Method for preparing high-silicon mordenite by using raw mineral material

A technology of mordenite and mineral raw materials, applied in the direction of mercerized crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve problems such as equipment corrosion, catalysts cannot be recycled, separation difficulties, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Utilize mineral raw material to prepare the method for high silicon mordenite, it comprises the steps:

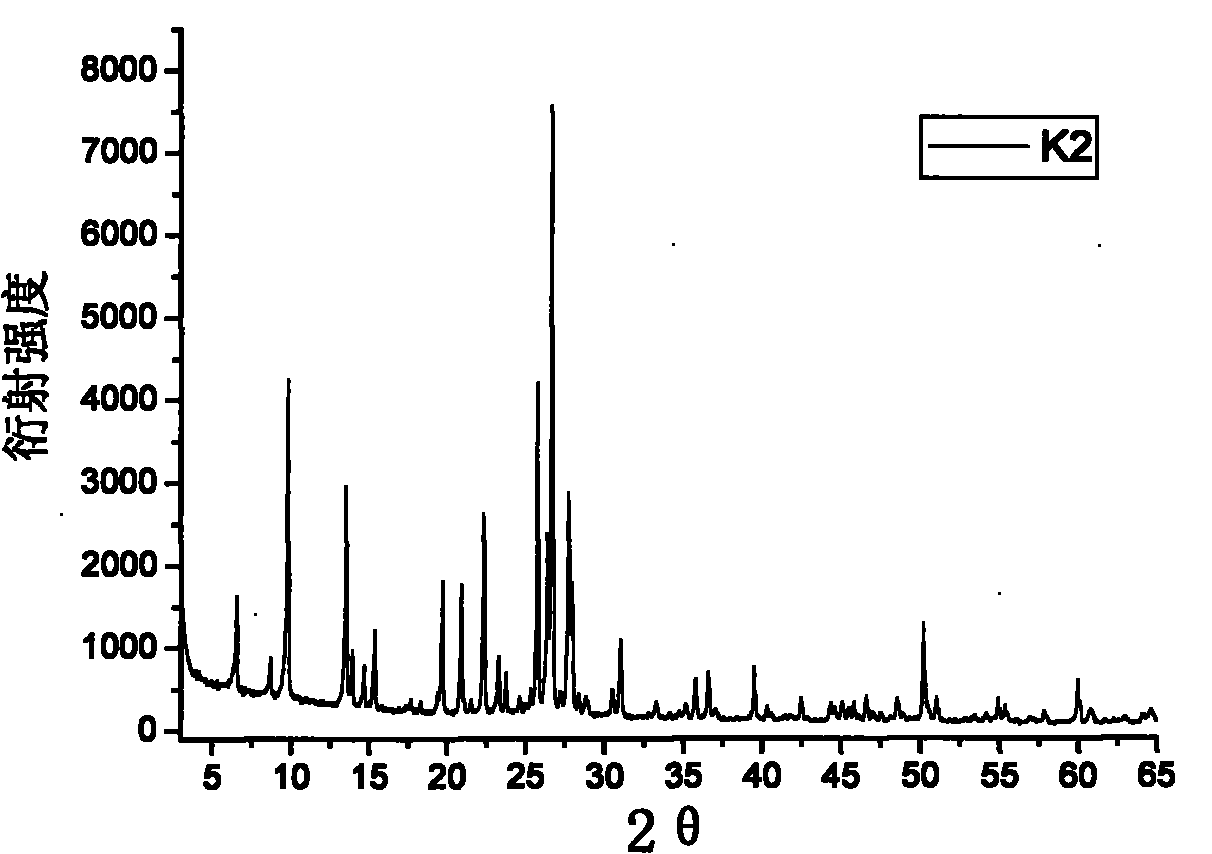

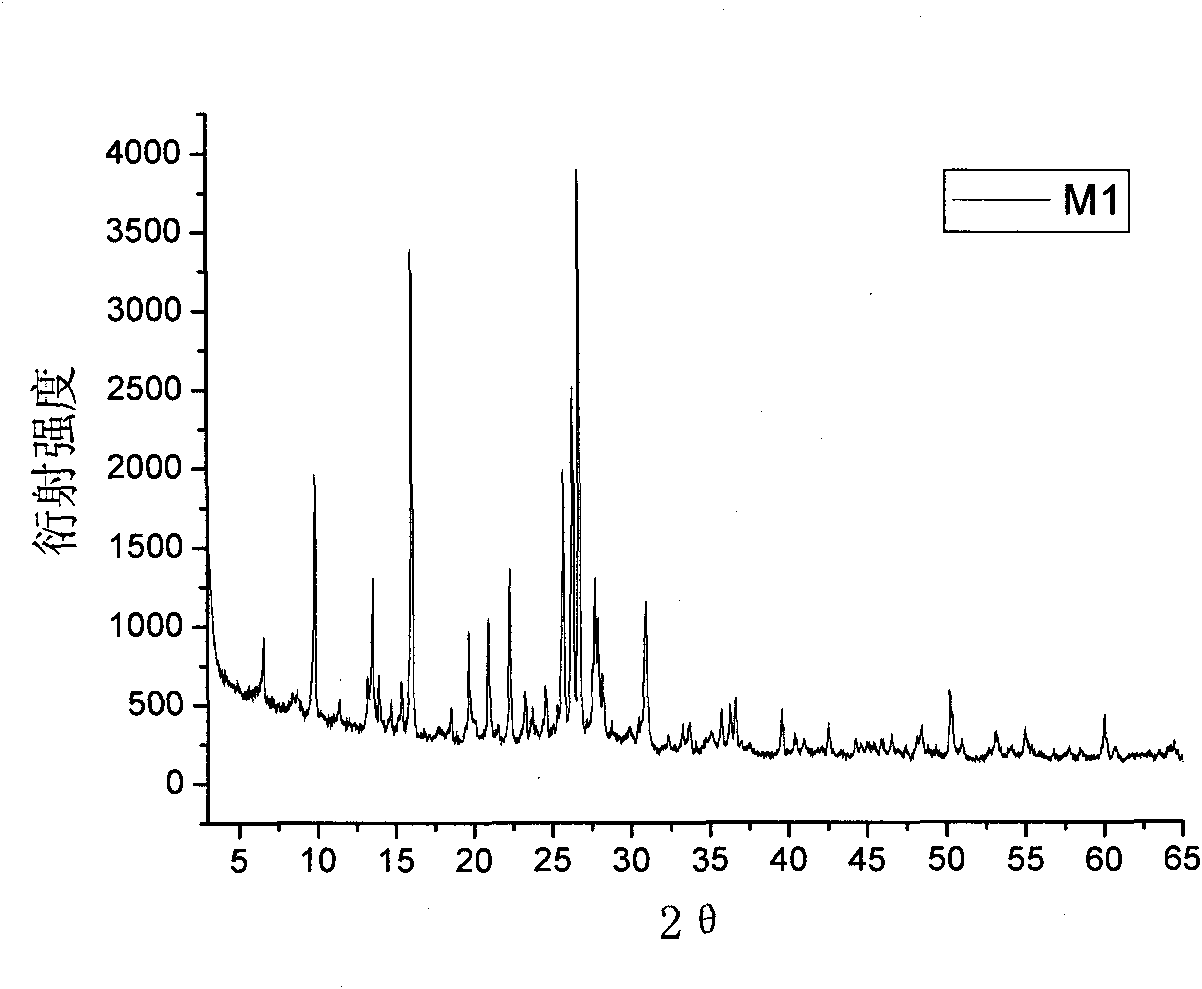

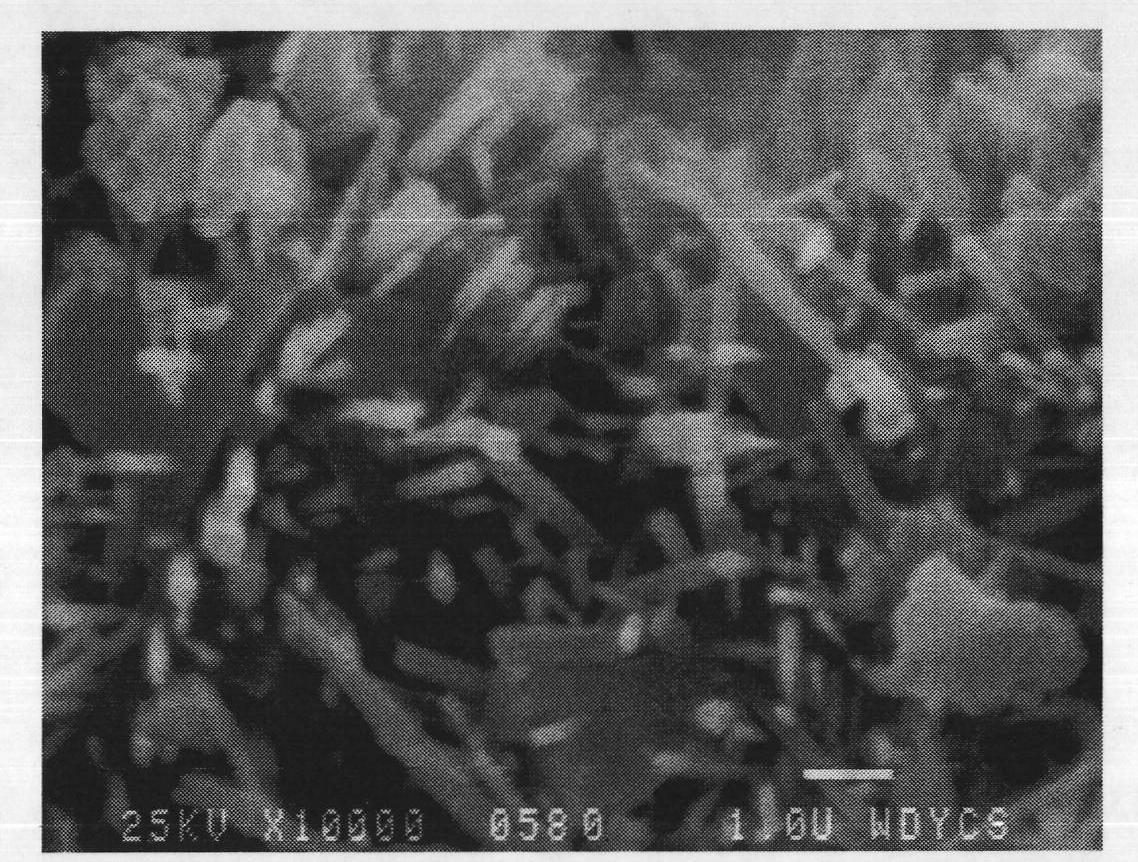

[0029] Dissolve 4.93g of ammonium fluoride in 70mL of water, add 5g of kaolin, 5g of activated silica powder, 23.67g of sodium metasilicate nonahydrate and 10mL of 4mol / L sodium hydroxide solution, stir and dissolve at 70°C; then Add SiO 2 Content 31% silica sol 49.2mL and 17mL tetraethylammonium hydroxide solution (content 25wt%), stir respectively 30min to make it mix homogeneously [in this embodiment: the SiO of silicon source 2 : Al of aluminum source 2 o 3 : inorganic base: fluoride: templating agent: the mol ratio of water=25: 1: 2.2: 7.4: 1.6: 402], obtain initial gel mixture; Initial gel mixture is adjusted pH value to 12.5 with sodium hydroxide and hydrochloric acid, It was transferred to a pressure-resistant reactor for static crystallization at 180°C for 60h. After the crystallization was completed, the reactor was naturally cooled to room temperature....

Embodiment 2

[0031] Dissolve 6.13g of ammonium fluoride in 60mL of water, add 5g of kaolin, 23.6g of sodium metasilicate nonahydrate and 8mL of 4mol / L sodium hydroxide solution, stir and dissolve at 70°C; then add SiO 2Content 31% silica sol 74mL and 17mL tetraethylammonium hydroxide solution, stir respectively 30min to make it mix homogeneously [in this embodiment: the SiO of silicon source 2 : Al of aluminum source 2 o 3 : inorganic base: fluoride: template agent: the molar ratio of water=27: 1: 2: 9.2: 1.6: 435] to obtain the initial gel mixture. The pH value was adjusted to 12 with sodium hydroxide and hydrochloric acid, and transferred to a pressure-resistant reactor for static crystallization at 180° C. for 60 h. After the crystallization was completed, the reactor was naturally cooled to room temperature. The product is filtered, washed until the pH value is 8, and dried to obtain the original powder of mordenite. Put the raw mordenite powder into a muffle furnace and roast at a...

Embodiment 3

[0033] Dissolve 5g of ammonium fluoride in 30mL of water, add 5g of coal gangue, 47.3g of sodium metasilicate nonahydrate and 10mL of 3mol / L sodium hydroxide solution, stir and dissolve at 70°C; then add SiO 2 Content 31% silica sol 50mL and 17mL tetraethylammonium hydroxide solution, stir respectively 30min to make it mix homogeneously [in this embodiment: the SiO of silicon source 2 : Al of aluminum source 2 o 3 : inorganic base: fluoride: template agent: the molar ratio of water=33:1:2.1:9.6:2.1:415], get initial gel mixture; Initial gel mixture is adjusted pH value to with sodium hydroxide and hydrochloric acid 12.5, transfer it to a pressure-resistant reactor for static crystallization at 180°C for 60h. After the crystallization was completed, the reactor was naturally cooled to room temperature. The product is filtered, washed until the pH value is 8, and dried to obtain the original powder of mordenite. Put the raw mordenite powder into a muffle furnace and roast at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com