Oil product hydrodeoxygenation upgrading catalyst and preparation method and application thereof

A deoxygenation upgrading and catalyst technology, which is used in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of low activity, easy deactivation and coking, poor stability, etc., to improve dispersibility and not easy to coke. , the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

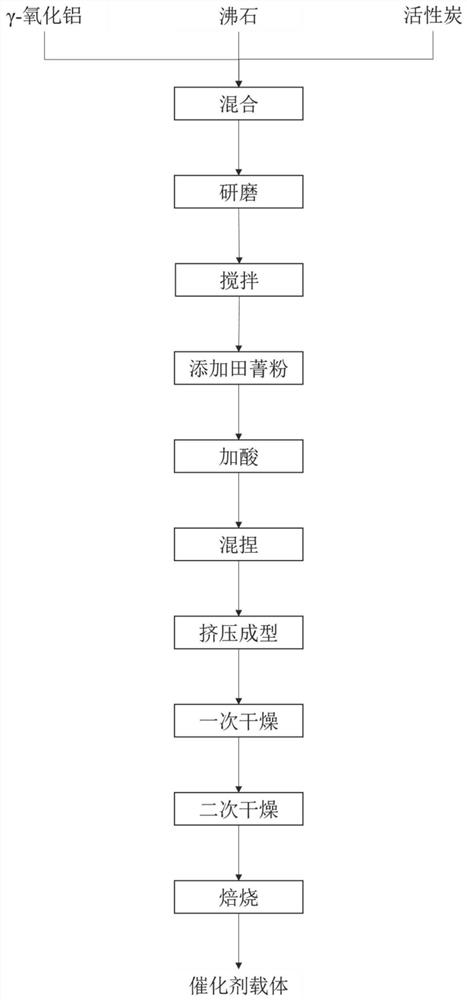

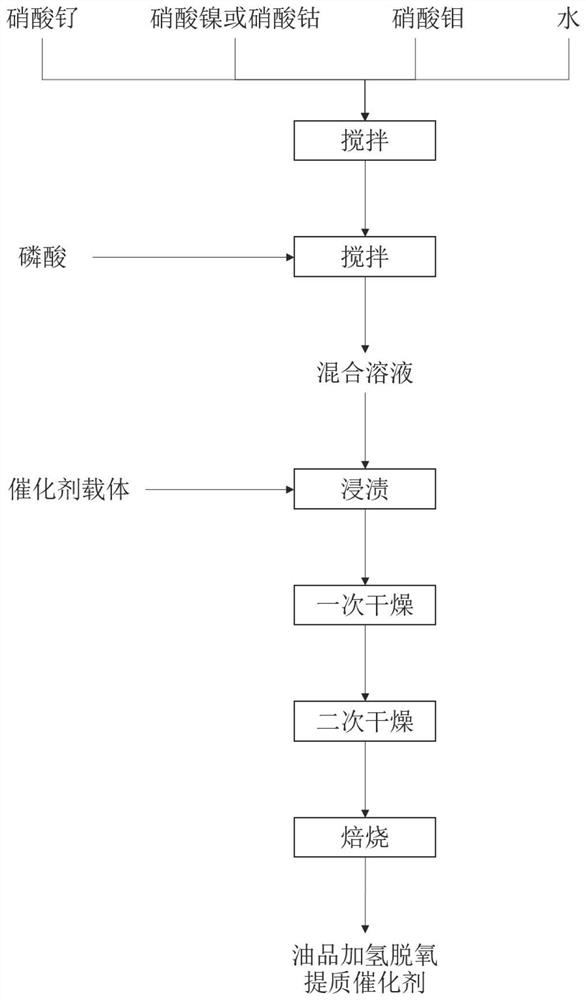

[0075] refer to figure 1 The schematic diagram of the preparation process of the catalyst support and figure 2 Schematic diagram of the catalyst preparation process, the preparation method of the oil hydrodeoxygenation upgrading catalyst in this example is as follows:

[0076] (1) Preparation of the catalyst carrier: mix active γ-alumina powder with Y-type zeolite and mesoporous activated carbon according to the required ratio to obtain a mixture. In the mixture, active gamma-alumina, Y-type zeolite and mesoporous activated carbon account for 80%, 16% and 4% of the mass of the mixture respectively. Then grind the mixture to below 200 mesh and stir well. Next, 1.5% of the total mass of scallop powder is added to the mixture, and then 1.5 times of the mass of the mixture is added with 10% nitric acid solution. After kneading for 60 minutes, it is repeatedly extruded on an extruder for several times and extruded to obtain a molding carrier. After drying the molded support at ...

preparation Embodiment 2

[0080] refer to figure 1 The schematic diagram of the preparation process of the catalyst support and figure 2 Schematic diagram of the catalyst preparation process, the preparation method of the oil hydrodeoxygenation upgrading catalyst in this example is as follows:

[0081] (1) Preparation of catalyst carrier: mix activated γ-alumina powder with HY-type zeolite and mesoporous activated carbon according to the required ratio to obtain a mixture. In the mixture, activated γ-alumina, HY type zeolite and mesoporous activated carbon account for 82%, 14% and 4% of the mixture mass respectively. Among them, mesoporous activated carbon was used as a pore expander. Then grind the mixture to below 200 mesh and stir well. Next, 1.5% of the total mass of scallop powder is added to the mixture, and then 1.5 times of the mass of the mixture is added with 10% nitric acid solution. After kneading for 60 minutes, it is repeatedly extruded on an extruder for several times and extruded to...

preparation Embodiment 3

[0085] refer to figure 1 The schematic diagram of the preparation process of the catalyst support and figure 2 Schematic diagram of the catalyst preparation process, the preparation method of the oil hydrodeoxygenation upgrading catalyst in this example is as follows:

[0086] (1) Preparation of catalyst carrier: Mix active γ-alumina powder with USY zeolite and mesoporous activated carbon according to the required ratio to obtain a mixture. In the mixture, active gamma-alumina, USY type zeolite and mesoporous activated carbon account for 80%, 15% and 5% of the mass of the mixture respectively. Then grind the mixture to below 200 mesh and stir well. Next, 1.5% of the total mass of scallop powder is added to the mixture, and then 1.5 times of the mass of the mixture is added with 10% nitric acid solution. After kneading for 60 minutes, it is repeatedly extruded on an extruder for several times and extruded to obtain a molding carrier. The molded support was dried at 40 °C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com