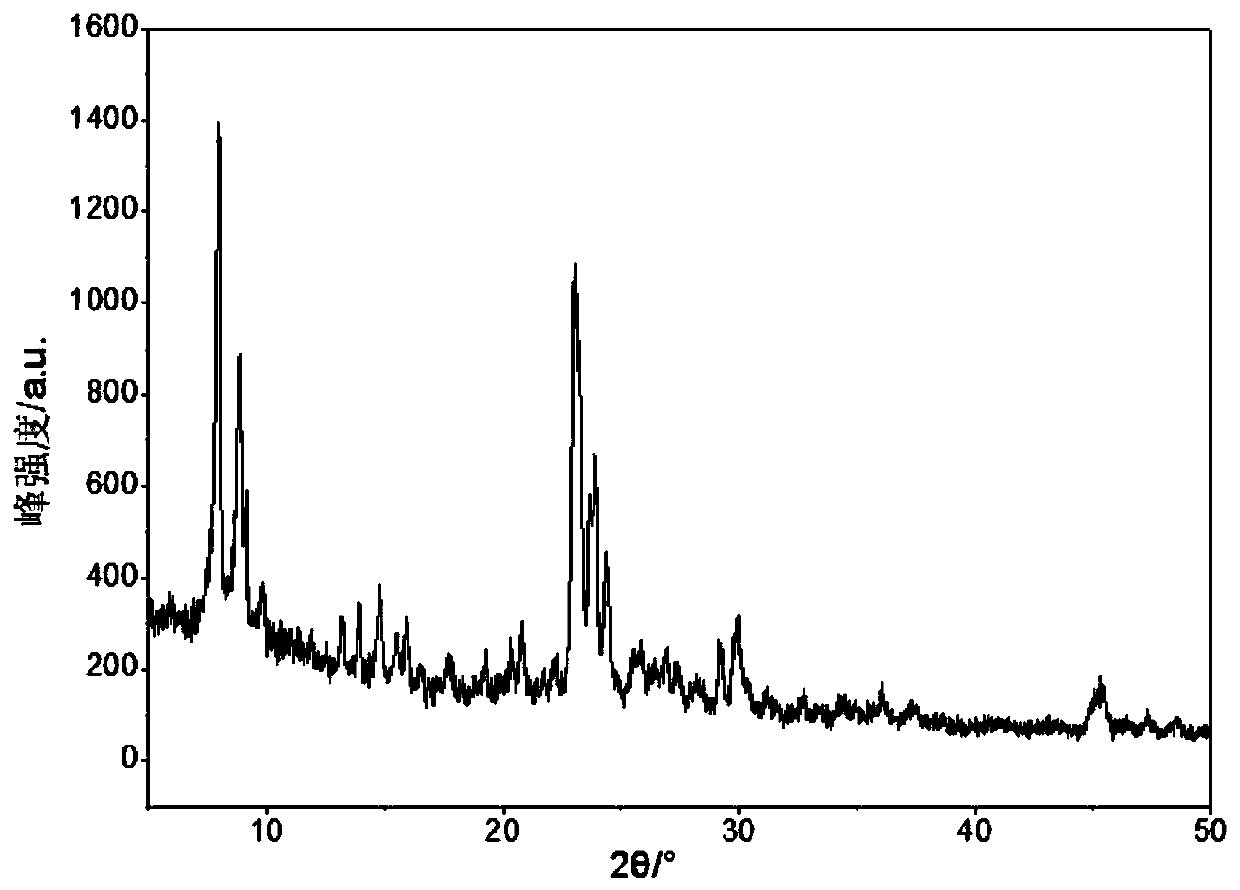

A kind of low-silicon multi-level structure ZSM-5 zeolite molecular sieve and its preparation method and application

A technology of ZSM-5 and zeolite molecular sieve, which is applied in borocarbane silicone crystalline aluminum silicate zeolite, molecular sieve catalyst, crystalline aluminosilicate zeolite, etc., can solve the problem of increasing the crystallization speed of molecular sieve and molecular sieve without multi-level structure and other problems, to achieve excellent mass transfer and diffusion properties, excellent diffusivity and reactivity, and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

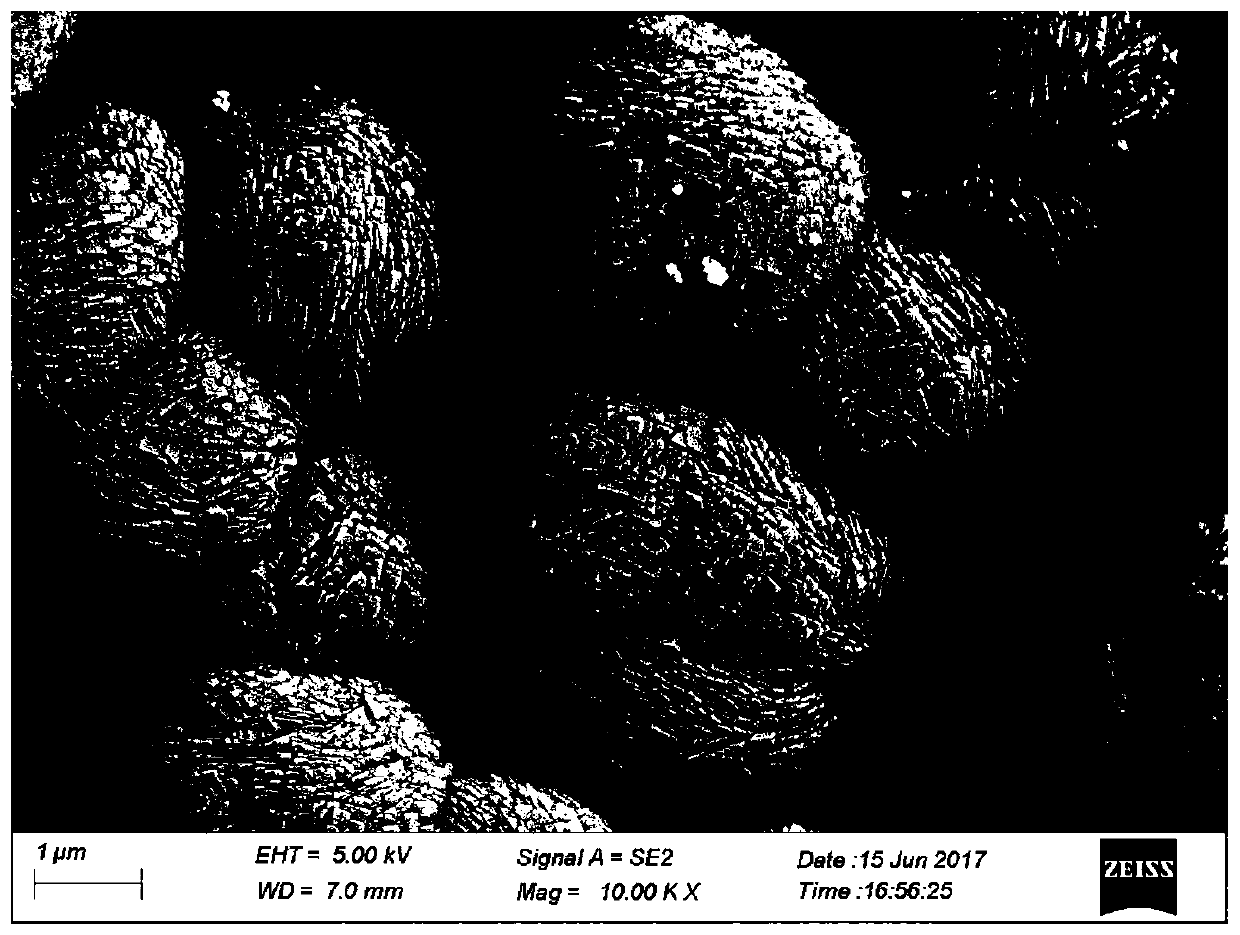

[0042] Example 1: Preparation of low-silicon multi-level structure ZSM-5 zeolite molecular sieve

[0043] (1) Raw material configuration: Take 4g tetrapropylammonium bromide (0.0150mol, equivalent to 0.120 times of coarse-pore silica gel) and 1.0g sodium hydroxide (0.025mol, equivalent to 0.2 times of coarse-pore silica gel) and add them to 18.75 g water (1.042mol, equivalent to 8.33 times that of coarse-porous silica gel), stir for 5-10min to dissolve and add 2.04g aluminum isopropoxide (0.005mol Al 2 o 3 , which is equivalent to 0.04 times that of coarse-pore silica gel), continue to stir for 10-50min until the solution is clear (pH value is about 13.2), and the solution is divided into two parts according to the mass fraction of 80% and 20%, wherein after 80% of the solution Slowly add 7.5 g (0.125 mol) of coarse-porous silica gel and stir at a constant speed for 3 h, then age at 40° C. for 6 h.

[0044] Introduction of seed crystals: the seed crystals are ZSM-5 zeolite w...

Embodiment 2

[0048] Example 2: Preparation of low-silicon multi-level structure ZSM-5 zeolite molecular sieve (without introducing crystal seeds)

[0049] (1) Raw material configuration: Take 3g of tetrapropylammonium bromide (0.0113mol, equivalent to 0.09 times of coarse-pore silica gel) and 0.9g of sodium hydroxide (0.0225mol, equivalent to 0.18 times of coarse-pore silica gel) and add them to 18.75 g water (1.042mol, equivalent to 8.33 times of coarse-porous silica gel), stir for 5-10min to dissolve, then add 0.1195g pseudo-boehmite (0.0015625mol Al 2 o 3 , equivalent to 0.0125 times that of coarse-pore silica gel), continue to stir for 10-50min until the solution is clear (pH value is about 13.2), the solution is divided into two parts according to the mass fraction of 80% and 20%, wherein after 80% of the solution Slowly add 7.5g (0.125mol) of coarse-porous silica gel and stir at a constant speed for 3h, then age at 90°C for 1h; then add another 20% solution, stir for 1h, and age at ...

Embodiment 3

[0053] Example 3: Preparation of low-silicon multi-level structure ZSM-5 zeolite molecular sieve

[0054] (1) Raw material configuration: Take 0.765g pseudoboehmite (0.005mol, equivalent to 0.04 times of coarse-pore silica gel) and add it to 40g tetrapropylammonium hydroxide (mass fraction 25%) (tetrapropylammonium hydroxide 0.0491 mol, equivalent to 0.39 times of coarse-pore silica gel; water 1.667mol, equivalent to 13.336 times of coarse-pore silica gel) stirred until the solution was clear, and the solution was divided into two parts according to the mass fraction of 80% and 20%, wherein 80% of the solution Then slowly add 7.5 g (0.125 mol) of coarse-porous silica gel and stir at a constant speed for 3 h, then age at 40° C. for 6 h.

[0055] Introduction of seed crystals: the seed crystals are ZSM-5 zeolite with a silicon-aluminum ratio of 25, the amount of which is 0.01 g, which is dissolved in the 20% aluminum source solution formed in step (1), and the pH value is adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com