Preparation method for mordenite with high Si/Al ratio and small crystal particle

A technology of mordenite and high silicon-aluminum ratio, which is applied in the direction of crystalline aluminosilicate zeolite, mercerized crystalline aluminosilicate zeolite, nanotechnology, etc., can solve the problem of large synthetic particle size, etc., and achieve reduced synthesis cost and excellent catalytic performance , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add 9.50 g of NaOH to 190 ml of deionized water, stir until a clear solution, add 4.8 g of sodium metaaluminate to the above solution, and continue stirring at room temperature until all the solids are dissolved. Add 29.1 g of fuming silica gel to the above mixed solution, continue strong magnetic stirring for 1 hour, then add 1.7 g of layered FER zeolite molecular sieves into the reaction system as a seed crystal, continue stirring for 0.5 hours after the addition, and finally put the mixture into Put it into a polytetrafluoroethylene-lined stainless steel crystallization kettle, seal it and crystallize in an oven at 170°C for 24 hours, and obtain a solid product after conventional suction filtration, washing, and drying; the molar composition of the initial sol of the mixture is: SiO 2 :Al 2 o 3 =20, Na 2 O: SiO 2 =0.25,H 2 O: SiO 2 =45.

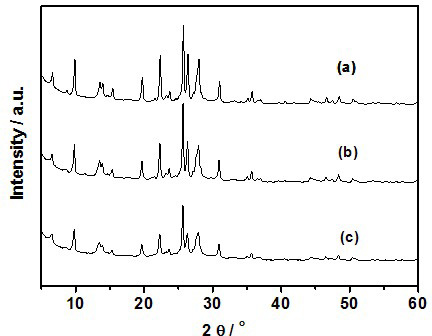

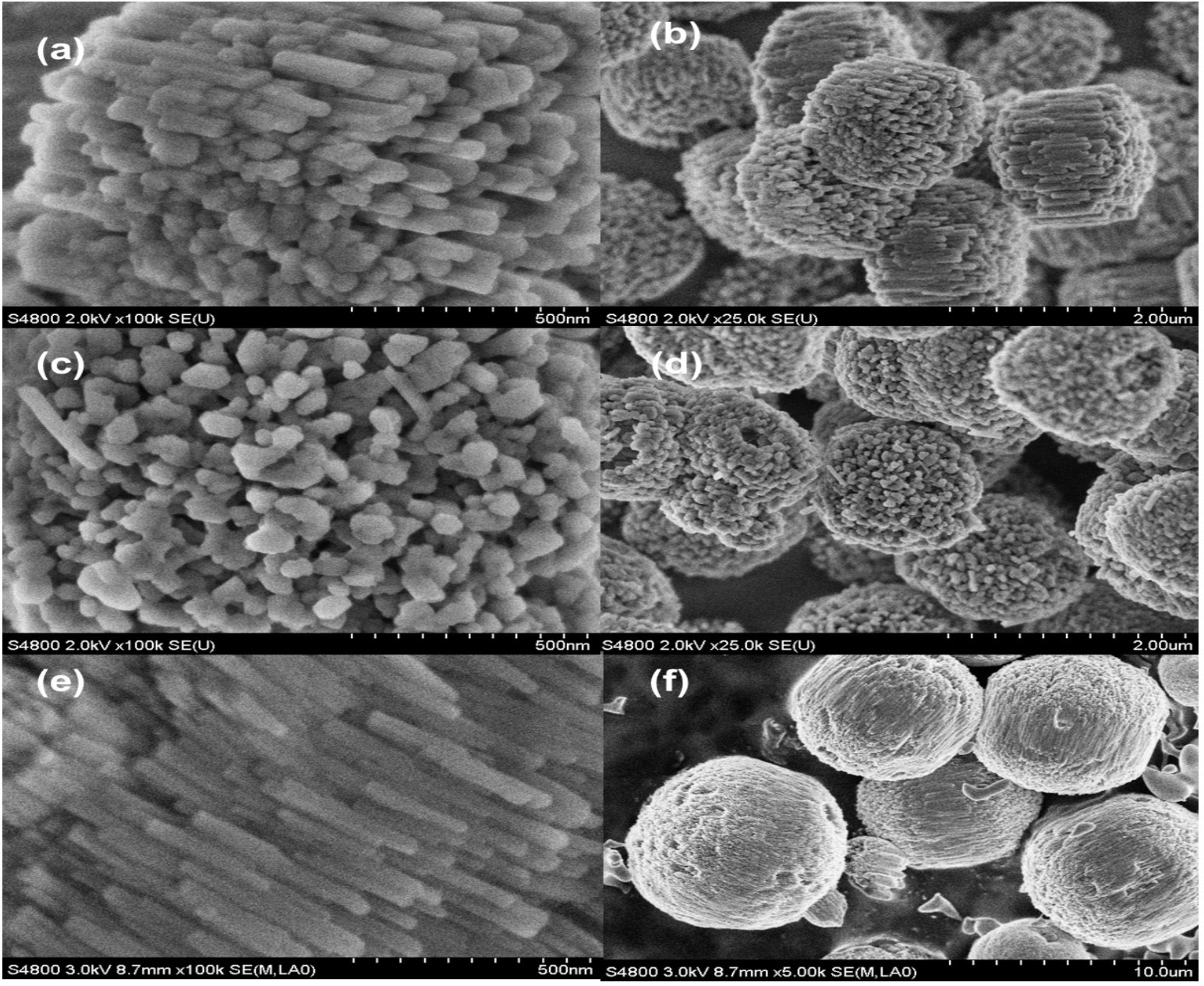

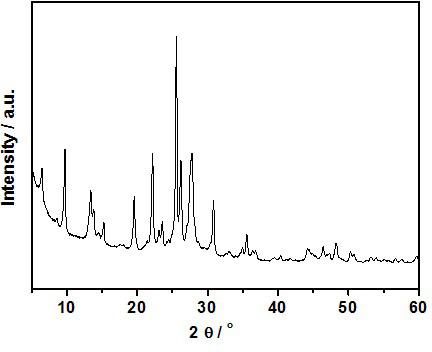

[0025]The solid product is analyzed as mordenite by X-ray, and its SiO 2 :Al 2 o 3 The molar ratio is 15.0, and the fin...

Embodiment 2

[0027] Except that decasil layered silicate (Octosilicate) was used instead of layered FER zeolite molecular sieve in Example 1 as the seed crystal, other preparation conditions were the same as in Example 1.

[0028] The solid product is analyzed as mordenite by X-ray, and its SiO 2 :Al 2 o 3 The molar ratio is 13.5, and the final 1 μm spherical particles are composed of spherical nanocrystals with particle sizes ranging from 50 to 100 nm. The results of X-ray diffraction and SEM characterization are as follows: figure 1 b and figure 2 c / d.

Embodiment 3

[0030] Except that the layered mesoporous molecular sieve MCM-50 was used as the seed crystal instead of the layered FER zeolite molecular sieve in Example 1, other preparation conditions were the same as in Example 1.

[0031] The solid product is analyzed as mordenite by X-ray, and its SiO 2 :Al 2 o 3 The molar ratio is 11.0, and the final 5 μm spherical particles are composed of needle-like nanocrystals with particle sizes ranging from 300 to 600 nm. The results of X-ray diffraction and SEM characterization are as follows: figure 1 c and figure 2 e / f.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com