Method for synthesizing flokite

A synthesis method and technology of mordenite, applied in the direction of mercerized crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of mordenite failure, crystallinity reduction, etc., and achieve the effect of improving conversion rate and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032](1) Weigh 40 g of raw corn starch (commercially available), add 400 g of distilled water, stir until it dissolves, and then gelatinize at 100°C for 18 hours to obtain gelatinized starch.

[0033] (2) Mix 122g of water and 16g of sodium hydroxide (purity 96%), stir and dissolve; then add SiO 2 Content is 28% silica sol (commercially available commodity) 93g, 7.6g NaY (commercially available commodity or synthesized with reference to open literature), stir respectively 20min and make it mix homogeneously, obtain initial gel mixture, wherein the ratio between each raw material ( According to the molar ratio of oxide molecules, the following are the same):

[0034] SiO 2 / Al 2 o 3 = 53,

[0035] Na 2 O / SiO 2 =0.43,

[0036] h 2 O / SiO 2 = 24;

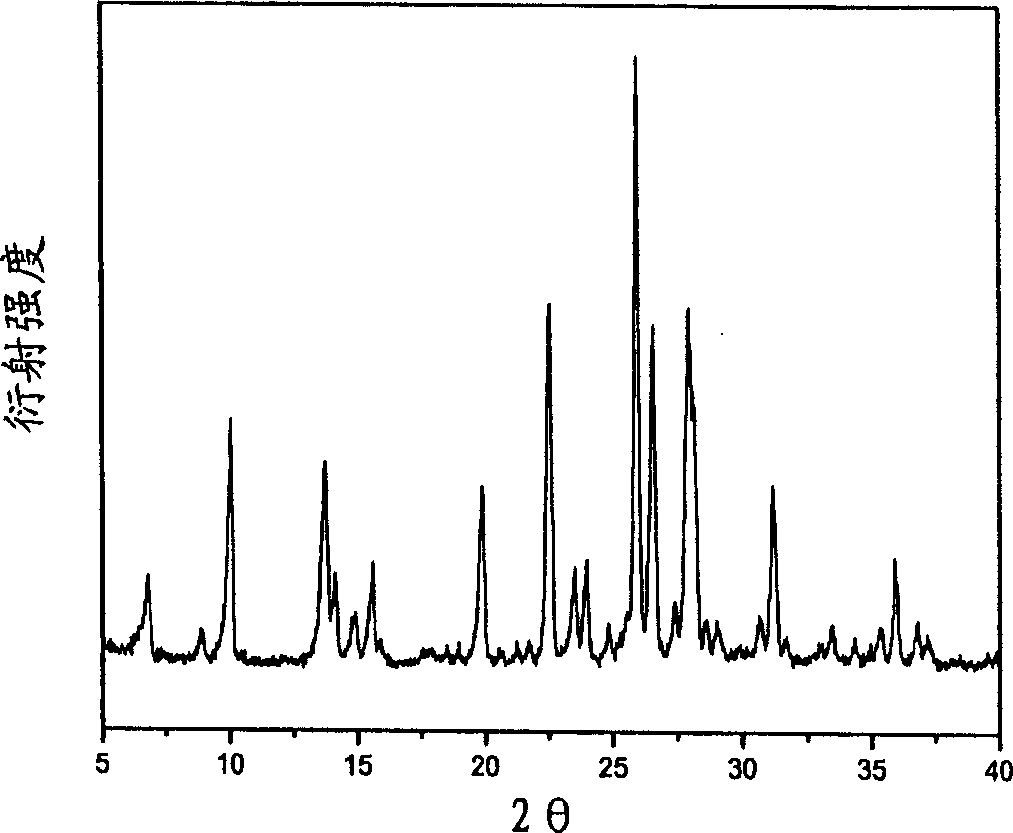

[0037] (3) Add the gelatinized starch (1) into the gel (2), stir for 20 minutes, transfer it to a pressure-resistant reactor and crystallize at 160° C. for 72 hours. After the crystallization was completed, the pressure-resi...

Embodiment 2

[0040] (1) Weigh 40g of quaternary ammonium cationic starch (commercially available, degree of substitution = 0.02), add 400g of distilled water and 0.8g of sodium hydroxide (purity 96%), stir until it dissolves, and then gelatinize in an oil bath at 100°C 3h to get gelatinized starch.

[0041] (2) Weigh 122g of water, 16g of sodium hydroxide (purity 96%), stir and dissolve; then add SiO 2 93g of silica sol (commercially available) with a content of 28% and 7.6g of dried conventional NaY (commercially available or synthesized with reference to open literature) were stirred for 20 min to make them evenly mixed to obtain the initial gel mixture, wherein each raw material The ratio between (according to the oxide molecular ratio) is:

[0042] SiO 2 / Al 2 o 3 = 53,

[0043] Na 2 O / SiO 2 =0.43,

[0044] h 2 O / SiO 2 = 24;

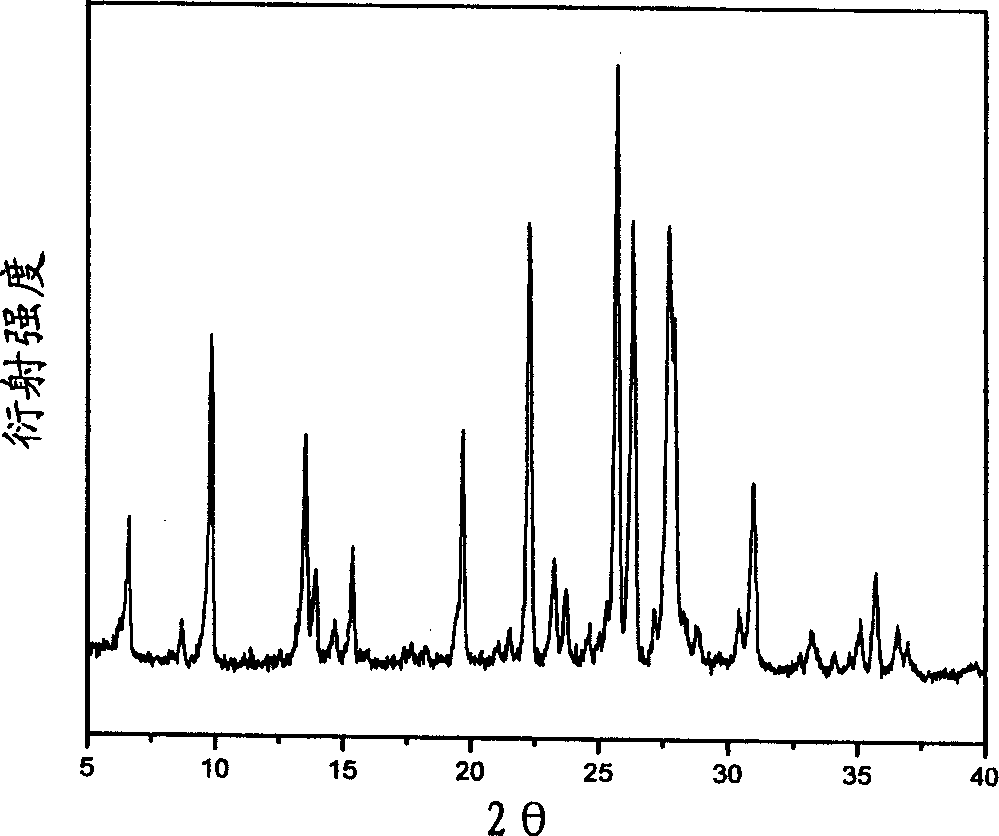

[0045] (3) Add the gelatinized starch (1) into the gel (2), stir for 20 minutes, transfer it to a pressure-resistant reactor and crystallize at 160°C ...

Embodiment 3

[0048] (1) Weigh 40 g of quaternary ammonium cationic starch (commercially available, substitution degree = 0.02), add 400 g of distilled water, stir until it dissolves, and then gelatinize at 100° C. for 18 hours to obtain gelatinized starch.

[0049] (2) Mix 271.5g of water and 27.5g of sodium hydroxide (purity 96%), stir and dissolve; then add SiO 2 214.3g, 1.56g Al(OH) of silica sol (commercially available) with a content of 28% 3 , respectively stirred for 20min to make it evenly mixed to obtain the initial gel mixture, wherein the ratio between the raw materials (by oxide molecular ratio) is:

[0050] SiO 2 / Al 2 o 3 =100,

[0051] Na 2 O / SiO 2 =0.33,

[0052] h 2 O / SiO 2 = 24;

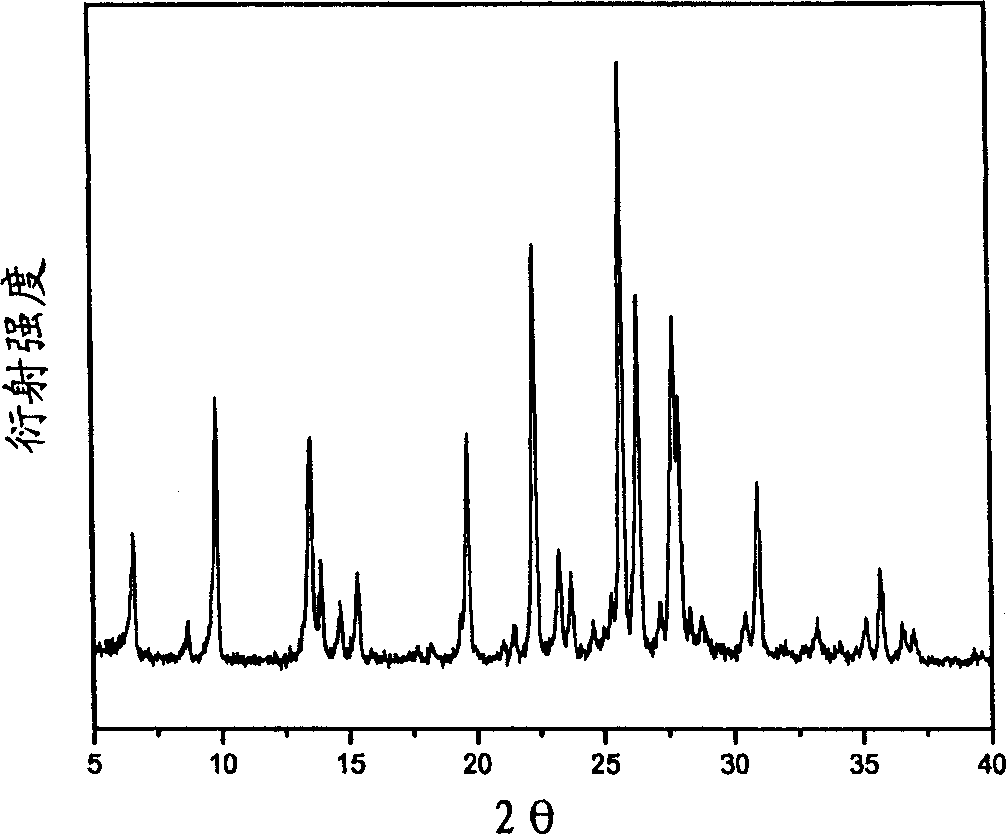

[0053] (3) Add the gelatinized starch (1) into the gel (2), stir for 20 minutes, add sulfuric acid to adjust the pH value to 12.0, transfer it to a pressure-resistant reactor, stir and crystallize at 180°C for 48 hours. After the crystallization was completed, the pressure-resistant r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com