A catalyst for pretreatment of inferior reforming raw materials, a preparing method thereof and a pretreatment method for inferior reforming raw materials

A catalyst and pretreatment technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems that do not meet the development requirements of "low-carbon" oil refining, high operating costs, and large comprehensive energy consumption, etc. problems, to achieve the effects of strong olefin saturation ability, strong anti-coking ability, and high activity of hydrodesulfurization and denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) 1000g of commercial pseudo-boehmite with a pore volume of 0.6ml / g large pore volume alumina / pore volume of 0.2ml / g small pore volume alumina ratio of 1.0, Tianqing powder 30g, silica gel 100g, Mix mechanically for 30 minutes; dissolve 30 g of citric acid in 80 g of deionized water, then add 20 g of nitric acid with a concentration of 60%, add it to the uniformly mixed powder, and wet mix for 35 minutes to obtain a plastic soft mass.

[0043] (2) Add the soft plastic mass obtained in the step (1) into the trough of the extruder, extrude with a clover-shaped orifice plate, and then pelletize to obtain a clover-shaped carrier. Then keep healthy at room temperature for 3 hours, dry at 120°C for 4 hours in the air atmosphere, put it in a muffle furnace at 450-550°C, and roast it for 4 hours in the air atmosphere to obtain SiO-containing 2 Clover-shaped alumina support 1.

[0044] (3) Add 40g of phosphoric acid to 300g of deionized water, stir evenly, add 90g of industri...

Embodiment 2

[0047] (1) 1000g of commercial pseudo-boehmite with a pore volume of 1.0ml / g large pore volume alumina / pore volume of 0.3ml / g small pore volume alumina ratio of 0.2, 30g of Tianqing powder, 100g of silica gel, mechanically Mix for 30 minutes; dissolve 30 g of citric acid in 80 g of deionized water, then add 20 g of nitric acid with a concentration of 60%, add it to the uniformly mixed powder, and wet mix for 35 minutes to obtain a plastic soft block.

[0048] (2) Add the soft plastic mass obtained in the step (1) into the trough of the extruder, extrude with a clover-shaped orifice plate, and then pelletize to obtain a clover-shaped carrier. Then keep healthy at room temperature for 3 hours, dry at 120°C for 4 hours in the air atmosphere, put it in a muffle furnace at 450-550°C, and roast it for 4 hours in the air atmosphere to obtain SiO-containing 2 Clover-shaped alumina support 2.

[0049] (3) 70g of phosphoric acid is added to 300g of deionized water, after stirring evenl...

Embodiment 3

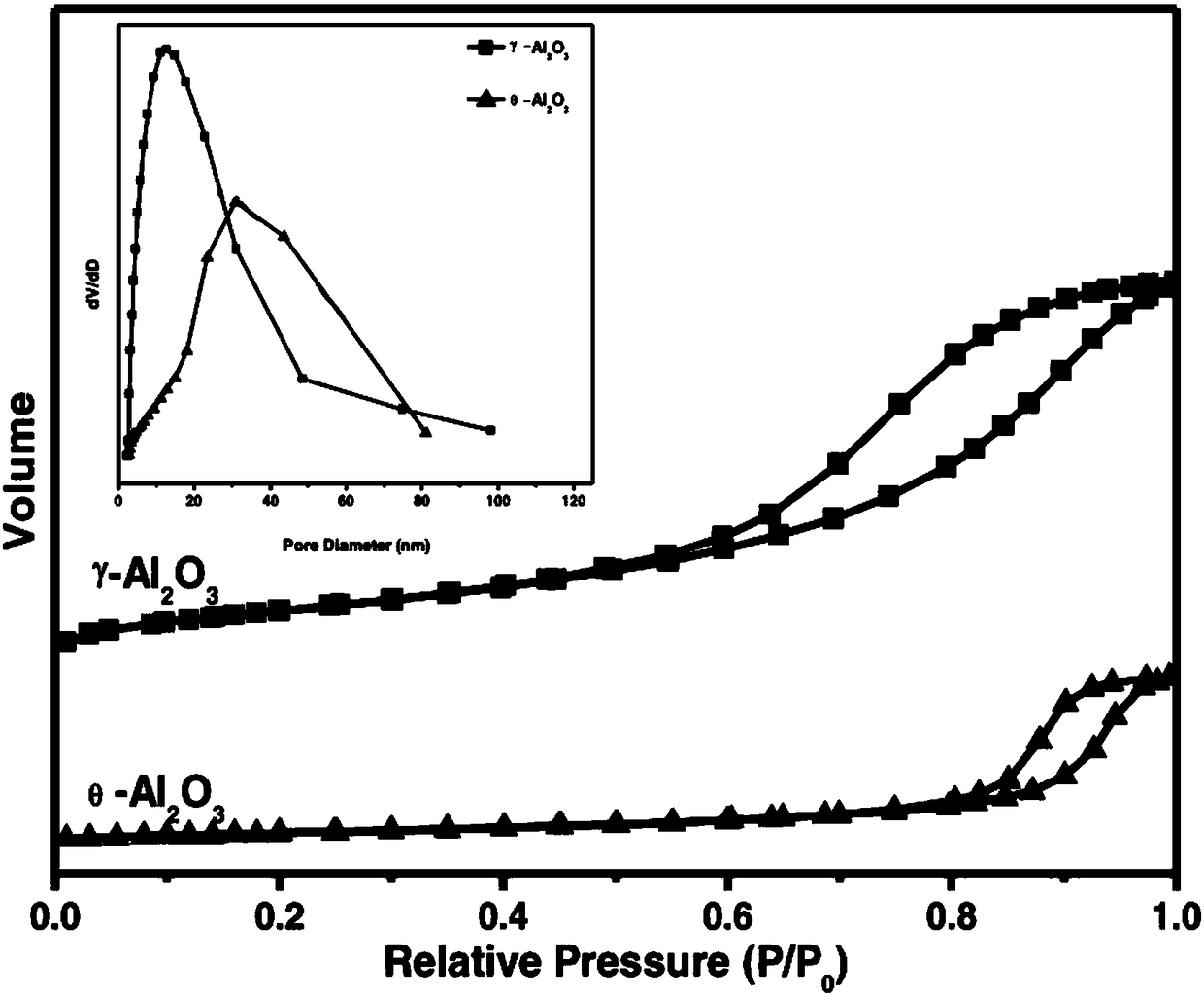

[0052] (1) γ-Al 2 o 3 / θ-Al 2 o 3 1000g of commercial pseudo-boehmite whose ratio is 0.8 (wherein the mass ratio of pore volume of 0.8ml / g alumina to 0.4ml / g alumina is 3.5), Tianqing powder 60g, mechanically mixed for 30min; Dissolve 40 g of acid in 80 g of deionized water, add 25 g of nitric acid with a concentration of 68%, add it to the uniformly mixed powder, and wet mix for 35 minutes to obtain a plastic soft block. Others are the same as in Example 1, and a clover-shaped alumina carrier 3 is obtained.

[0053] (2) 40g of phosphoric acid is added to 300g of deionized water, after stirring evenly, 120g of industrial grade molybdenum trioxide, 100g of industrial grade ammonium metatungstate, and 100g of industrial grade basic nickel carbonate are added to the phosphoric acid solution and stirred continuously, 40 Minutes later, the temperature was raised to 90-100°C, 50g of industrial-grade cobalt nitrate and 80g of citric acid were added, and after stirring for 20 minu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com