ZSM-48/Silicalite-1 composite molecular sieve and preparation method thereof

A technology of ZSM-48 and composite molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of expensive hexamethylenediamine chloride, easy carbon deposition, unfavorable long-term operation of catalyst, etc., achieve suitable pore volume, improve acid Quantity, the effect of inhibiting side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

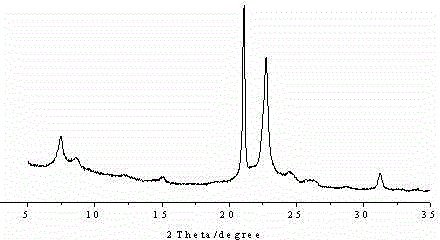

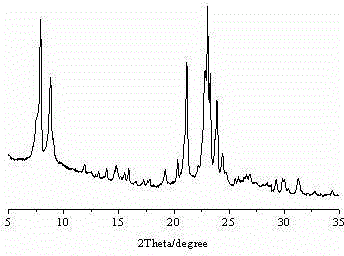

Image

Examples

Embodiment 1

[0024] Weigh sodium hydroxide and sodium aluminate (Al 2 o 3 , 43wt%; Na 2 O, 38wt%) was dissolved in deionized water, and then the templating agent R (12-crown-4, content >97%) was added while stirring at a water bath temperature of 60°C, and after stirring for 0.5 hours, white carbon black was added, After stirring for 1 hour, add ZSM-48 seed crystal S, continue stirring for 2 hours, and then move to a closed stainless steel reaction kettle. Crystallized at 160°C for 6 days to obtain ZSM-48 molecular sieve with low silicon-aluminum ratio (D1-ZSM-48). See Table 1 for the specific raw material ratio and product properties.

Embodiment 2

[0026] Weigh sodium hydroxide and sodium aluminate (Al 2 o 3 , 43wt%; Na 2 O, 38wt%) was dissolved in deionized water, and then the templating agent R (12-crown-4, content >97%) was added while stirring at a water bath temperature of 60°C, and after stirring for 0.5 hours, white carbon black was added, After stirring for 1 hour, add ZSM-48 seed crystal S, continue stirring for 2 hours, and then move to a closed stainless steel reaction kettle. Crystallized at 158°C for 8 days to obtain a ZSM-48 molecular sieve (D2-ZSM-48) with a low silicon-aluminum ratio. The specific raw material ratio and product properties are shown in Table 1.

Embodiment 3

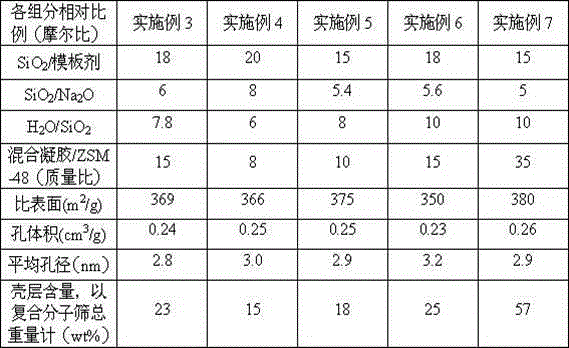

[0028] Weigh sodium hydroxide and TPABr and dissolve them in deionized water, then add D1-ZSM-48 molecular sieve while stirring at room temperature, stir for 0.5 hours, then add white carbon black, stir for 0.5 hours, then move the reaction mixture gel to an airtight In a stainless steel reaction kettle, crystallize at 140°C for 12 hours, and the crystallized product is washed, centrifuged, dried, and roasted to obtain ZSM-48 / Silicalite-1 composite molecular sieve. The specific raw material ratio and product properties are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com