slurry is formed; extrusion molding is carried out; and drying and roasting are carried out, such that a silica-alumina carrier containing the modified Y type molecular sieve is obtained; and 2, the carrier obtained in the step 1 is impregnated with an impregnation solution containing active metals; after impregnation, the carrier is dried and the dried carrier is roasted, such that the hydro-cracking catalyst is obtained. A preparation method of the modified Y type molecular sieve comprises the following steps: NaY zeolite is adopted as raw powder; ammonium salt ion exchange, ammonium fluorosilicate dealumination and silicon reinsertion treatment, hydrothermal treatment, and aluminum salt solution treatment are carried out; impregnation is carried out in organic solvents; and fast drying, alkali desilication, drying and roasting treatments are carried out, such that the modified Y type molecular sieve is obtained. The hydro-cracking catalyst composition provided by the invention has good temperature increase sensitivity and operation flexibility. The composition can be widely used in hydro-cracking reaction processes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for ZSM-48 molecular sieve

ActiveCN102910642BLow costReduce the ratio of silicon to aluminumCrystalline aluminosilicate zeolitesMolecular sieveTrimethylamine

The invention relates to a preparation method for a ZSM-48 molecular sieve. The method comprises the steps of mixing silicon source, aluminium source, alkali, water and template uniformly; crystallizing, filtering, washing, drying and roasting to obtain the ZSM-48 molecular sieve, wherein the template is dibromohexane (DBH), trimethylamine (TMA) and ethanol (ETA); and properly adjusting the amount of the reaction mixture, and thus the ZSM-48 molecular sieve is obtained. Compared with a molecular sieve prepared by a conventional technology, the ZSM-48 molecular sieve synthesized by the method has the characteristics of low synthetic cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y-Beta composite molecular sieve as well as preparation method and application thereof

ActiveCN107344115ALarge mesostructure distributionReduce the ratio of silicon to aluminumMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveOrganic base

The invention discloses a modified Y-Beta composite molecular sieve as well as a preparation method and application thereof. The preparation method comprises the following steps of under a stirring condition, adding a Y-Beta composite molecular sieve into a pressure container full of an organic base solution, sealing a system, pressurizing to 0.2 to 1.0MPa, then heating to 50 to 90 DEG C, treating for 0.5 to 3 hours at constant temperature, depressurizing, carrying out suction filtration, drying, and roasting to obtain the modified Y-Beta composite molecular sieve. The modified Y-Beta composite molecular sieve prepared through the method has mesopore pore size distribution with a larger size, can provide more reaction spaces for macromolecules, and is beneficial to improving a catalytic performance of the molecular sieve, simple in the preparation method, and applicable to industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

NU-87 molecular sieve and preparation method thereof

ActiveCN102211780AImprove catalytic performanceAdjust the ratioCrystalline aluminosilicate zeolitesInorganic saltsMolecular sieve

The invention discloses an NU-87 molecular sieve and a preparation method thereof. The method comprises a preparation process of a crystallization material, a crystallization process and a recovery and treatment process of a crystallization product, wherein in the preparation process of the crystallization material, an aluminum source, a silicon source, alkali, a template agent, inorganic salt, an EU-1 molecular sieve and water are mixed; and the mass ratio of the EU-1 molecular sieve fed into the crystallization material to SiO2 contained in other components is 0.1-0.4. The NU-87 molecular sieve prepared by the method has the advantages of low silicon-aluminum ratio, high pore volume, low cost, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hierarchical structure ZSM-5 molecular sieve containing lanthanum and nickel or/and zinc , and preparation method and application thereof

PendingCN113042094AImprove diffusivityHigh reactivityMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention relates to a hierarchical structure ZSM-5 molecular sieve containing lanthanum and nickel or / and zinc, a preparation method thereof, and application of the hierarchical structure ZSM-5 molecular sieve in catalytic gasoline olefin reduction. The molecular sieve is ZSM-5 zeolite which is obtained by adopting a hydrothermal synthesis method and has a silicon-aluminum atomic ratio of 10-50, and pores in the zeolite contain lanthanum and zinc or / and nickel; the hierarchical structure ZSM-5 molecular sieve has a mesoporous structure formed by secondary accumulation of crystal grains of the molecular sieve, the volume of mesopores is not less than 0.09 cm<3> / g, the specific surface area is greater than 200 cm<2> / g, the size of primary particles of the molecular sieve is about 300 nm to 2 [mu]m, and the size of secondary accumulation particles is 2 [mu]m to 8 [mu]m. The hierarchical structure ZSM-5 molecular sieve containing lanthanum and nickel or / and zinc has high acid content and L acid / B acid ratio, and more mesoporous structures improve the diffusion rate of macromolecular reactants or products and enhance the carbon containing capacity of the catalyst, so the hierarchical structure ZSM-5 molecular sieve has high desulfurization and olefin reduction-octane number recovery activity and long-period stability in catalytic gasoline olefin reduction-modification reaction.

Owner:PETROCHINA CO LTD

A kind of low-silicon multi-level structure ZSM-5 zeolite molecular sieve and its preparation method and application

ActiveCN108178163BImprove diffusivityHigh reactivityMolecular sieve catalystsPentasil aluminosilicate zeoliteMolecular sieveCarbon deposit

The invention relates to a low-silicon multistage structure ZSM-5 zeolite molecular sieve, and a preparation method and application thereof. The low-silicon multistage structure ZSM-5 zeolite molecular sieve is provided with a micropore-mesoporous multistage structure, wherein a one-time particle size is smaller than 300nm, and a secondary accumulation particle size is 300nm-4mu m; the silica-alumina ratio of the ZSM-5 zeolite molecular sieve is 10-80, the outer superficial area is greater than 100m<2> / g, mesoporous volume is not smaller than 0.1cm<3> / g, and total acid content is greater than1.5mmol / g. The low-silicon multistage structure ZSM-5 zeolite molecular sieve is high in acid content and reaction activity, more mesoporouses enable a reactant or products to be quickly diffused, side reaction and carbon deposition generation can be reduced, the carbon containing ability of the molecular sieve is increased, and the service life of the molecular sieve is prolonged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Multistage structure ZSM-5 molecular sieve containing molybdenum and nickel or/and zinc and preparation method and application thereof

InactiveCN111905800AImprove diffusivityHigh reactivityMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention relates to a multilevel structure ZSM-5 molecular sieve containing molybdenum and nickel or / and zinc, a preparation method of the multilevel structure ZSM-5 molecular sieve, and application of the multilevel structure ZSM-5 molecular sieve as a catalyst in gasoline desulfurization and olefin reduction. The multilevel structure ZSM-5 molecular sieve has a low silica-alumina ratio, high molybdenum and zinc or nickel loading capacity and many mesopores, wherein the primary particle size of the molecular sieve is 300 nm-2 [mu]m, and the secondary accumulated particle size of the molecular sieve is 2 [mu]m-8 [mu]m. The whole preparation process of the multilevel structure ZSM-5 molecular sieve containing molybdenum and nickel or / and zinc is simple to operate. The multilevel structure ZSM-5 molecular sieve containing molybdenum and nickel or / and zinc has higher acid content and L acid / B acid ratio, and more mesopores improve the diffusion rate of macromolecular reactants or products, so the carbon capacity of the catalyst is enhanced; the catalyst has high desulfurization and olefin reduction octane number recovery activity and long-period stability in the catalytic gasoline desulfurization and olefin reduction reaction.

Owner:PETROCHINA CO LTD

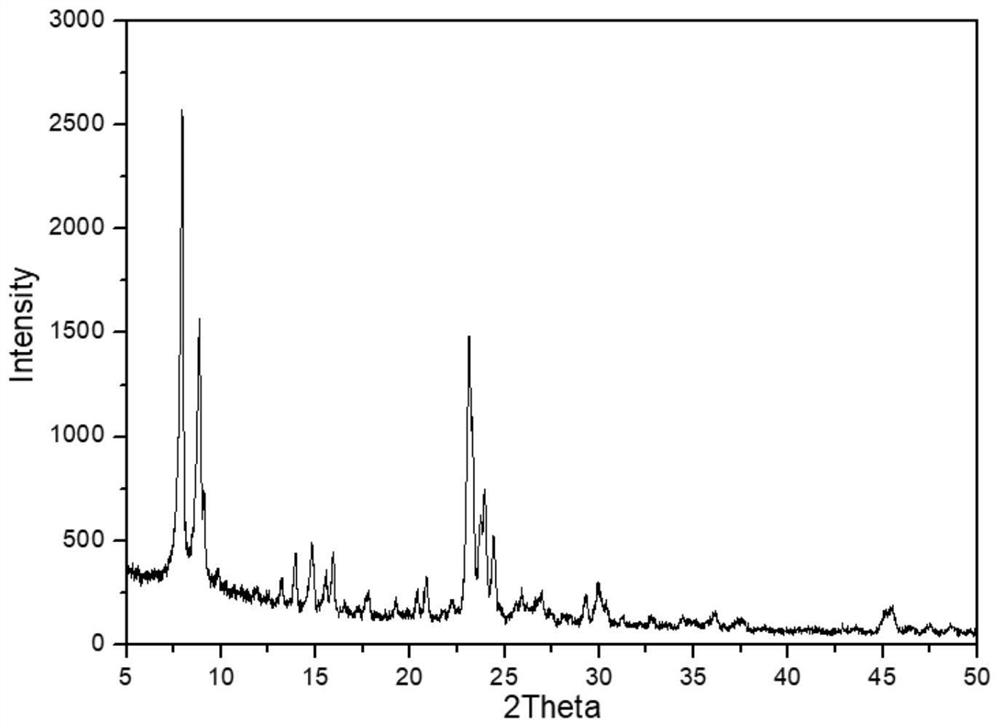

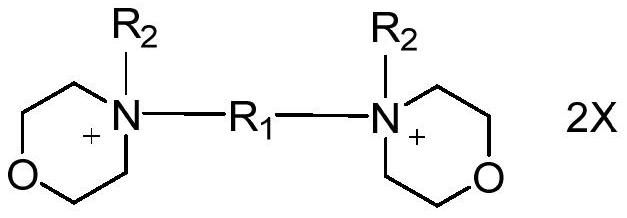

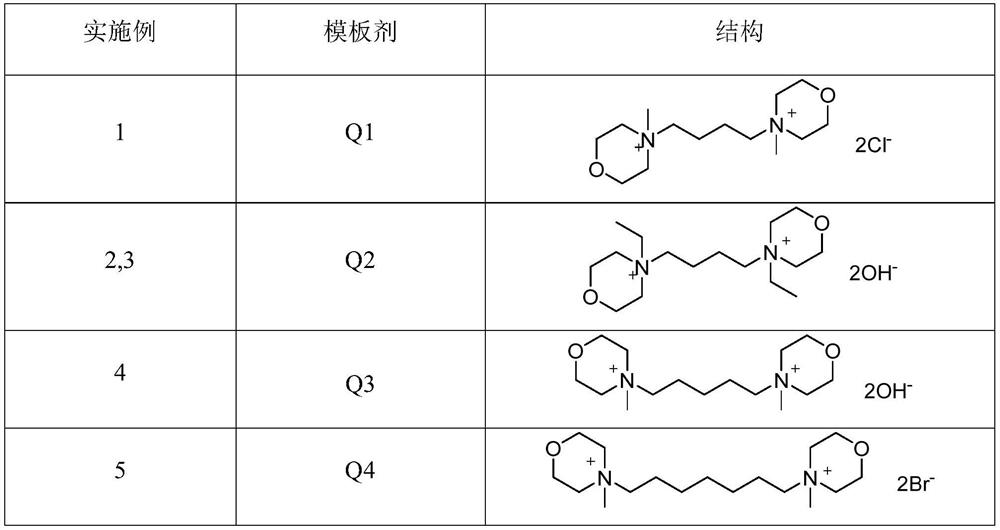

Low-silicon-aluminum-ratio ZSM-12 type zeolite molecular sieve synthesis method

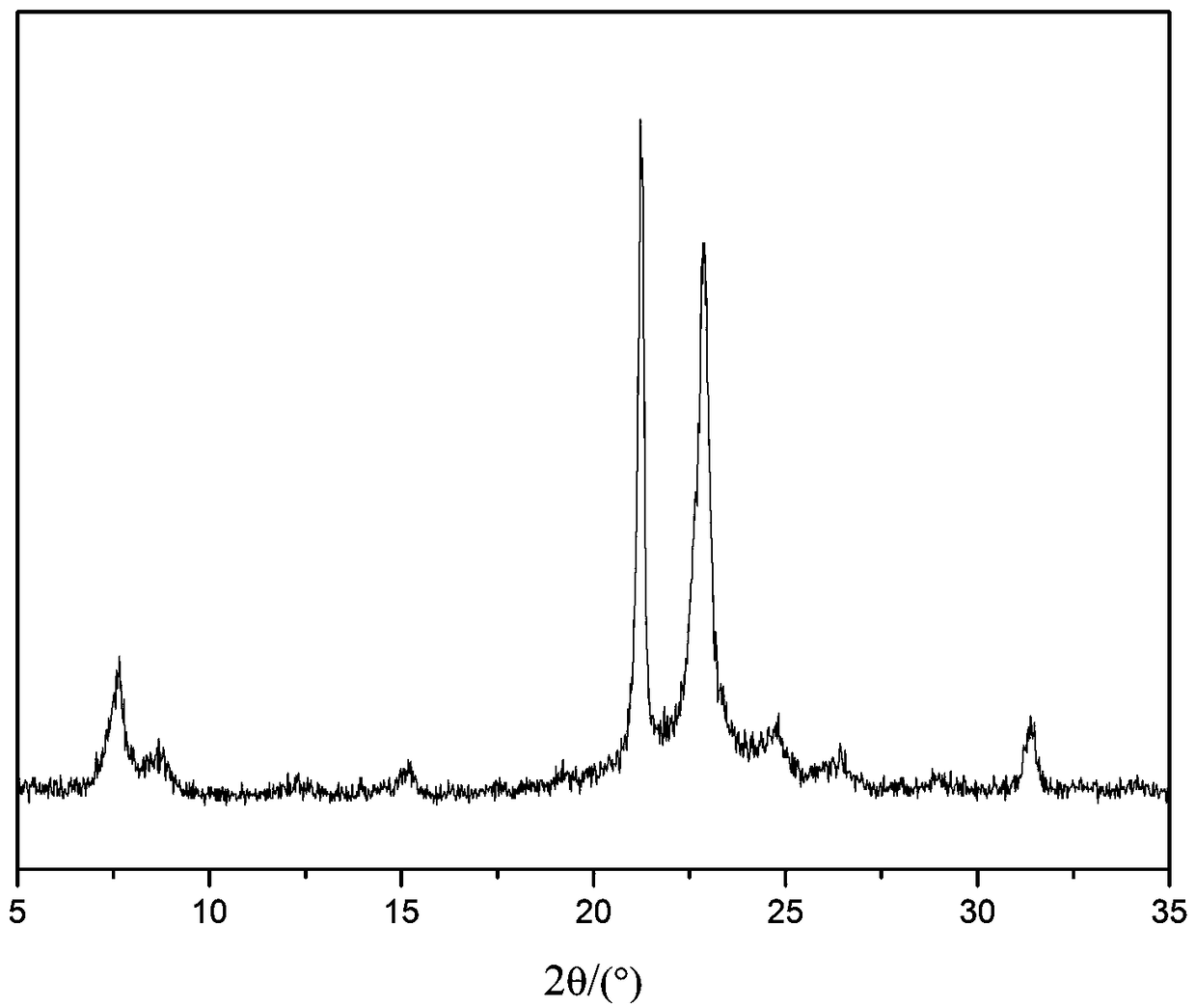

ActiveCN109665541ASmall sizeLow impurity contentAluminosilicate zeolite type ZSM-12Molecular sieveSynthesis methods

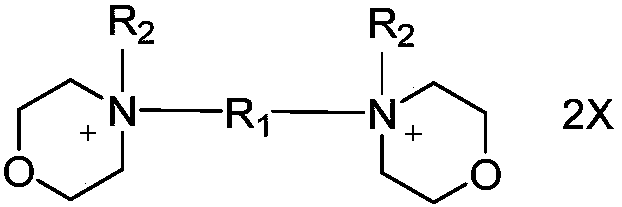

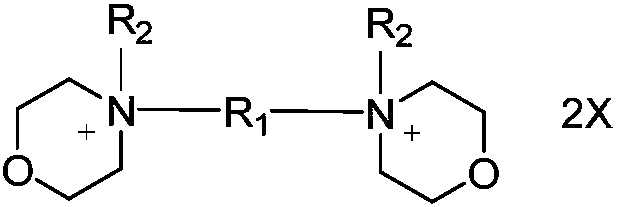

The invention relates to a low-silicon-aluminum-ratio ZSM-12 type zeolite molecular sieve synthesis method. In the prior art, the templating agent for synthesizing the low-silicon-aluminum-ratio ZSM-12 type zeolite molecular sieve has low feasibility, and the obtained ZSM-12 type zeolite molecular sieve has more impurities. A purpose of the present invention is mainly to solve the problems in theprior art. According to the technical scheme, the method comprises: uniformly mixing a silicon source, an aluminum source, a templating agent Q and water according to a molar ratio of SiO2 to Al(OH)3to the templating agent Q to H2O of 1:(0.02-0.2):(0.1-2.0):(30-200) to obtain a mixture, carrying out hydrothermal crystallization on the mixture for 20-200 h at a temperature of 95-180 DEG C, washingthe obtained product, and drying to obtain the low silicon-aluminum-ratio ZSM-12 type zeolite molecular sieve. With the technical scheme, the problem in the prior art can be well solved. The obtainedproduct of the present invention can be used in industrial catalytic applications.

Owner:CHINA PETROLEUM & CHEM CORP +1

Beta zeolite molecular sieve and amine-free synthetic method thereof

InactiveCN104445248AReduce energy consumptionEasy post-processingCrystalline aluminosilicate zeolitesMolecular sieveCrystallinity

The invention provides a Beta zeolite molecular sieve and an amine-free synthetic method thereof, and belongs to the technical field of molecular sieve preparation. The amine-free synthetic method of the Beta zeolite molecular sieve comprises the following steps: gel forming, crystallization and aftertreatment, wherein sodium hydroxide is taken as an alkali source, and the seed crystal adopts the Beta zeolite molecular sieve; and in the raw materials, the mole ratio of SiO2 to Al2O3 ranges from 15 to 30, the mole ratio of Na2O to SiO2 ranges from 0.14 to 0.34, and the mole ratio of H2O to SiO2 ranges from 16 to19. The amine-free synthetic method of the Beta zeolite molecular sieve does not use an organic template, the aftertreatment of the molecular sieve is convenient, and the production process is environment-friendly. The Beta zeolite molecular sieve with good crystallinity can be stilled obtained while the ratio of silicate to aluminum in the raw materials is reduced, and application to industrial production is facilitated.

Owner:天津神能科技有限公司

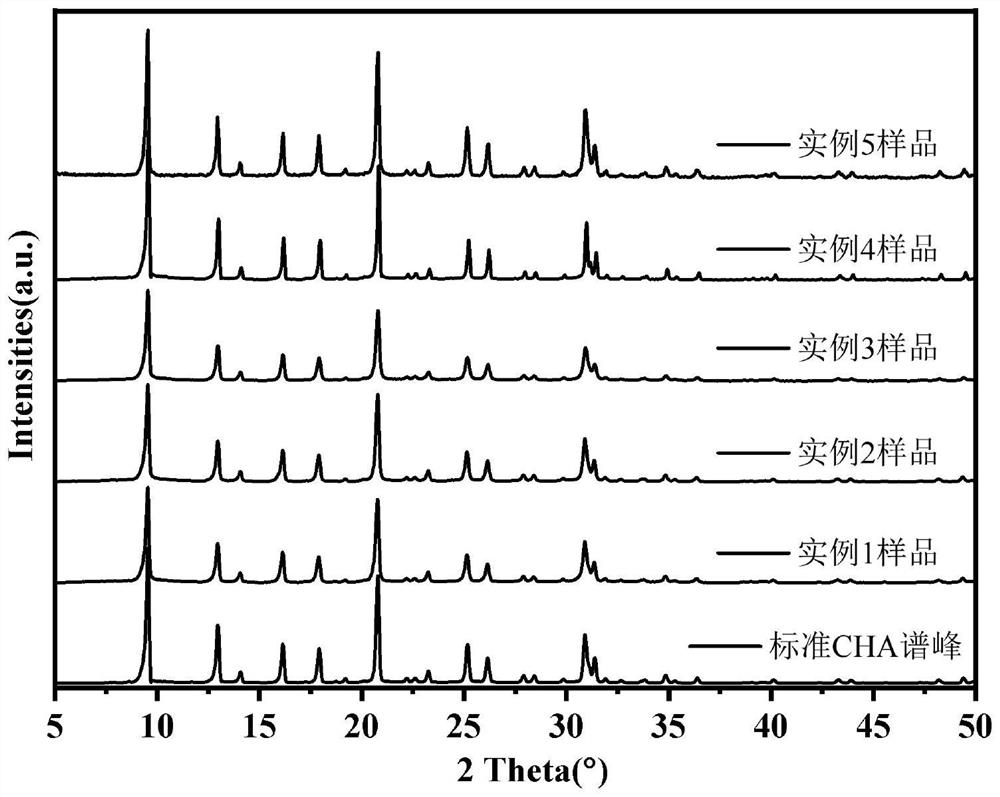

Preparation method for rapidly synthesizing Cu-SSZ-13 molecular sieve with low silica-alumina ratio and application of Cu-SSZ-13 molecular sieve

ActiveCN113135579ASynthesis fastReduce the ratio of silicon to aluminumMolecular sieve catalystsDispersed particle separationMolecular sieveOrganic chemistry

The invention discloses a preparation method for rapidly synthesizing a Cu-SSZ-13 molecular sieve with a low silica-alumina ratio, which comprises a process of synthesizing an SSZ-13 molecular sieve with a silica-alumina ratio of 4-10 under the combined action of an organic template agent and inorganic cations by taking a Y molecular sieve as an aluminum source.

Owner:安徽纳蓝环保科技有限公司

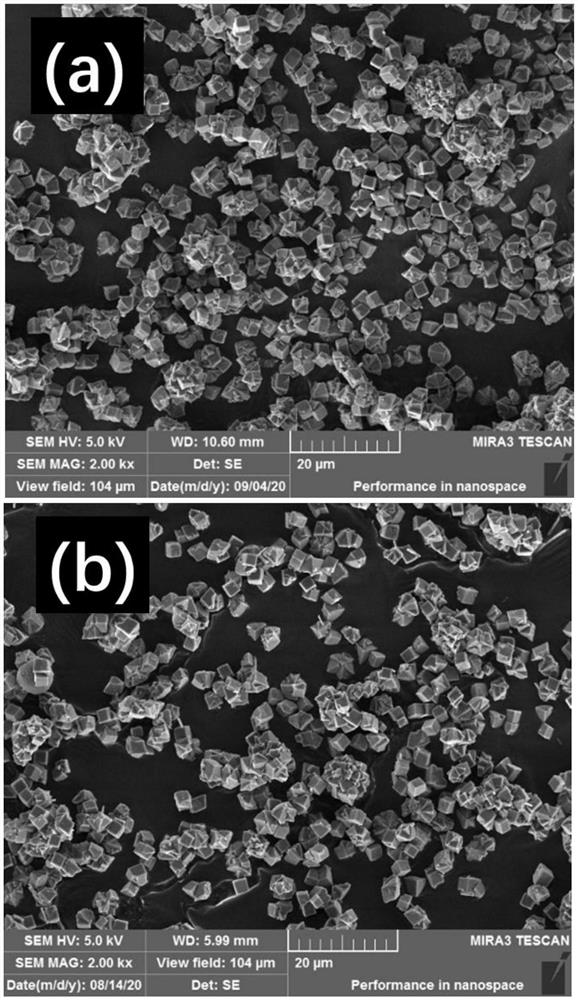

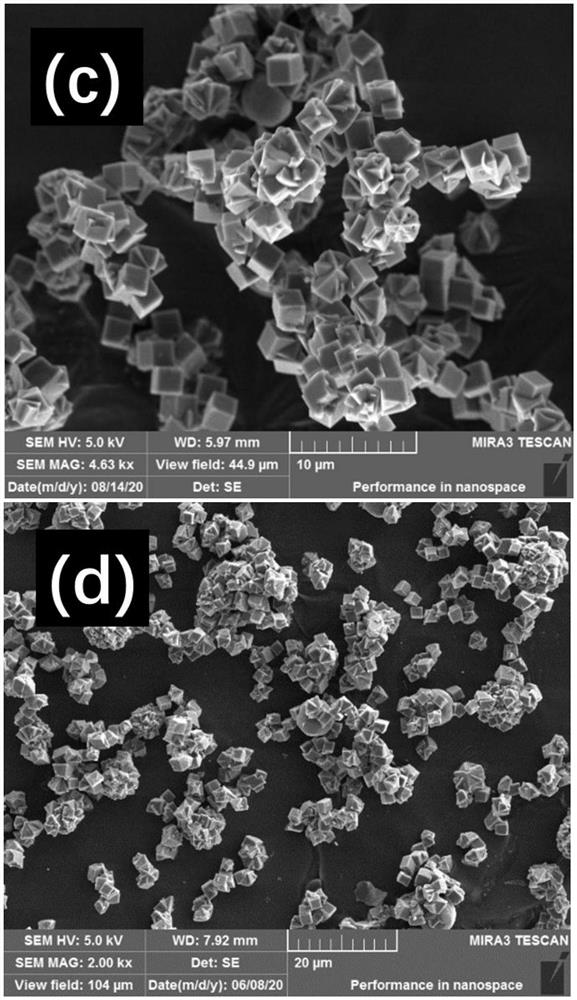

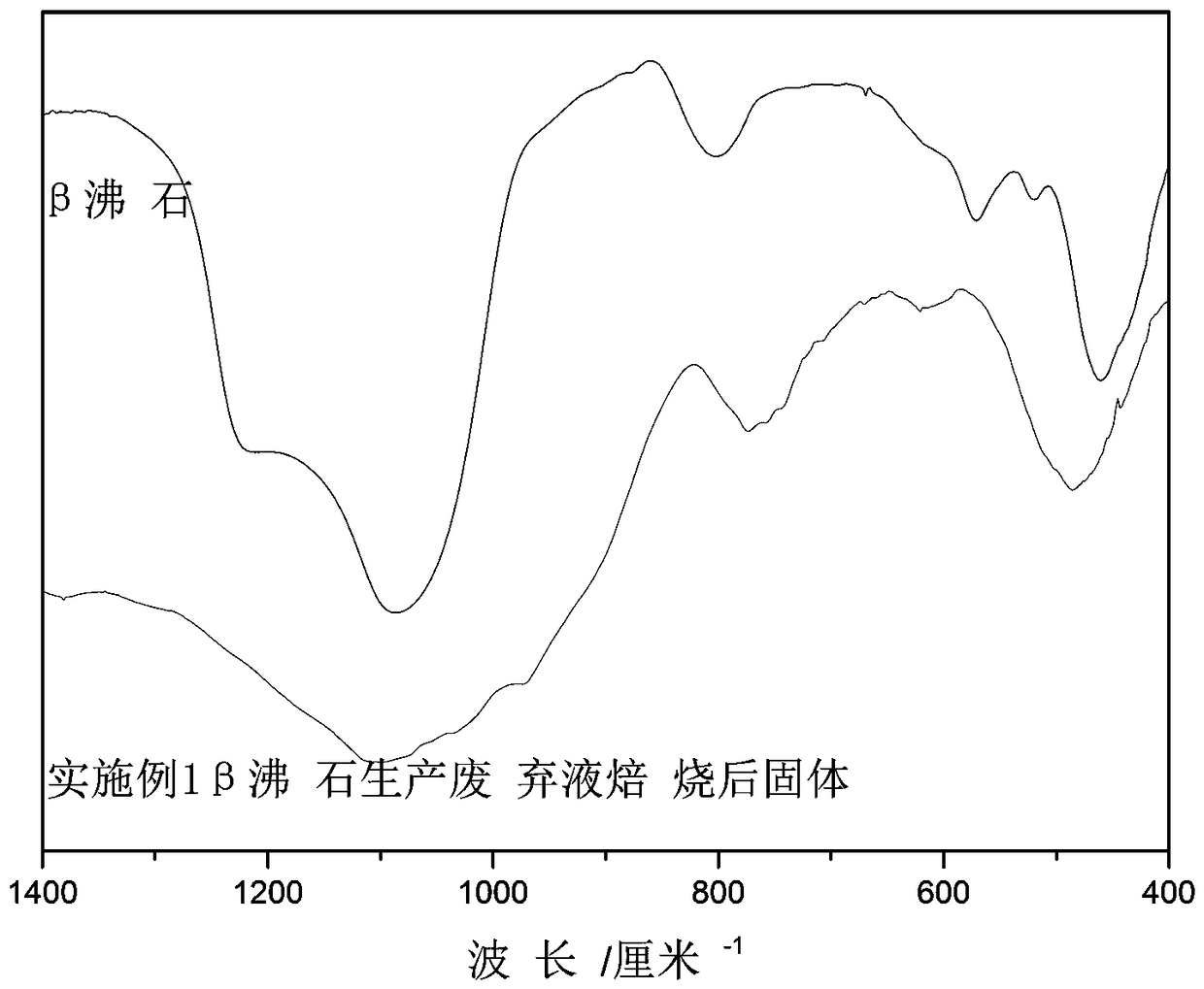

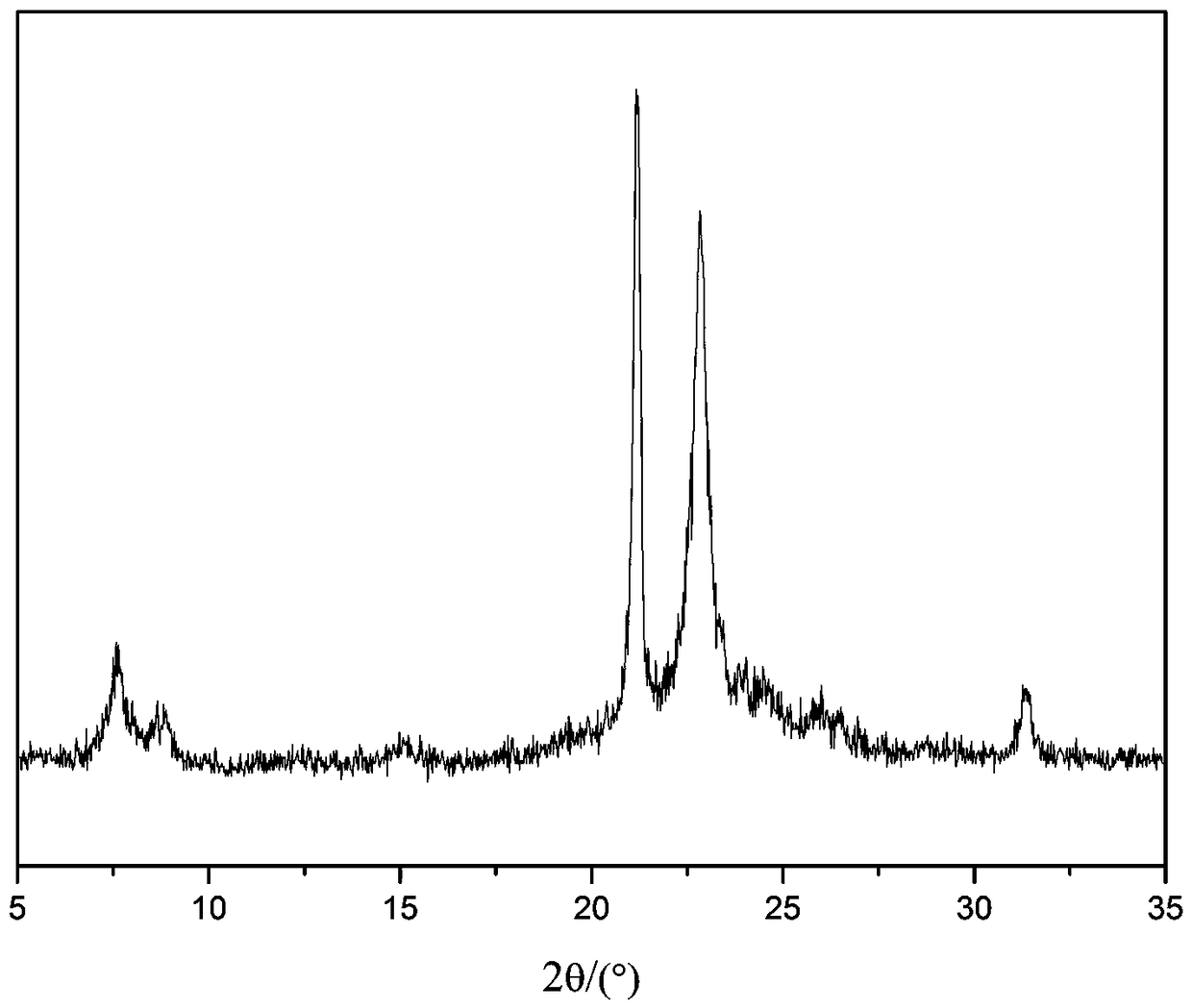

A kind of synthetic method of low silicon aluminum ratio zsm-48 molecular sieve

InactiveCN105967202BNovel low-cost synthetic routeConvenient and low-cost synthetic routeCrystalline aluminosilicate zeolitesMolecular sieveStructural unit

The invention discloses a synthetic method of a ZSM-48 molecular sieve with a low silica-alumina ratio. The ZSM-48 molecular sieve with the low silica-alumina ratio is prepared by the following steps: beta-zeolite synthesis waste liquid is used as a raw material part; the raw material, an organic template, a silicon source, an aluminium source, an alkali source and water are mixed into a gel mixture; a hydrothermal crystallization reaction is carried out, in order to obtain the ZSM-48 molecular sieve with the low silica-alumina ratio (SiO2 / Al2O3) which is lower than 100. In a condition without addition of crystal seed, silicon and aluminium substances existed in the heterogeneous molecular sieve waste liquid in primary and secondary constitutional unit forms are used for inducing synthesis of ZSM-48, and a novel and convenient synthesis approach with low cost is provided for preparing the ZSM-48 molecular sieve with the low silica-alumina ratio.

Owner:TAIYUAN UNIV OF TECH

Synthesis method of zsm-12 zeolite molecular sieve with low silicon-aluminum ratio

ActiveCN109665541BSmall sizeLow impurity contentAluminosilicate zeolite type ZSM-12Molecular sievePhysical chemistry

The invention relates to a method for synthesizing a ZSM-12 zeolite molecular sieve with a low silicon-aluminum ratio, which mainly solves the low feasibility of the template agent used in synthesizing a low-silicon-aluminum ratio ZSM-12 type zeolite molecular sieve in the prior art, and the obtained ZSM-12 type Zeolite molecular sieve has more impurities. The present invention adopts according to 1SiO 2 :(0.02~0.2)Al(OH) 3 :(0.1~2.0) Template Q:(30~200)H 2 The initial molar ratio of O, the silicon source, the aluminum source, the template Q and water are uniformly mixed to obtain a mixture, and then the mixture is hydrothermally crystallized at 95-180°C for 20-200 hours, and the obtained product is washed and dried. The technical solution for obtaining a ZSM‑12 zeolite molecular sieve with a low silicon-aluminum ratio better solves this technical problem and can be used in industrial catalytic applications.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrocracking catalyst containing Y molecular sieve and preparation method thereof

ActiveCN105618112BImprove heat sensitivityImprove operational flexibilityMolecular sieve catalystsHydrocarbon oil crackingMolecular sievePtru catalyst

The invention discloses a hydrocracking catalyst containing Y molecular sieve and a preparation method thereof, which comprises the following components based on the total weight of the catalyst: 55% to 85% of silicon-aluminum carrier containing modified Y molecular sieve, and 15% to 15% of active metal 45%; wherein the modified Y molecular sieve unit cell constant is 2.425~2.455nm; the bulk phase silicon-aluminum ratio is 10-60, the surface layer silicon-aluminum ratio is 7-30, and the surface layer silicon-aluminum ratio is lower than the bulk phase silicon-aluminum ratio Ratio; specific surface area of modified Y molecular sieve is 600~800m2 / g, pore volume is 0.40~0.70ml / g; infrared acid content is 0.3~1.5mmol / g; relative crystallinity is 70%~110%. The hydrocracking catalyst of the invention can be applied to the hydrocracking reaction of flexible production of chemical raw materials or middle distillate oil, and has good temperature raising sensitivity and operational flexibility.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y molecular sieve with its surface rich in mesopores, and preparation method thereof

ActiveCN110540213AFast consumptionRapid concentrationFaujasite aluminosilicate zeoliteMolecular sieveCell parameter

The invention relates to a modified Y molecular sieve with its surface rich in mesopores, and a preparation method thereof. A molar ratio of the bulk phase SiO2 / Al2O3 of the modified Y molecular sieveis 10.0 to 13.0; the modified Y molecular sieve has a BET-process total pore volume of no less than 0.38 cm <3> / g and a BET-process secondary pore volume of no less than 0.06 cm <3> / g; the cell parameters a, b and c are equal and are in a range of 2.44-2.46 nm; and the content of sodium oxide in the modified Y molecular sieve is not more than 0.1 wt% based on the total weight of the modified Y molecular sieve. Compared with conventional Y molecular sieves, the modified Y molecular sieve of the invention has a larger surface mesoporous volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of modified Y-type molecular sieve and preparation method thereof

ActiveCN106672997BLarge mesostructure distributionReduce the ratio of silicon to aluminumFaujasite aluminosilicate zeoliteMolecular sieveOrganic base

The invention discloses a modified Y type molecular sieve and a preparation method thereof. The molecular sieve has the following properties: the total pore volume is 0.76-1.25ml / g, wherein the mesoporous volume is 0.55-1.05ml / g and the mesoporous volume is 65-90% of the total pore volume; the mole ratio of silicon oxide to aluminum oxide is 10-35; and the specific surface area is 680-1050m<2> / g. The preparation method comprises the following steps: under a stirring condition, adding the Y type molecular sieve into a pressure container filled with organic aqueous alkali; closing the system; increasing the pressure to 0.2-1.0MPa, and then increasing temperature to 50-90 DEG C and treating for 0.5-3 hours under constant temperature; and relieving pressure, performing suction filtration, drying and roasting, thereby acquiring the modified Y type molecular sieve. The molecular sieve has larger-size mesoporous distribution and can supply much more reaction space for macromolecules; the catalytic performance of the molecular sieve is promoted; and the preparation method is simple and is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Surface-rich modified y molecular sieve with mesopores and preparation method thereof

ActiveCN110540213BFast consumptionRapid concentrationFaujasite aluminosilicate zeoliteMolecular sievePhysical chemistry

The present disclosure relates to a modified Y molecular sieve whose surface is rich in mesopores and a preparation method thereof. The bulk phase SiO of the modified Y molecular sieve 2 / Al 2 o 3 The molar ratio is 10.0~13.0, the total pore volume of BET method is not less than 0.38cm 3 / g, BET method secondary pore volume not less than 0.06cm 3 / g, unit cell parameters: a=b=c=2.44-2.46nm, based on the total weight of the modified Y molecular sieve, the content of sodium oxide in the modified Y molecular sieve is not more than 0.1% by weight. The modified Y molecular sieve has larger surface mesopore volume than conventional Y molecular sieves.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method and application of a modified Y molecular sieve and single-stage hydrocracking catalyst

ActiveCN107303495BImprove nitrogen resistanceReduce the ratio of silicon to aluminumMolecular sieve catalystsHydrocarbon oil crackingPtru catalystIon exchange

The invention discloses a preparation method and application of modified Y molecular sieve and a single-stage hydrocracking catalyst. The method includes the following contents: (1) using NaY zeolite as raw powder to carry out ammonium salt ion exchange; (2) carrying out dealumination and silicon filling treatment on the Y molecular sieve of step (1); (3) treating the Y after step (2) The molecular sieve is subjected to hydrothermal treatment; (4) the Y molecular sieve treated in step (3) is subjected to acid dealumination treatment; (5) the Y molecular sieve obtained in step (4) is rapidly dried; (6) the Y obtained in step (5) is The molecular sieve undergoes a carbon deposition reaction; (7) the molecular sieve obtained in step (6) is desiliconized; (8) the Y molecular sieve after desiliconization in step (5) is filtered and dried, and then subjected to charcoal treatment to obtain the modified Y molecular sieve. Y molecular sieve. The single-stage hydrocracking catalyst prepared by the modified Y molecular sieve prepared by the method of the present invention is used in the single-stage hydrocracking process and has good reactivity and nitrogen resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Surface aluminum-rich nay molecular sieve and preparation method thereof

ActiveCN110540214BFast consumptionRapid concentrationFaujasite aluminosilicate zeoliteMolecular sievePhysical chemistry

The present disclosure relates to a surface aluminum-rich NaY molecular sieve and a preparation method thereof. The surface SiO of the molecular sieve 2 / Al 2 o 3 The molar ratio is 2.5 to 5, bulk SiO 2 / Al 2 o 3 The molar ratio of the molecular sieve is 6-10, and the Al distribution parameter D of the molecular sieve satisfies: 1.2≤D≤4, wherein, D=Al(S) / Al(C), and Al(S) represents the molecular sieve surface measured by XPS method and the aluminum content in the region of 2-6nm below the surface, Al(C) means the overall aluminum content of the molecular sieve determined by XRF method. The NaY molecular sieve has a larger aluminum distribution gradient than conventional molecular sieves from the particle surface to the center.

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified Y molecular sieve and preparation method thereof

ActiveCN105618115BReduce the ratio of silicon to aluminumMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSilicon

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of modified y-beta composite molecular sieve and its preparation method and application

ActiveCN107344115BLarge mesostructure distributionReduce the ratio of silicon to aluminumMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveOrganic base

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com