Ferroelectric metal hetero-junction based memristor and preparation method thereof

A technology of memristor and electric lithium niobate, which is applied in the field of microelectronic materials, can solve the problems of few reports and difficult to predict the application prospect of memristor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation method of ferroelectric lithium niobate, its preparation steps are as follows:

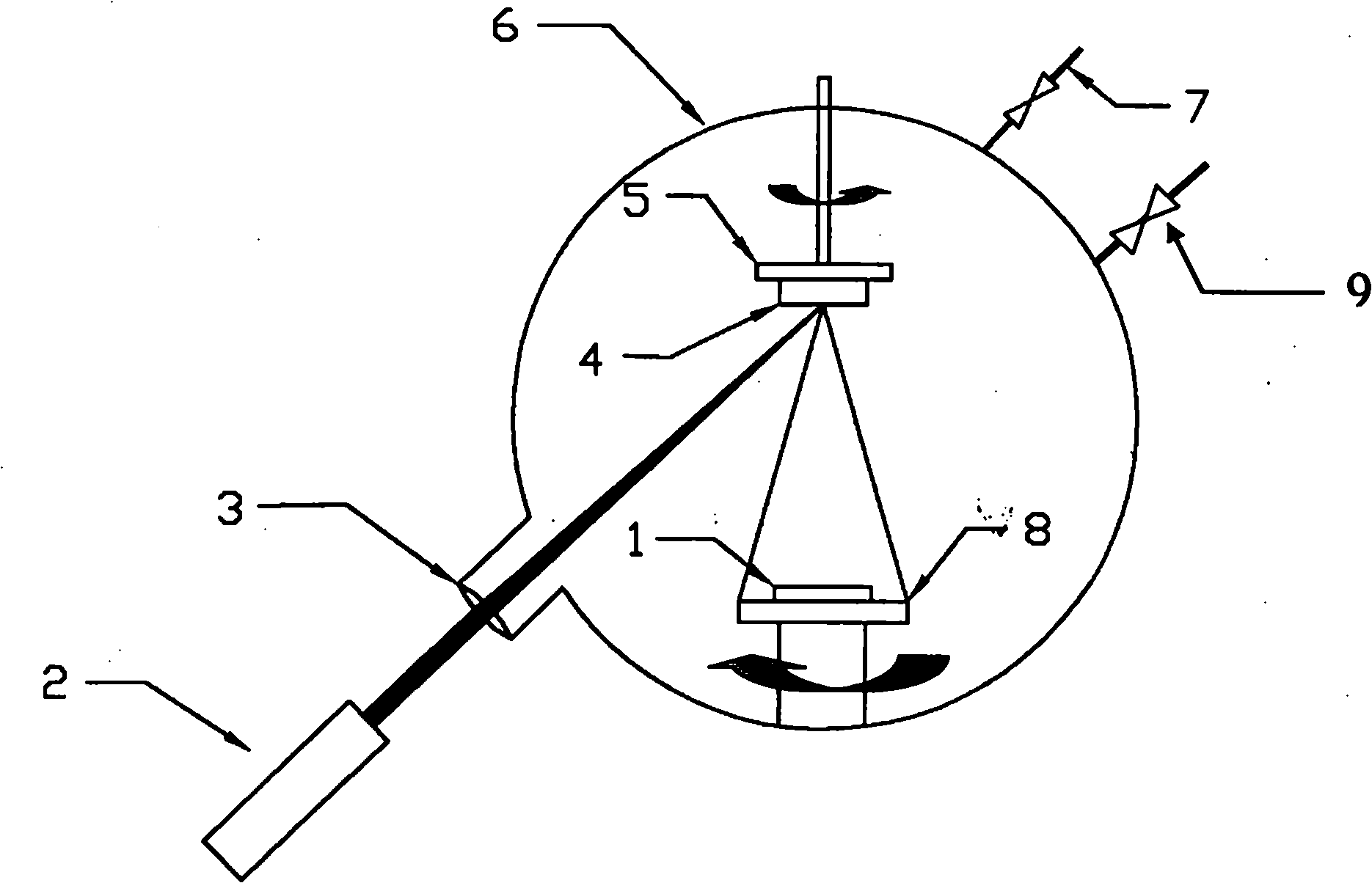

[0037] a) fixing the single crystal LN target material 4 on the target table 5 of the pulsed laser deposition film-making system, fixing the substrate 1 on the substrate table 8, and placing them in the growth chamber 6 of the pulsed laser deposition film-making system;

[0038] b) Use a vacuum pump to evacuate the growth chamber 6 to 0.8×10 through the interface valve 7 of the mechanical pump and the molecular pump -4 Below Pa, turn off the molecular pump;

[0039] c) Adjust the intake valve 9 so that the pressure of the flowing oxygen in the growth chamber is 25-35 Pa;

[0040] d) using a resistance heating furnace to heat the substrate table 5 to raise the temperature of the substrate 4 to 600-650°C;

[0041] e) rotating the substrate table 5 and the target table 8;

[0042] f) Start the KrF excimer laser 2 with a wavelength of 248nm, a pulse width of 30n...

Embodiment 2

[0045] Embodiment 2. The preparation method of the sandwich structure memristor unit based on the ferroelectric metal junction, the specific preparation steps are as follows:

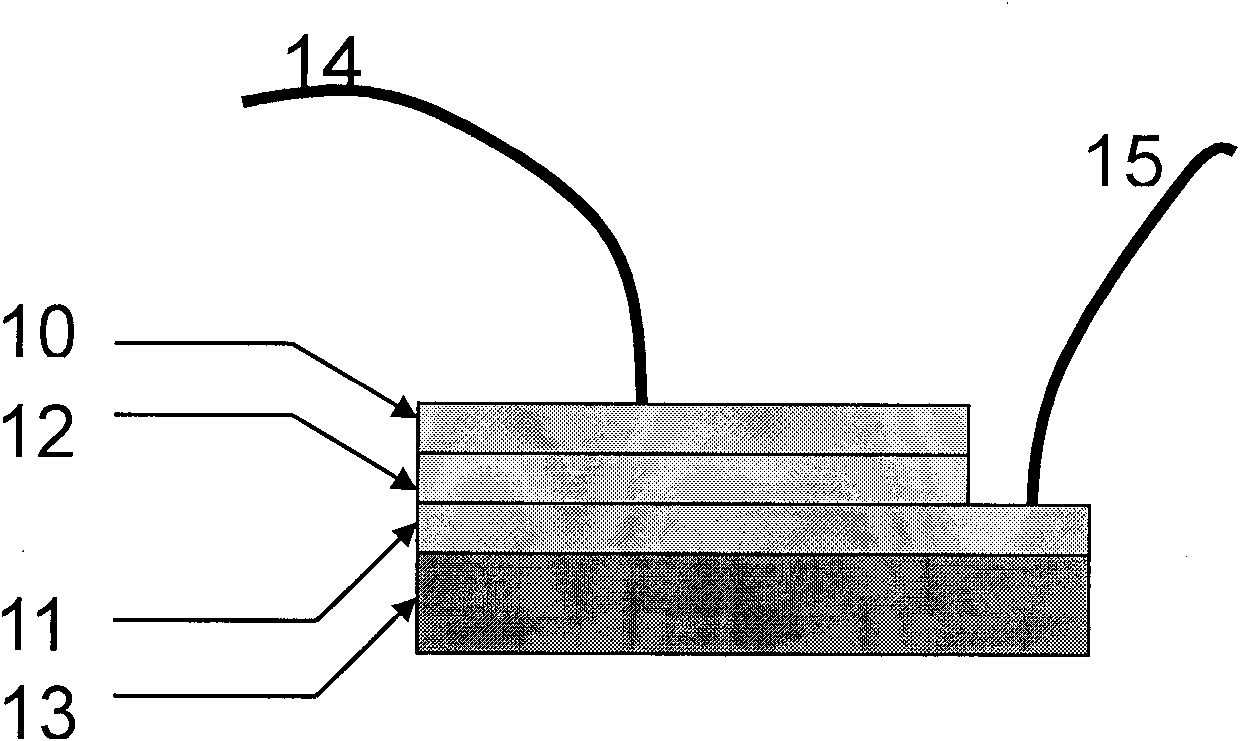

[0046] a) on Pt / Ti / SiO 2 / Si(111) substrate, grow a LN film with a thickness of about 50nm to 100nm by PLD method, and press a corner of the substrate with a clamp during the deposition process, so that the leaked part of the Pt film will be used as the lower electrode;

[0047] b) Take out the crystallized LN thin film from the PLD growth chamber, cover it with a mask, and use magnetron sputtering or other coating methods to grow the Pt electrode with a thickness of 100nm-150nm, thus forming a miniature sandwich structure; if Au / Ti / SiO 2 / Si(111) substrate, the growth of the upper electrode Au obtained basically the same results;

[0048] c) Finally, the copper leads 14, 15 are respectively connected from the upper and lower electrode films 10, 11, thus forming a memristor unit.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com