Synthesis method of high-activity TiO2 nanodisk photocatalyst

A technology of photocatalyst and synthesis method, applied in chemical instruments and methods, physical/chemical process catalyst, chemical/physical process, etc., to achieve the effects of high photocatalytic activity, simple and easy preparation process, and high-efficiency photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

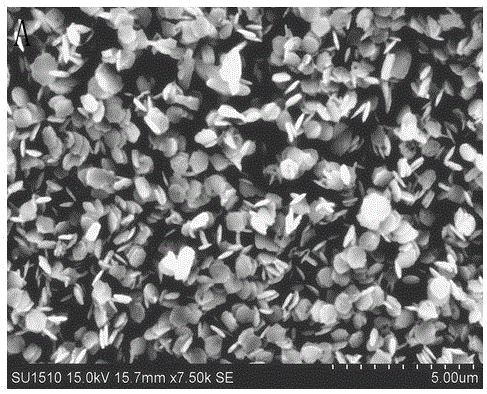

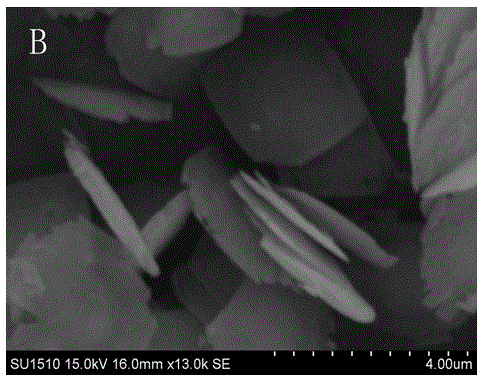

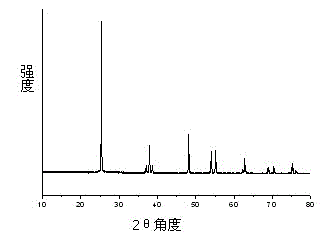

Image

Examples

Embodiment 1

[0030] Take 6g of water, add 0.5g of hydrofluoric acid and 30.03g of glacial acetic acid with a mass fraction of 40%, and then add 1.71g of tetrabutyl titanate (Ti:H 2 O molar ratio = 1:70), stir evenly, put into the reaction kettle and heat at 180°C for 24h, separate the precipitate, wash the precipitate with water for 3 times, dry at 60°C, and calcined at 600°C for 2h; naturally cool to room temperature to obtain high activity TiO 2 Nanodisk photocatalyst.

Embodiment 2

[0032] Take 4.2g of water, add 0.5g of hydrofluoric acid and 30.03g of glacial acetic acid with a mass fraction of 40%, and then add 1.71g of tetrabutyl titanate (Ti:H 2 O molar ratio = 1:50), stir evenly, put into the reaction kettle and heat at 180°C for 24h, separate the precipitate, wash the precipitate with water for 3 times, dry at 60°C, and calcined at 600°C for 2h; naturally cool to room temperature to obtain high activity TiO 2 Nanodisk photocatalyst.

Embodiment 3

[0034] Take 8.7g of water, add 0.5g of hydrofluoric acid and 30.03g of glacial acetic acid with a mass fraction of 40%, and then add 1.71g of tetrabutyl titanate (Ti:H 2 O molar ratio = 1:50), stir evenly, put into the reaction kettle and heat at 180°C for 24h, separate the precipitate, wash the precipitate with water for 3 times, dry at 60°C, and calcined at 600°C for 2h; naturally cool to room temperature to obtain high activity TiO 2 Nanodisk photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com