Preparation method for rapidly synthesizing Cu-SSZ-13 molecular sieve with low silica-alumina ratio and application of Cu-SSZ-13 molecular sieve

A technology of cu-ssz-13 and low silicon-aluminum ratio, which is applied in the field of rapid synthesis of low-silicon-aluminum ratio Cu-SSZ-13 molecular sieves, can solve the constraints of industrial scale-up application, high temperature requirements, and failure to meet engine NOx emission standards Treatment and other problems, to achieve the effect of excellent anti-hydrothermal aging stability, high metal ion exchange capacity, and excellent SCR catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

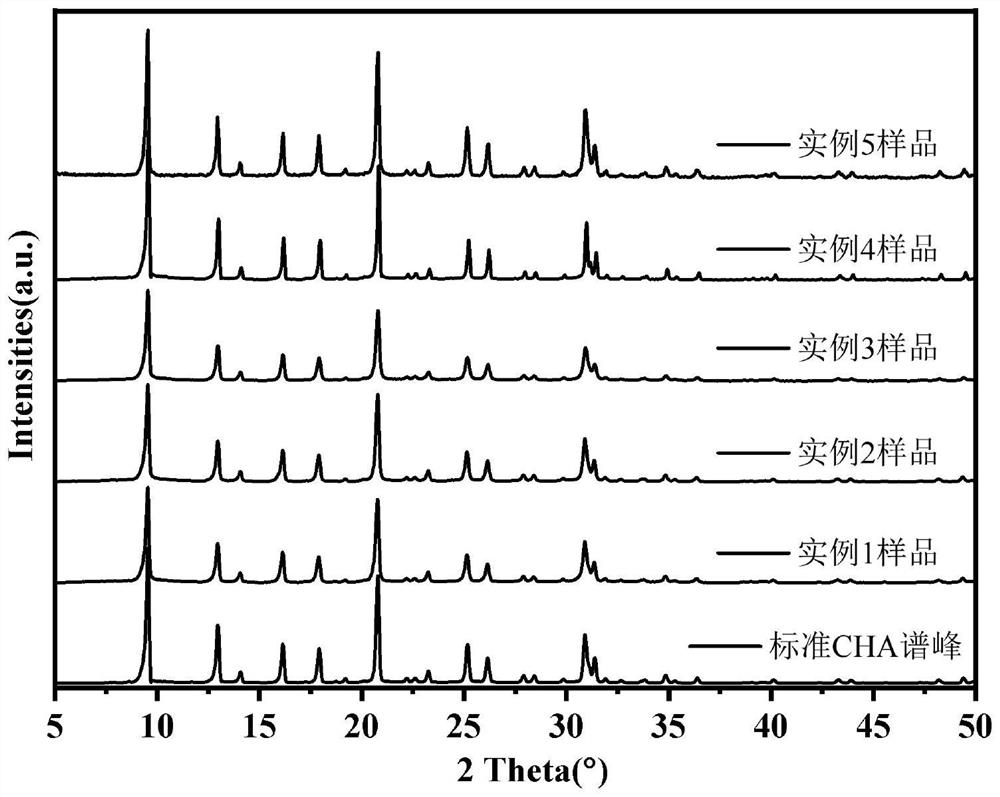

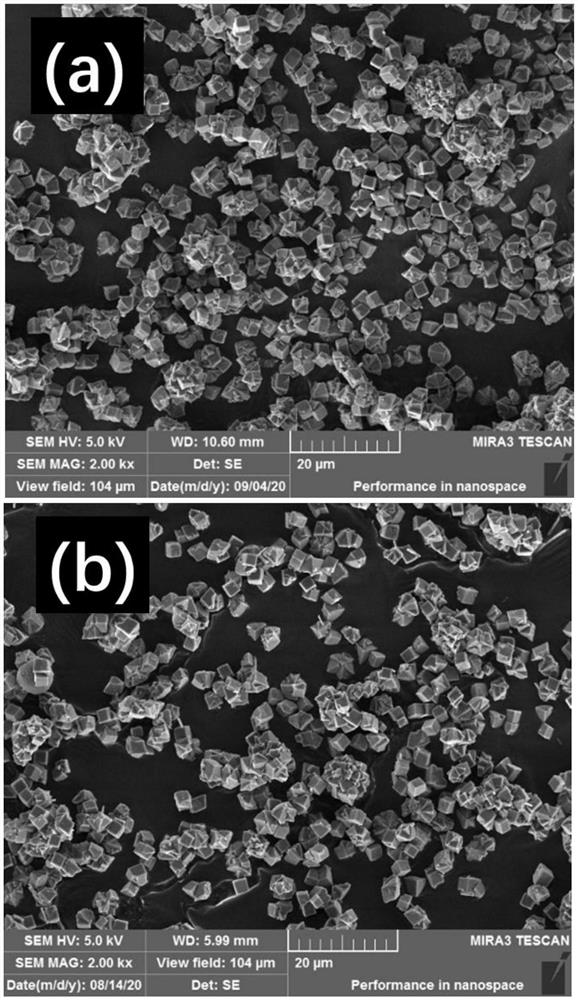

Embodiment 1

[0043] First, add 1.3g of solid NaOH (mass fraction 99.5%) into 30.0g of water, stir at room temperature for 0.5 hours, until the solution is clear, then add 21.0g of TMAdaOH solution (mass fraction 30%), continue stirring for 0.5h, and then add 20.0g of silicon Sodium acid aqueous solution (modulus 3.5), after stirring at room temperature for 1 hour, add 5.5 g of NaY molecular sieve (silicon-aluminum ratio: 5.1), and continue stirring at room temperature for 1 hour to obtain the initial gel. Transfer the initial gel to a 100mL stainless steel hydrothermal reaction kettle with a polytetrafluoroethylene liner, raise the temperature to 120°C at a speed of 5°C / min in a homogeneous reactor at a speed of 80rpm, and keep it warm for 0.5h. Then increase the temperature to 140°C at a rate of 1°C / min, keep the rotation speed constant, and crystallize for 8 hours. After the reaction, the temperature was lowered and the pressure was released. After the product was filtered and fully wash...

Embodiment 2

[0047] First, 1.82g of solid KOH (mass fraction 99.5%) was added to 30.0g of water, stirred at room temperature for 0.5 hours, and the solution was clarified, then 21.0g of TMAdaOH solution (mass fraction of 30%) was added, continued stirring for 0.5h, and then 20.0g of silicon Sodium acid aqueous solution (modulus 3.5), after stirring at room temperature for 0.5 h, add 5.5 g of NaY molecular sieve (silicon-aluminum ratio: 5.2), and continue stirring at room temperature for 0.5 h to obtain the synthetic initial gel. Transfer the initial gel to a 100mL stainless steel hydrothermal reaction kettle with a polytetrafluoroethylene liner, raise the temperature to 120°C at a speed of 5°C / min in a homogeneous reactor at a speed of 100rpm, and keep it warm for 0.5h. Then increase the temperature to 140°C at a rate of 1°C / min, keep the rotation speed constant, and crystallize for 12 hours. After the reaction, the temperature was lowered and the pressure was released. After the product w...

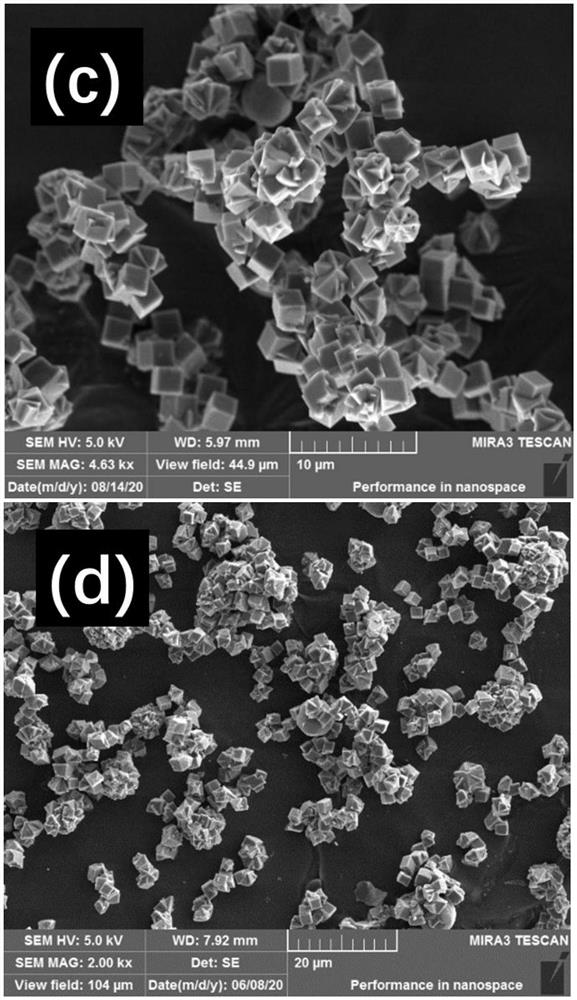

Embodiment 3

[0051] First, add 1.3g of solid NaOH (mass fraction 99.5%) into 30.0g of water, stir at room temperature for 0.5 hours, until the solution is clear, then add 21.0g of TMAdaOH solution (mass fraction 30%), continue stirring for 0.5h, and then add 20.0g of silicon Sol (SiO 2 Mass fraction 30%), after continuing stirring at room temperature for 0.5h, add 5.5g NH 4 Y molecular sieve (silicon-aluminum ratio: 2.5), continue to stir at room temperature for 0.5h to obtain the initial gel. Transfer the initial gel to a 100mL stainless steel hydrothermal reaction kettle with a polytetrafluoroethylene liner, raise the temperature to 120°C at a speed of 5°C / min in a homogeneous reactor at a speed of 100rpm, and keep it warm for 0.5h. Then increase the temperature to 140°C at a rate of 1°C / min, keep the rotation speed constant, and crystallize for 18h. After the reaction, the temperature was lowered and the pressure was released. After the product was filtered and fully washed, it was dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com