Mordenite and preparation method thereof

A technology of mordenite and zeolite, which is applied in the direction of mordenite crystalline aluminosilicate zeolite, chemical instruments and methods, crystalline aluminosilicate zeolite, etc., can solve the problem of little research on mordenite grain morphology, harsh synthesis conditions, and unfavorable environment Protection and other issues, to achieve the effect of eliminating dislocations and lattice defects, high selectivity of isomerization activity, and improving catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

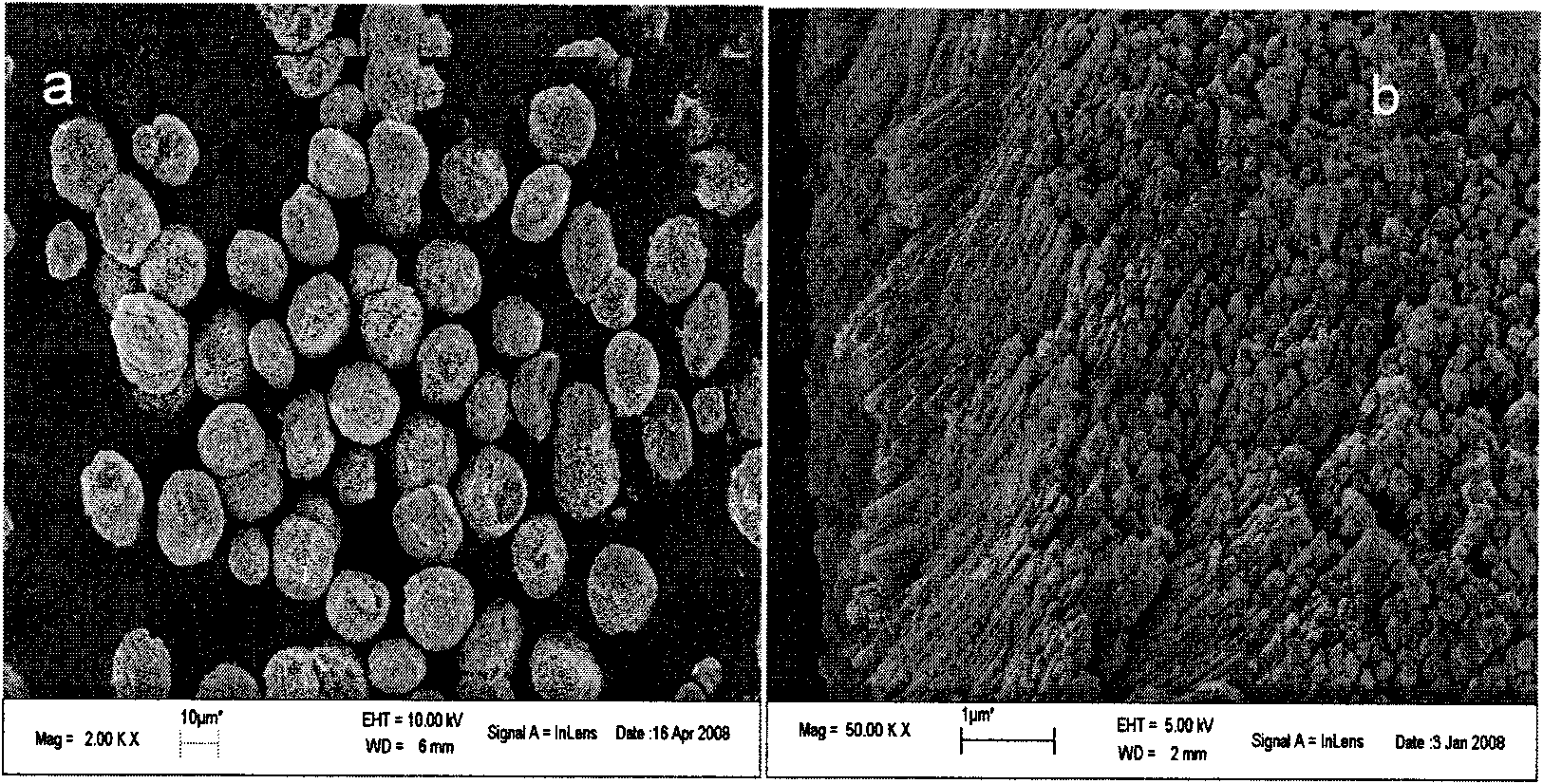

Embodiment 1

[0050] First, 0.5g of sodium hydroxide (96%) was added to a certain amount of deionized water and mixed uniformly to obtain a sodium hydroxide solution, to which 5g of silica-alumina microspheres (commercially purchased) were added, stirred for 2 hours and mixed uniformly to obtain an initial gel Glue mixture, which is placed in a closed reaction kettle to prepare for crystallization, the molar composition of the crystallization reaction system is:

[0051] Na 2 O: SiO 2 : Al 2 o 3 :H 2 O=1.3:10:1:67

[0052] The crystallization reaction material is self-pressurized and crystallized in a closed reaction kettle. First, the first-stage crystallization reaction is carried out at a controlled temperature of 80°C. Crystallization takes 8 hours to form zeolite microcrystals, and then the temperature is raised to 180°C to continue crystallization for 24 hours. After the reaction, the product was filtered, washed, dried, and calcined at 550° C. for 5 hours in an air atmosphere to...

Embodiment 2

[0060] At first the sodium hydroxide (96%) of 0.65g is joined into a certain amount of deionized water and mixed uniformly to form a sodium hydroxide solution, add 5g of silica-alumina microspheres, stir for 2 hours, then add 1.5g of white carbon black, Continue to stir evenly to form an initial gel mixture, and place it in a closed reaction kettle for crystallization: carry out the first stage of crystallization at 90°C, crystallize for 6 hours to form zeolite microcrystals, and then heat up to 170°C for crystallization for 48 hours . The molar composition of this crystallization reaction system is:

[0061] Na 2 O: SiO 2 :Al 2 o 3 :H 2 O=0.85:20:1:67

[0062] After the reaction, the product was filtered, washed, dried, and calcined to obtain a mordenite molecular sieve sample 2 with a special structure and morphology of high silicon. The morphology of the sample was similar to Example 1.

[0063] Catalytic reaction results: ethylbenzene conversion rate 20%, p-xylene ...

Embodiment 3

[0065] First, 0.6g of sodium hydroxide (96%) is added to a certain amount of deionized water and mixed uniformly to form a sodium hydroxide solution, and 5g of silicon-aluminum microspheres are added, stirred evenly and then placed in a closed reaction kettle for crystallization. The molar composition of this crystallization reaction system is:

[0066] Na 2 O: SiO 2 : Al 2 o 3 :H 2 O=1.6:10:1:65

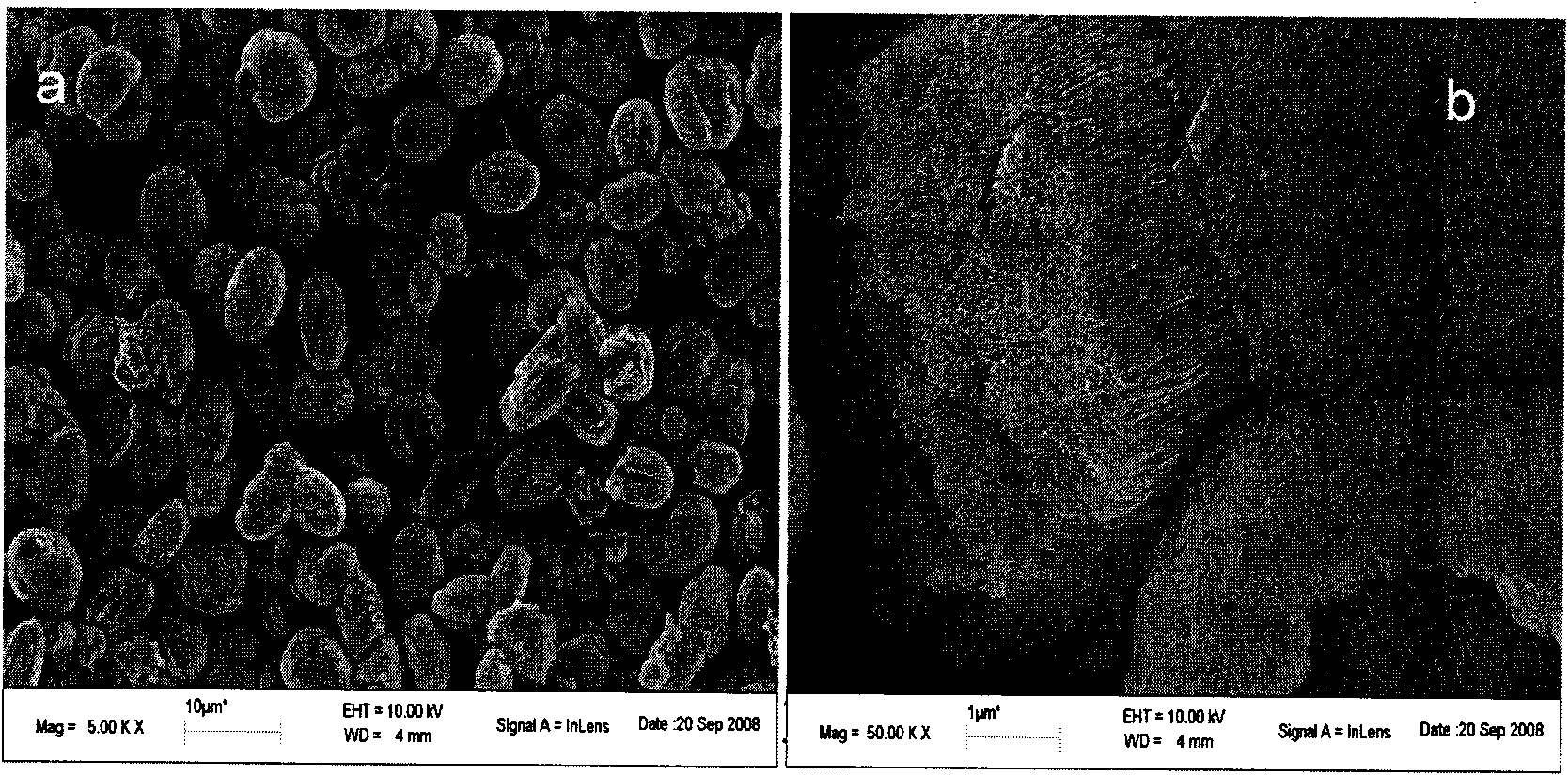

[0067] After crystallization at 60° C. for 10 hours, after cooling, 2.10 g of tetrapropylammonium bromide (TPABr) was added and stirred evenly, and then the temperature was raised to 200° C. for crystallization for 24 hours. After the reaction, the product was filtered, washed, and dried to obtain a mordenite molecular sieve sample 3 with a special structure and morphology with a grain size of about 5-7 μm. See details image 3 . Such as image 3 The SEM photo shows that this sample 3 is a uniform ellipsoid grain (a), in which each small grain is formed by many strip crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com