Modified Y-Beta composite molecular sieve as well as preparation method and application thereof

A composite molecular sieve and modification technology, which is applied in molecular sieve catalysts, chemical instruments and methods, and hydrocarbon oil treatment, can solve the problems of insufficient hydrogenation and ring opening, and achieve good catalytic activity and diffusion performance, strong anti-coking ability, The effect of reducing the silicon-aluminum ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

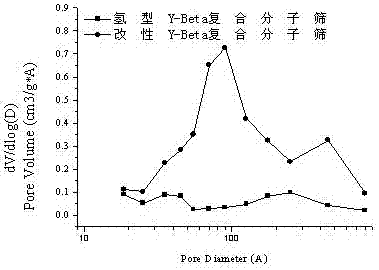

[0022] Under stirring conditions, mix the hydrogen-type Y-Beta composite molecular sieve and the tetrapropylammonium hydroxide solution in the high-pressure reactor, feed nitrogen to control the system pressure at 0.5MPa, then raise the temperature to 60°C, and continue stirring at constant temperature for 2 hours , pressure relief, cooling, suction filtration until the pH value is less than 9, drying at 120°C for 13 hours, and calcining at 520°C for 3 hours to obtain a modified Y-Beta composite molecular sieve. The concentration of the tetrapropylammonium hydroxide solution is 0.12mol / L, and the mass ratio of the hydrogen-type Y-Beta composite molecular sieve to the water in the solution is 1:9. The specific properties are shown in Table 1.

Embodiment 2

[0024] Under the condition of stirring, mix the hydrogen type Y-Beta composite molecular sieve and the tetrabutylammonium hydroxide solution in the autoclave, feed air to control the system pressure at 0.6MPa, then raise the temperature to 75°C, continue to stir at constant temperature for 1 hour, discharge Pressed, cooled, suction filtered until the pH value was less than 9, dried at 110°C for 18 hours, and calcined at 550°C for 4 hours to obtain a modified Y-Beta composite molecular sieve. The concentration of tetrabutylammonium hydroxide solution is 0.14mol / L, and the mass ratio of hydrogen Y-Beta composite molecular sieve to water in the solution is 1:12. The specific properties are shown in Table 1.

Embodiment 3

[0026] Under stirring conditions, mix the hydrogen-type Y-Beta composite molecular sieve and tetraethylammonium hydroxide solution in a high-pressure reactor, feed nitrogen to control the system pressure at 0.2MPa, then raise the temperature to 65°C, and continue stirring at constant temperature for 3 hours , pressure relief, cooling, suction filtration until the pH value is less than 9, drying at 100°C for 22 hours, and calcining at 520°C for 6 hours to obtain a modified Y-Beta composite molecular sieve. The concentration of the tetraethylammonium hydroxide solution is 0.14mol / L, and the mass ratio of the hydrogen-type Y-Beta composite molecular sieve to the water in the solution is 1:10. The specific properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com