Process for synthesis of nano mordenite molecular sieve

A synthesis method, the technology of denzeolite, which is applied in the field of synthesis of nano-mordenite molecular sieves, can solve the problems of high cost, slow progress, and environmental pollution, and achieve the effect of reducing synthesis cost, less pollution, and good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

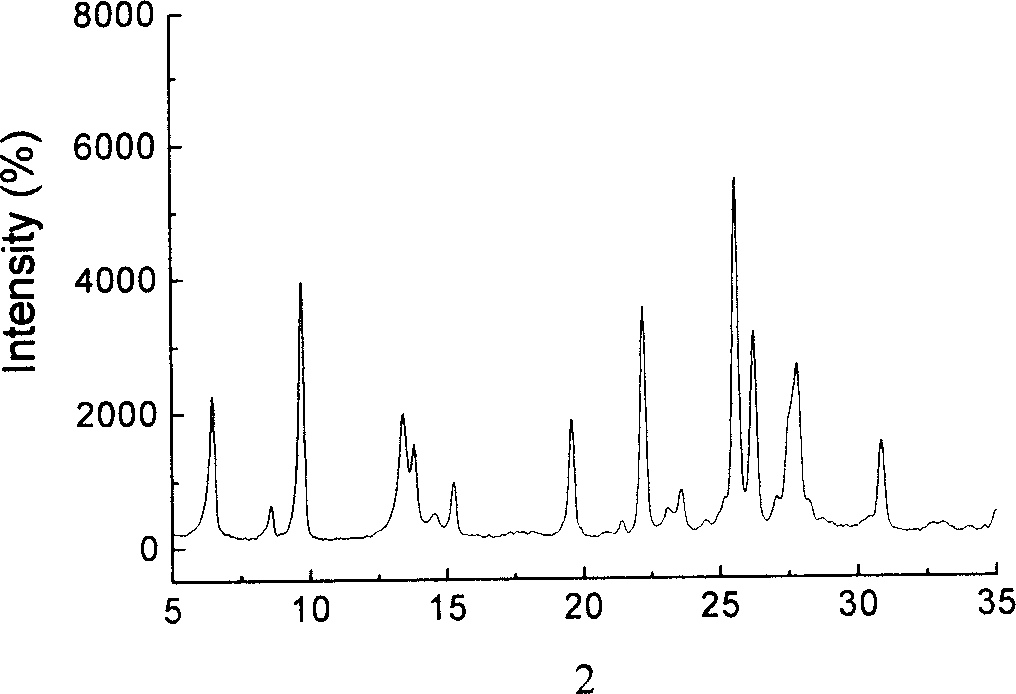

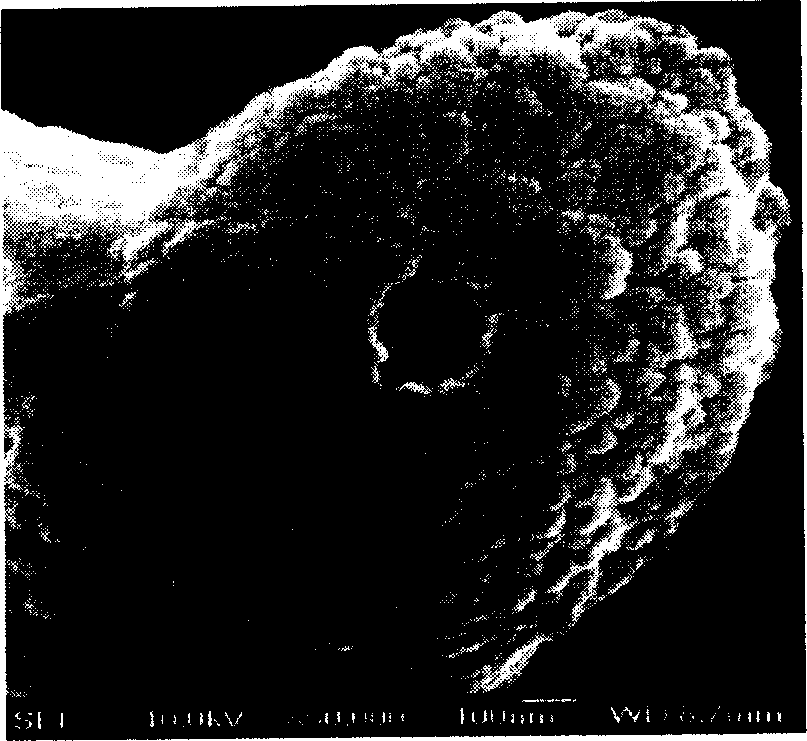

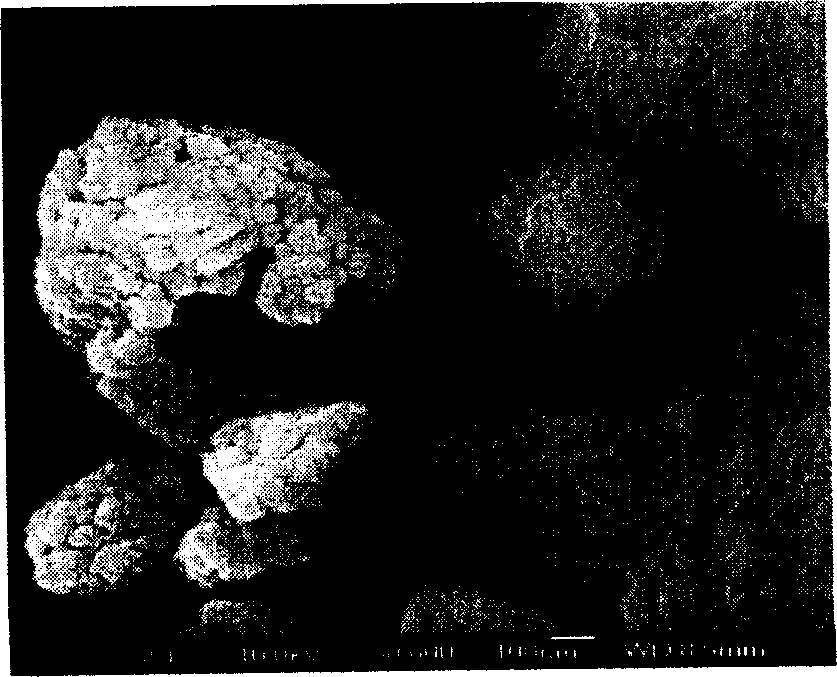

Method used

Image

Examples

Embodiment 1

[0026] First take 5 ml of silica sol solution (SiO 2 : 30wt%, Qingdao Marine Chemical Co., Ltd. provides), 2 milliliters of deionized water, 0.7 milliliters of concentration is (8.036mol / l) sodium hydroxide solution mixes evenly and stirs 1.5 hours; Then get the same sodium hydroxide solution of 0.81 milliliters of concentrations, 1 ml of deionized water and 0.325 g of sodium metaaluminate (Al 2 o 3 : 41wt%, Na 2 (2: 30wt%) and mix evenly, add the sodium metaaluminate solution to the evenly dispersed silica sol solution, then add 5.3 milliliters of deionized water, stir vigorously continuously for 1 hour, add 3.48 grams of sodium chloride, and continue stirring until after 1 hour , add 0.163g mordenite molecular sieve powder as crystal seed, continue to stir for 45 minutes and measure the pH value at about 13, the molar composition of the crystallization reaction system is:

[0027] Na 2 O:NaCl:Al2 o 3 : SiO 2 :H 2 O=3:30:1:15:390 Stirring and aging at room temperature ...

Embodiment 2

[0029] First take 5 ml of silica sol solution (SiO 2 : 30wt%, provided by Qingdao Ocean Chemical Co., Ltd.), 2 milliliters of deionized water, 1 milliliter of concentration is (8.036mol / l) sodium hydroxide solution mixes evenly and stirs 1.5 hours; Then get the same sodium hydroxide solution of 1.12 milliliters of concentrations, 1 ml of deionized water and 0.325 g of sodium metaaluminate (Al 2 o 3 : 41wt%, Na 2 (2: 30wt%) and mix evenly, add the sodium metaaluminate solution to the uniformly dispersed silica sol solution, then add 2.2 ml of deionized water, stir vigorously for 1 hour, add 3.48 grams of sodium chloride, and continue stirring until after 1 hour , add 0.131g mordenite molecular sieve powder as the seed crystal, continue stirring for 60 minutes and then measure the pH value at about 13.5, the molar composition of the crystallization reaction system is:

[0030] Na 2 O:NaCl:Al 2 o 3 : SiO 2 :H 2 O = 4.2: 30: 1: 15: 270 Stirring and aging at room temperatur...

Embodiment 3

[0032] First take 5 ml of silica sol solution (SiO 2 : 30wt%, Qingdao Marine Chemical Co., Ltd. provides), 2 milliliters of deionized water, 0.7 milliliters of concentration is (8.036mol / l) sodium hydroxide solution mixes evenly and stirs 1.5 hours; Then get the same sodium hydroxide solution of 0.81 milliliters of concentrations, 1 ml of deionized water and 0.244 g of sodium metaaluminate (Al 2 o 3 : 41wt%, Na 2 (2: 30wt%) and mix evenly, add the sodium metaaluminate solution to the uniformly dispersed silica sol solution, then add 3.2 ml of deionized water, stir vigorously for 1 hour, add 4.64 grams of sodium chloride, and continue stirring until after 1 hour , add 0.141g mordenite molecular sieve powder as the seed crystal, continue to stir for 45 minutes and measure the pH value at about 12.5, the molar composition of the crystallization reaction system is:

[0033] Na 2 O:NaCl:Al 2 o 3 : SiO 2 :H 2 O=3:40:1:20:330 Stir and age at room temperature for 4 hours, tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com