Modified Y type molecular sieve and preparation method thereof

A molecular sieve and modification technology, applied in the direction of octahedral crystalline aluminum silicate zeolite, crystalline aluminosilicate zeolite, etc., to achieve good catalytic activity and diffusion performance, strong anti-coking ability, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

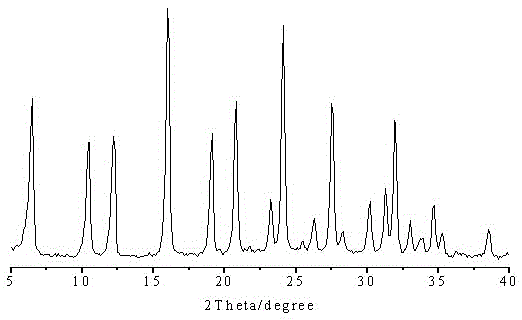

Image

Examples

Embodiment 1

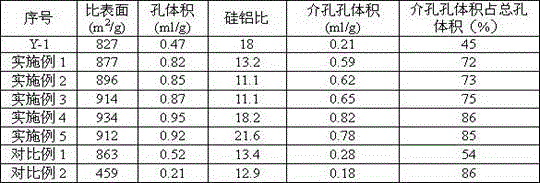

[0020] Under stirring conditions, mix Y-1 and tetrapropylammonium hydroxide solution in a high-pressure reactor, feed nitrogen to control the system pressure at 0.4MPa, then raise the temperature to 70°C, continue stirring at constant temperature for 2 hours, and release the pressure. Cool, filter with suction until the pH value is less than 9, dry at 120°C for 12 hours, and calcinate at 500°C for 3 hours to obtain a modified Y-type molecular sieve. The concentration of the tetrapropylammonium hydroxide solution is 0.12mol / L, and the mass ratio of Y-1 to water in the solution is 1:9. The specific properties of molecular sieves are shown in Table 1.

Embodiment 2

[0022] Under stirring conditions, Y-1 and tetrabutylammonium hydroxide solution were mixed in a high-pressure reactor, and air was introduced to control the system pressure at 0.6MPa, then the temperature was raised to 80°C, and constant temperature stirring was continued for 1 hour, pressure relief, cooling, Suction filtration until the pH value is less than 9, drying at 110°C for 18 hours, and calcining at 550°C for 4 hours to obtain a modified Y-type molecular sieve. The concentration of tetrabutylammonium hydroxide solution is 0.15mol / L, and the mass ratio of Y-1 to water in the solution is 1:11. The specific properties of molecular sieves are shown in Table 1.

Embodiment 3

[0024] Under stirring conditions, mix Y-1 and tetraethylammonium hydroxide solution in a high-pressure reactor, feed nitrogen to control the system pressure at 0.2MPa, then raise the temperature to 60°C, continue stirring at constant temperature for 3 hours, and release the pressure. Cool, filter with suction until the pH value is less than 9, dry at 100°C for 24 hours, and calcinate at 520°C for 6 hours to obtain a modified Y-type molecular sieve. The concentration of tetraethylammonium hydroxide solution is 0.14mol / L, and the mass ratio of Y-1 to water in the solution is 1:10. The specific properties of molecular sieves are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com