Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

277results about "Mordenite aluminosilicate zeolite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Alkylaromatics production

The present invention provides a process for producing a monoalkylated aromatic compound, particularly ethylbenzene or cumene, in which a polyalkylated aromatic compound is contacted with an alkylatable aromatic compound in the liquid phase and in the presence of a transalkylation catalyst comprising TEA-mordenite having an average crystal size of less than 0.5 micron.

Owner:EXXONMOBIL CORP (US)

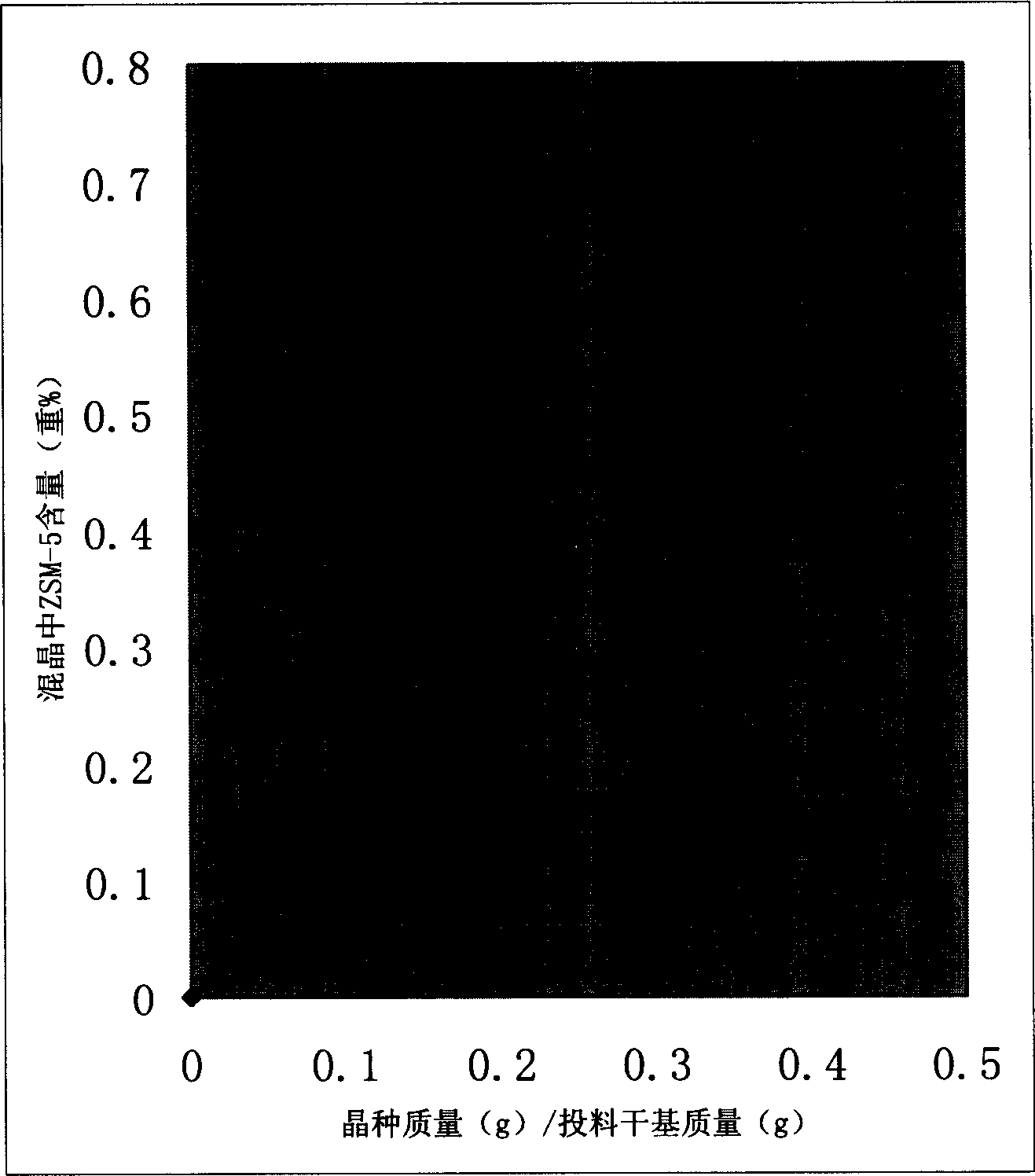

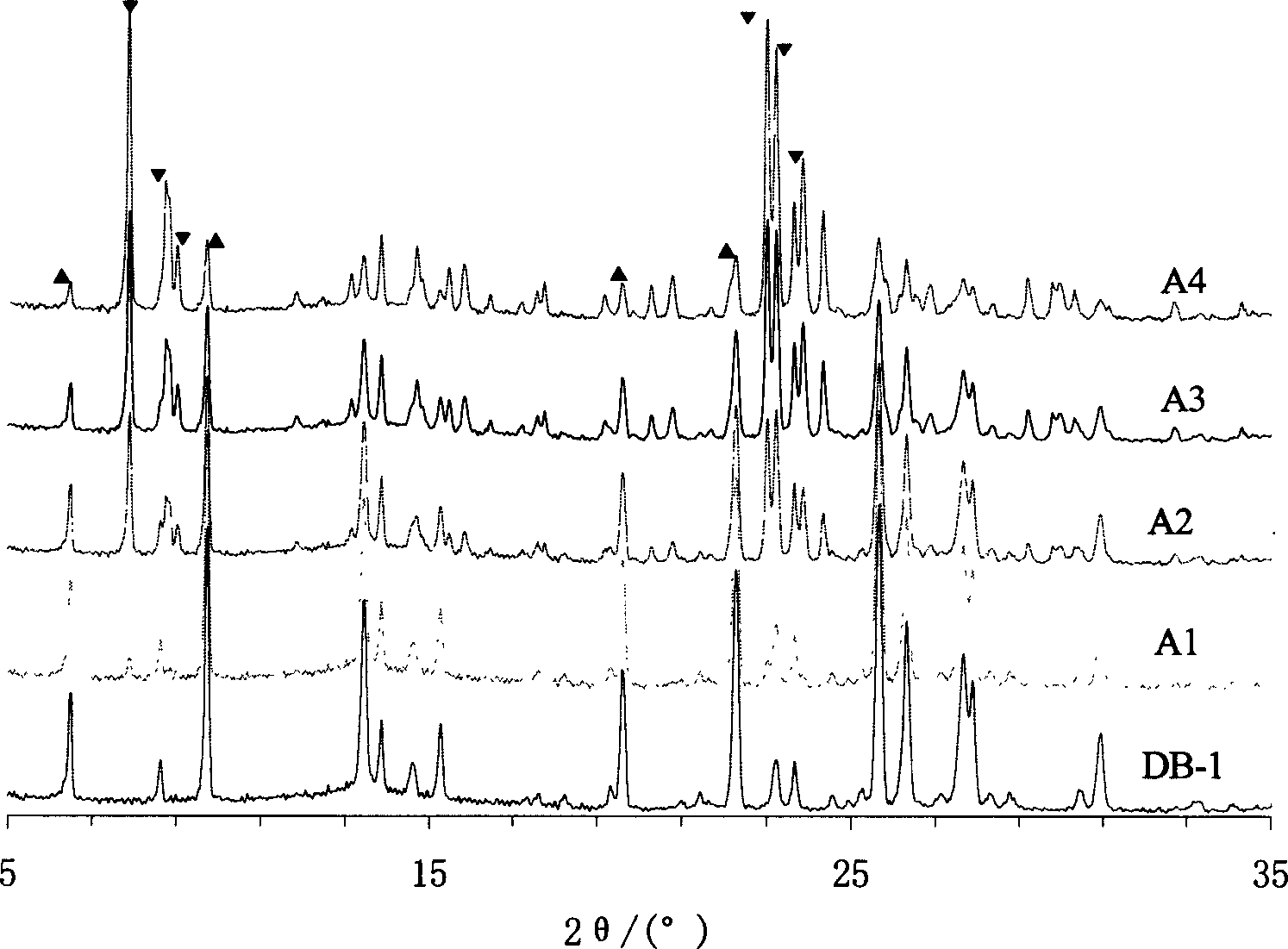

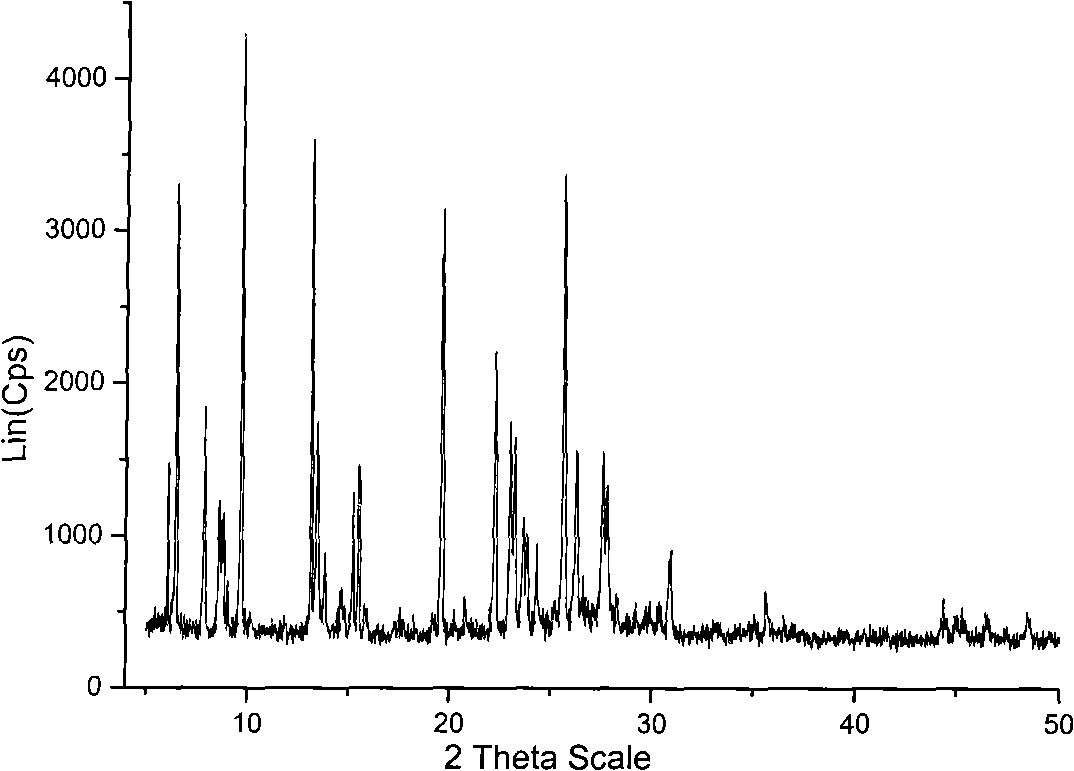

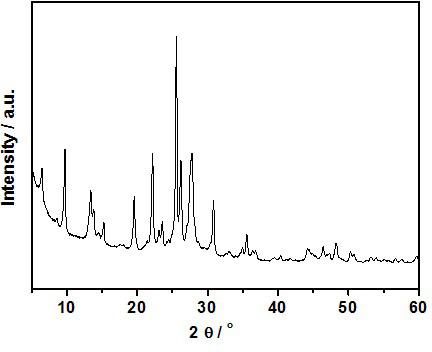

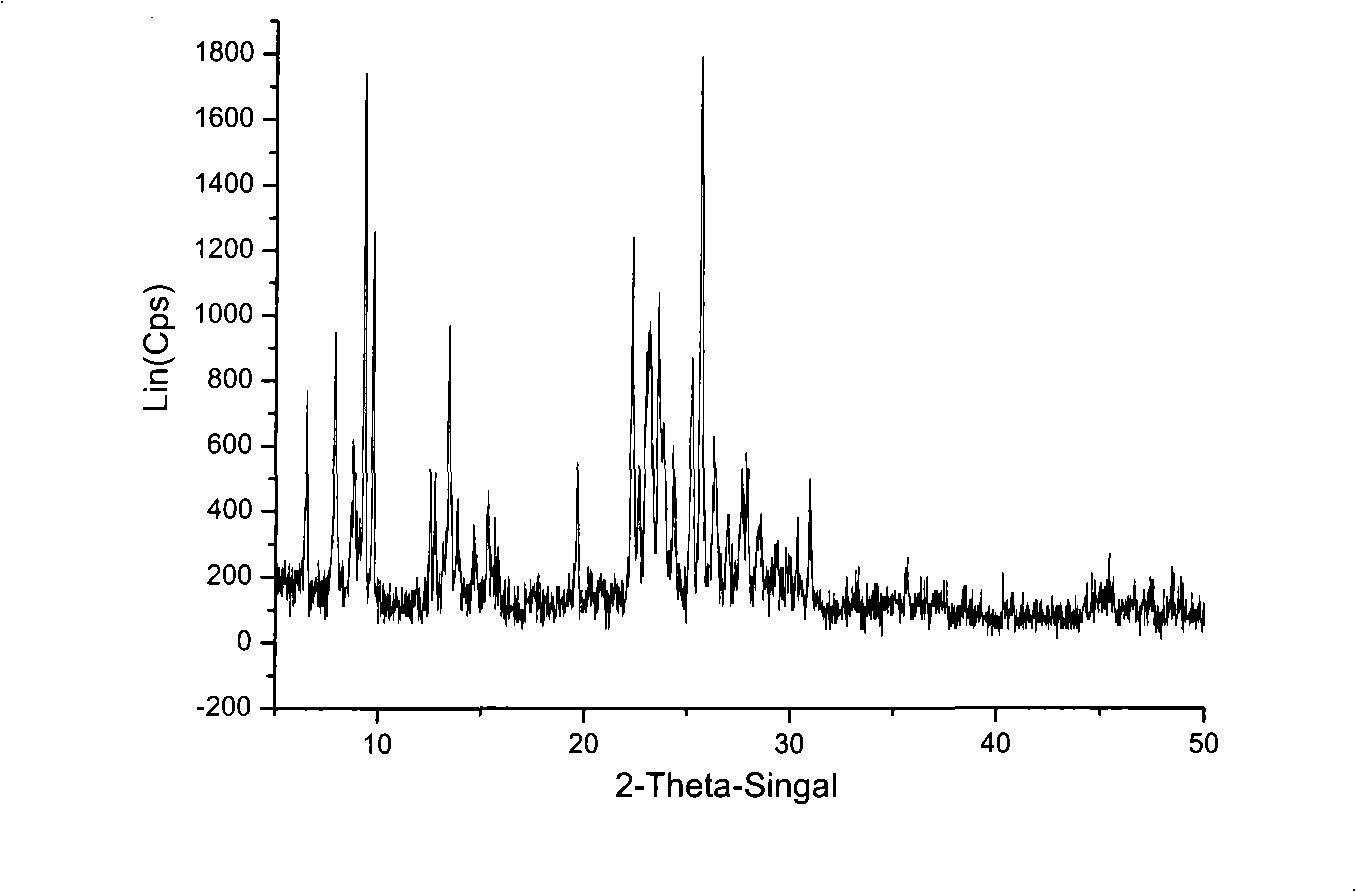

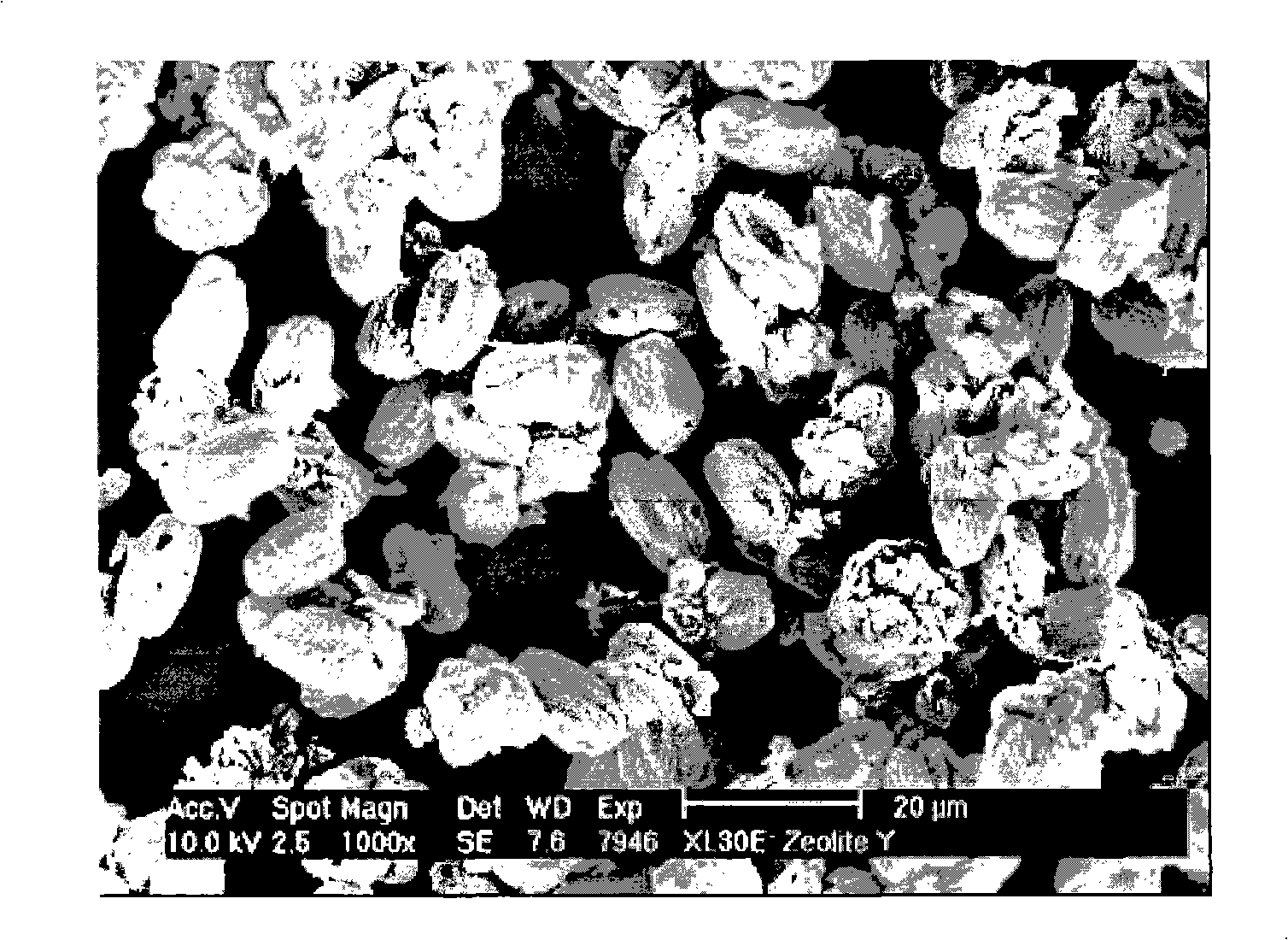

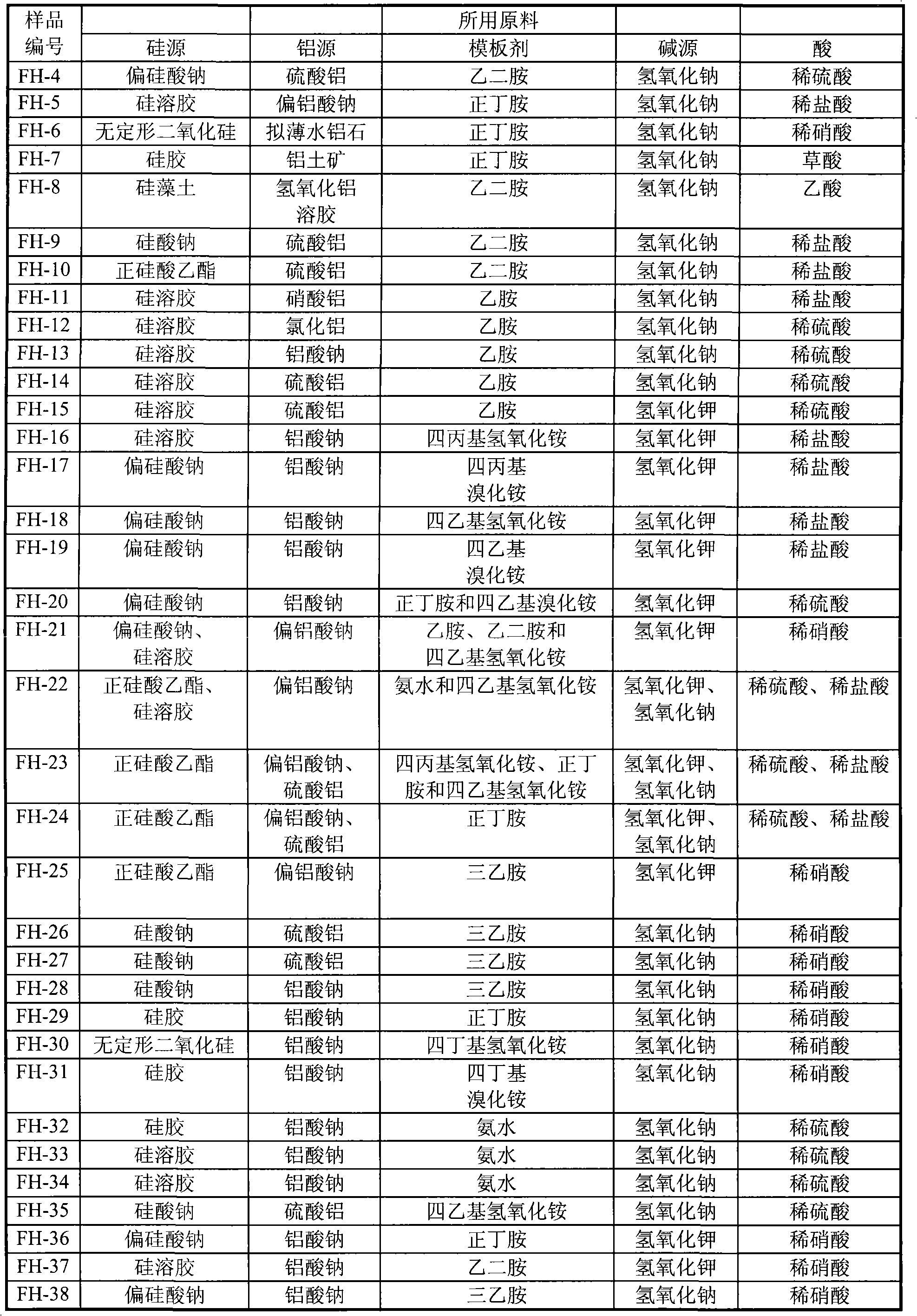

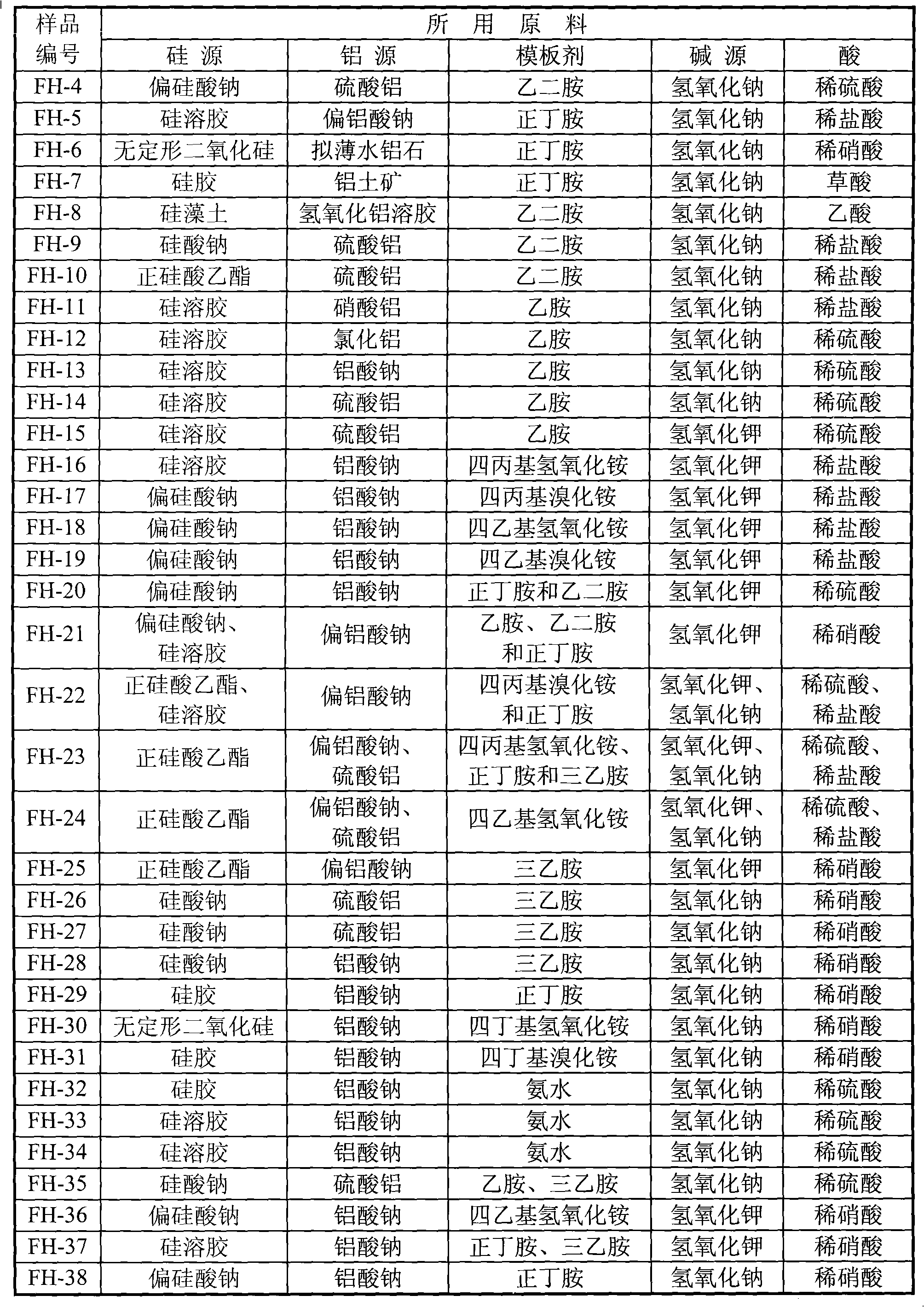

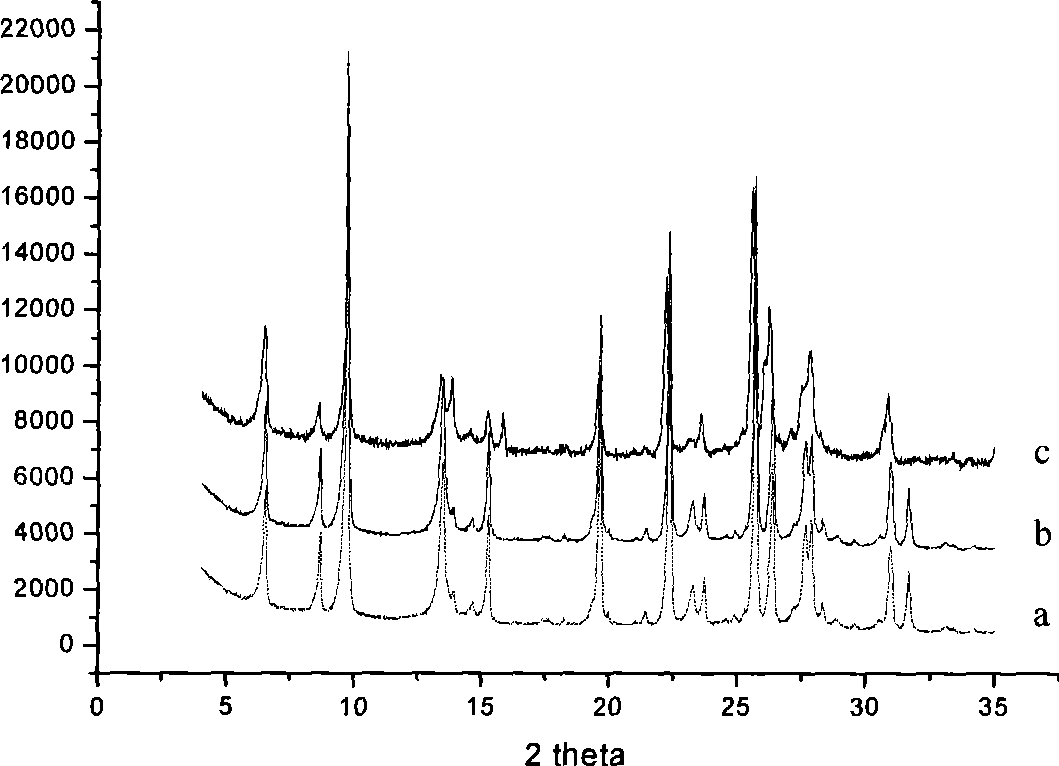

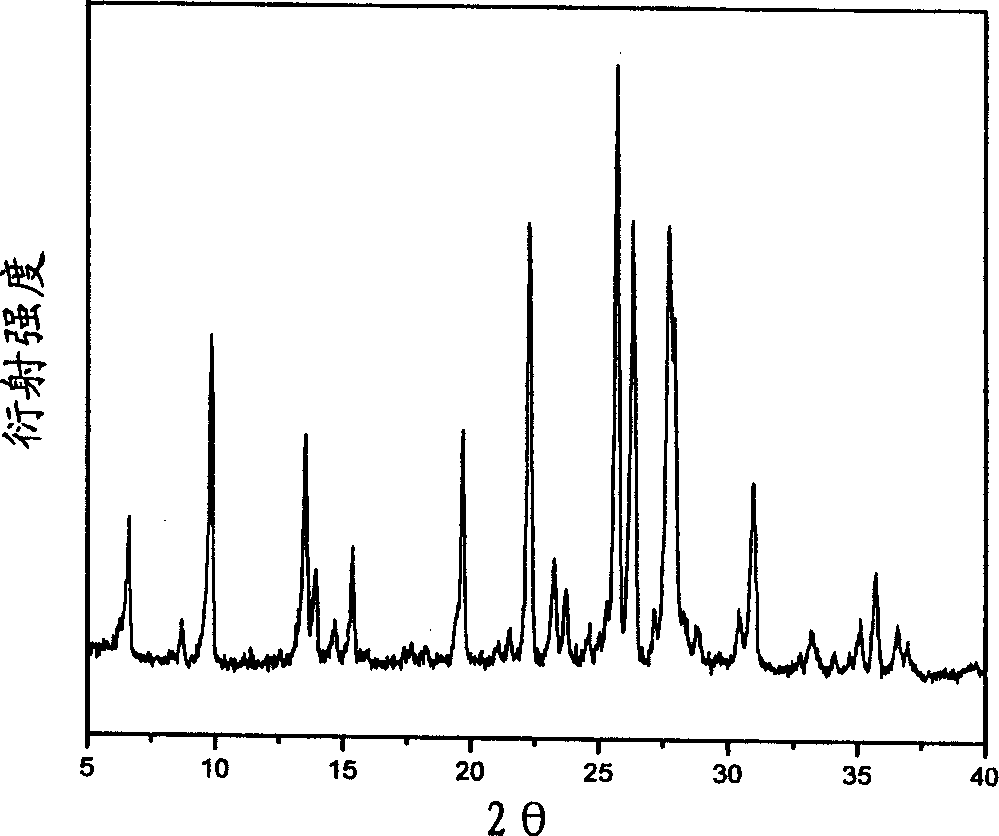

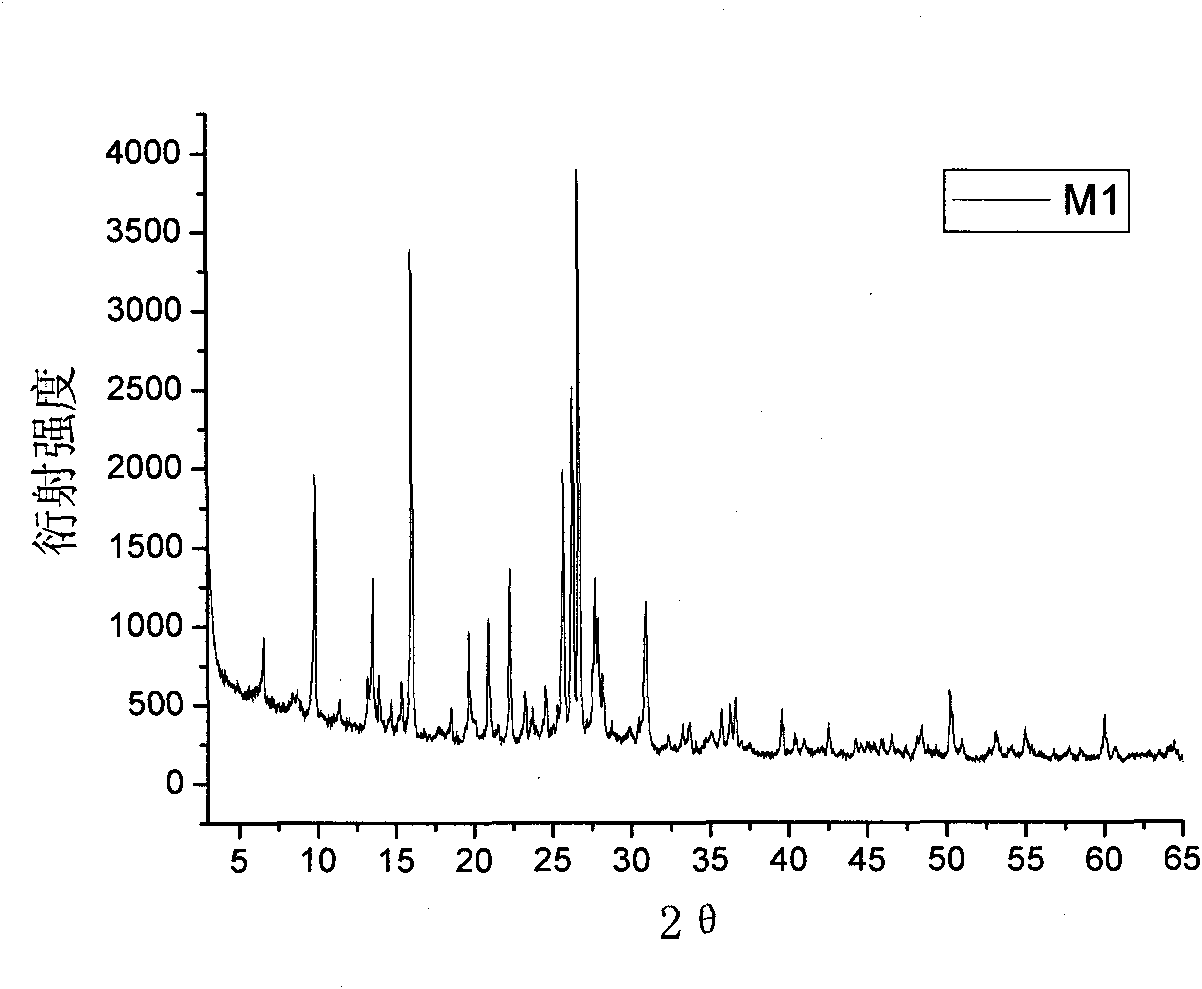

Synthetic method for ZSM-5/mordenite mixed crystal material

InactiveCN1565970ALower synthesis costEasy to adjustMolecular sieve catalystsMordenite aluminosilicate zeoliteMordeniteThermal crystallization

The invention discloses a synthetic method for ZSM-5 / mordenite mixed crystal material, wherein ZSM-5 molecular sieve is charged into the synthesized reaction mixture of mordenite as seed crystal, and said material is prepared through water thermal crystallization. The invention realizes low making cost and more ideal catalyzing performance.

Owner:CHINA PETROLEUM & CHEM CORP +2

Microwave method for synthesizing nanometer silicate basic hole material

InactiveCN1730391AFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteMolecular sieveMicrowave method

The invention relates to a microwave synthesizing process for nano-size silicate based poromeric material, which consists of dissolving aluminium source into water, charging silicon source while agitating, continuously agitating, carrying out microwave processing directly for 3-180 minutes to the reaction solution, microwave heating 3-30 minutes, crystallizing 1-8 days at 60-100 deg C, centrifugally separating, filtering, scouring, dry scouring to neutral, thus obtaining nano-size molecular sieve with adjustable particle size.

Owner:朱广山

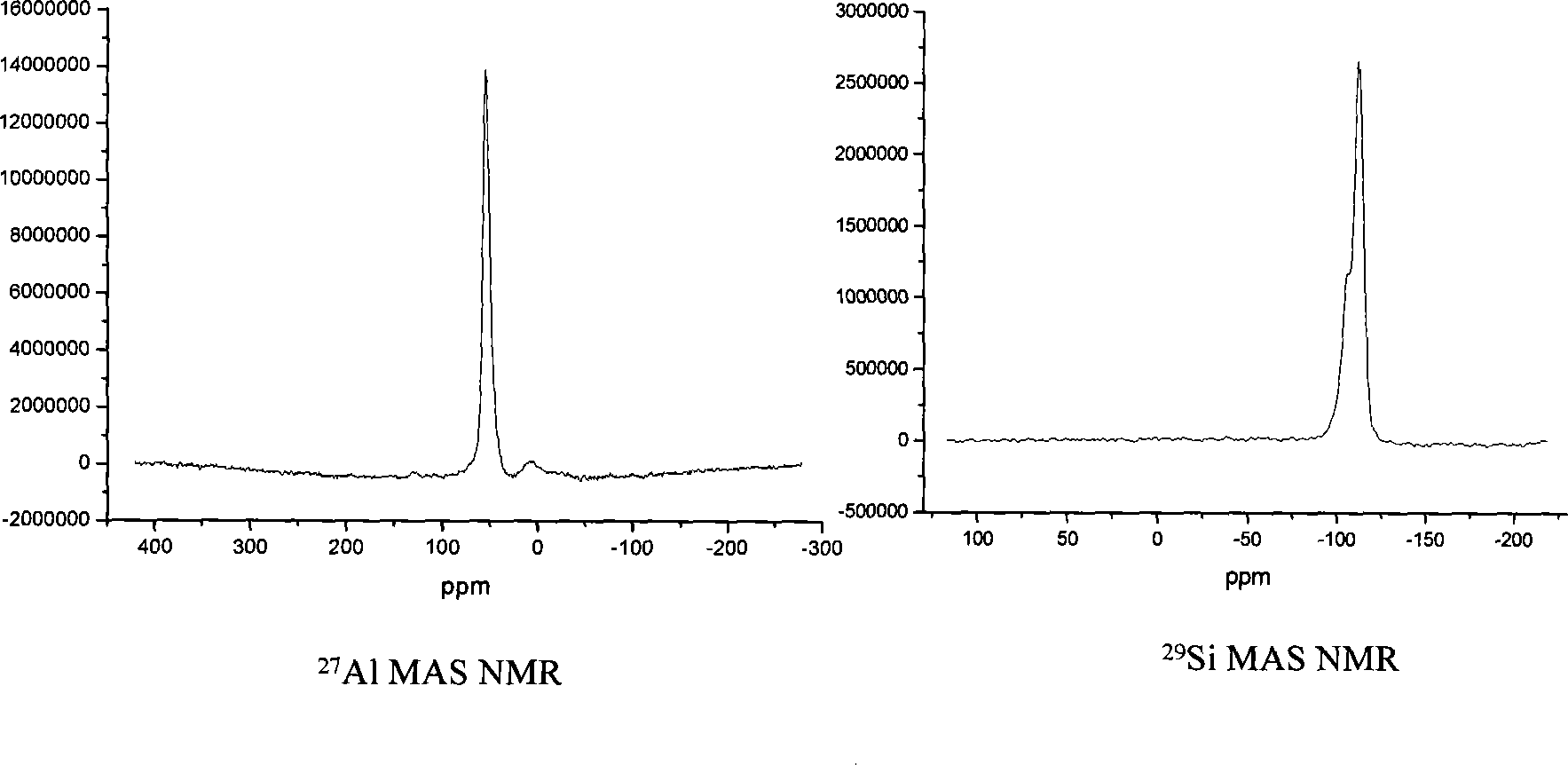

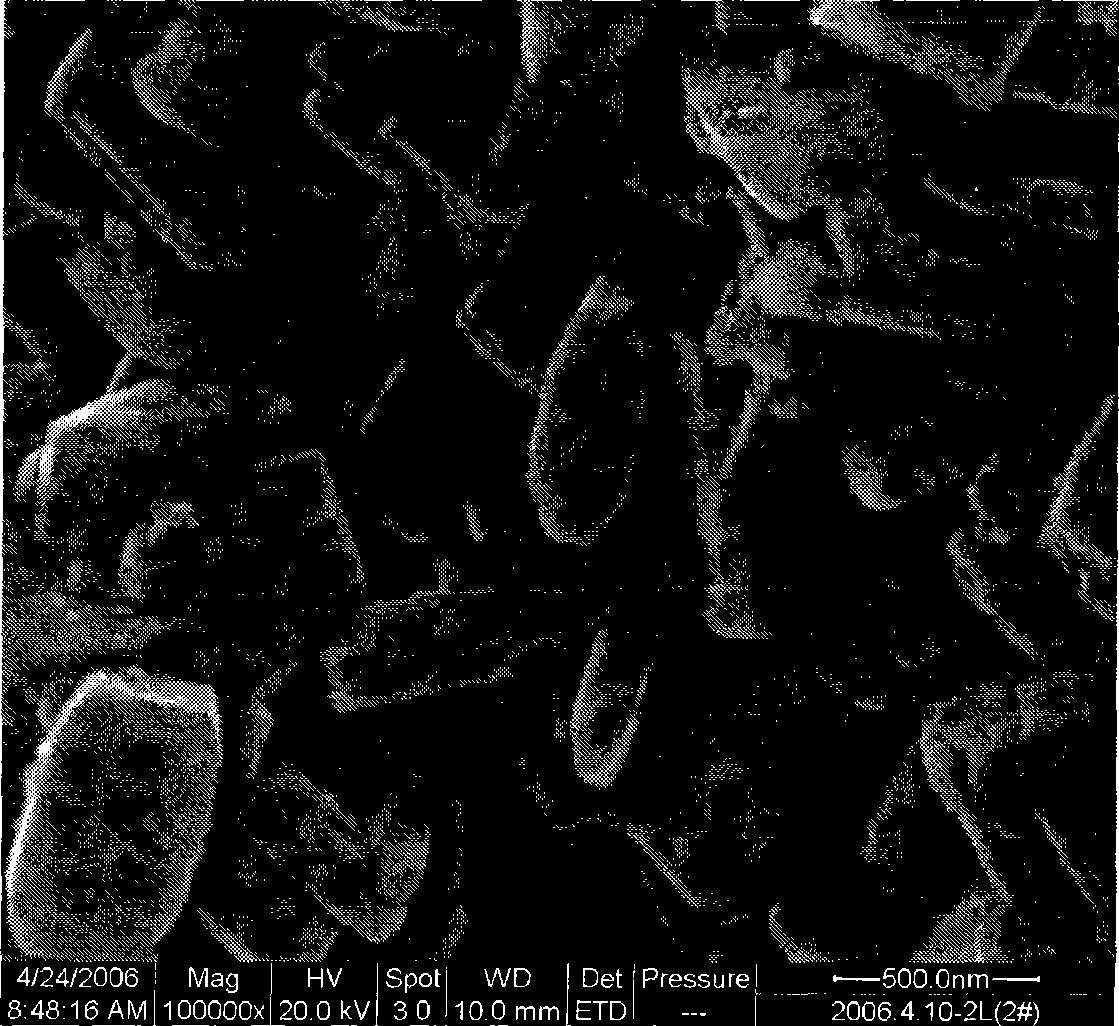

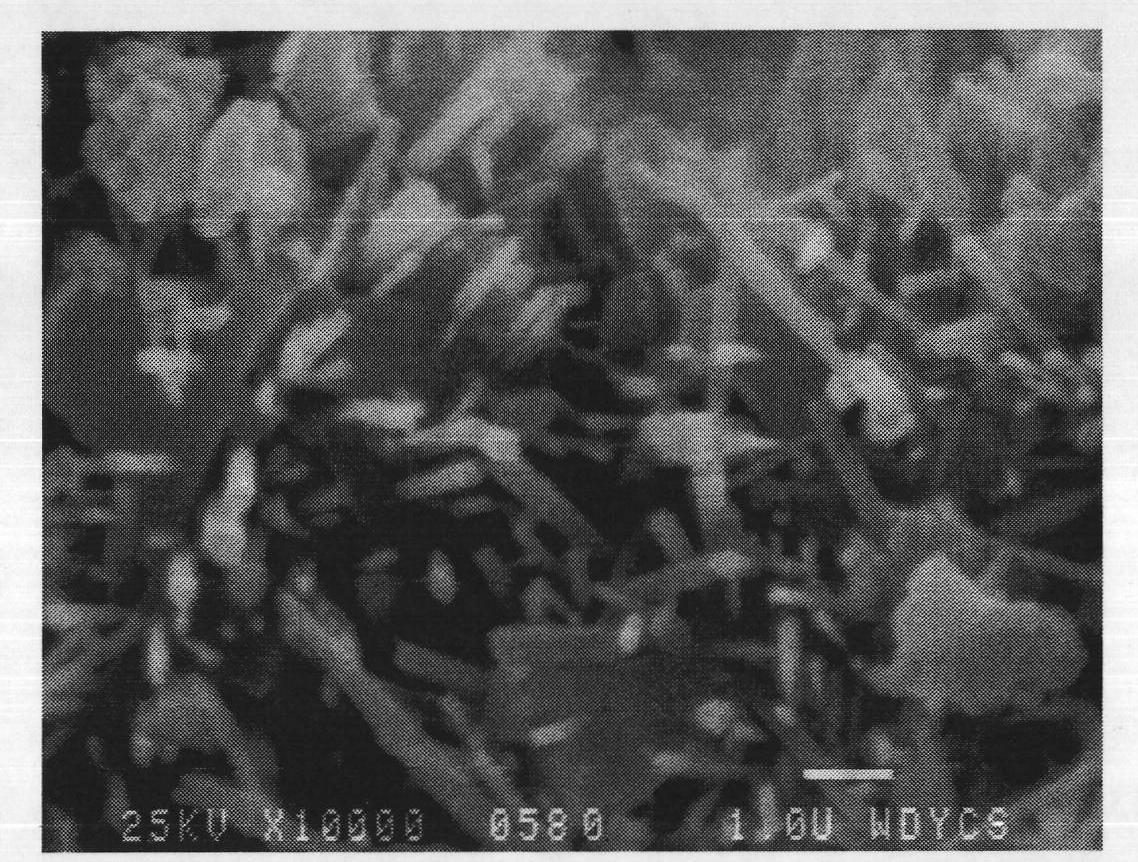

Method for synthesizing nanometer size mordenite

InactiveCN1666956AHigh crystallinityLow costPhysical/chemical process catalystsMordenite aluminosilicate zeoliteIonNanometer size

This invention discloses a synthetic method of nanometer level mordenite. The procedures are that silica resource and aluminum resource are added into water solution of tetraethyl or four-propyl organic amine-group compound, addictives are organic weak acid and NaCl. Ageing 1-10 hours in greenhouse, then crystallize at 140-2000C for 15-30 hours, the pH value of reaction system is 8-13, then the nanometer level mordenite can be collected from the reactive product. The feature of this invention is that few organic ammonium ion is used as template agent, the silica resource is inexpensive silica flour, the aluminum source is sold sodium aluminate. The synthetic nanometer level mordenite has high crystallinity and low cost, it is convenient for industrial generation.

Owner:EAST CHINA UNIV OF SCI & TECH +1

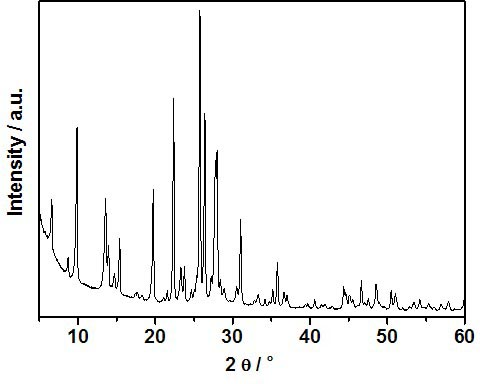

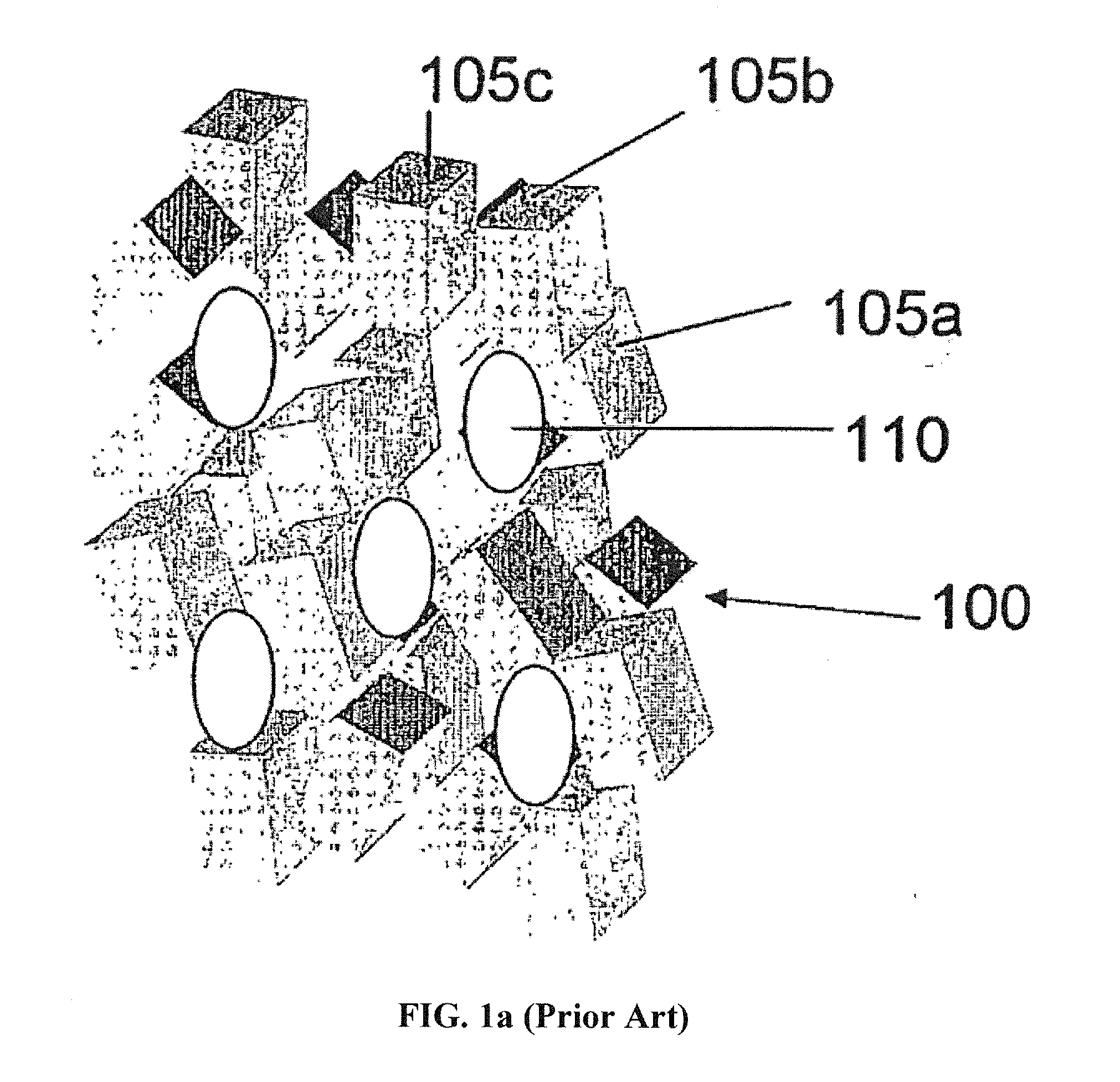

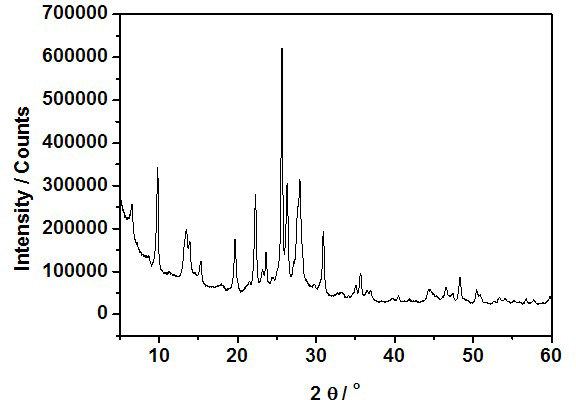

Mordenite/beta zeolite/Y zeolite coexisting material and method for synthesizing same

ActiveCN101514009AStrong acidImprove catalytic performanceFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteCatalytic pyrolysisNaphtha

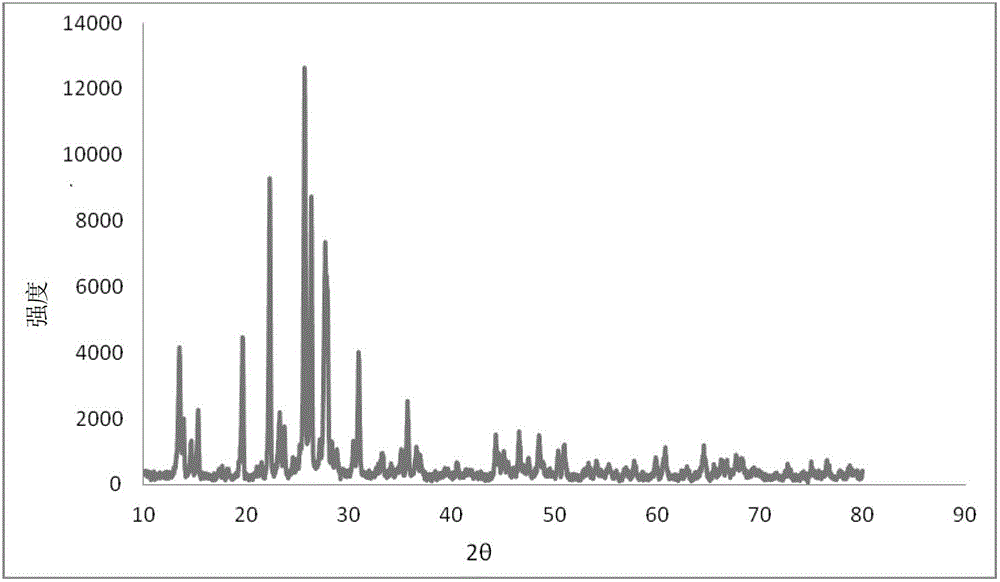

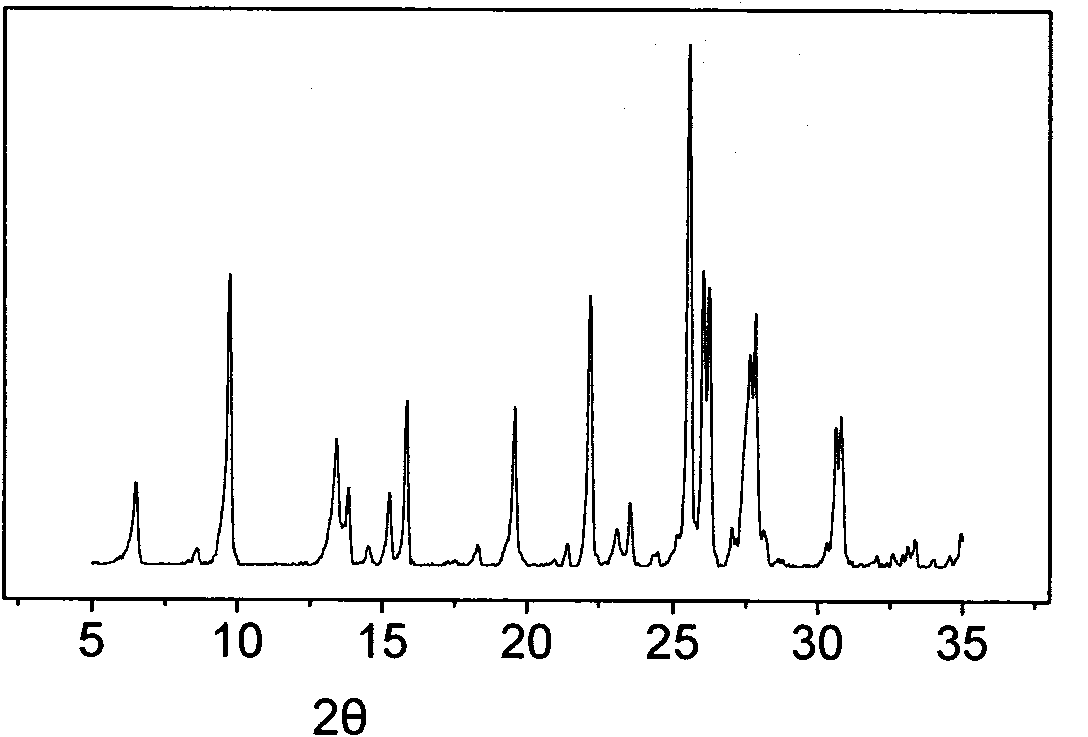

The invention relates to a mordenite / beta zeolite / Y zeolite coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the mordenite / beta zeolite / Y zeolite coexisting material by adding a seed crystal containing a Y zeolite precursor during a synthesis process of mordenite / beta zeolite / Y zeolite coexisting material. A mole relation of the components of the synthesized mordenite / beta zeolite / Y zeolite coexisting material is nSiO2 :Al2O3, wherein n is between 4 and 400; the XRD diffraction pattern of the mordenite / beta zeolite / Y zeolite coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.1 and 14.52+0.1 A, 13.52-0.1 and 13.52+0.1 A,11.32-0.1 and 11.32+0.1 A, 8.96-0.1 and 8.96+0.1 A, 6.71-0.1 and 6.71+0.1 A, 5.71-0.1 and 5.71+0.1 A, 4.51-0.05 and 4.51+0.05 A, 4.15-0.05 and 4.15+0.05 A, 3.97-0.05 and 3.97+0.05 A, 3.78-0.05 and 3.78 +0.05 A, 3.51-0.05 and 3.51+0.05 A, 3.02-0.05 and 3.02+0.05 A, and 2.86-0.1 and 2.86+0.1 A; therefore, the problems are solved well. The mordenite / beta zeolite / Y zeolite coexisting material can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

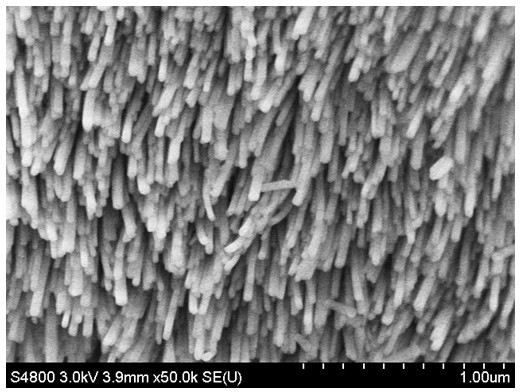

Preparation method for mordenite with high Si/Al ratio and small crystal particle

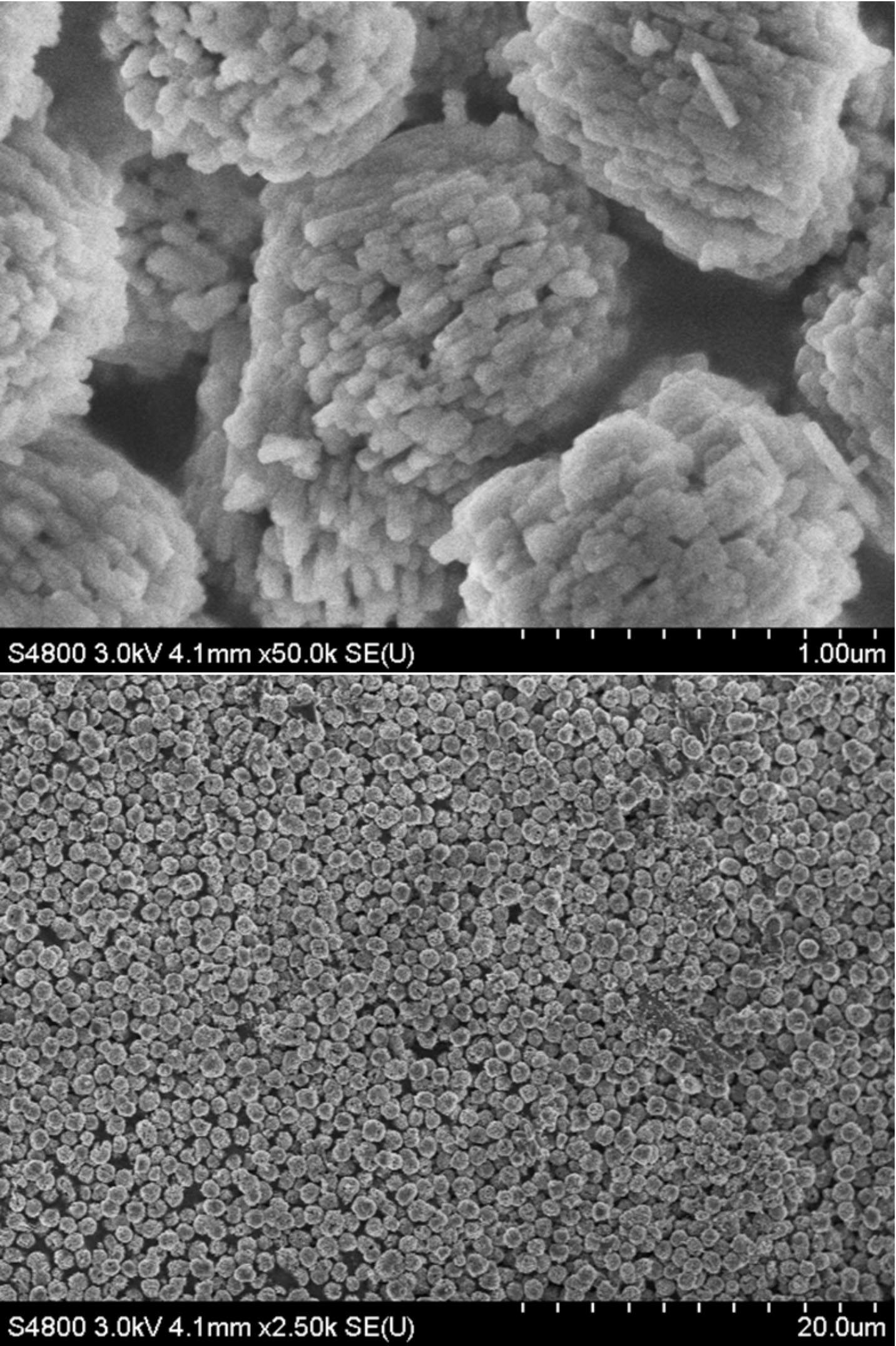

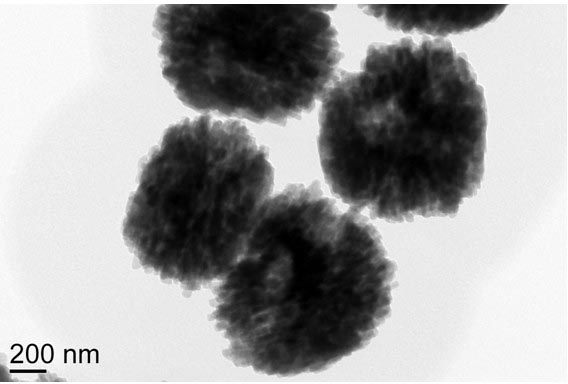

ActiveCN102602957ANovel Crystal MorphologyIncrease surface areaNanotechnologyMordenite aluminosilicate zeoliteSynthesis methodsFiltration

The invention discloses a preparation method for mordenite with a high Si / Al ratio and a small crystal particle, which comprises the following steps of: firstly, dissolving an Al source in sodium oxide solution; after an Si source is added, stirring and dispersing for certain time at room temperature and under strong magnetic force; mixing the Al source solution and the Si source solution which are evenly dispersed into glue at the room temperature; adding inorganic lamellar precursors, such as lamellar zeolite molecular sieves, lamellar silicate and the like to serve as seed crystal; after mixture is stirred and mixed evenly at the room temperature and under the strong magnetic force, transferring into a reaction crystallization kettle; at the temperature of 150-170DEG C, carrying out crystallization reaction for 0.5-3 days; and obtaining a solid product after common suction filtration, washing and drying. The synthesis method disclosed by the invention has the characteristics that expensive organic amine template is not used as structure-directing agent, and instead, the easily-obtained inorganic lamellar precursors with abundant source and low price are used as the seed crystal to directly synthesize a mordenite molecular sieve with the high Si / Al ratio. The prepared nanometer mordenite molecular sieve has the advantages of high degree of crystallinity and purity, controllable particle size and morphology, low cost and small environment pollution, and is convenient for industrially producing on a large scale.

Owner:EAST CHINA NORMAL UNIV

Process for synthesis of nano mordenite molecular sieve

InactiveCN1837046AIncrease alkali concentrationReduce pollutionNanostructure manufactureMordenite aluminosilicate zeoliteMolecular sieveAluminium

The inventon discloses a method of Nanomercerization zeolite molecular sieve. Containing steps as follows: magnetic stirring and dispersing the silicasol in strong caustic lye for a period of time, mixing the even dispersed silicon fountain and aluminium fountain to glue in room temperature, taking common mercerization zeolite molecular sieve powder as seed crystal, natrii chloridum or sulfuric acid disodium metal salt as additive, strong magnetic stirring aging for 2-6h in room temperature, low temperature ageing for 3-24h in 100Deg C, and then crystallization in 130-150Deg C, the crystallization time is 22-80h, the pH value of reaction system>12, finally collecting naonodimension mercerization zeolite molecular sieve from reaction product.

Owner:NANKAI UNIV

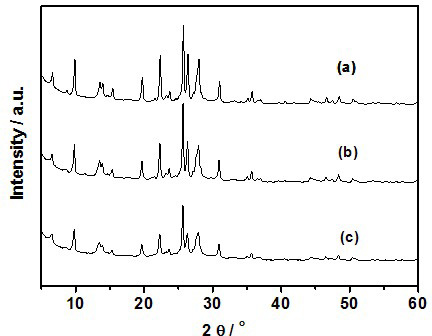

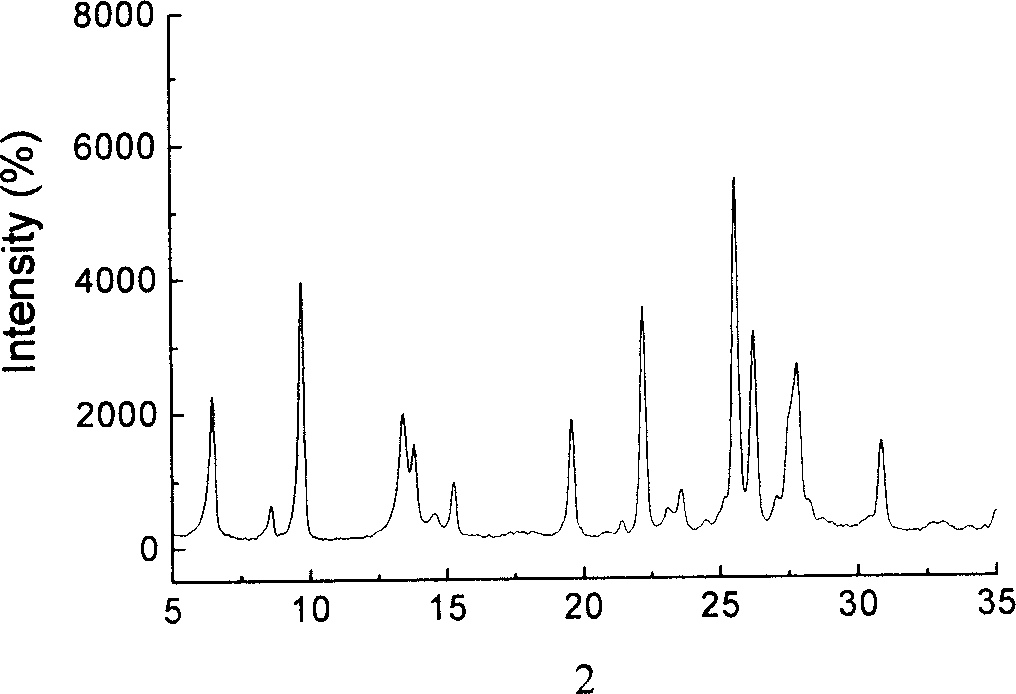

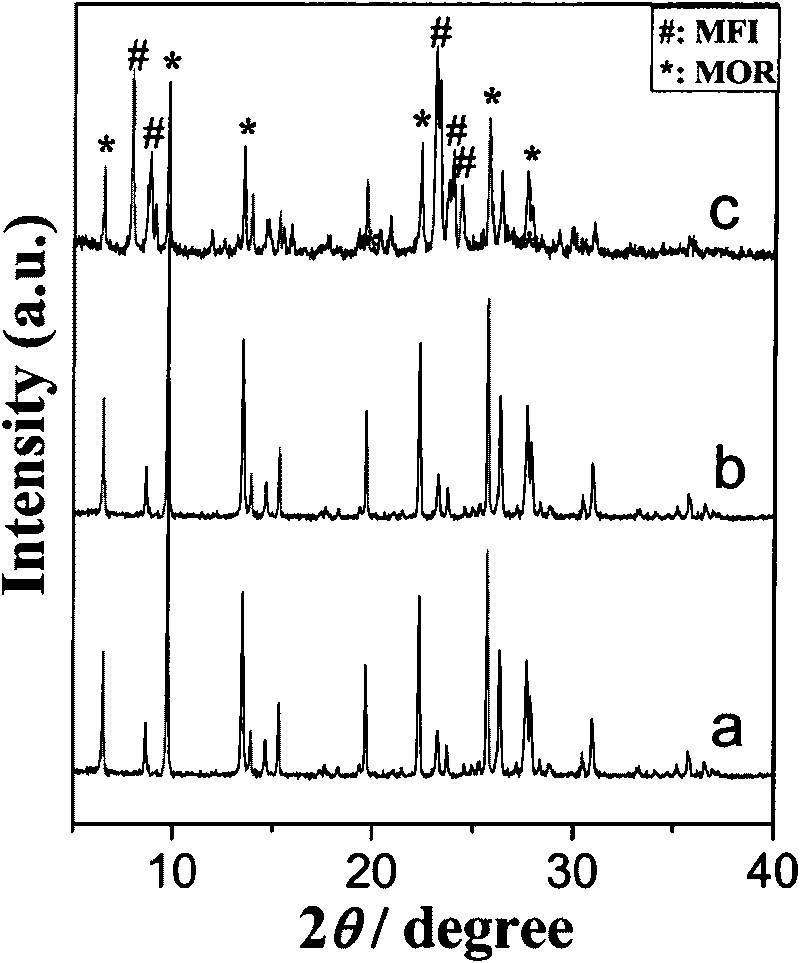

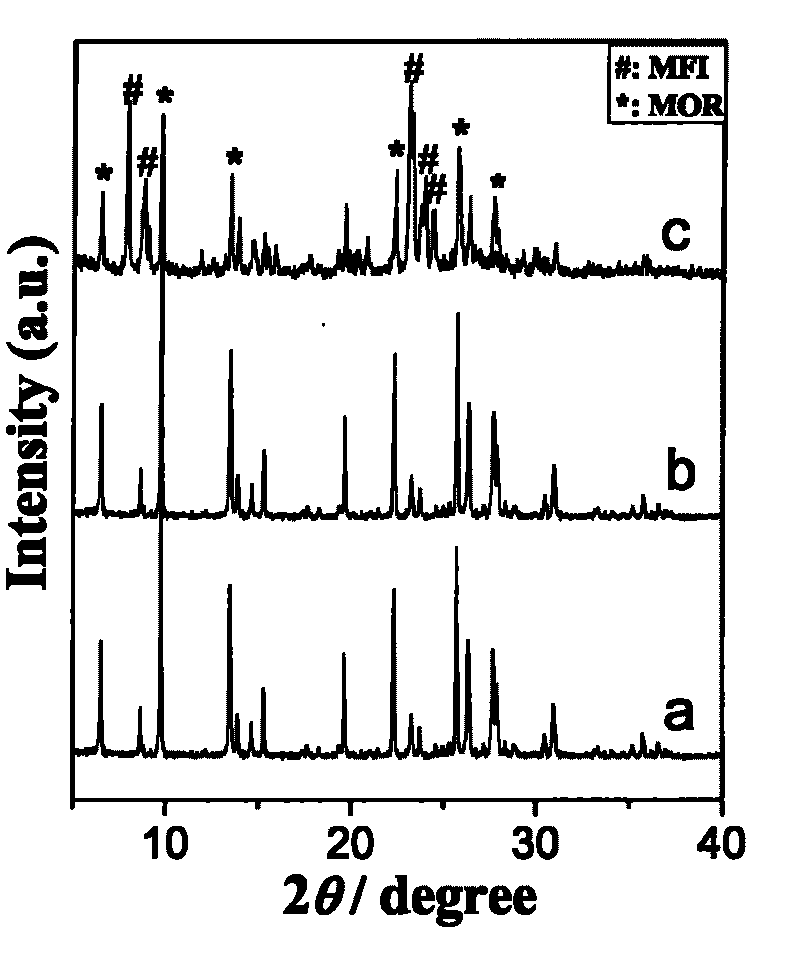

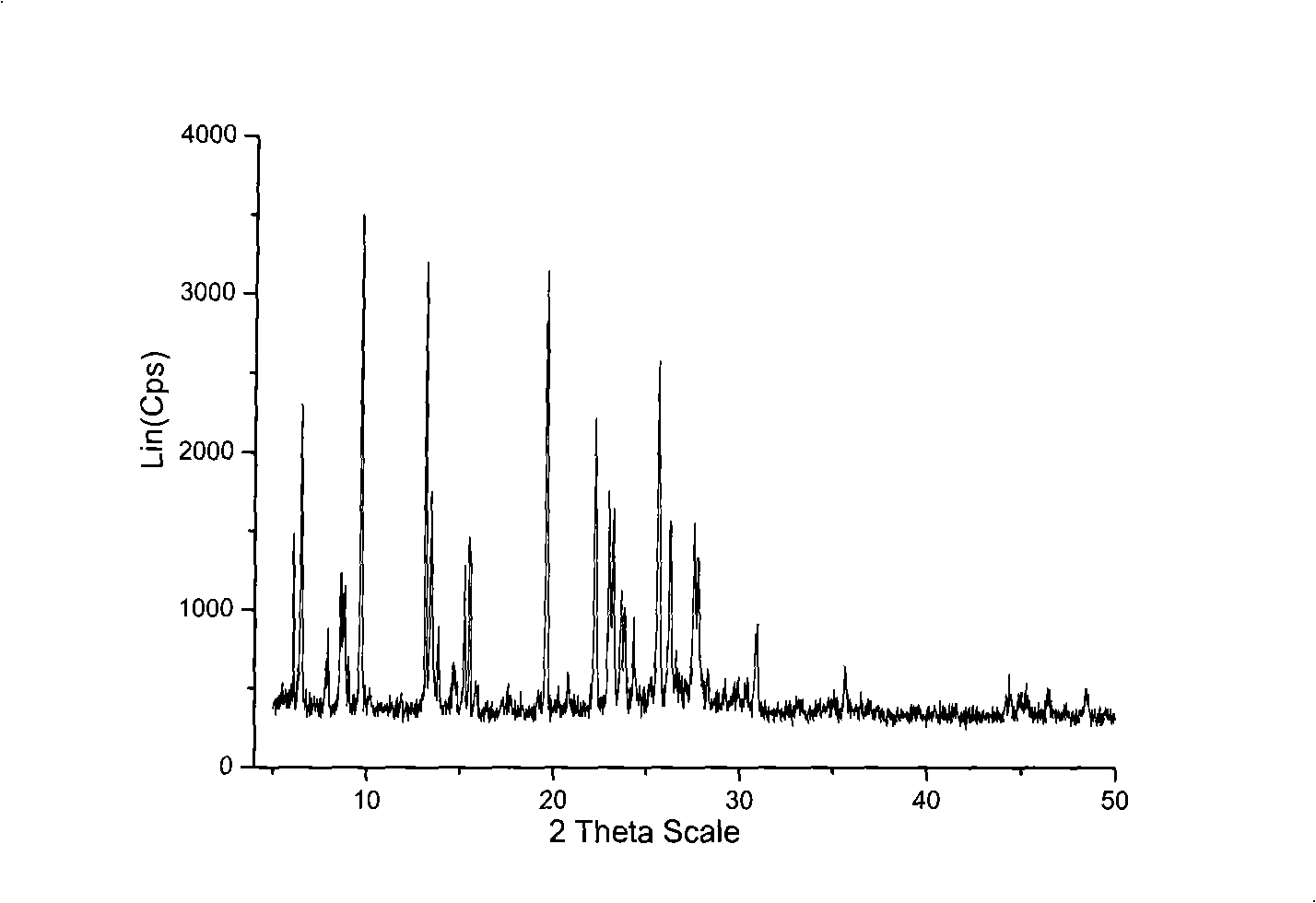

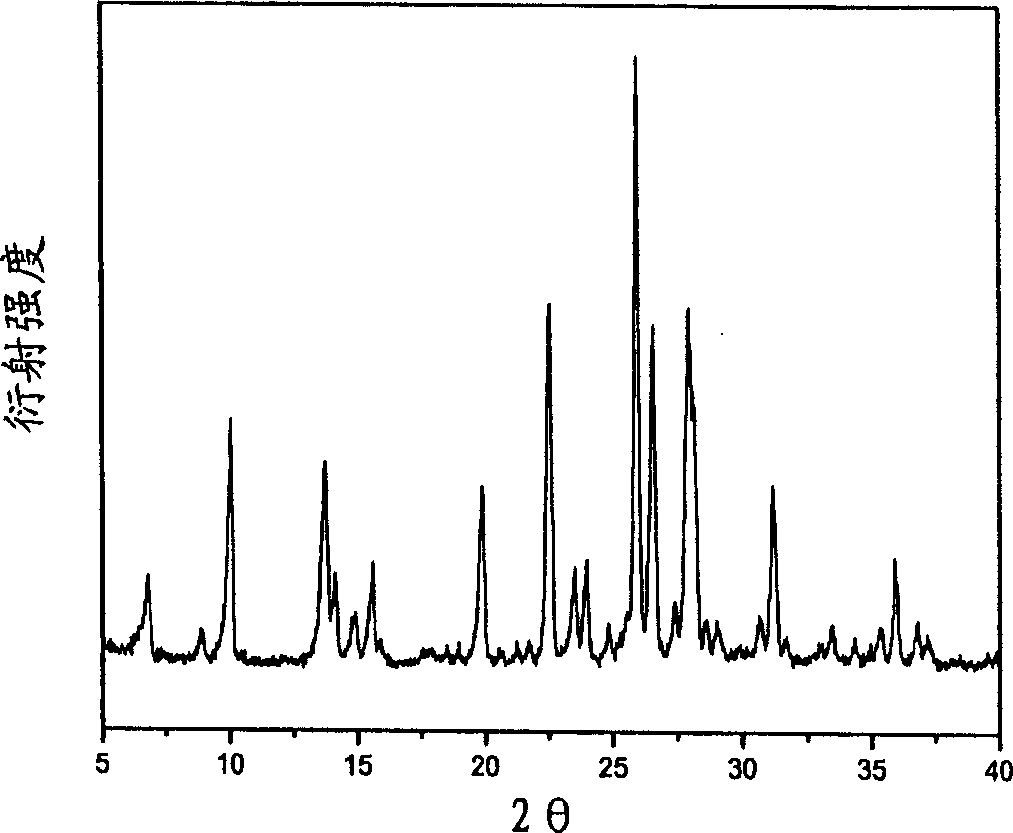

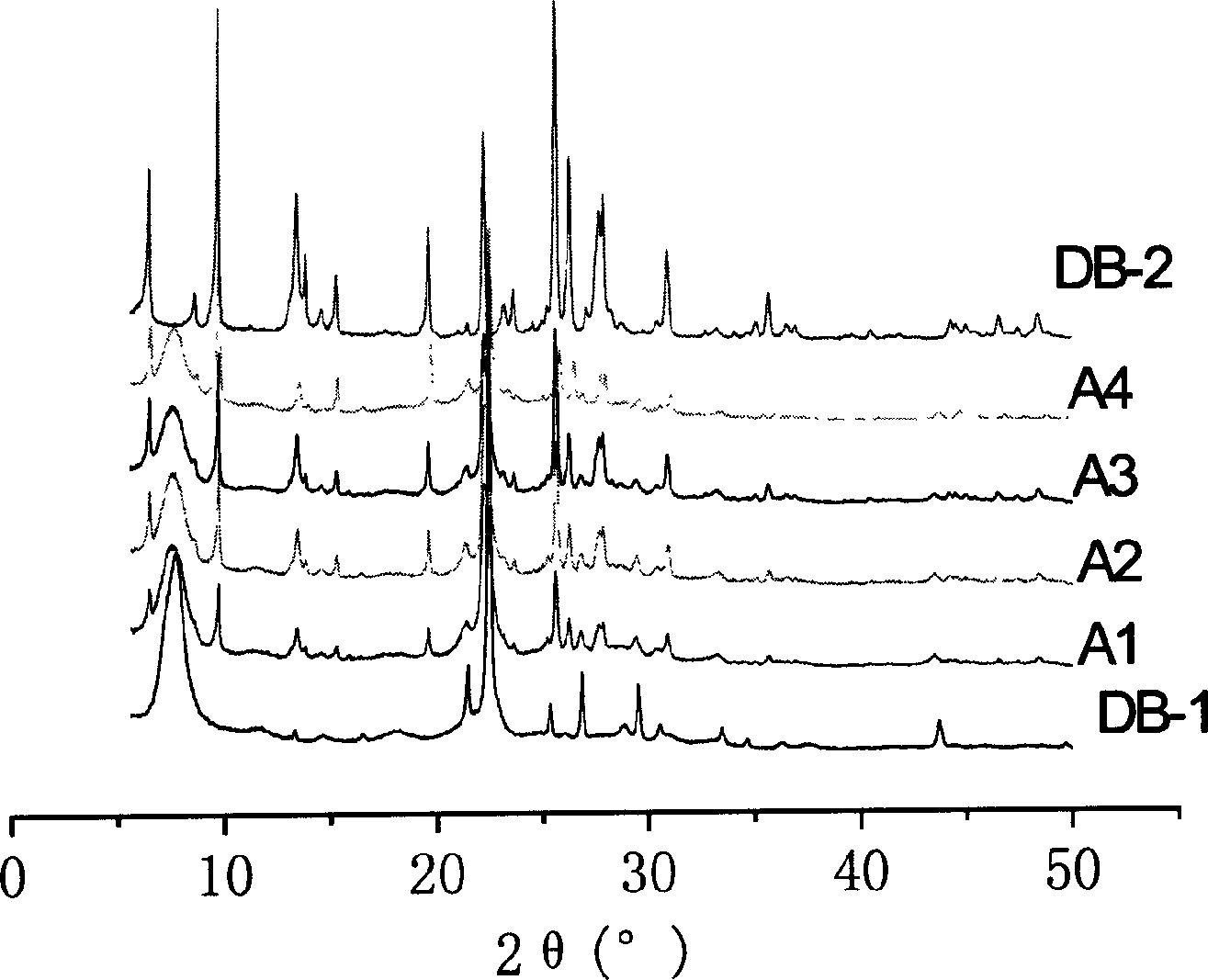

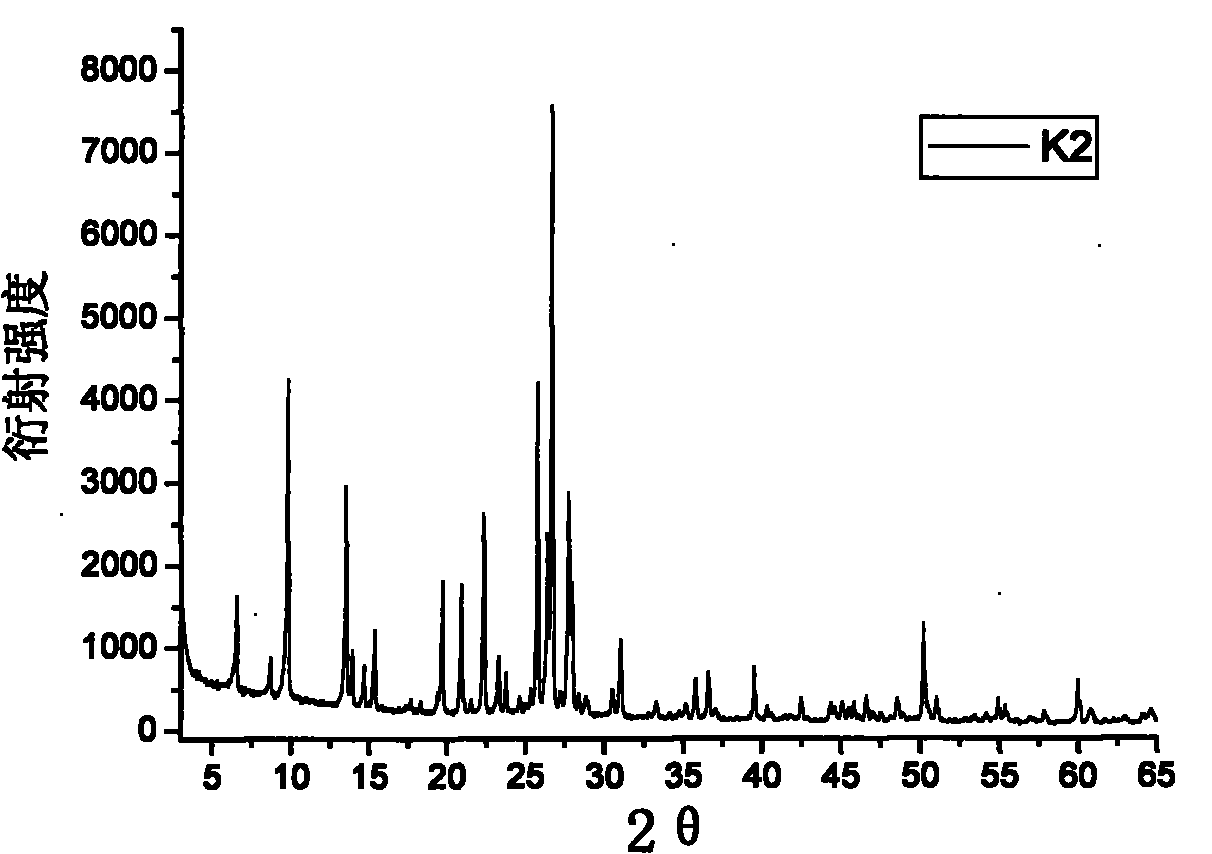

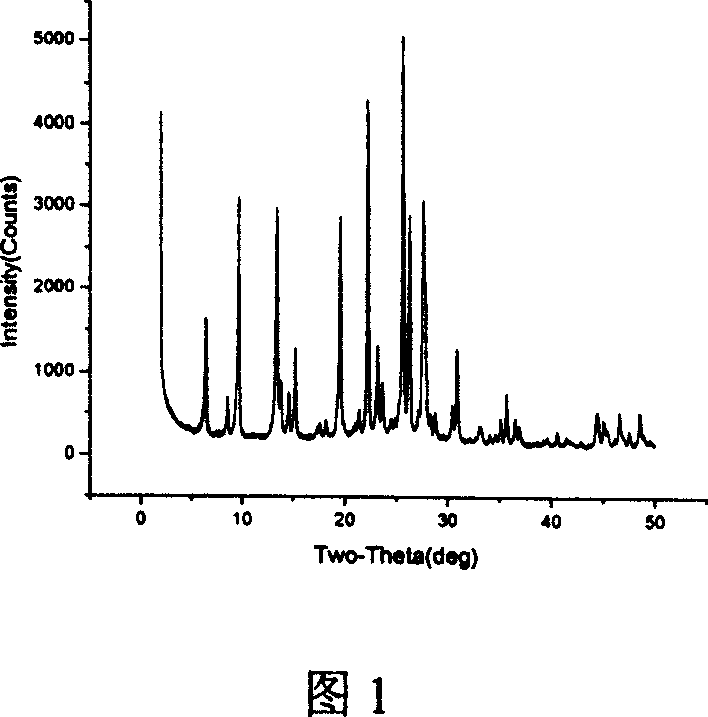

ZSM-5/mordenite/Yzeolite intergrowth molecular sieve and synthetic method thereof

ActiveCN101279747AIncrease acidityStrong acidFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteLow activityChemistry

The invention relates to a ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve and a synthetic method thereof, which mainly solves the problems of singular aperture, rather weak acidity and low activity of porous materials synthesized by the prior art. The invention adopts the technical proposal that the nucleation and process of growth of the molecular sieve are controlled properly by adding crystal seeds containing zeolite Y precursors in the synthetic process of the intergrowth molecular sieve for producing the ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve, wherein the proportion of intergrowth phases is adjustable, and the synthesized ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve adopts the compositions including the following mole relation: nSiO2:Al2O3, where n is between 4 and 400 in the formula, and the method is characterized in that the ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve has more than two phases and an XRD diffraction pattern thereof has the d-space maximum value at the lengths of 14.3+-0.1, 13.58+-0.1, 11.21+-0.1, 10.04+-0.1, 9.47+-0.1, 9.09+-0.1, 6.6+-0.1, 5.7 +-0.1, 4.5+-0.1, 3.98+-0.05, 3.76+-0.04, 3.64+-0.04, 3.53+-0.04, 3.38+-0.02, 3.19+- 0.05 and 2.88+-0.1 angstroms, thereby solving the problems properly. The ZSM-5 / mordenite / zeolite Y intergrowth molecular sieve can be used for preparing ethylene and propylene by catalytic-cracking naphtha in the industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing a crystalline metalloaluminosilicate by direct synthesis

The invention concerns a method for preparing a crystalline metalloaluminosilicate by direct synthesis using at least one source of aluminium and, as the source of silicon and as the source of at least one other metal M, at least one lamellar siliceous material containing metals in its framework. The invention also concerns the novel solids obtained, in particular solids with a given zeolitic structure containing particular metals in its zeolitic framework.

Owner:INST FR DU PETROLE

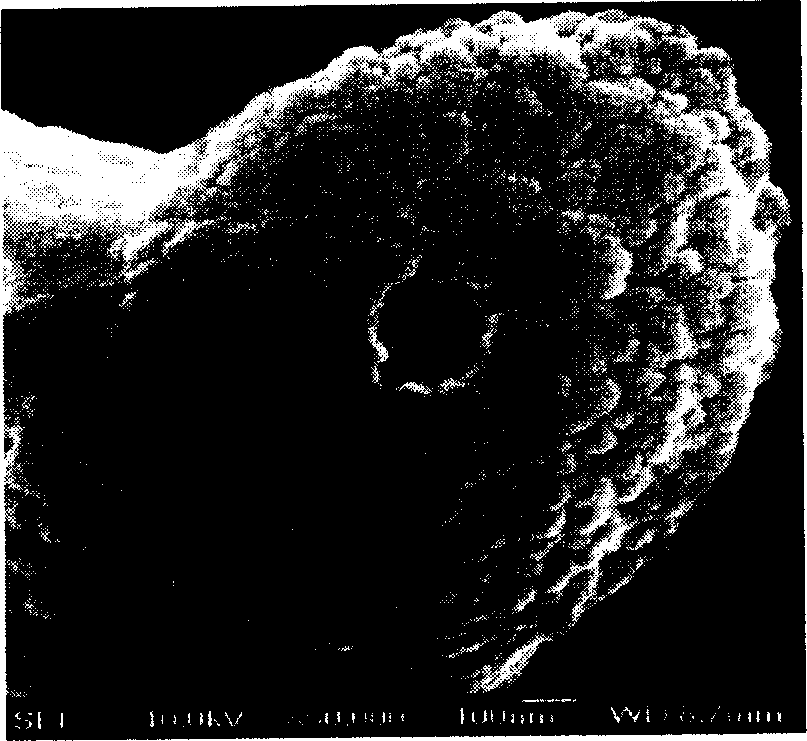

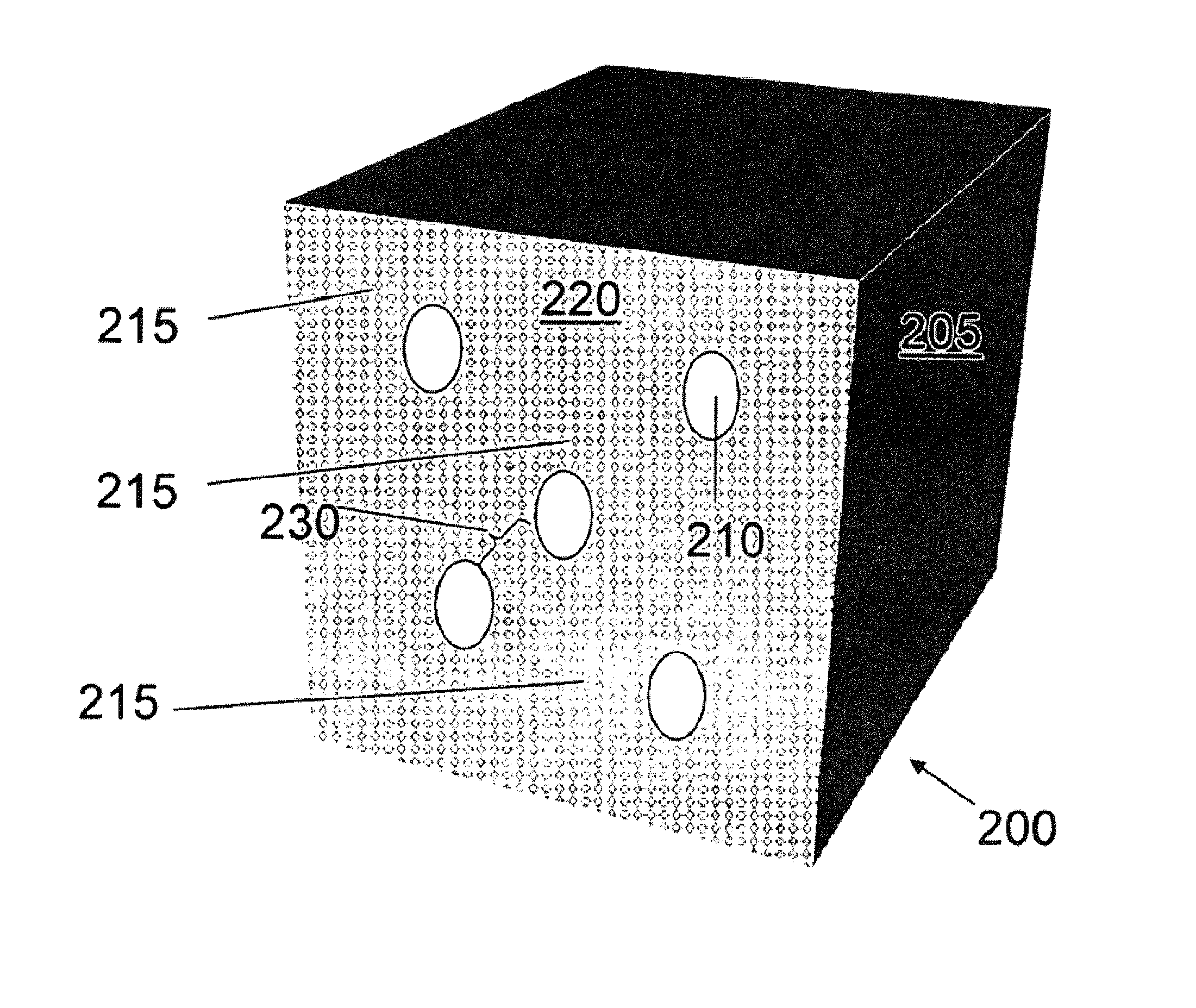

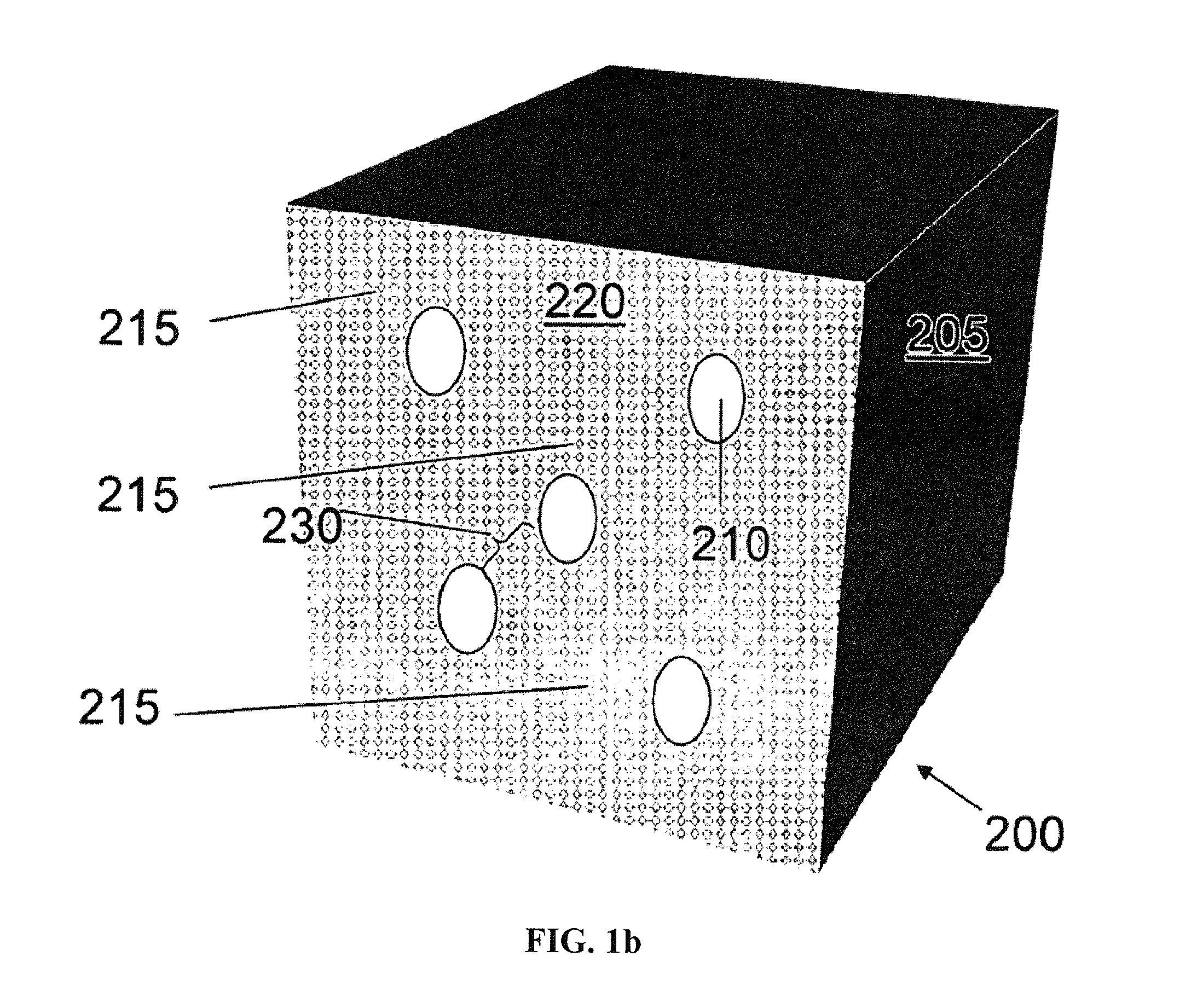

Preparation method of mordenite/ZSM-5 core-shell type molecular sieve material

InactiveCN101722034APromote growthLower synthesis costMolecular sieve catalystsMordenite aluminosilicate zeoliteMordeniteCore shell

The invention relates to a preparation method of a mordenite / ZSM-5 core-shell type molecular sieve material, mainly solving the problems that mordenite and ZSM-5 zeolite molecular sieve are difficult for compound growth in the prior art. The method comprises the following steps of: (1) treating mordenite crystal grains in a modified agent solution; (2) adding the mordenite crystal grains treated by a modified agent into a ZSM-5 synthetic system comprising a template agent R, a silicon source, an aluminum source and water, wherein the mol ratio of R2O to SiO2 is 0.05-0.5, the mol ratio of SiO2 to Al2O3 is 50-infinity, the mol ratio of SiO2 to Na2O is 2-10 and the mol ratio of H2O to SiO2 is 20-100; and (3) hydrothermally crystallizing, filtering, washing and roasting to obtain the mordenite / ZSM-5 core-shell type molecular sieve material, thus the problems are better solved. The invention can be used for industrial production of the mordenite / ZSM-5 core-shell type molecular sieve materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing zeolite molecular sieve via solid phase method without organic template

InactiveCN102992343AHigh crystallinityHigh purityMolecular sieve catalystsCatalyst activation/preparationMolecular sieveCrystallinity

The invention relates to a preparation method for a molecular sieve, and aims to provide a method for synthesizing a zeolite molecular sieve via a solid phase method without an organic template. The method comprises the steps of grinding and mixing weighed solid raw materials of silicon source, aluminium source and alkali source; putting the above mixture in a reaction kettle; performing a crystallization reaction for 5 h-20 d at a temperature of 50-200 DEG C; suction-filtering a product, and drying the product to obtain various molecular sieve raw powder. A ZSM-5 zeolite molecular sieve, a Beta zeolite molecular sieve, an FAU zeolite molecular sieve, an MOR zeolite molecular sieve, an LTA zeolite molecular sieve an a GIS zeolite molecular sieve which have relatively good crystallinity and controllable silica-alumina ratio in a certain range can be obtained through the method. The product has good crystallinity and purity; no organic template and solvent is used in the whole production process; so that unnecessary loss in the production process can be prevented greatly. Besides, a conventional method is simplified greatly; and single-kettle yield is increased greatly.

Owner:BASF AG

Preparation method of mesoporous mordenite

ActiveCN102602958ANovel Crystal MorphologyAbundant secondary stacking poresNanotechnologyMordenite aluminosilicate zeoliteFiltrationSynthesis methods

The invention discloses a method for synthesizing a mesoporous mordenite molecular sieve. The method comprises the following steps of: dissolving an aluminum source in a sodium hydroxide solution; adding a silicon source and stirring to disperse for a certain period of time at room temperature under strong magnetic force, wherein the uniformly dispersed solution of silicon source and aluminum source is mixed into glue at room temperature; adding a dealuminated mordenite molecular sieve as seed crystal; stirring and uniformly mixing at room temperature under strong magnetic force, and transferring the product into a reaction crystallization kettle; performing crystallization reaction at 150-170 DEG C for 0.5-3 days; and performing conventional suction filtration, washing and drying to obtain a solid product. The synthesis method disclosed by the invention has the characteristics that the expensive organic amine template agent is not used as a structure directing agent, and the cheap and easily-available inorganic layered precursor with wide source is used as the seed crystal to directly synthesize a mordenite molecular sieve with high silica-alumina ratio; and the prepared nano mordenite molecular sieve has the advantages of high crystallinity and purity, abundant accumulation meso pores, controllable particle size, form and low cost, less environment pollution and convenience for industrial large-scale production.

Owner:EAST CHINA NORMAL UNIV

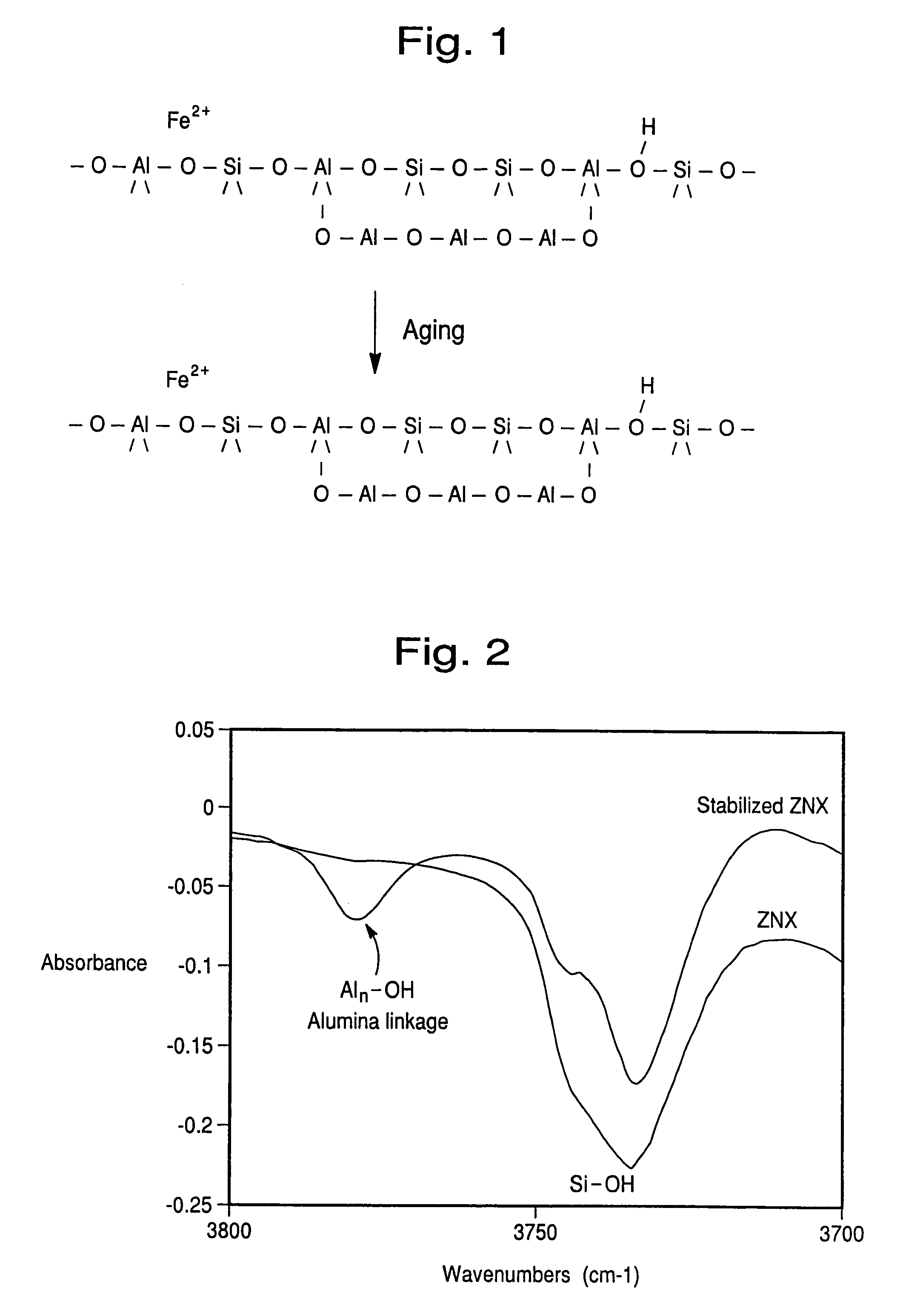

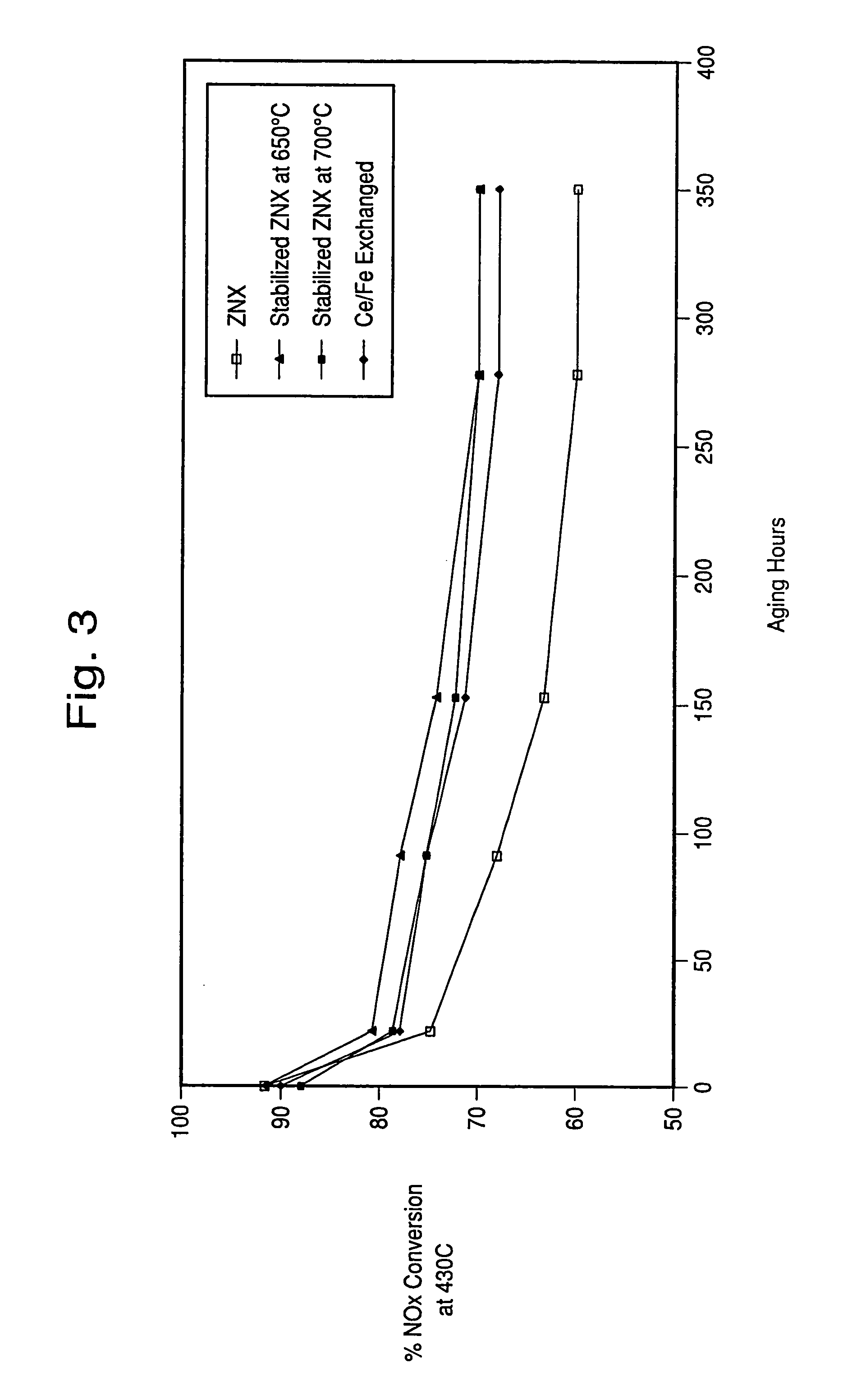

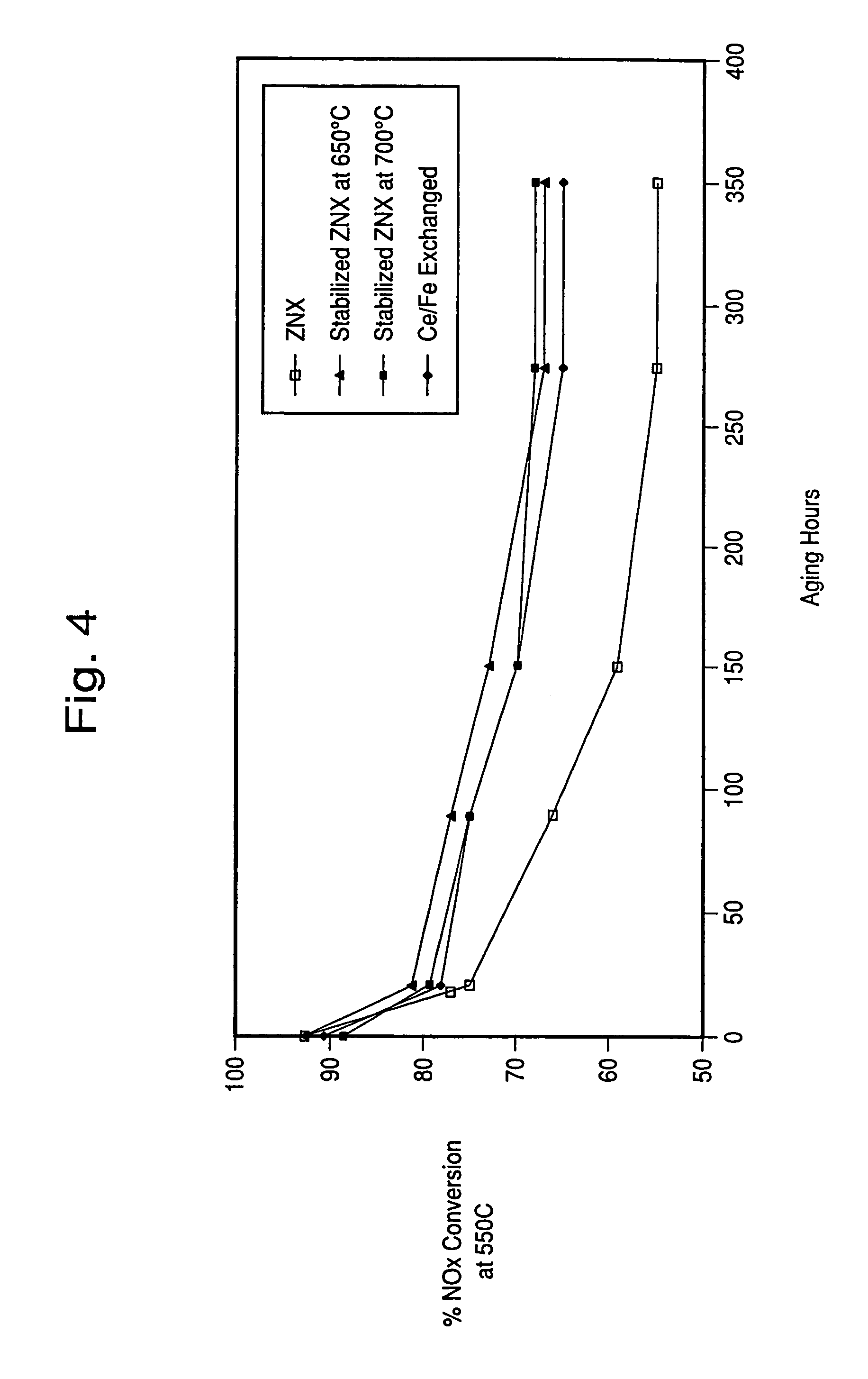

Hydrothermally stable metal promoted zeolite beta for NOx reduction

InactiveUS7332148B2Good hydrothermal stabilityImprove stabilityAluminosilicate zeolite type ZSM-12Aluminium compoundsNitrogen oxidesIr absorption

A stabilized metal promoted aluminosilicate zeolite, useful in the selective catalytic reduction of nitrogen oxides with ammonia, having a silica to alumina mole ratio of at least 8 and less than 30 and an FT-IR absorption peak at 3781 plus or minus 2 cm−1 which stabilizes the zeolite against further dealumination such as under oxidizing and harsh hydrothermal conditions.

Owner:ENGELHARD CORP

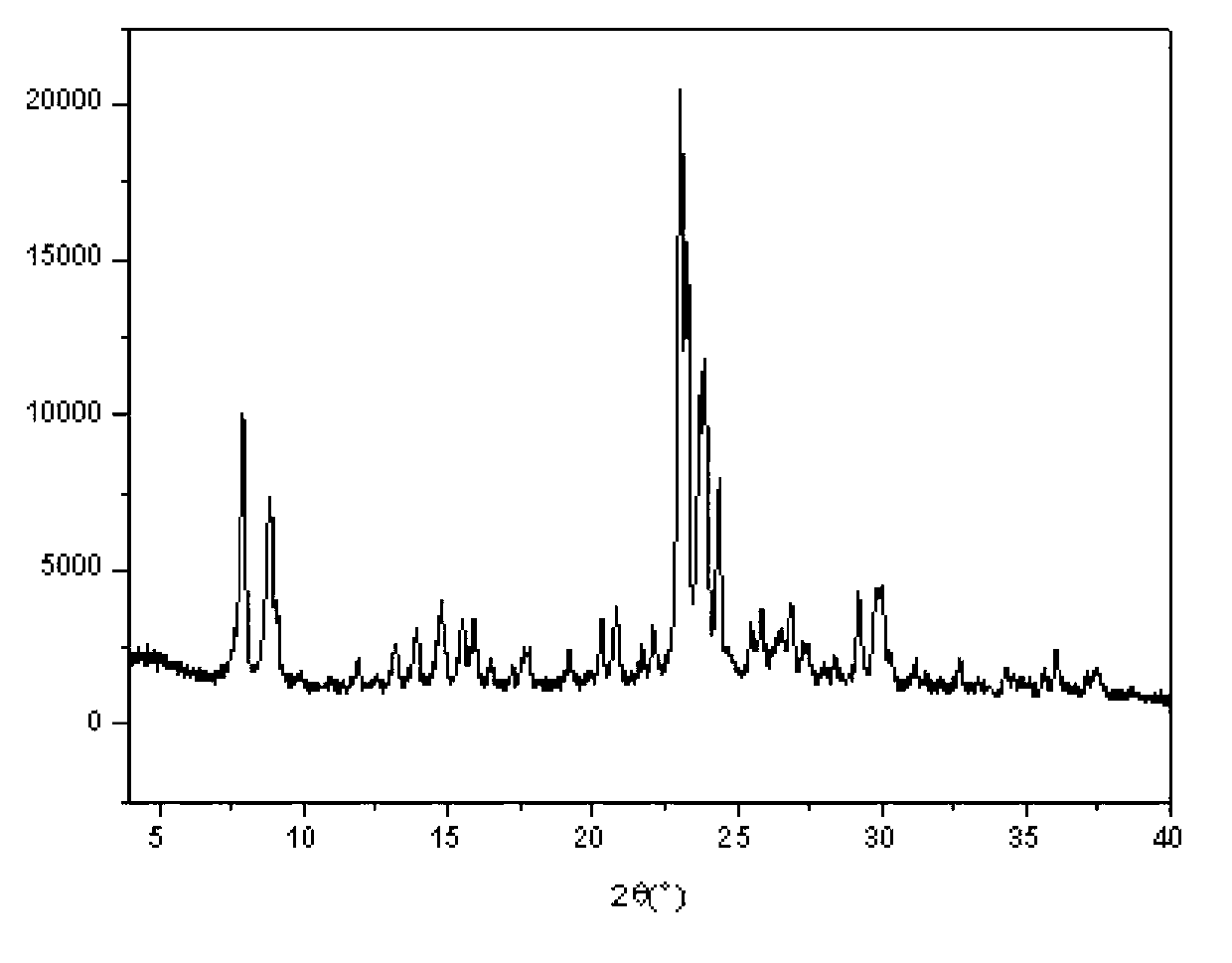

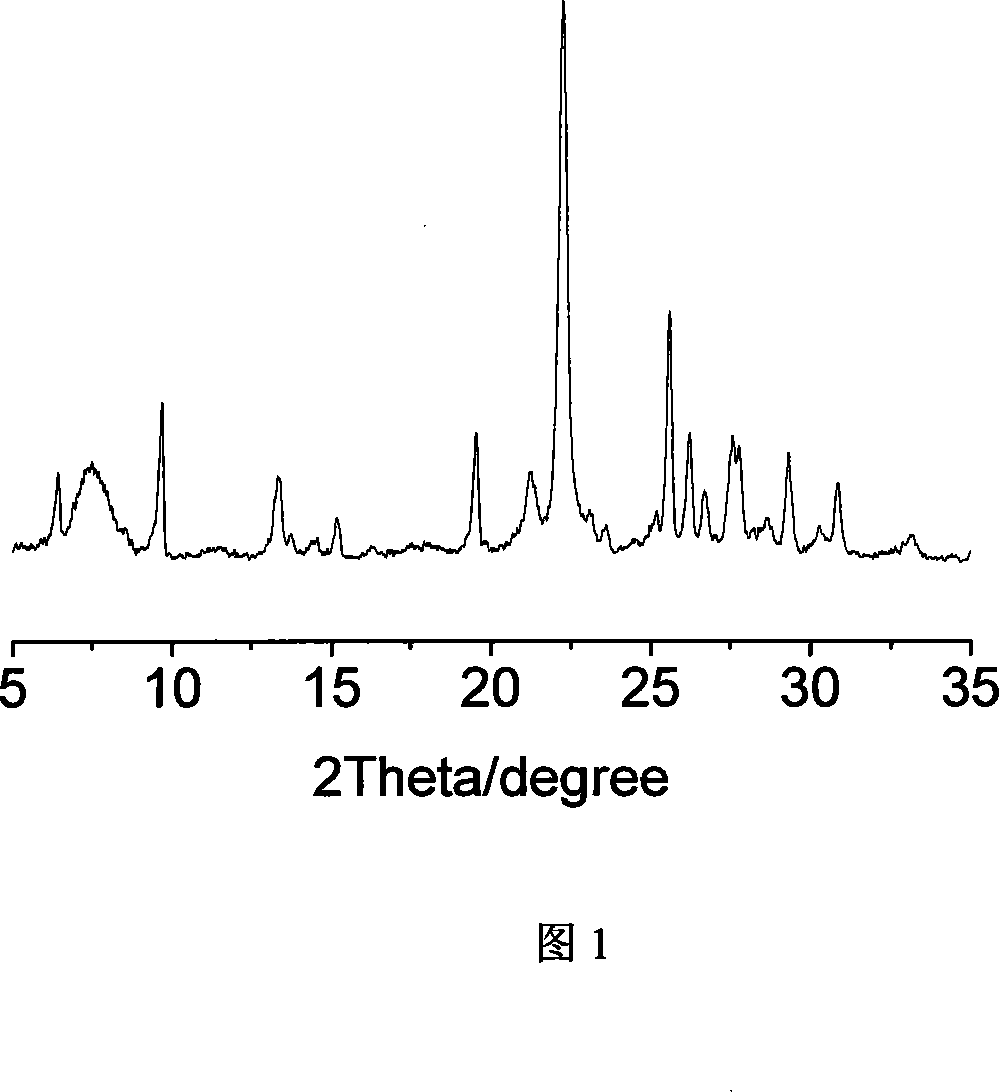

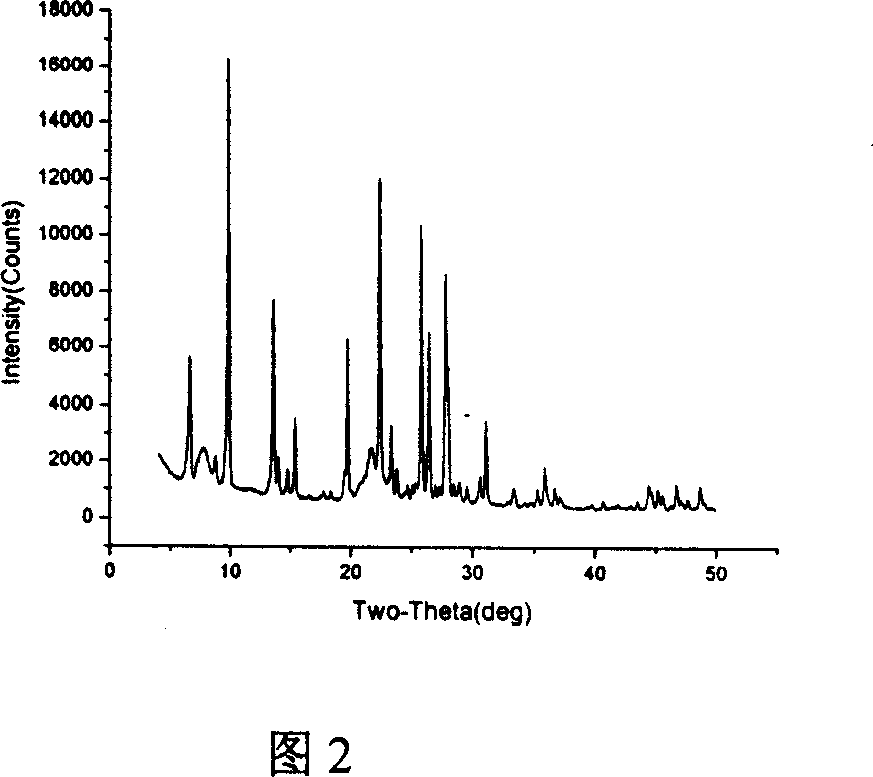

Mordenite/Y zeolite coexisting molecular sieve and method for synthesizing same

ActiveCN101514008AIncrease acidityStrong acidFaujasite aluminosilicate zeoliteMordenite aluminosilicate zeoliteMolecular sieveCatalytic pyrolysis

The invention relates to a mordenite / Y zeolite coexisting molecular sieve and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the mordenite / Y zeolite coexisting molecular sieve by adding a seed crystal containing a Y zeolite precursor and well controlling the nucleating and growing process of a molecular sieve during a synthesis process of mordenite. The coexistence phase ratio of the mordenite / Y zeolite coexisting molecular sieve is adjustable, and a mole relation of the components of the synthesized coexisting molecular sieve is nSiO2 :Al2O3, wherein n is between 4 and 400; the coexisting molecular sieve has more than two phases, the XRD diffraction pattern of the coexisting molecular sieve comprises a technical proposal that a maximum value of a distance d is at positions between 14.52-0.05 and 14.52+0.05 A, 13.52-0.05 and 13.52+0.05 A, 8.96-0.05 and 8.96+0.05 A, 8.83-0.05 and 8.83+0.05 A, 6.71-0.1 and 6.71+0.1 A, 5.71-0.1 and 5.71 +0.1 A, 4.51-0.1 and 4.51+0.1 A, 3.98-0.1 and 3.98+0.1 A, 3.78-0.05 and 3.78+0.05 A, 3.47-0.1 and 3.47+0.1 A, and 2.86-0.1 and 2.86+0.1 A; therefore, the problems are solved well. The coexisting molecular sieve can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Core-shell structural dibasic composite zeolite and preparation method thereof

InactiveCN101177276AEmission reductionSave raw materialsMolecular sieve catalystsMordenite aluminosilicate zeoliteHydrogenMordenite

A binary composite zeolite with a core-shell structure and a preparation method thereof, which belong to the field of inorganic synthesis and catalyst preparation, specifically relate to a binary composite zeolite with a Beta core and a mordenite shell structure and a preparation method thereof. The material will contain two phases of Beta zeolite and mordenite at the same time, and the ratio of the two phases and the surface L / B acid can be adjusted. Directly add aluminum, organic template agent tetraethylammonium bromide and alkali, and use Beta zeolite as the silicon source for mordenite synthesis to prepare a binary composite zeolite material with a double microporous core-shell structure, which is transformed by amine exchange After forming hydrogen form, it is used as a catalyst for the conversion of methanol to prepare dimethyl ether. At a weight space velocity of 2.26 (g / g) h-1, a partial pressure of methanol of 11.4Kpa and a reaction temperature of 300°C, after 72 hours of reaction, methanol The conversion rate still remains above 80%, and the selectivity of dimethyl ether is above 99%.

Owner:TAIYUAN UNIV OF TECH

Preparation method of microcrystal mordenites

ActiveCN101519217ASmall grain sizeWide variation range of silicon-aluminum ratioMordenite aluminosilicate zeoliteIsomerizationMordenite

The invention discloses a preparation method of microcrystal mordenites, which comprises the following steps of: blending an aluminum resource, a sodium resource, a template agent and water to obtain a mixed solution; applying the mixed solution to moisten the surface of silica gel so as to form a synthetic system with the mole ratio as follows: the mole ratio of SiO2 to A12O3 is 10 to 100, the mole ratio of template agent to SiO2 is 0.01 to 0.10, the mole ratio of Na2O to SiO2 is 0.01 to 0.10 and the mole ratio of H2O to SiO2 is 4.0 to 8.0; and conducting two-segment crystallization over the synthetic system at different temperatures and then collecting, washing and drying the solid substances. The mordenites synthesized by the method has small grain and high silica alumina ratio, and has rather high isomerized selectivity when being applied to the isomerization reaction of C5 / C6 light hydrocarbon.

Owner:CHINA PETROLEUM & CHEM CORP

Method for synthesizing flokite

ActiveCN1891627AImprove conversion rateHigh yieldMordenite aluminosilicate zeoliteMordeniteCrystallinity

This invention provides a method for synthesizing mordenite, which takes brei starch as the template agent to add it into an initial gel mixture prepared with alkali material, silicon and Al raw substances to become a reacted mixture gel then to be hydrothermal-crystallized to get the mordenite, in which, the mol ratio of the compositions of the gel mixture according to its oxide is: M2O : SiO2 : Al2O3 : H2O=2-100 : 9-550 : 1 : 100-9000, and M is alkali metal.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

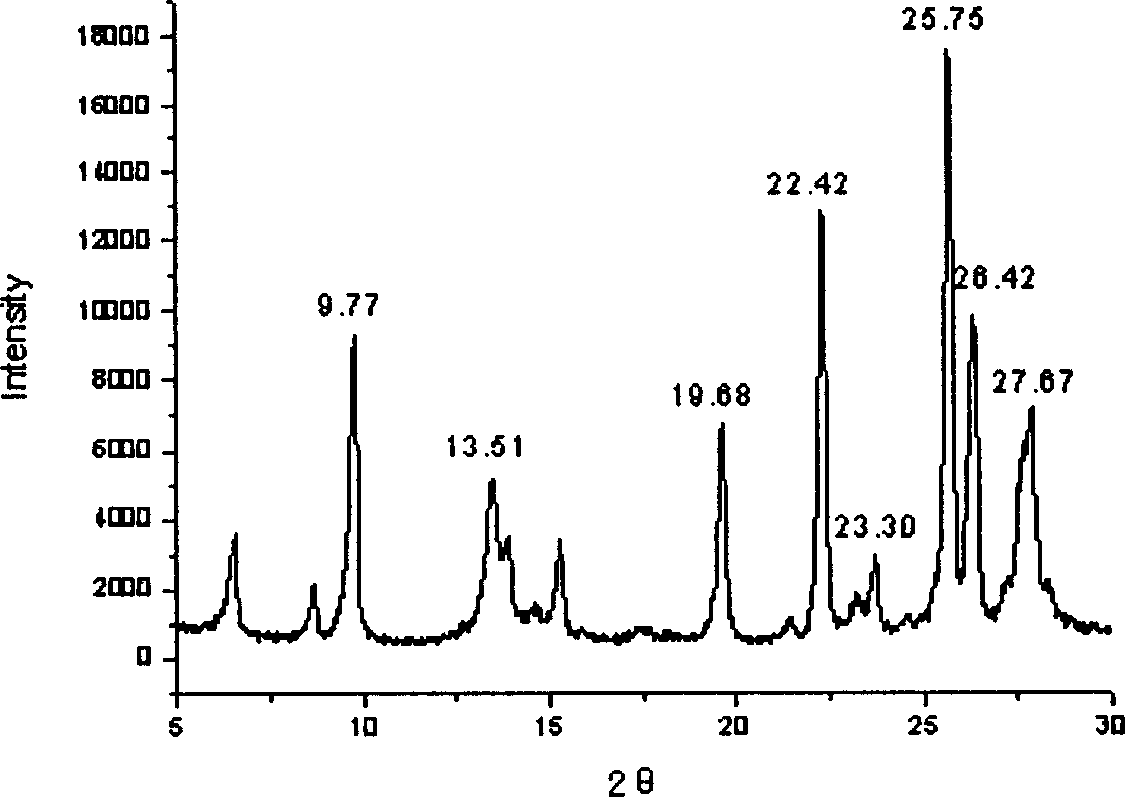

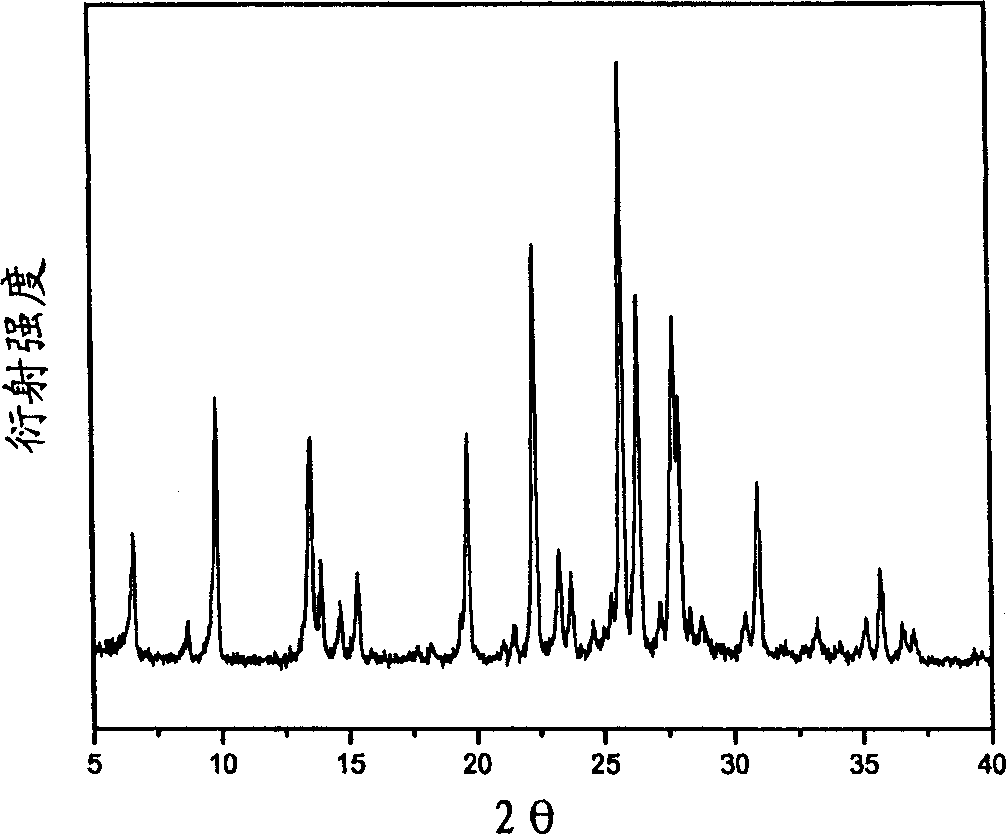

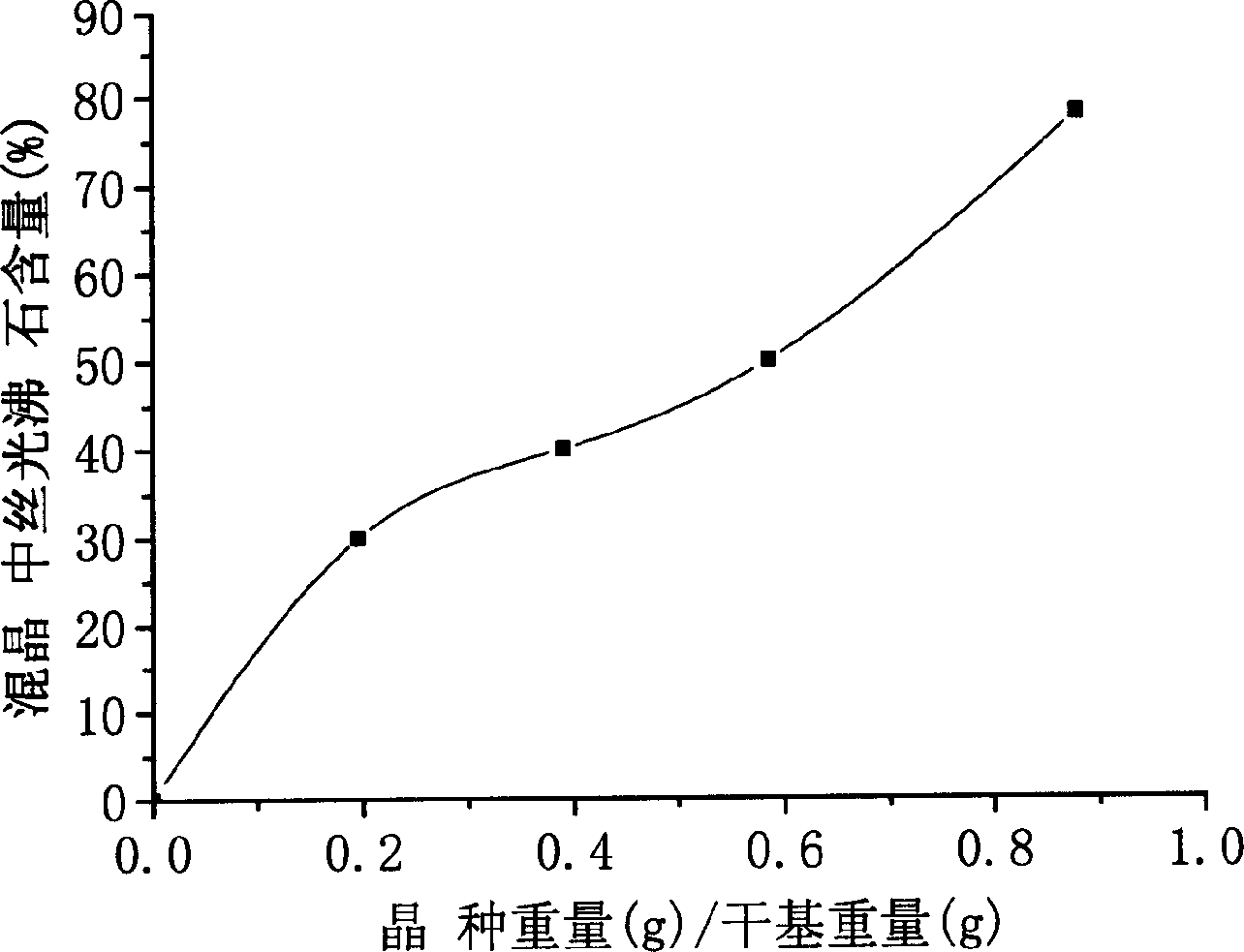

Processfor preparing mordenite and beta zeolite mixed crystal material

ActiveCN1648046AEasy to adjustMolecular sieve catalystsMordenite aluminosilicate zeoliteSeed crystalMixed crystal

The present invention discloses the preparation process of mixed crystal material of mordenite and beta zeolite, and features that mordenite is used as crystal seed added into synthesis reaction of beta zeolite and through further hydrothermal crystallization the mixed crystal material is prepared. The mixed crystal material thus synthesized has adjustable mixed crystal ratio and even higher catalyst performance than the mixed crystal material obtain through mechanical mixing of mordenite and beta zeolite.

Owner:CHINA PETROLEUM & CHEM CORP +2

Process for Preparing a Molecular Sieve

ActiveUS20160221832A1Increase mesopore surface areaGood removal effectMolecular sieve catalystsMolecular sieve catalystMolecular sieveZeolite

Owner:EXXONMOBIL CHEM PAT INC

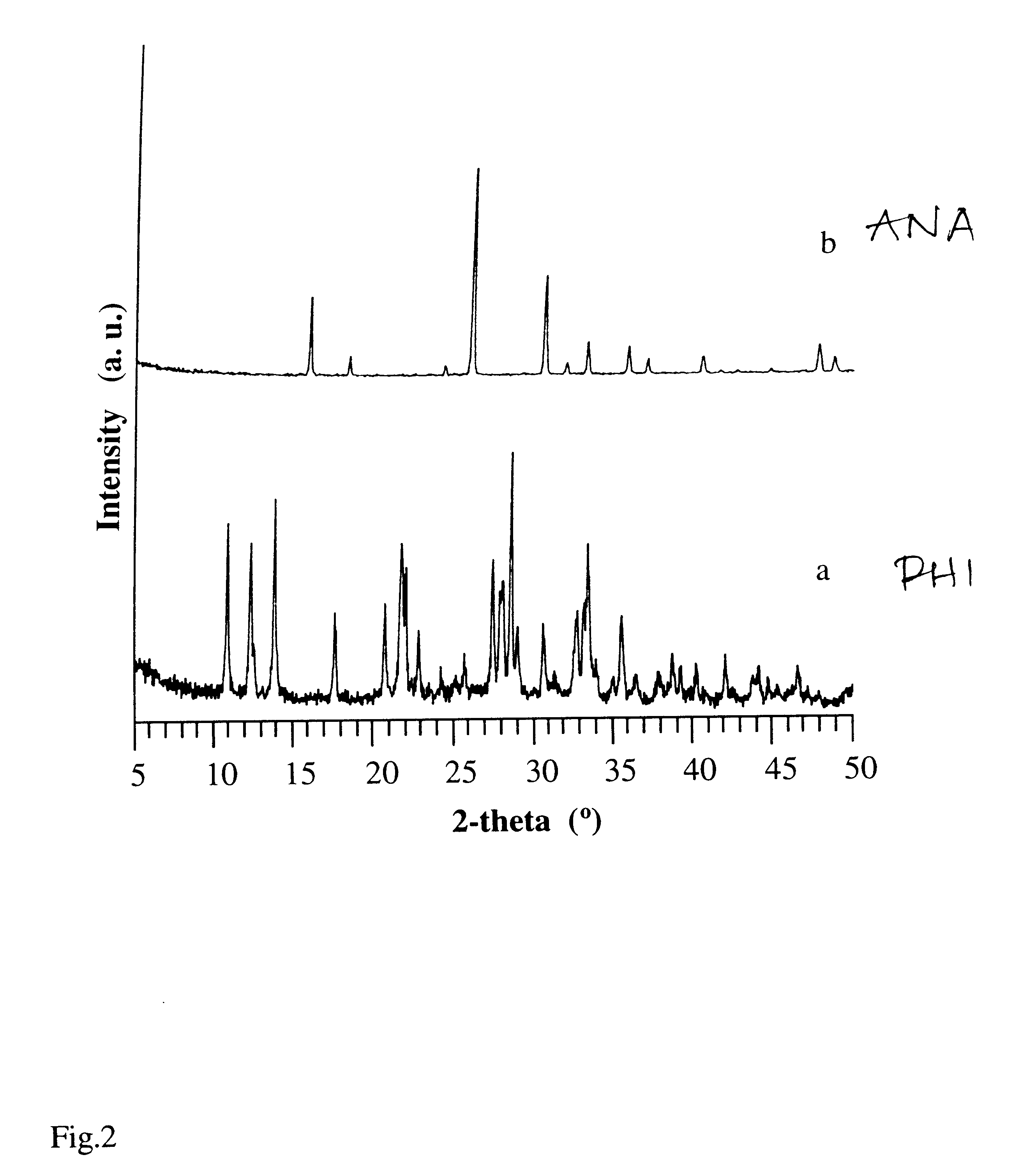

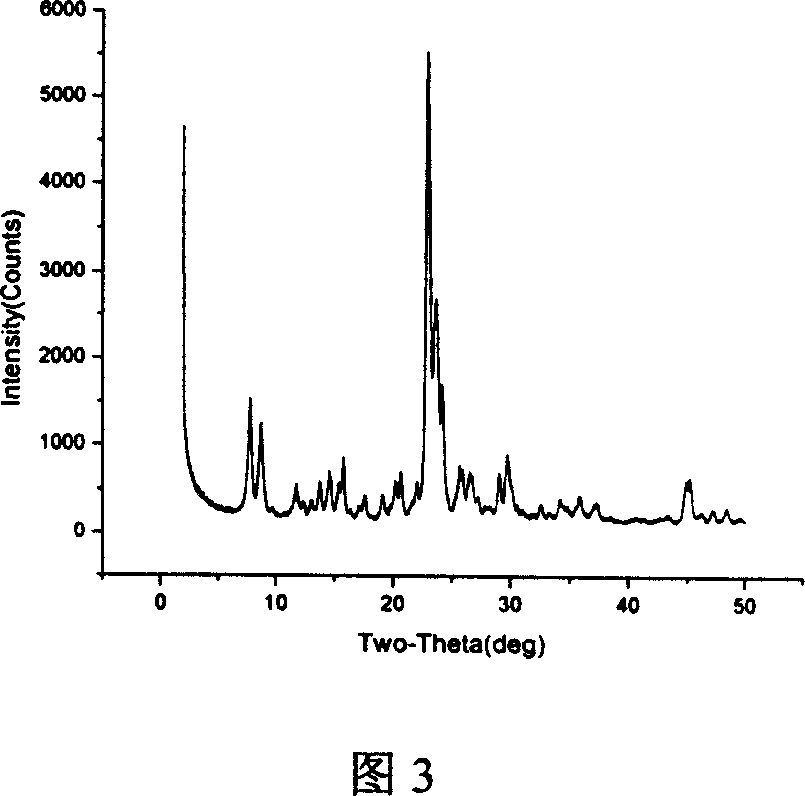

Mordenite/beta zeolite/analcime porous coexisting material and method for synthesizing same

ActiveCN101514010AIncrease acidityStrong acidMordenite aluminosilicate zeoliteCatalytic pyrolysisMolecular sieve

The invention relates to a mordenite / beta zeolite / analcime porous coexisting material and a method for synthesizing the same, and mainly solves the problems that a porous material synthesized by the prior art is single in pore-size, weak in acid and low in activity. The method prepares the porous coexisting material by well controlling the nucleating and growing process of a molecular sieve during a synthesis process of porous material. The coexistence phase ratio of the porous coexisting material is adjustable, and a mole relation of the components of the synthesized porous coexisting material is nSiO2 :Al2O3, wherein n is between 4 and 400; the porous coexisting material has more than three phases; the XRD diffraction pattern of the porous coexisting material comprises a technical proposal that a maximum value of a distance d is at positions between 13.52-0.1 and 13.52+0.1 A,11.32-0.1 and 11.32+0.1 A, 9.47-0.1 and 9.47+0.1 A, 8.96-0.1 and 8.96+0.1 A, 7.07-0.1 and 7.07+0.1 A, 6.71-0.1 and 6.71+0.1 A, 4.51-0.1 and 4.51+0.1 A, 4.15-0.1 and 4.15+0.1 A, 3.98-0.05 and 3.98+0.05 A, 3.76-0.05 and 3.76 +0.05 A, 3.65-0.05 and 3.65+0.05 A, 3.53-0.02 and 3.53+0.02 A, 3.47-0.02 and 3.47+0.02 A, 3.31-0.05 and 3.31+0.05 A, and 3.02-0.05 and3.02+0.05 A; therefore, the problems are solved well. The mordenite / beta zeolite / analcime porous coexisting material can be used in the industrial production of ethylene and propylene through the catalytic pyrolysis of naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

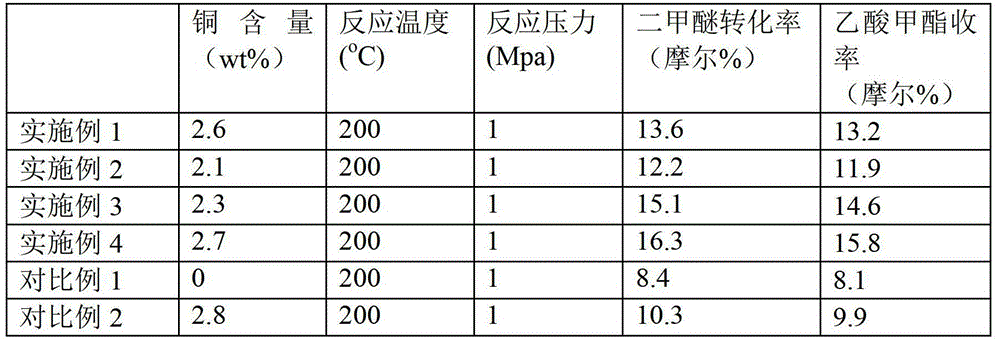

In-situ synthetic method of geolyte containing copper wires

The invention provides an in-situ synthetic method of geolyte containing copper wires. The method comprises the steps of mixing silicon sources, aluminum sources, organic template agents, copper sources and water to obtain raw material solutions; aging the raw material solutions and crystallizing under a hydrothermal condition; washing, drying and roasting to prepare the geolyte containing copper wires. The invention also provides the geolyte containing copper wires prepared by using the method and a method for synthesizing ethyl formate by means of dimethyl ether carbonylation by using the geolyte containing copper wires as a catalyst. The geolyte containing copper wires represents high activity and high product selectivity in reaction of dimethyl ether carbonylation synthesized methyl acetate.

Owner:SHANGHAI BI KE CLEAN ENERGY TECH

Zeolite molecular sieve and its prepn process with palygorskite as material

InactiveCN101066766AMolecular sieve catalystsAluminosilicate zeolite type-AMolecular sievePalygorskite

The present invention discloses one kind of zeolite molecular sieve and its preparation process with palygorskite as material. The zeolite molecular sieve is prepared through reacting palygorskite and alkali solution in 5-20 times, and the subsequent washing and drying. The prepared zeolite molecular sieve has type controlled through altering the ratio between palygorskite and alkali solution. The process of preparing zeolite molecular sieve with palygorskite as material is simple.

Owner:ZHEJIANG UNIV

Method for preparing high-silicon mordenite by using raw mineral material

The invention relates to a method for preparing high-silicon mordenite by using a low-cost raw mineral material. The method for preparing the high-silicon mordenite by using the raw mineral material is characterized by comprising the following steps of: 1) selecting SiO2 of a silicon source, Al2O2 of an aluminum source, an inorganic base, a fluoride, a template agent and water in a mole ratio of the SiO2 of the silicon source to the Al2O2 of the aluminum source to the inorganic base to the fluoride to the template agent to the water of (20-50):1:(2-5):(5-10):(1.5-6):(300-600); 2) mixing and pulping the aluminum source, the silicon source, the inorganic base, the fluoride and the template agent with the water, stirring and mixing the mixture at the temperature form the room temperature to 80 DEG C to form a glue so as to obtain an initial gel mixture; adjusting the pH value of the initial gel mixture to between 11 and 13; performing a hydrothermal crystallization synthetic reaction in a reaction kettle under a condition that the temperature is between 160 and 180 DEG C and the crystallization is performed for 48 to 70 hours to obtain a crystallization product; and filtering, washing and drying the crystallization product, then baking the crystallization product for 5 to 10 hours at 500 DEG C, and demoulding the baked crystallization product to obtain the high-silicon mordenite. The method has the characteristic of low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Dehydroxylation pretreatment of inorganic materials in mesopore introduction process

Mesoporous compositions and methods for preparing mesoporous and / or mesostructured materials from inorganic materials are provided. Various embodiments described herein relate to the preparation of mesoporous and / or mesostructured zeolites via a dehydroxylation pretreatment followed by a mesopore introduction step.

Owner:RIVE TECH

Method for preparing mordenite molecular sieve

ActiveCN102659134AEasy to synthesizeLower synthesis costNanotechnologyMordenite aluminosilicate zeoliteMolecular sieveCrystallinity

The invention relates to a method for preparing a mordenite molecular sieve. The method comprises the following steps of: dissolving an aluminum source in a sodium hydroxide solution, adding silicon sources, stirring at room temperature by strong magnetic force, and dispersing for a period of time; mixing the silicon sources which are dispersed uniformly and an aluminum source solution to form glue, adding a zeolite molecular sieve containing a five-membered ring as a crystal seed, stirring and mixing uniformly by the strong magnetic force at room temperature, and transferring the mixture into a reaction crystallization kettle, and performing crystallization reaction at the temperature of between 150 and 170 DEG C for 0.5 to 3 days; and performing suction filtration, washing and drying conventionally to obtain the mordenite molecular sieve. According to the method, an expensive organic amine template agent is not used as a structure guiding agent, and the zeolite molecular sieve which is wide in using, low in cost and readily available and contains the five-membered ring is used as the crystal seed to synthesize the mordenite molecular sieve with a high silica-alumina ratio directly, so the prepared mordenite molecular sieve has the advantages of high crystallinity and purity, controllable granular sizes and appearance, high yield, convenience for industrial production and the like.

Owner:EAST CHINA NORMAL UNIVERSITY

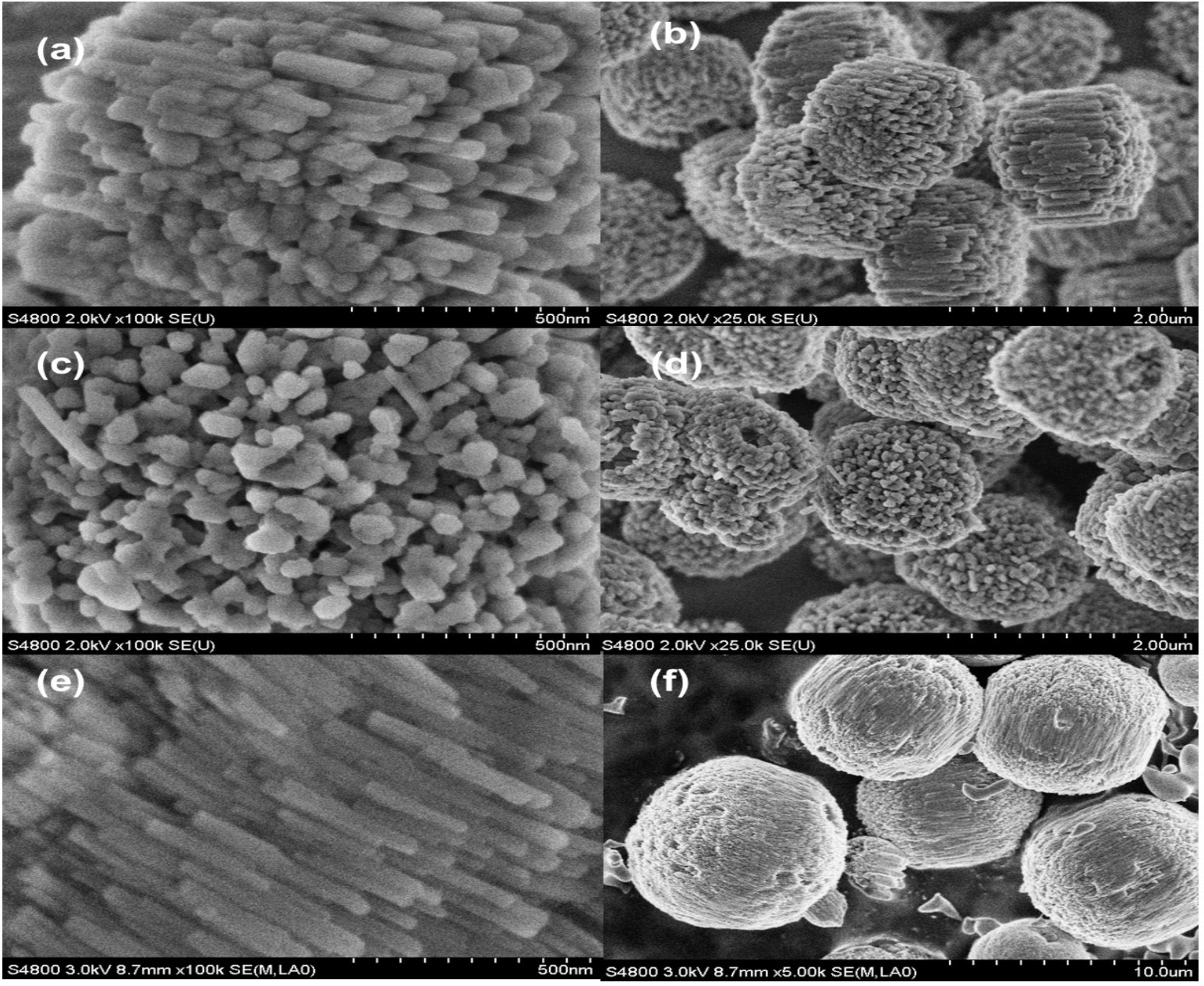

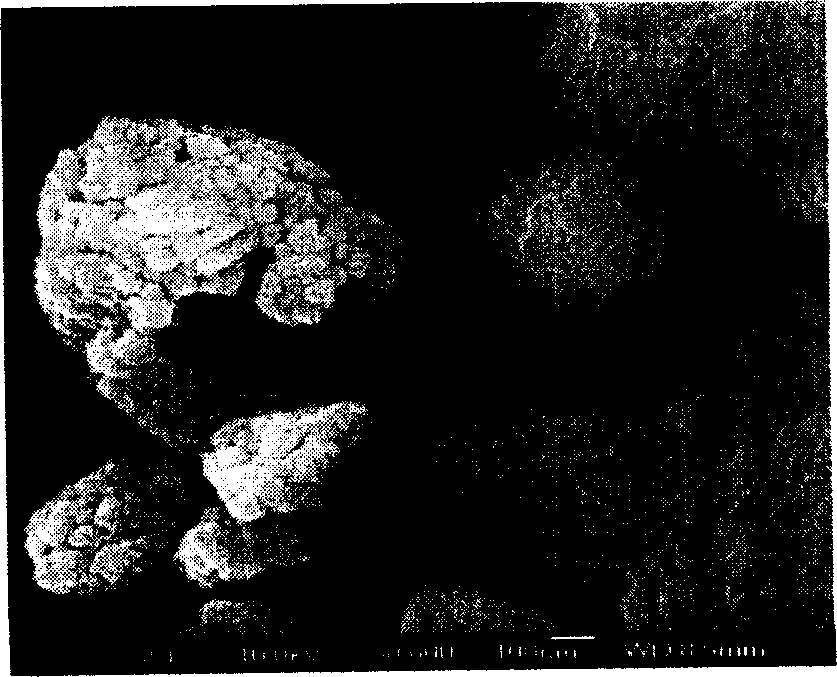

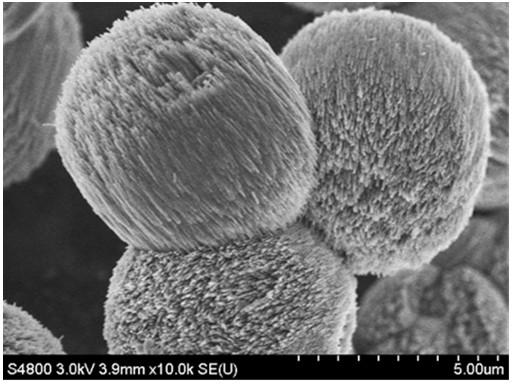

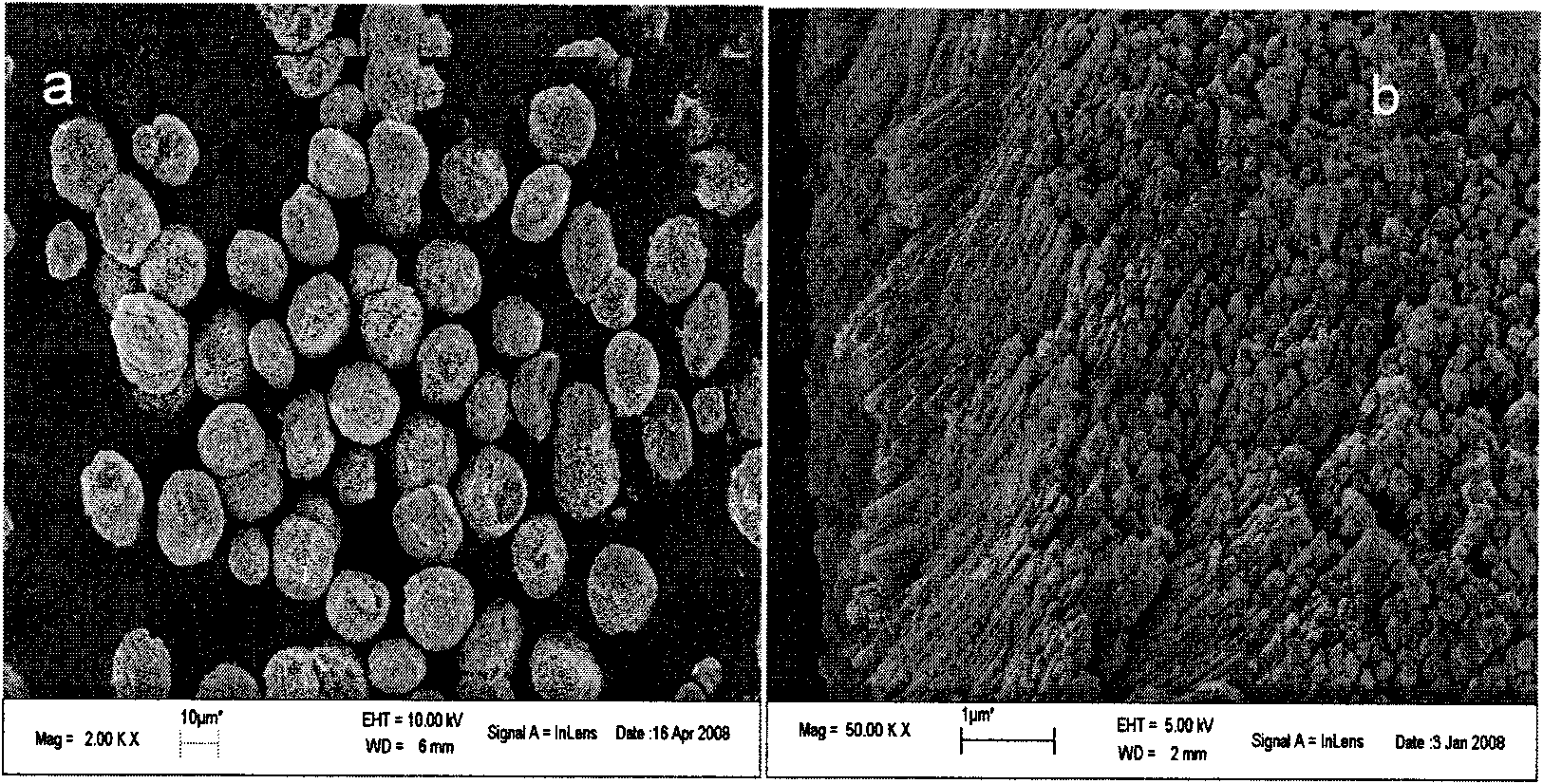

Mordenite and preparation method thereof

InactiveCN102060309AReduce or eliminate dislocationsReduce or eliminate lattice defectsCatalyst carriersHydrocarbon by isomerisationIsomerizationSilicon dioxide

The invention provides mordenite and a preparation method thereof. The mordenite has an ellipsoidal structural topography formed by stacking a plurality of strip zeolite crystals in the one-dimensional direction in order; and the method for preparing the mordenite with the special structural topography comprises that: a solid silicon-aluminum source raw material is subjected to two-stage crystallization reaction in an extremely thick system, the molar ratio of water to silicon dioxide in the crystallization system is 1-7, the structural topography of the obtained mordenite is obviously difference from that of the conventional product by optimizing and controlling synthesis process and condition parameters, and mesopores and macropores are introduced into the mordenite structure to contribute to solving the problems of dislocation and surface defects of the mordenite structure and better contribute to improving the catalytic performance in xylene isomerization reaction. The invention also provides application of the mordenite with the special structural topography to catalysis in the xylene isomerization reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for synthesizing high-silicon mordenite in the absence of amine

InactiveCN1843915AIncrease productionLow priceMordenite aluminosilicate zeoliteMordenitePolytetrafluoroethylene

The invention discloses a method for preparing high silica mordenite without amine. The method employs silicon, alumina and deionized water as raw amaterial, and employs polyatomic alcohol as addictive; proceeds thermal crystallization in steeless autoclave interlined with politef, the crystallization temperature is 120-200 Deg. C and time is 12-240 hours; sucts, washes and dried the mixture got after crystallization and gets high silia mordenite with molar proportion of SiO2 / Al2O3 is 15-30:1. The invention employs pentaerythrite which is cheap, abundant and environment-friendly to replace the organic amine which is dear and environment-pollutant, and uses no inorganic acid or alkali corrosive to device. The pentaerythrite is helpful for generation of high silica mordenite and for reducing crystallization time. The invention is characterized by low production cost, high output, simple process and environment-friendly.

Owner:ZHEJIANG UNIV

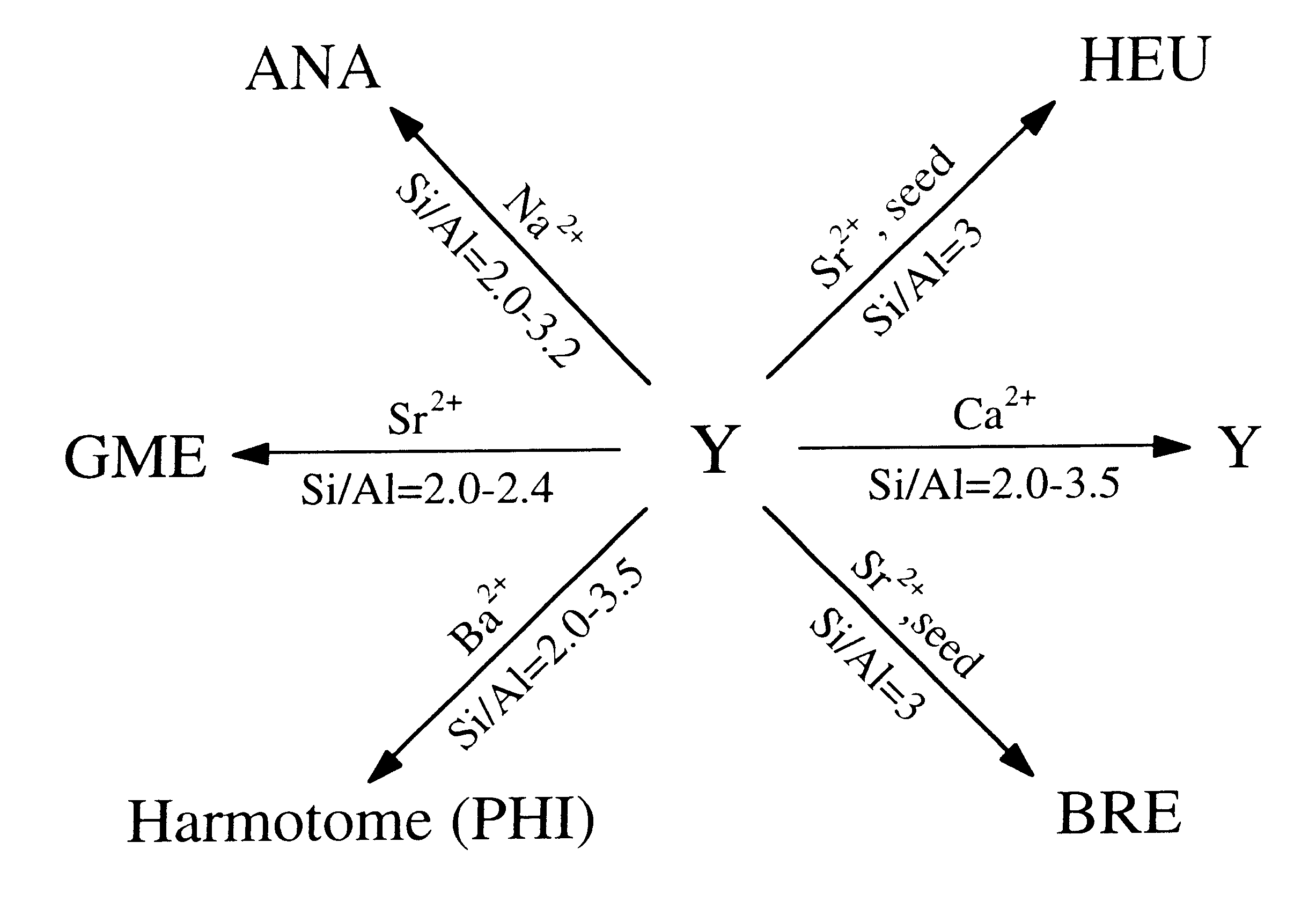

Hydrothermal conversion of Y-zeolite using alkaline earth cations

InactiveUS6436364B1Shorten the timeAluminium compoundsPhilipsite/harmotome aluminosilicate zeoliteBrewsteriteAlkaline earth metal

Hydrothermal synthesis of the natural, alkaline earth zeolites via the alteration of Y-zeolite is presented. Synthetic versions of the zeolites harmotome, heulandite, brewsterite and gmelinite are synthesized from Y-zeolite using alkaline earth cations containing solutions. The effect of the composition of the starting zeolite, the composition of the solution phase, the presence or absence of seeds and the experimental conditions are discussed.

Owner:CALIFORNIA INST OF TECH

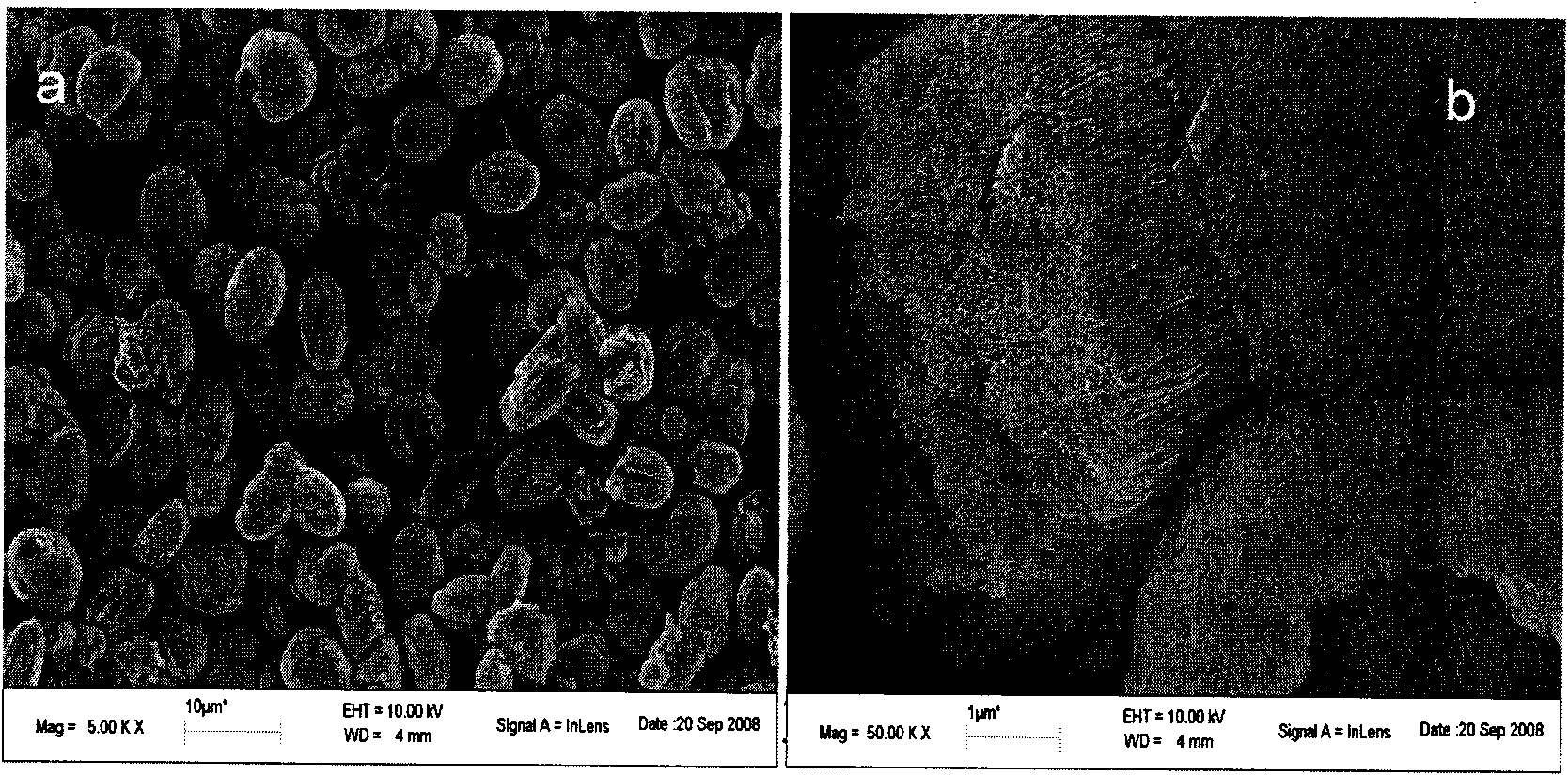

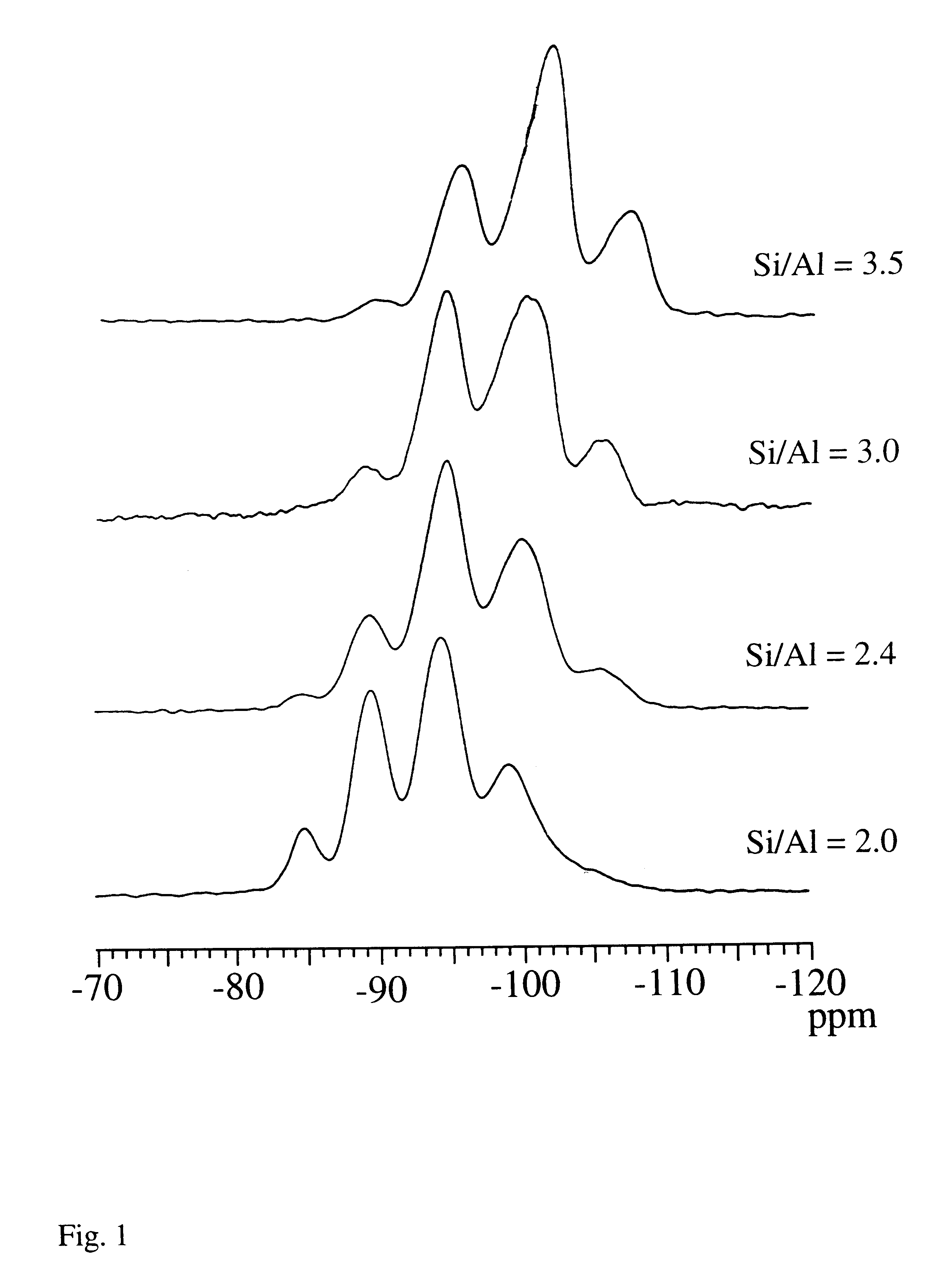

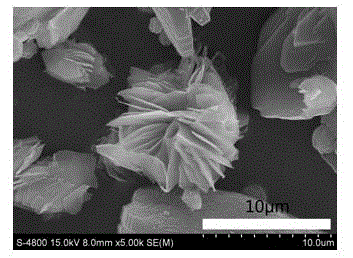

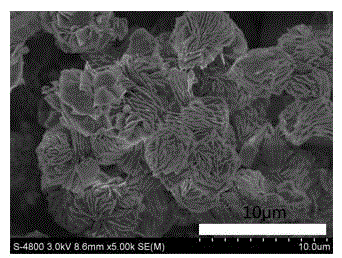

Preparation method for low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve

InactiveCN103601213AWide variety of sourcesReduce the ratio of silicon to aluminumMaterial nanotechnologyMordenite aluminosilicate zeoliteIsomerizationReaction rate

The invention discloses a preparation method for a low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve. The preparation process of the mordenite molecular sieve includes: dissolving an aluminum source and an alkali source in deionized water, adding silica sol into the obtained clarified solution to obtain a uniform white colloid, transferring the white colloid into a reaction kettle to undergo hydrothermal reaction, thus obtaining the low silicon-aluminum ratio nanosheet flower cluster-like mordenite molecular sieve. The mordenite molecular sieve prepared by the invention has the advantages of wide silicon source and aluminum source, low silicon-aluminum ratio, multiple active centers, no adding of any surfactant, low preparation cost, less environmental pollution and large specific surface area, and is conducive to spread of the reactants and product and acceleration of the reaction rate, thus being widely applicable in adsorption, separation, catalytic cracking, isomerization and other fields.

Owner:TIANJIN UNIV

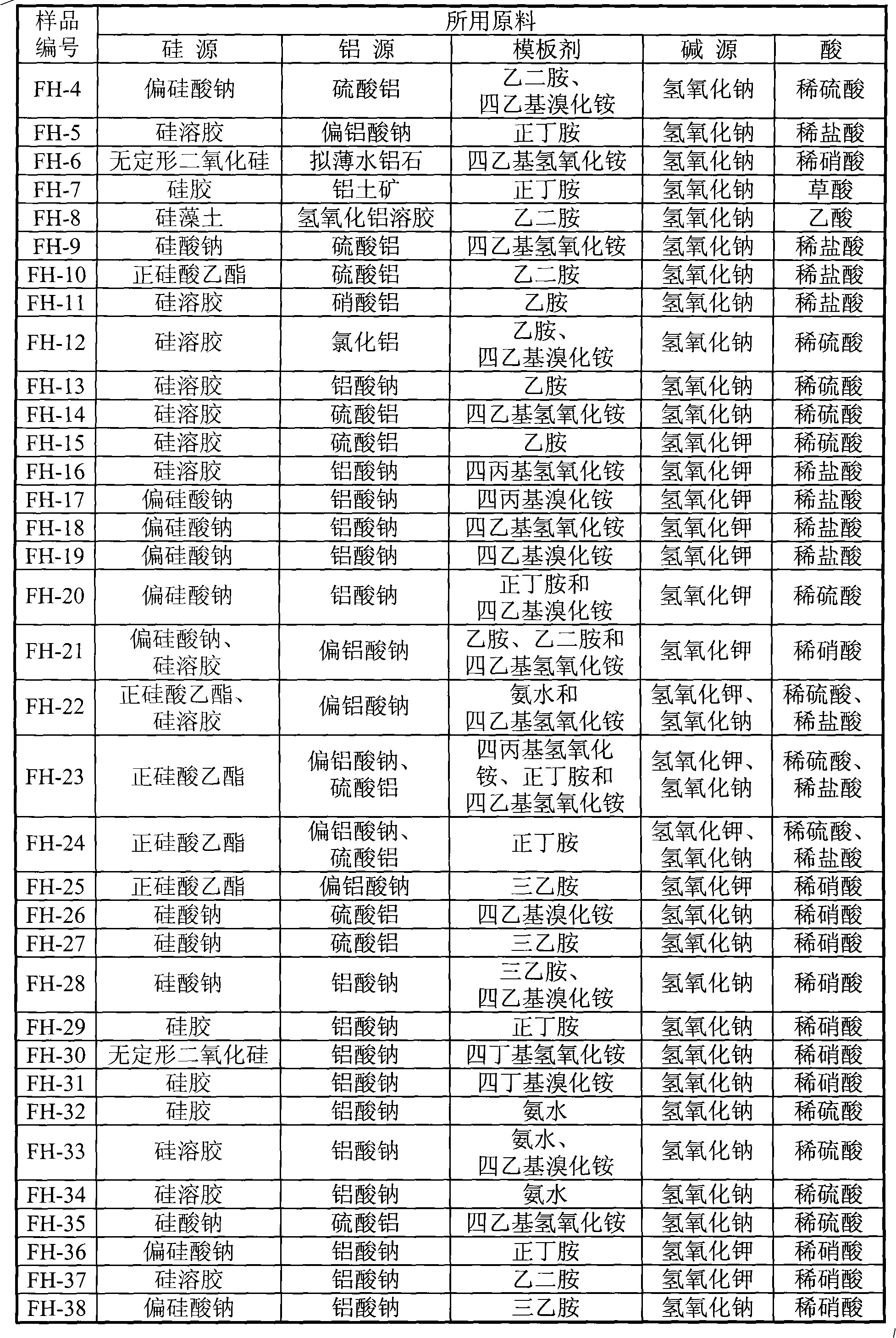

Synthesis method for zeolite

InactiveCN101033071AHigh yieldAvoid lostMordenite aluminosilicate zeoliteSynthesis methodsCombinatorial chemistry

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com