A kind of modified y-beta composite molecular sieve and its preparation method and application

A composite molecular sieve and molecular sieve technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as insufficient hydrogenation ring opening, achieve good catalytic activity and diffusion performance, and strong anti-coking ability , The effect of reducing the ratio of silicon to aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

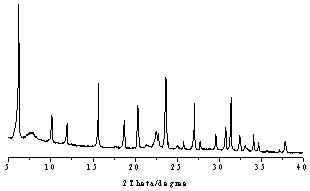

Image

Examples

Embodiment 1

[0022] Under stirring conditions, mix the hydrogen-type Y-Beta composite molecular sieve and the tetrapropylammonium hydroxide solution in the high-pressure reactor, feed nitrogen to control the system pressure at 0.5MPa, then raise the temperature to 60°C, and continue stirring at constant temperature for 2 hours , pressure relief, cooling, suction filtration until the pH value is less than 9, drying at 120°C for 13 hours, and calcining at 520°C for 3 hours to obtain a modified Y-Beta composite molecular sieve. The concentration of the tetrapropylammonium hydroxide solution is 0.12mol / L, and the mass ratio of the hydrogen-type Y-Beta composite molecular sieve to the water in the solution is 1:9. The specific properties are shown in Table 1.

Embodiment 2

[0024] Under the condition of stirring, mix the hydrogen type Y-Beta composite molecular sieve and the tetrabutylammonium hydroxide solution in the autoclave, feed air to control the system pressure at 0.6MPa, then raise the temperature to 75°C, continue to stir at constant temperature for 1 hour, discharge Pressed, cooled, suction filtered until the pH value was less than 9, dried at 110°C for 18 hours, and calcined at 550°C for 4 hours to obtain a modified Y-Beta composite molecular sieve. The concentration of tetrabutylammonium hydroxide solution is 0.14mol / L, and the mass ratio of hydrogen Y-Beta composite molecular sieve to water in the solution is 1:12. The specific properties are shown in Table 1.

Embodiment 3

[0026] Under stirring conditions, mix the hydrogen-type Y-Beta composite molecular sieve and tetraethylammonium hydroxide solution in a high-pressure reactor, feed nitrogen to control the system pressure at 0.2MPa, then raise the temperature to 65°C, and continue stirring at constant temperature for 3 hours , pressure relief, cooling, suction filtration until the pH value is less than 9, drying at 100°C for 22 hours, and calcining at 520°C for 6 hours to obtain a modified Y-Beta composite molecular sieve. The concentration of the tetraethylammonium hydroxide solution is 0.14mol / L, and the mass ratio of the hydrogen-type Y-Beta composite molecular sieve to the water in the solution is 1:10. The specific properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com