Preparation method of hollow USY molecular sieve

A molecular sieve and composite molecular sieve technology, which is applied in the field of preparation of hollow USY molecular sieves, can solve the problems of poor hydrothermal stability and cannot be used in industrial applications, and achieve the effects of strong anti-coking ability, good catalytic activity and diffusion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

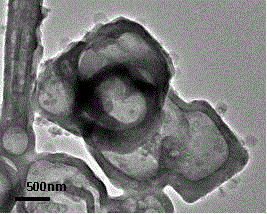

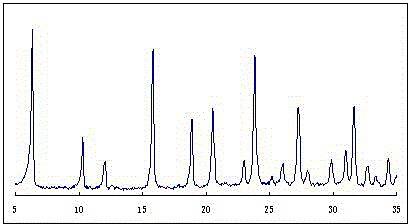

Image

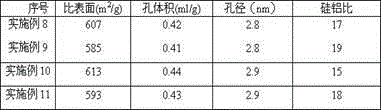

Examples

Embodiment 1

[0024] According to molar ratio n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=18:1:19:370, under stirring, add sodium aluminate, sodium hydroxide, water, and water glass to the beaker in turn to form a mixed solution, and then age at 35°C for 1 day to prepare the directing agent .

Embodiment 2

[0026] According to molar ratio n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=17:1:120:390, under stirring, add sodium aluminate, sodium hydroxide, water, and water glass to the beaker in turn to form a mixed solution, and then age at 35°C for 1.5 days to obtain the directing agent .

Embodiment 3

[0028] According to molar ratio n (Na 2 O): n (Al 2 o 3 ): n (SiO 2 ): n (H 2 O)=16:1:121:360, in the state of stirring, add sodium aluminate, sodium hydroxide, water, and water glass to the beaker in turn to form a mixed solution, and then age at 40°C for 1 day to obtain the directing agent .

[0029] Composite molecular sieve preparation:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com