In-situ synthetic method of geolyte containing copper wires

A technology of zeolite and copper wire, applied in the field of catalysis, can solve the problems of high preparation cost, cumbersome operation steps, affecting the commercial prospects of the catalyst and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

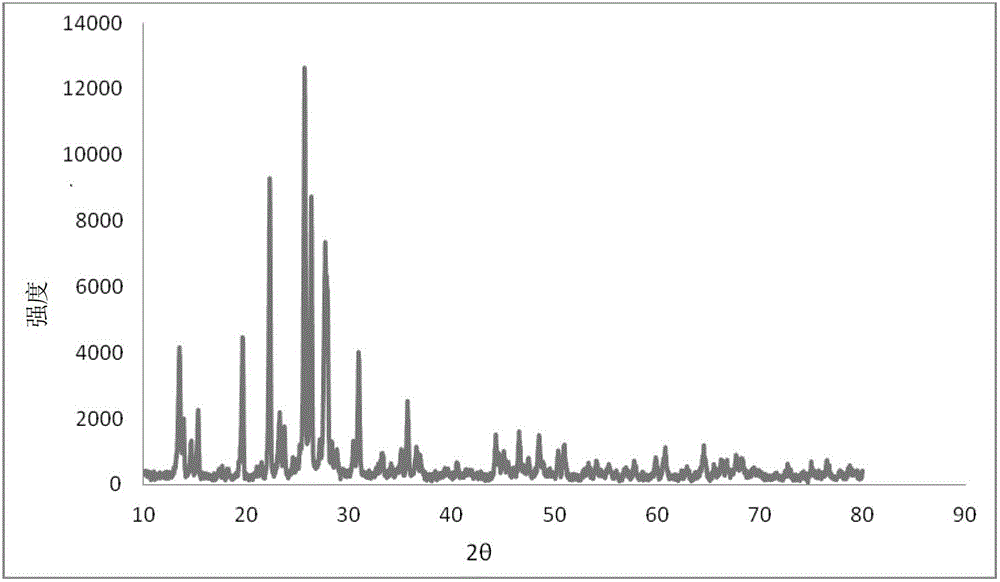

Image

Examples

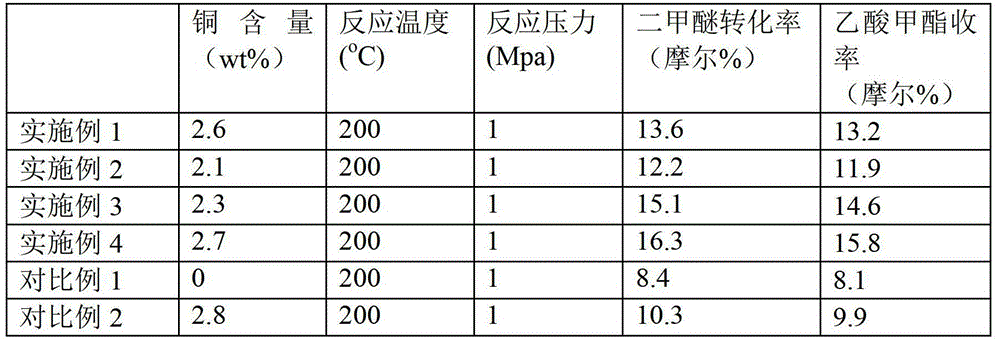

Embodiment 1

[0053] Mole ratio Na 2 O:CuO:Al 2 o 3 :n-Butylamine:SiO 2 :H 2 O=2.9:0.4:1:3:18:380 ingredients. Take 135 milliliters of deionized water, add 2.6 grams of sodium hydroxide to it and mix well, then weigh 4.7 grams of sodium metaaluminate and add it to the above solution, stir for 0.5 hours, then weigh 4.3 grams of n-butylamine and add it to the solution , continue to stir for 0.5 hours to obtain solution A; then weigh 70 grams of silica sol (purchased from Qingdao Ocean Chemical Co., Ltd., SiO 2 Content: 30% by weight, average particle size 10-20 nanometers, pH value 8.5-10) was added into solution A, and continued stirring for 1.5 hours to obtain sol B. Then weigh 75ml Cu(NH 3 ) 4 SO 4 The solution (0.1mol / L) was added to sol B, and the pH of the system was measured as 13±0.1 using a pH meter. After stirring and aging at room temperature for 1 hour, it was transferred to a stainless steel reactor, and the reactor was sealed and heated to 180°C. Crystallize under hydro...

Embodiment 2

[0055] Mole ratio Na 2 O:CuO:Al 2 o 3 :Triethylamine:SiO 2 :H 2 O=2.9:0.35:1:3:18:360 ingredients. Take 128 milliliters of deionized water, add 2.6 grams of sodium hydroxide to it and mix well, then weigh 4.7 grams of sodium metaaluminate and add it to the above solution, stir for 0.5 hours, then weigh 6.0 grams of triethylamine and add it to the solution , continue to stir for 0.5 hours to obtain solution A; then weigh 70 grams of silica sol (purchased from Qingdao Ocean Chemical Co., Ltd., SiO 2 Content: 30% by weight, average particle size 10-20 nanometers, pH value 8.5-10) was added into solution A, and continued stirring for 1.5 hours to obtain sol B. Then weigh 65ml Cu(NH 3 ) 4 (NO 3 ) 2 ) solution (0.1mol / L) was added to sol B, and the pH of the system was measured to be 13±0.1 using a pH meter. After stirring and aging at room temperature for 1 hour, it was transferred into a stainless steel reaction kettle, and the reaction kettle was sealed and heated to 180...

Embodiment 3

[0057] Mole ratio Na 2 O:CuO:Al 2 o 3 :Tetraethylammonium bromide:SiO 2 :H 2 O=2.8:0.4:1:2.9:17:390 ingredients. Take 140 milliliters of deionized water, add 2.5 grams of sodium hydroxide to it and mix well, then weigh 5.0 grams of sodium metaaluminate and add it to the above solution, stir for 0.5 hours, then weigh 12.6 grams of tetraethylammonium bromide and add Into the solution, continue to stir for 0.5 hours to obtain solution A; then weigh 70 grams of silica sol (purchased from Qingdao Ocean Chemical Co., Ltd., SiO 2 Content: 30% by weight, average particle size 10-20 nanometers, pH value 8.5-10) was added into solution A, and continued stirring for 1.5 hours to obtain sol B. Then weigh 75ml Cu(NH 3 ) 4 (NO 3 ) 2 ) solution (0.1mol / L) was added to sol B, and the pH of the system was measured as 13±0.1 using a pH meter. After stirring and aging at room temperature for 1 hour, it was transferred to a stainless steel reactor, and the reactor was sealed and heated t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com