Preparation method of mordenite/ZSM-5 core-shell type molecular sieve material

A technology of ZSM-5 and mordenite, which is applied in the field of preparation of core-shell molecular sieve materials, can solve problems such as difficulty in compound growth, and achieve the effects of low synthesis cost, avoidance of mass use and good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

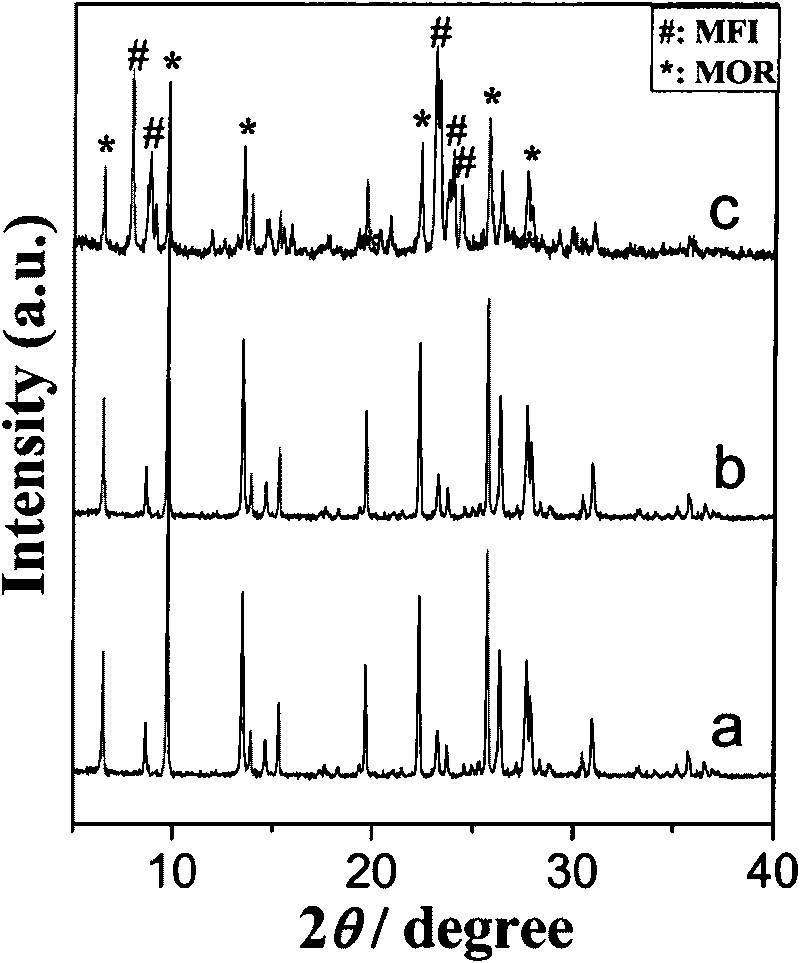

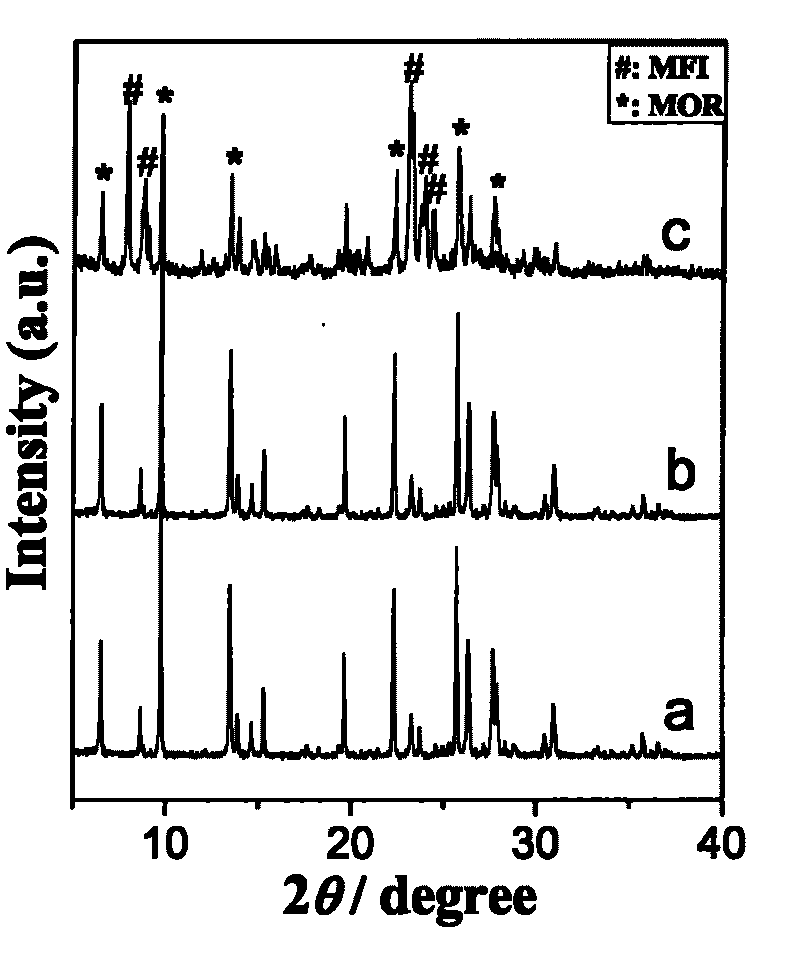

[0036] 110 milliliters of n-butylamine was dissolved in 480 milliliters of deionized water and stirred evenly, 320 grams of mordenite raw powder was added to this surface modifier solution, and the temperature was raised to 30 ° C under stirring and kept for 120 hours, filtered and cooled in 100 ° C air After drying in the atmosphere, the treated mordenite powder is obtained. 124 grams of water glass, 1 gram of aluminum sulfate, 18 grams of sodium chloride, 6 milliliters of sulfuric acid, 20 milliliters of ethylamine, 10 milliliters of ammonia water and 600 milliliters of water are evenly gelled to obtain the ZSM-5 zeolite molecular sieve synthesis system. Add 320 grams of processed mordenite powder into the gelling solution and stir for 2 hours. The mixed system was transferred into a polytetrafluoroethylene-lined stainless steel crystallization kettle, and statically crystallized in an oven at 120°C for 48 hours. The XRD spectrum of gained sample has the characteristic diff...

Embodiment 2

[0038] Dissolve 45 grams of tetrapropylammonium bromide in 80 milliliters of deionized water and stir evenly. Add 50 grams of mordenite raw powder into this surface modifier solution, heat up to 170° C. under stirring and keep it for 2 hours, filter and After drying in air atmosphere at 100°C, the treated mordenite powder is obtained. 124 grams of water glass, 0.38 grams of aluminum nitrate, 7.5 milliliters of nitric acid, 24 milliliters of n-butylamine, and 420 milliliters of water are uniformly gelled to obtain the ZSM-5 zeolite molecular sieve synthesis system. Add 32 grams of treated mordenite powder B into the gelling solution and stir for 2 hours. The mixed system was transferred into a polytetrafluoroethylene-lined stainless steel crystallization kettle, and statically crystallized in an oven at 135°C for 36 hours. The XRD pattern of the obtained sample has both the characteristic diffraction peaks of mordenite and ZSM-5 zeolite molecular sieve, and it can be calculate...

Embodiment 3

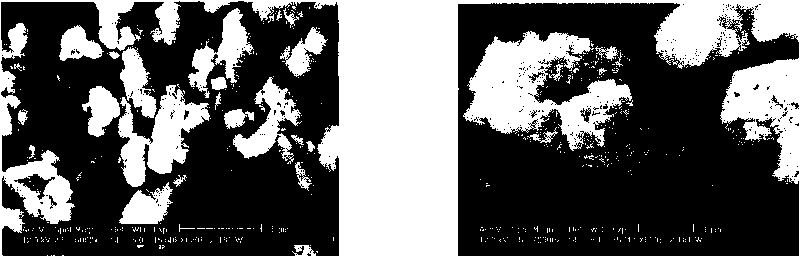

[0040] Add 100 g of mordenite raw powder into 120 ml of n-butylamine, raise the temperature to 80° C. under stirring and keep it for 60 hours, filter and dry in air atmosphere at 100° C. to obtain the treated mordenite powder. After 49 grams of silica gel, 2.45 grams of sodium aluminate, 18 grams of sodium chloride, 6 milliliters of sulfuric acid, 26 milliliters of ethylamine and 1200 milliliters of water are uniformly gelled, the ZSM-5 zeolite molecular sieve synthesis system can be obtained. Add 96 grams of processed mordenite powder B into the gelling solution and stir for 2 hours. The mixed system was transferred into a polytetrafluoroethylene-lined stainless steel crystallization kettle, and statically crystallized in an oven at 150°C for 24 hours. The XRD pattern of the obtained sample has both the characteristic diffraction peaks of mordenite and ZSM-5 zeolite molecular sieve, and it can be calculated that the phase content of ZSM-5 accounts for more than 60%. In the S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com