Preparation method of mesoporous mordenite

A mordenite and mesoporous technology, which is applied in the synthesis field of high-purity mesoporous mordenite molecular sieves, to achieve the effect of shortening the crystallization time and facilitating the growth of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 9.50 g of NaOH to 190 ml of deionized water, stir until a clear solution, add 4.8 g of sodium metaaluminate to the above solution, and continue stirring at room temperature until all the solids are dissolved. Add 29.1 g of fuming silica gel to the above mixed solution, continue strong magnetic stirring for 1 hour, then mix 1.7 g of dealuminated mordenite molecular sieve (SiO 2 :Al 2 o 3 = 80) into the reaction system as a seed crystal, and continued to stir for 0.5 hours after the addition, and finally put the mixture into a polytetrafluoroethylene-lined stainless steel crystallization kettle, sealed it and crystallized it in an oven at 170 °C for 24 hours. The solid product was obtained after conventional suction filtration, washing and drying. The molar composition of the initial sol of the mixture is: SiO 2 :Al 2 o 3 =20, Na 2 O: SiO 2 =0.25,H 2 O: SiO 2 =45.

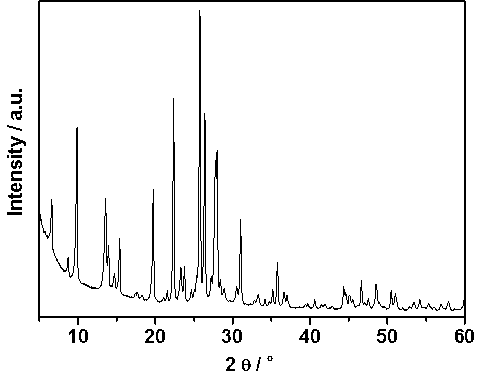

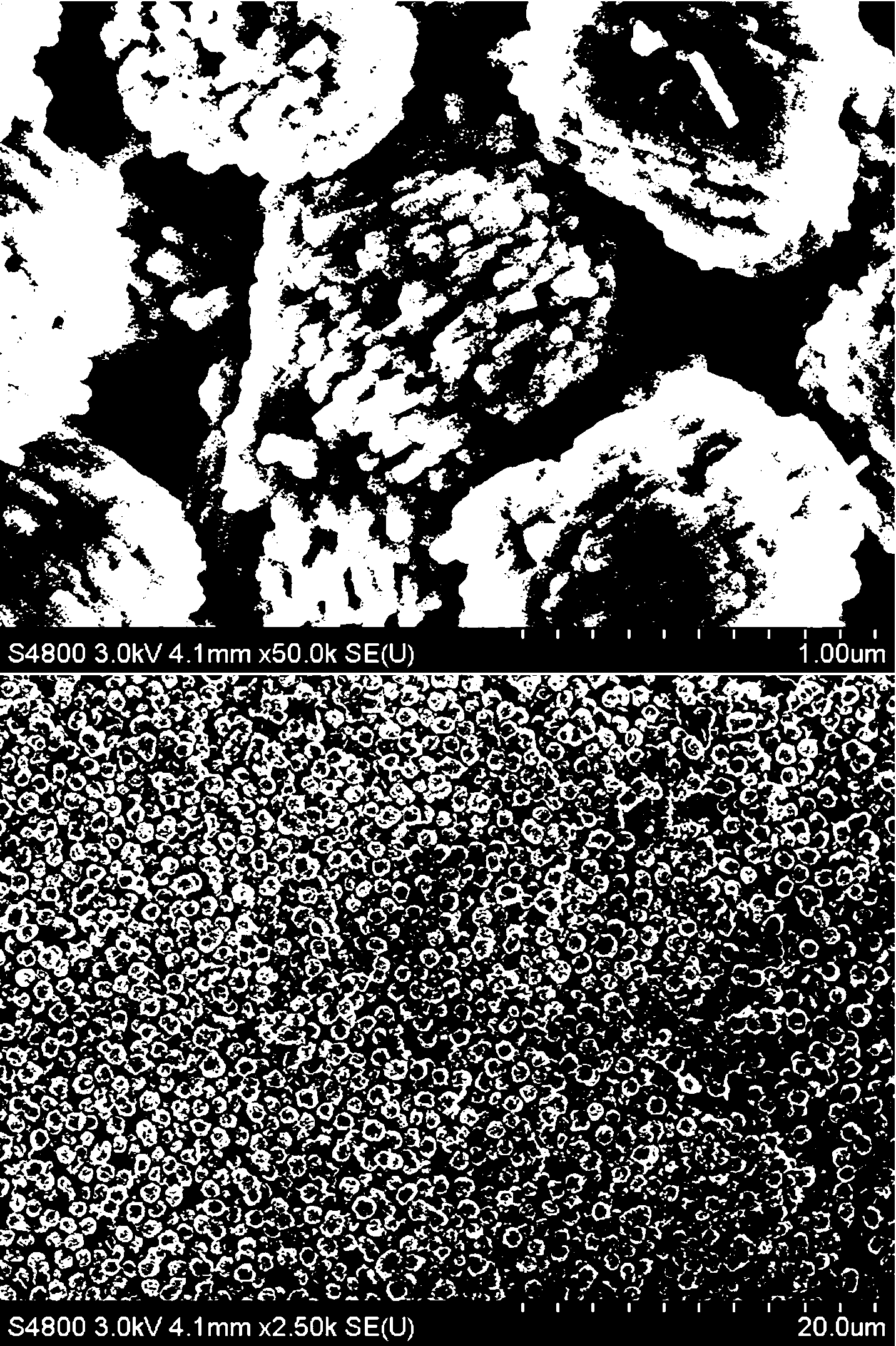

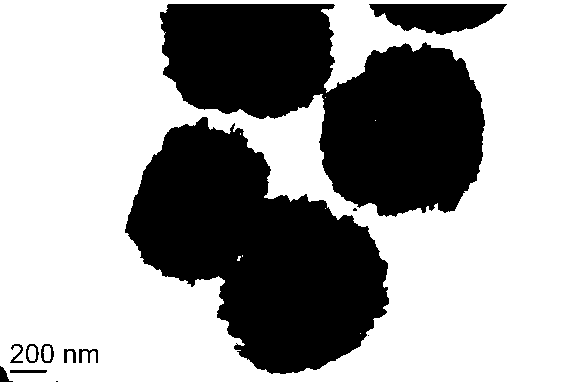

[0024] The solid product is analyzed as mordenite by X-ray, and its SiO 2 :Al 2 o 3 The ...

Embodiment 2

[0026] SiO 2 : Al 2 o 3 The dealuminated mordenite with a mol ratio of 40.0 replaces SiO in Example 1 2 : Al 2 o 3 Except that dealuminated mordenite with a molar ratio of 80.0 was used as the seed crystal, other preparation conditions were the same as in Example 1, and the specific surface area of mordenite was 419 m 2 / g, pore volume 0.32 ml / g, mesopore volume 0.20 ml / g.

Embodiment 3

[0028] Except that aluminum nitrate was used instead of sodium metaaluminate in Example 1 as the aluminum source, other preparation conditions were the same as in Example 1, and a high-purity mordenite molecular sieve with abundant mesoporous pores was obtained, with a specific surface area of 410 m 2 / g, pore volume 0.31 ml / g, mesopore volume 0.21 ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com