NU-87 molecular sieve and preparation method thereof

A technology of NU-87 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems that affect the catalytic activity of molecular sieves, such as adjustable denaturation of molecular sieves, reduced acidity of molecular sieves, and large dosage of template agents, so as to achieve good catalytic performance and reduce dosage , the effect of reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

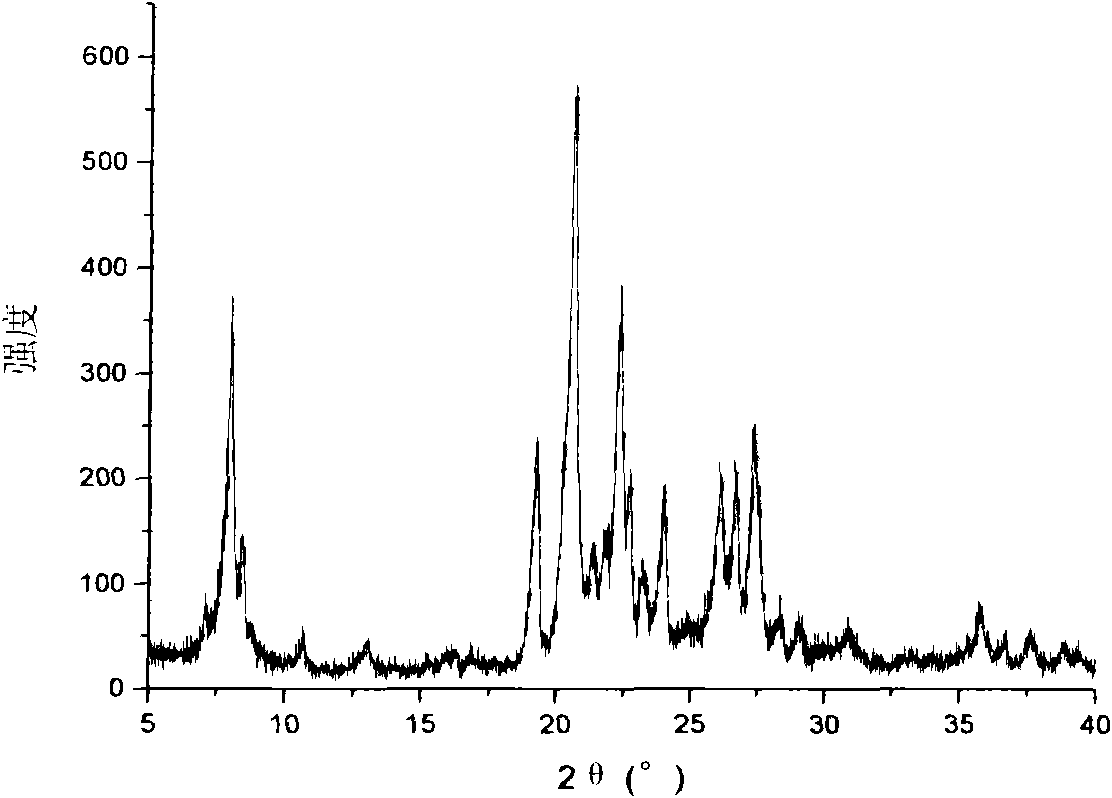

[0024] Prepare solution 1: add 9.84g sodium hydroxide, 5.23g sodium aluminate (Al 2 o 3 The weight content is 45%), 7.5g decane diammonium bromide, 5.36g sodium chloride and 156ml distilled water, stir evenly, then add 3.6g roasted EU-1 molecular sieve (silicon-aluminum molar ratio is 27). Preparation solution 2: 59.80g silica sol (SiO 2 weight content is 30%) was added into 60ml distilled water, and stirred evenly. Slowly add solution 2 into solution 1, stir evenly, and then put it into a synthesis kettle for dynamic hydrothermal crystallization.

[0025] The crystallization conditions were as follows: the temperature was raised from room temperature to 100° C., and then kept at 100° C. for 1.2 days, and the stirring speed of the synthesis tank was 350 rpm. Then the temperature was raised to 180° C., and the temperature was kept at 180° C. for 5 days, and the stirring speed of the synthesis tank was 250 rpm. Then the temperature was naturally cooled down to room temperatu...

Embodiment 2

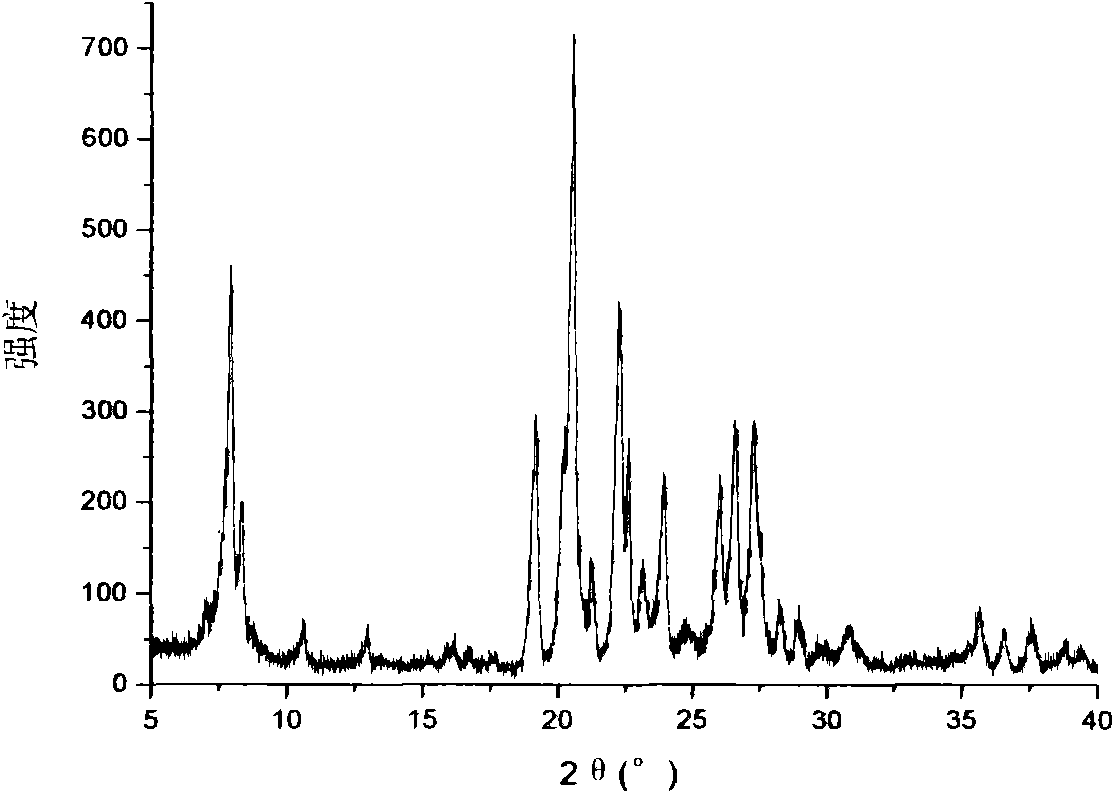

[0028] Prepare solution 1: Add 10.5g sodium hydroxide and 4.2g sodium aluminate (Al 2 o 3 The weight content is 45%), 7.5g decane bisammonium bromide, 5.36g sodium chloride and 156ml distilled water, stir evenly, then add 4.5g roasted EU-1 seed crystals (the molar ratio of silicon to aluminum is 27). Preparation solution 2: 59.80g silica sol (SiO 2 weight content is 30%) was added into 40ml distilled water, and stirred evenly. Slowly add solution 2 into solution 1, stir evenly, and then put it into a synthesis kettle for dynamic hydrothermal crystallization.

[0029] The crystallization conditions were as follows: the temperature was raised from room temperature to 80° C., and then kept at 80° C. for 1.5 days, and the stirring speed of the synthesis tank was 450 rpm. Then the temperature was raised to 185° C., and the temperature was maintained at 185° C. for 4.5 days. The stirring speed of the synthesis tank was 350 rpm. Then the temperature was naturally cooled down to r...

Embodiment 3

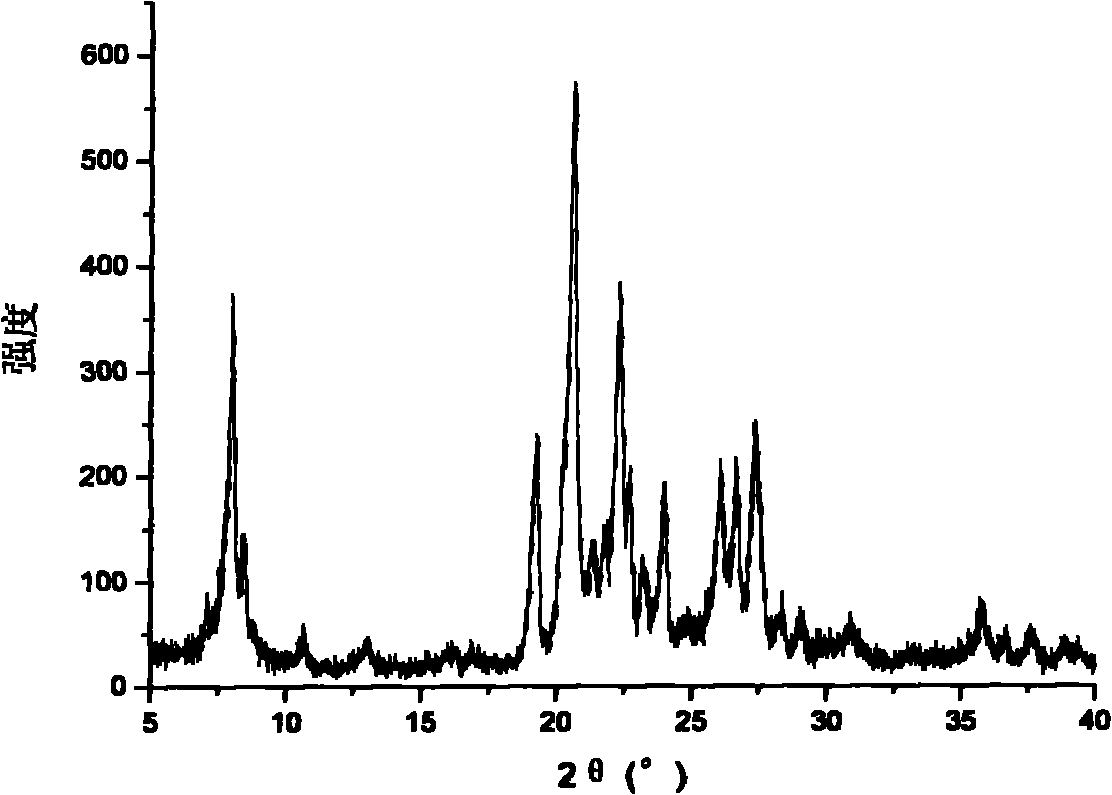

[0032] Prepare solution 1: add 9.84g sodium hydroxide, 3.4g sodium aluminate (Al 2 o 3The weight content is 45%), 13g of decane bis ammonium bromide, 4.47g of sodium chloride and 156ml of distilled water, and stir evenly, then add 5.38g of roasted EU-1 seed crystals (the molar ratio of silicon to aluminum is 27). Preparation solution 2: 59.80g silica sol (SiO 2 weight content is 30%) was added into 60ml distilled water, and stirred evenly. Slowly add solution 2 into solution 1, stir evenly, and then put it into a synthesis kettle for dynamic hydrothermal crystallization.

[0033] The crystallization conditions were as follows: the temperature was raised from room temperature to 100° C., and then kept at 100° C. for 1.2 days, and the stirring speed of the synthesis tank was 350 rpm. Then the temperature was raised to 170° C., and the temperature was maintained at 170° C. for 5 days, and the stirring speed of the synthesis tank was 250 rpm. Then the temperature was naturally...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com