Synthesis method for zeolite

A technology for synthesizing zeolite and seed crystals, which is applied in the direction of crystalline aluminosilicate zeolite, mercerized crystalline aluminosilicate zeolite, etc., to achieve the effects of cost reduction, environmental friendliness, and saving dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The synthesis of embodiment 1 mordenite

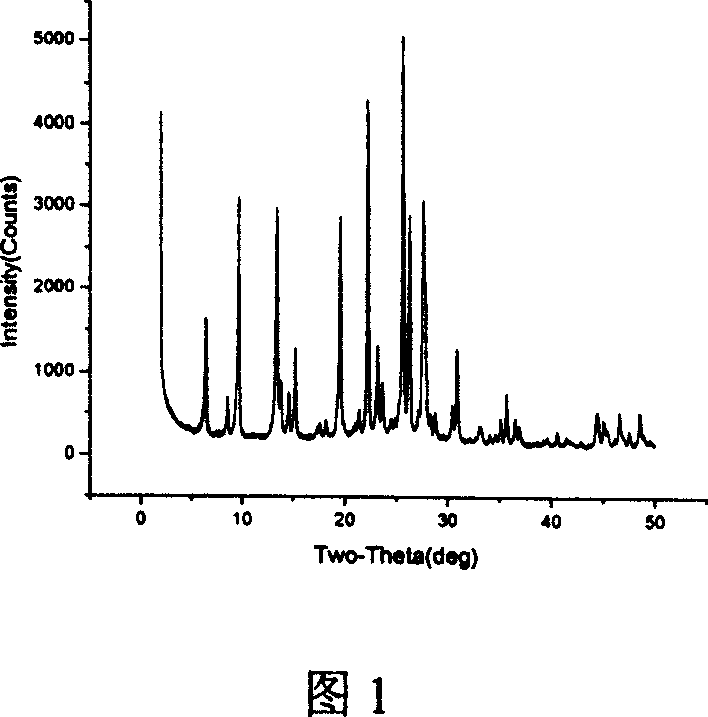

[0024] Weigh solid SiO 2 4.9 grams (0.08mol), Al 2 o 3 1.36 g (0.01 mol), 0.96 g (0.024 mol) of sodium hydroxide, put it into a blender for mechanical mixing, after fully stirring, put the mixture on a support, feed water vapor, and maintain the system temperature at 170 ° C to start crystallization , the crystallization time is 6 days, and the mordenite-type zeolite can be obtained (the structure determined by XRD is shown in Figure 1).

Embodiment 2

[0025] The synthesis of embodiment 2 mordenite

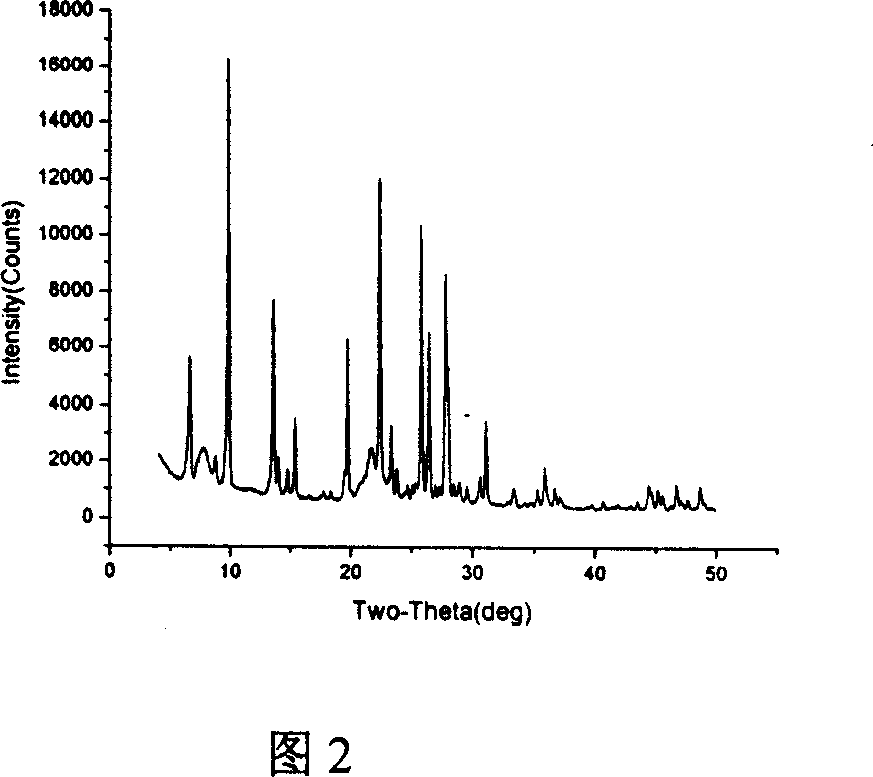

[0026] Weigh SiO 2 10.0 g (0.16 mol), Al 2 o 3 1.36 g (0.01 mol), 3.2 g (0.08 mol) of sodium hydroxide, put it into a blender for mechanical mixing, after fully stirring, put the mixture on a stand, feed water vapor, and maintain the system temperature at 260 ° C to start crystallization , the crystallization time is 3 days, and the mordenite-type zeolite can be obtained (the structure determined by XRD is shown in Figure 2).

Embodiment 3

[0027] Embodiment 3: the synthesis of ZSM-5 type zeolite

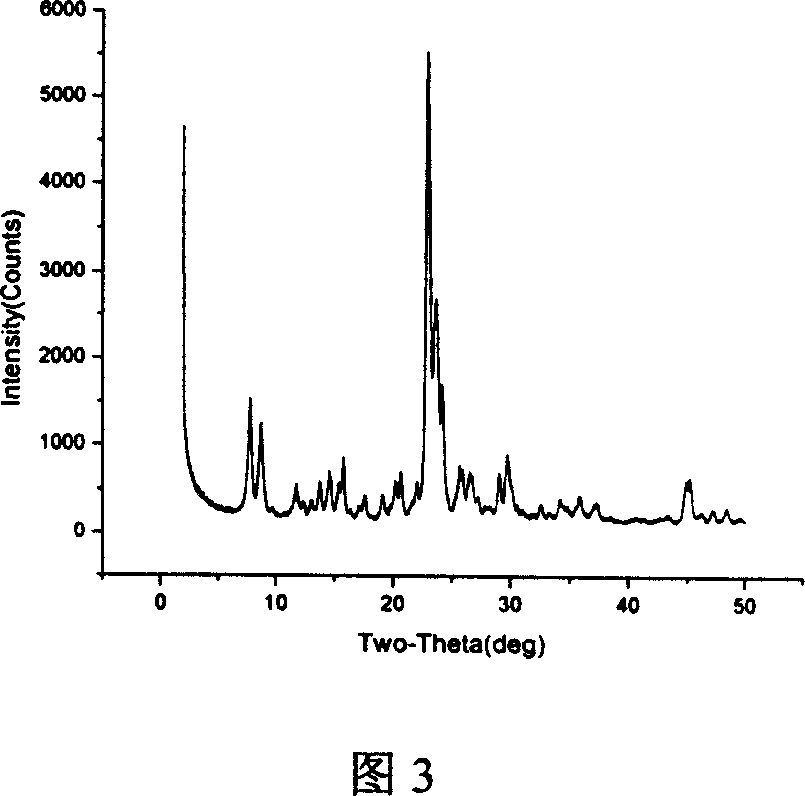

[0028] Weigh SiO 2 18.0 g (0.3 mol), Al 2 o 3 1.36 grams (0.01mol), 3.6 grams (0.09mol) of sodium hydroxide, 0.8 grams of ZSM-5 seed crystals, 6.6 grams (0.09mol) of butylamine, put it into a stirrer and carry out mechanical mixing, after fully stirring, the The mixture was placed on a support, fed with water vapor, and the crystallization started at a system temperature of 150°C. The crystallization time was 1 day to obtain a ZSM-5 zeolite (the structure determined by XRD is shown in Figure 3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com