Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

870 results about "Pulsed laser deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pulsed laser deposition (PLD) is a physical vapor deposition (PVD) technique where a high-power pulsed laser beam is focused inside a vacuum chamber to strike a target of the material that is to be deposited. This material is vaporized from the target (in a plasma plume) which deposits it as a thin film on a substrate (such as a silicon wafer facing the target). This process can occur in ultra high vacuum or in the presence of a background gas, such as oxygen which is commonly used when depositing oxides to fully oxygenate the deposited films.

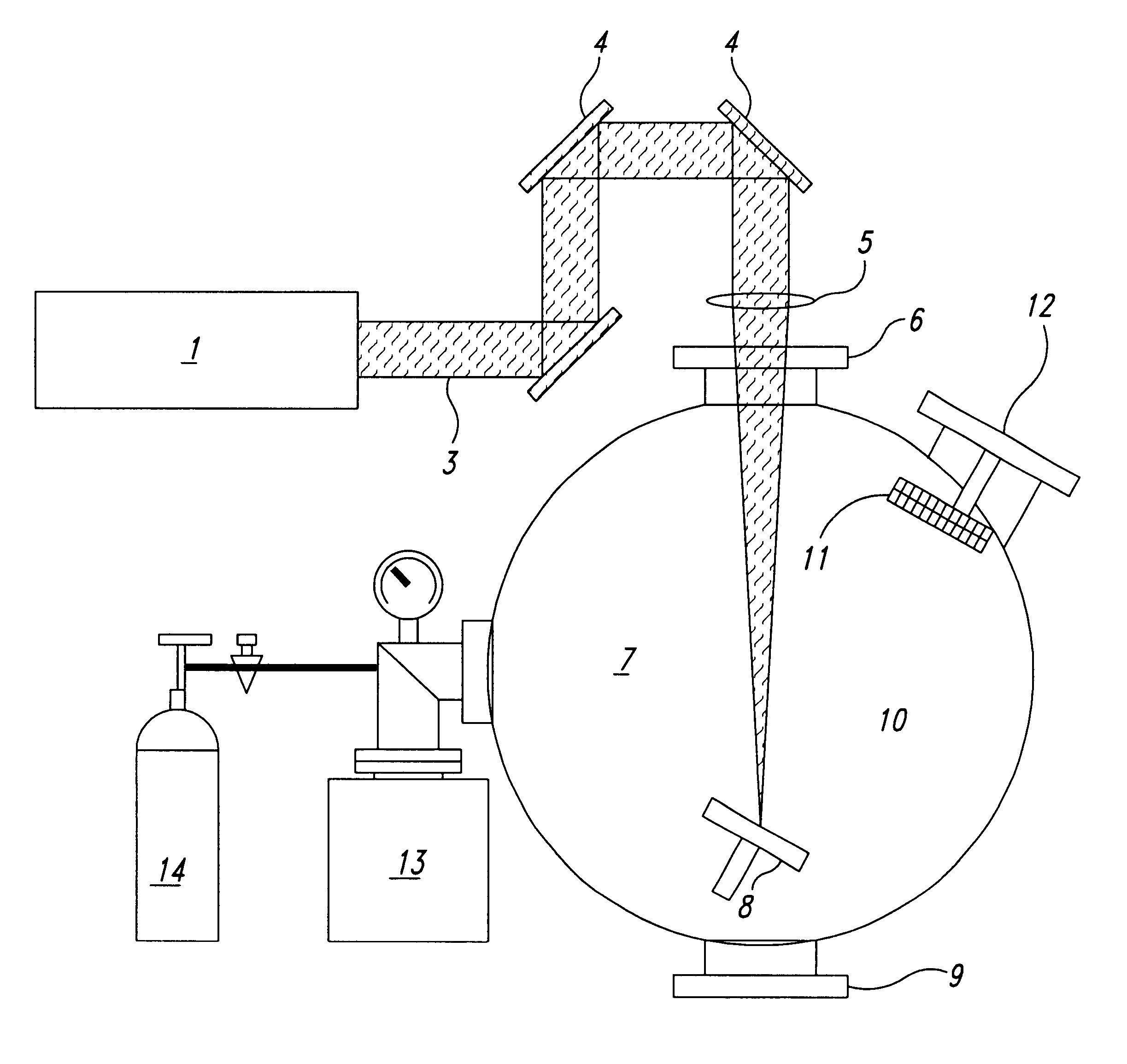

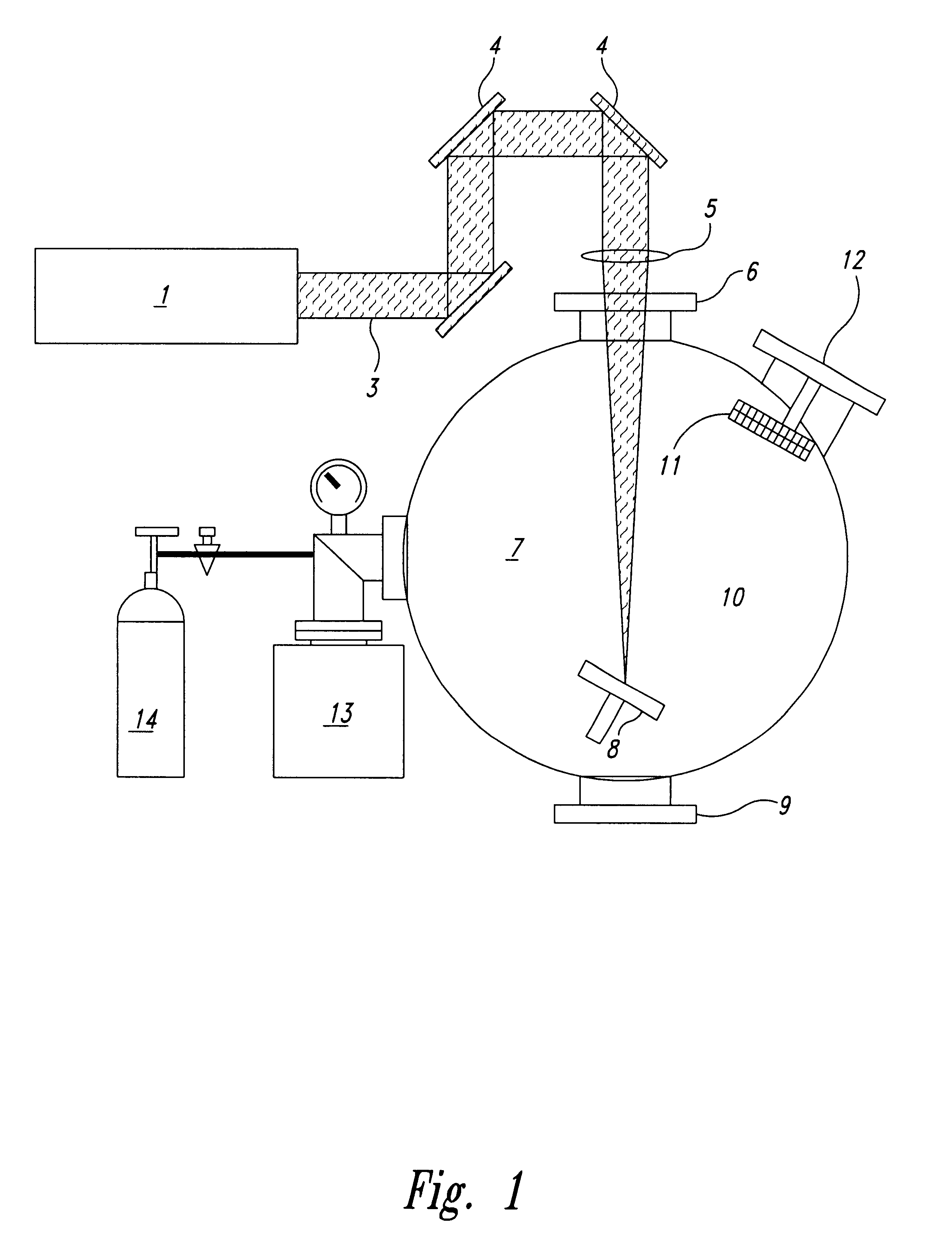

Method of deposition of thin films of amorphous and crystalline microstructures based on ultrafast pulsed laser deposition

InactiveUS6312768B1Improve surface qualityImprove efficiencyMaterial nanotechnologyElectric discharge heatingMacroscopic scaleCarbon nanotube

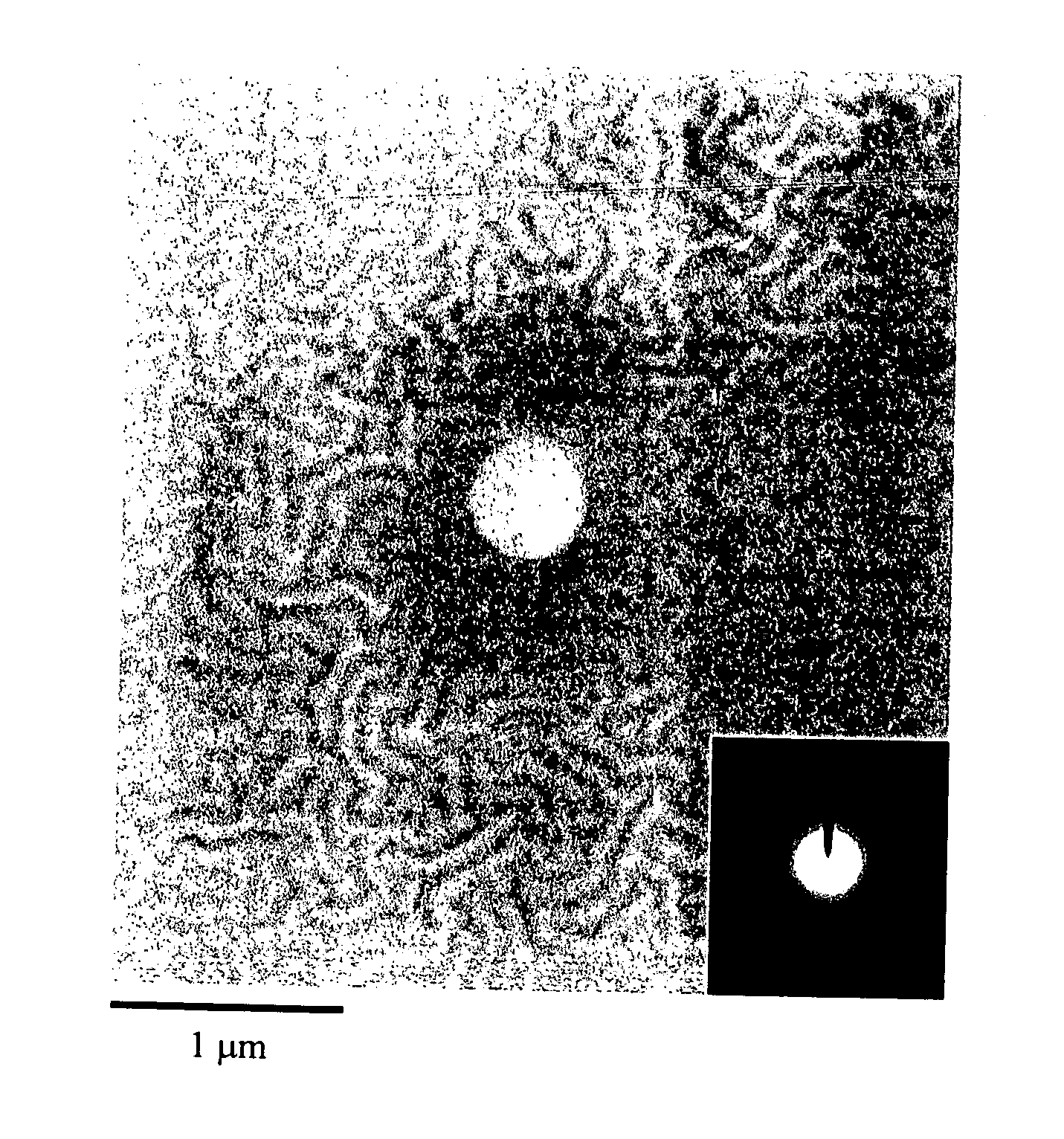

Powerful nanosecond-range lasers using low repetition rate pulsed laser deposition produce numerous macroscopic size particles and droplets, which embed in thin film coatings. This problem has been addressed by lowering the pulse energy, keeping the laser intensity optional for evaporation, so that significant numbers of the macroscopic particles and droplets are no longer present in the evaporated plume. The result is deposition of evaporated plume on a substrate to form thin film of very high surface quality. Preferably, the laser pulses have a repetition rate to produce a continuous flow of evaporated material at the substrate. Pulse-range is typically picosecond and femtosecond and repetition rate kilohertz to hundreds of megahertz. The process may be carried out in the presence of a buffer gas, which may be inert or reactive, and the increased vapour density and therefore the collision frequency between evaporated atoms leads to the formation of nanostructured materials of increasing interest, because of their peculiar structural, electronic and mechanical properties. One of these is carbon nanotubes, which is a new form of carbon belonging to the fullerene (C60) family. Carbon nanotubes are seamless, single or multishell co-axial cylindrical tubules with or without dome caps at the extremities. Typically diameters range from 1 nm to 50 nm with a length >1 mum. The electronic structure may be either metallic or semiconducting without any change in the chemical bonding or adding of dopant. In addition, the materials have application to a wide range of established thin film applications.

Owner:AUSTRALIEN NAT UNIV

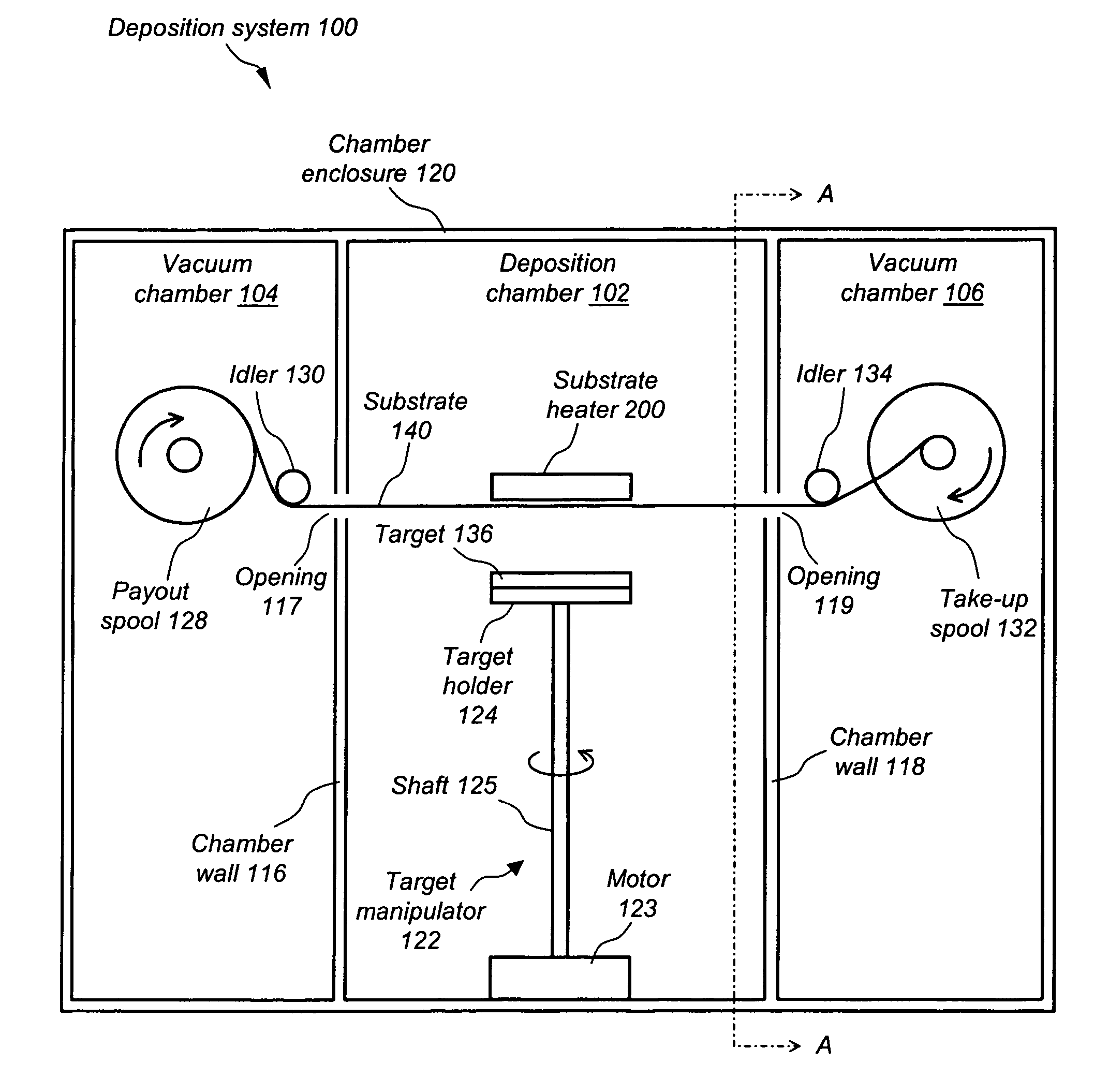

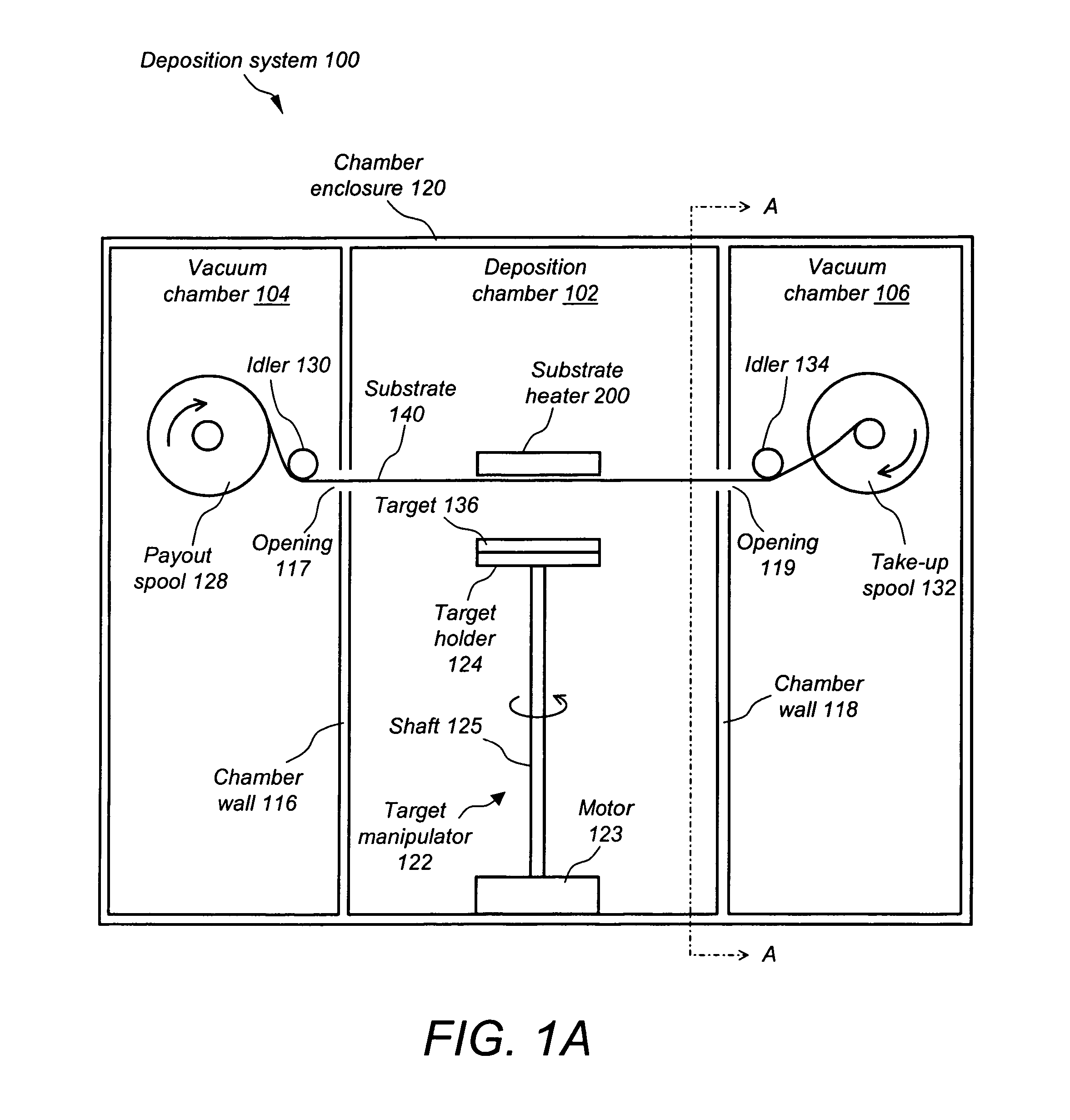

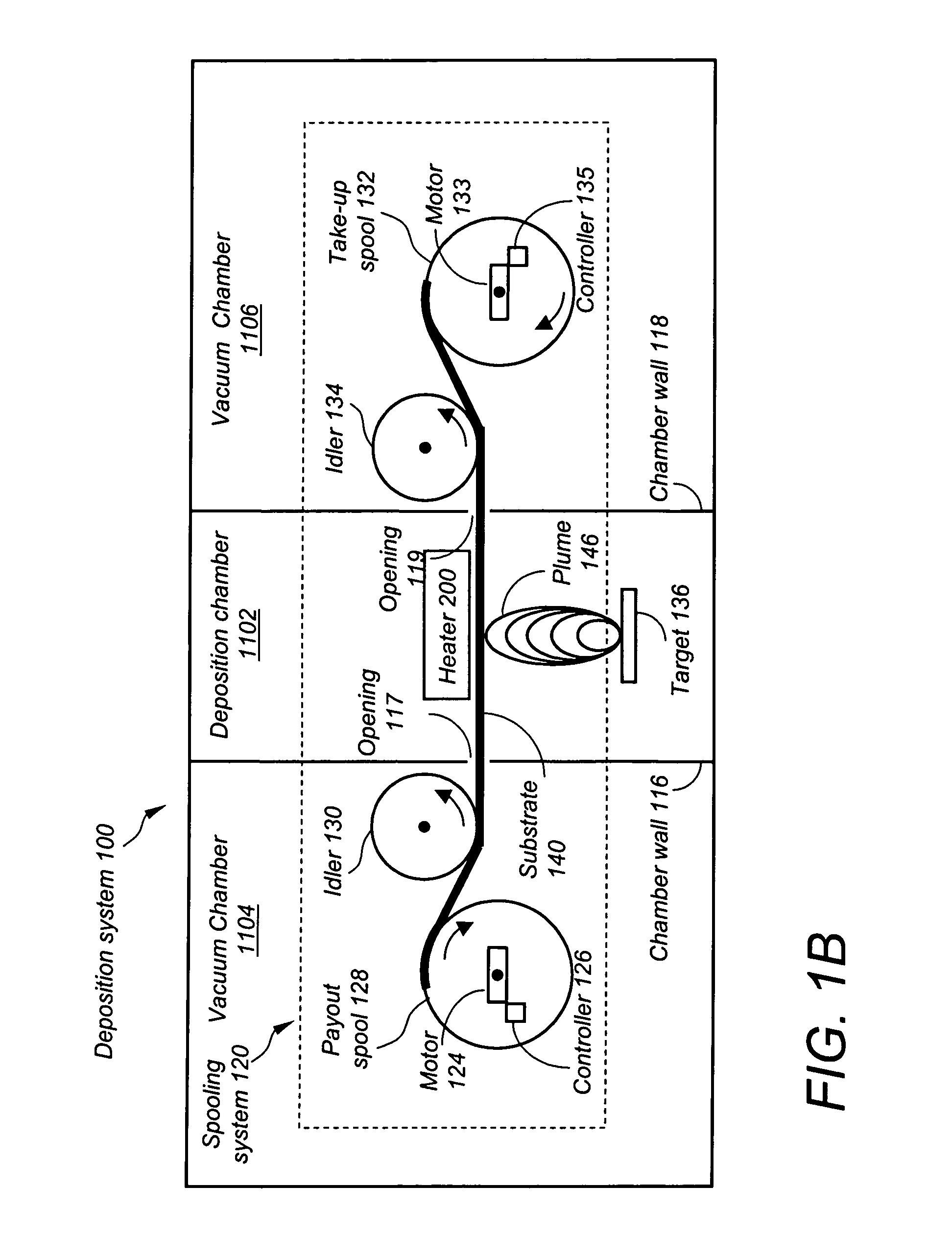

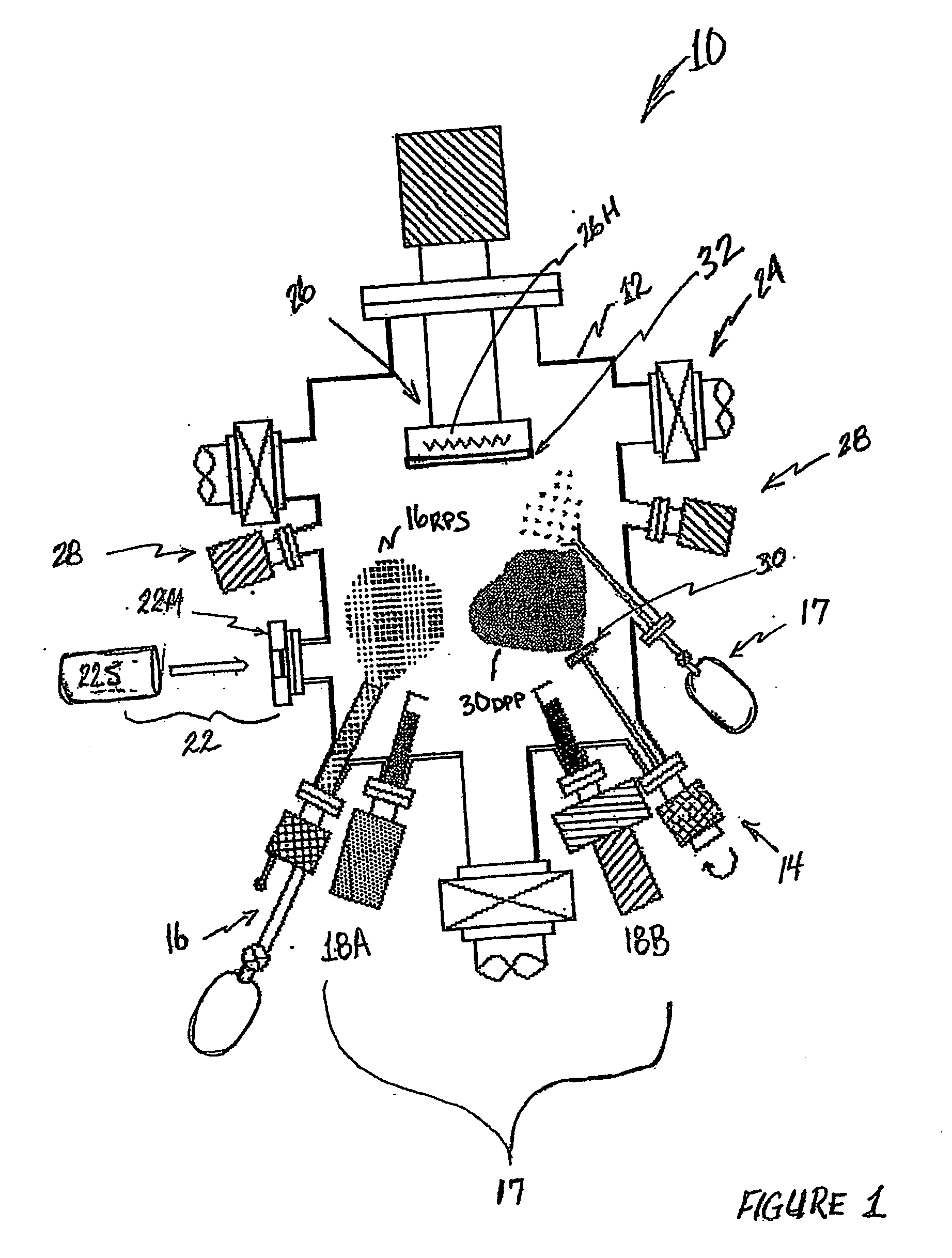

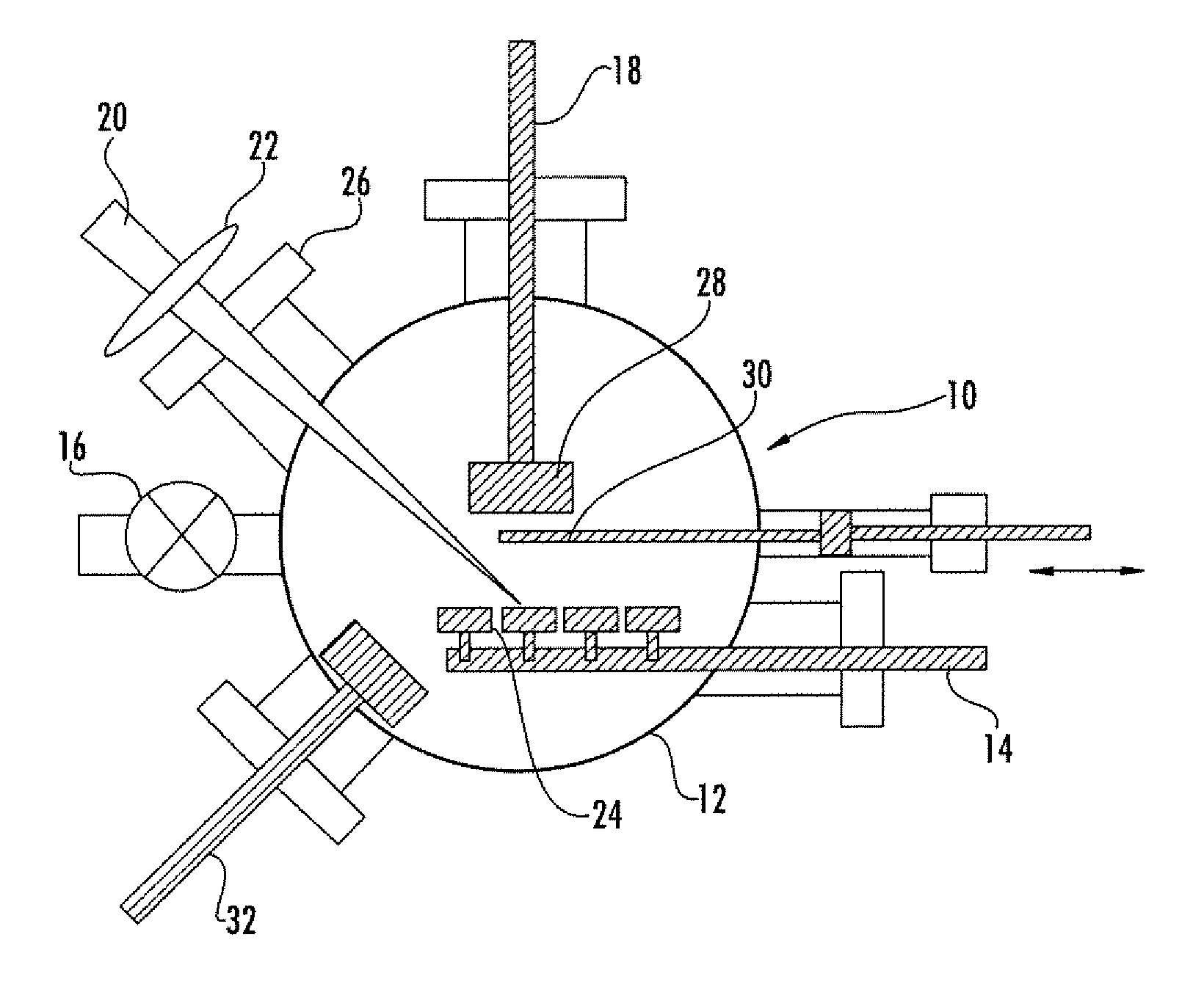

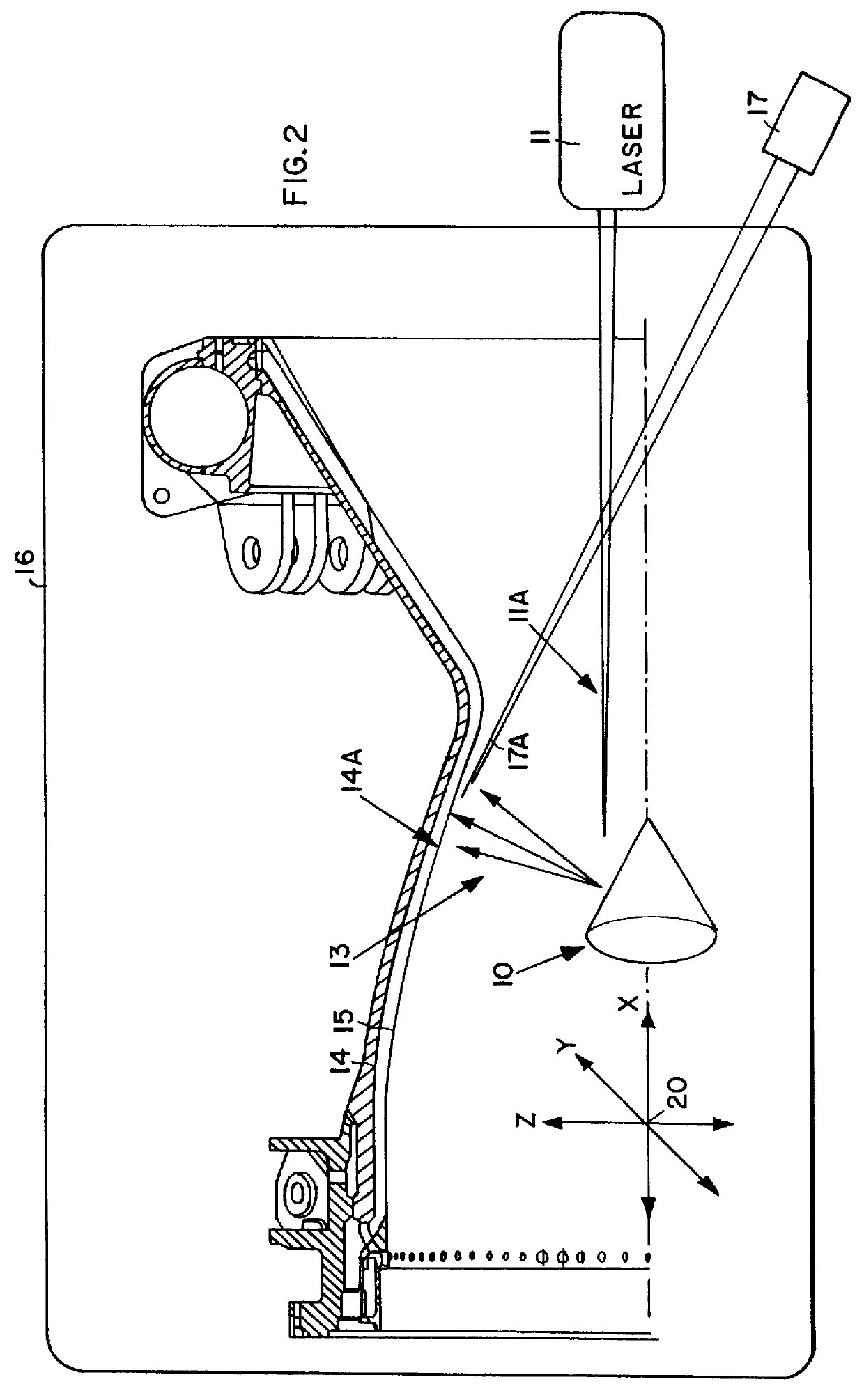

High throughput continuous pulsed laser deposition process and apparatus

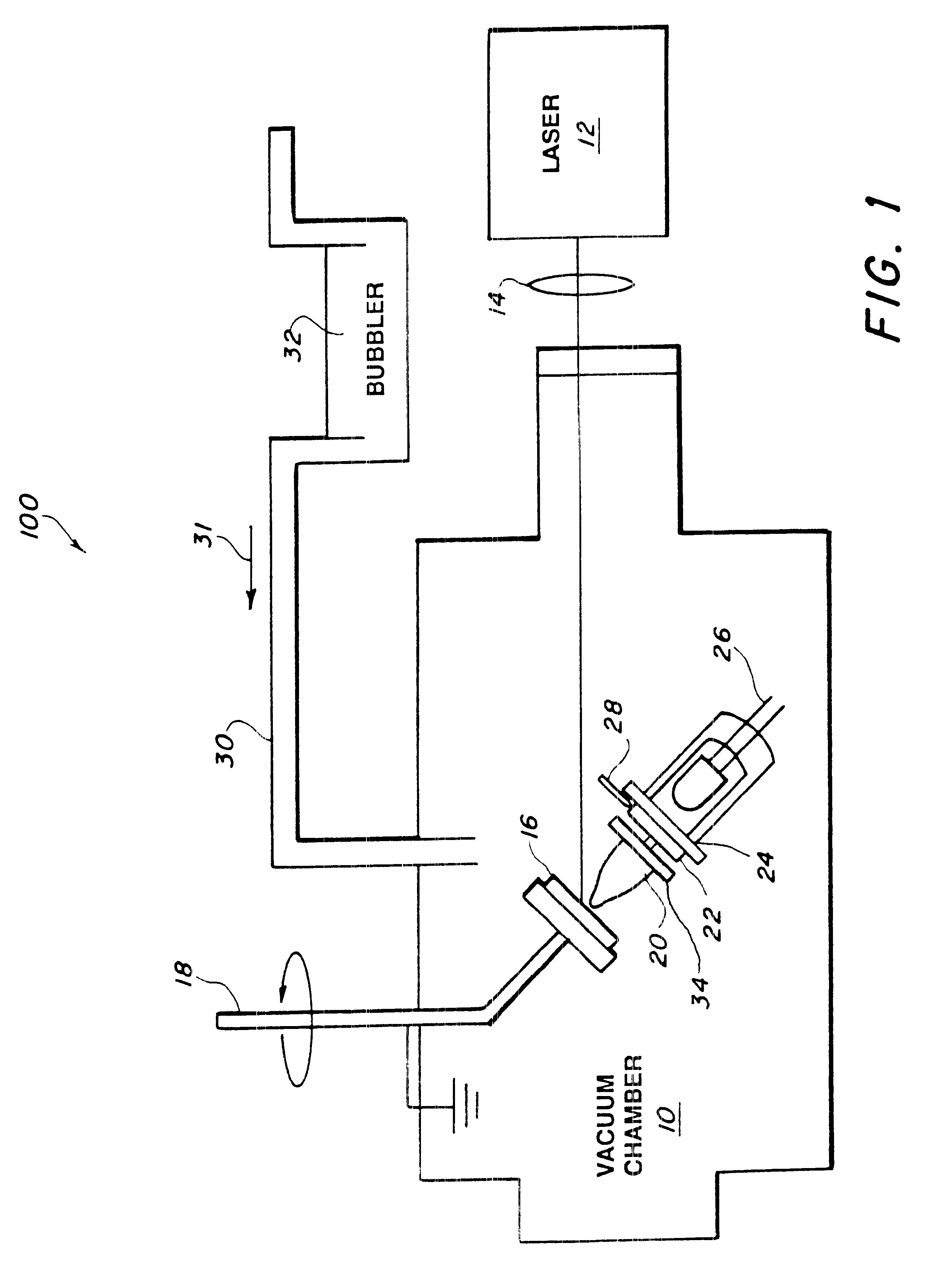

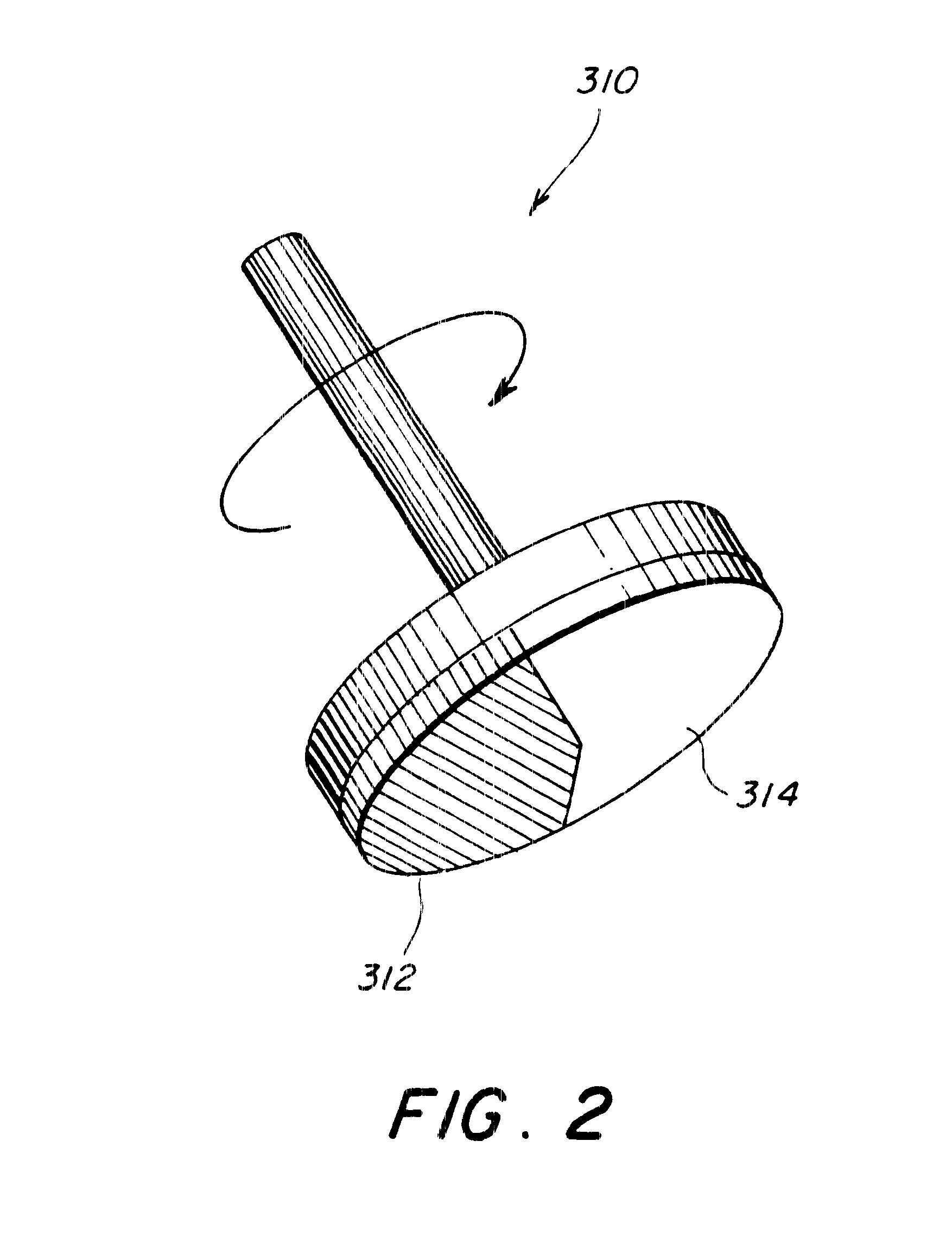

InactiveUS20050005846A1Ensure uniformityAvoid scratchesVacuum evaporation coatingSputtering coatingYttrium barium copper oxideHigh flux

The present invention relates to an apparatus and method for forming a high-temperature superconducting film on a long tape substrate at speeds suitable for large-scale production. The method includes a spooling system for use in a high-throughput, continuous pulsed laser deposition (PLD) process in which a superconducting layer, such as yttrium-barium-copper-oxide (YBCO), is deposited atop a buffered metal substrate tape that is translated through one or more deposition chambers via the action of a reel-to-reel spooling system and a conductive-radiant multi-zone substrate heater. It also optionally includes a multi-target manipulator apparatus and multiple laser beams in which multiple targets are impinged upon simultaneously.

Owner:SUPERPOWER INC

Fabrication of conductive/non-conductive nanocomposites by laser evaporation

A composite layer of a sorbent, chemoselective, non-electrically-conducting polymer and nano-particles of an electrically conducting material dispersed throughout the polymer is formed on a substrate by pulsed laser deposition, matrix assisted pulsed laser evaporation or matrix assisted pulsed laser evaporation direct writing.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Fabrication of conductive/non-conductive nanocomposites by laser evaporation

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

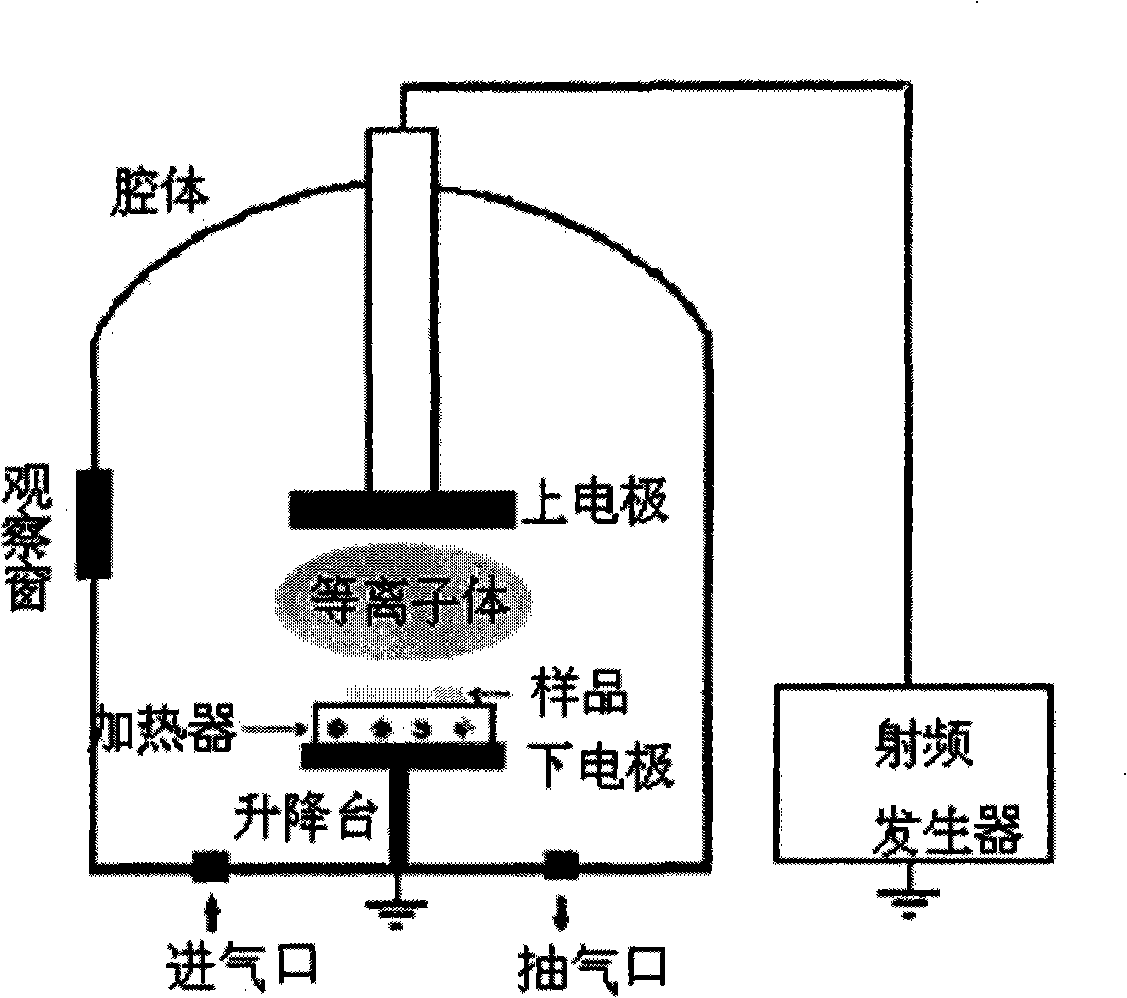

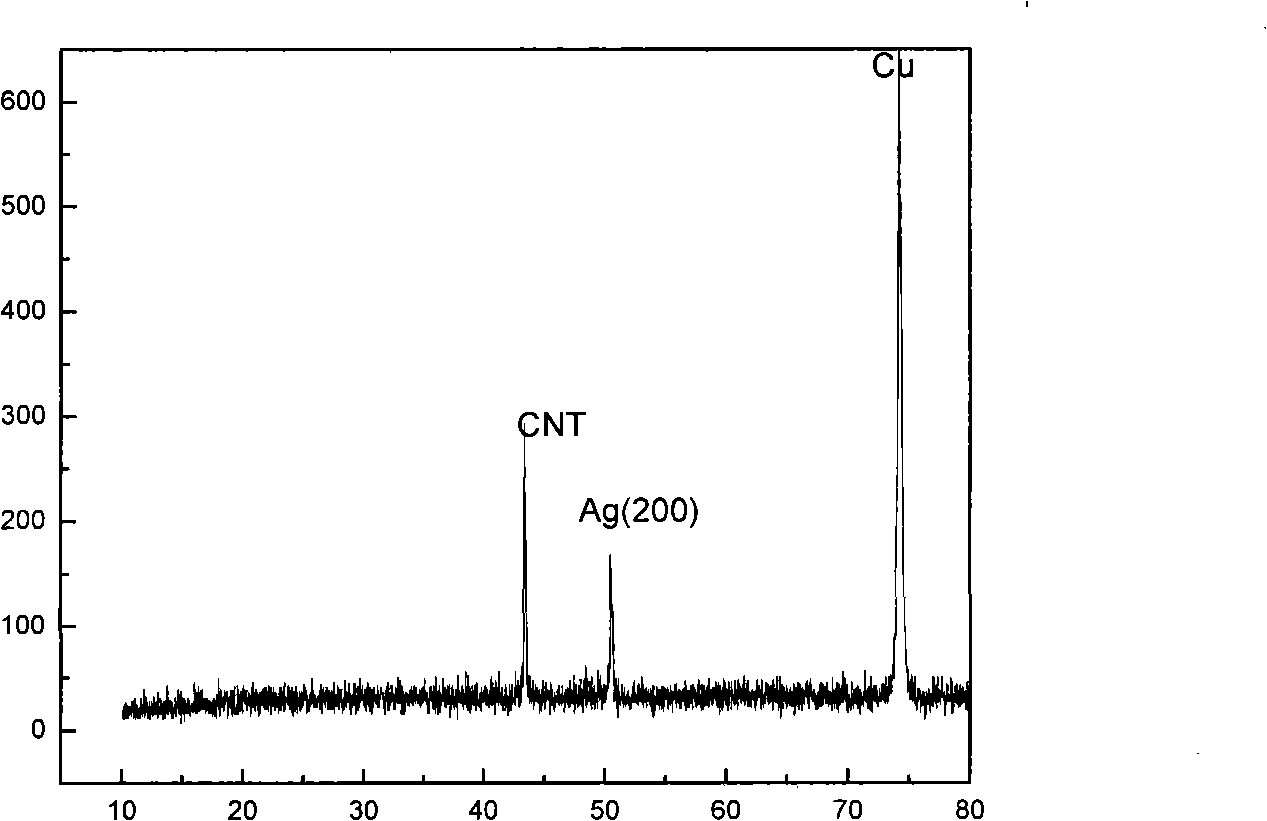

Method for preparing nano metal or metal oxide/carbon nano-tube composite material

InactiveCN101255544AShort processStable production processFrom normal temperature solutionsAfter-treatment detailsEvaporationCarbon nanotube

The invention relates to a simple practical preparation for metal or metal oxide / carbon nano-tube nano-composite, characterized in: with carbon nano-tube as the matrix, Fe, Co, Ni, Si, Ag, Au, Ti, Zn, Al, Mg, Ta, Pd, Mo, Sn and Pt as well as oxide nano-materials thereof are prepared by any method of radio frequency sputtering deposition, pulsed laser deposition, spraying schizolysis, hot evaporation or hydrothermal method, metal or metal oxide nano-grain or nano-film is formed on the surface of a carbon nano-tube. By this method, carbon nano-tube matrix composite material having multiple forms can be prepared, the process is simple, the cost is low, the carbon nana-tube matrix composite material has special optical property, electrical property, and magnetic property, thus having wide application prospect.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

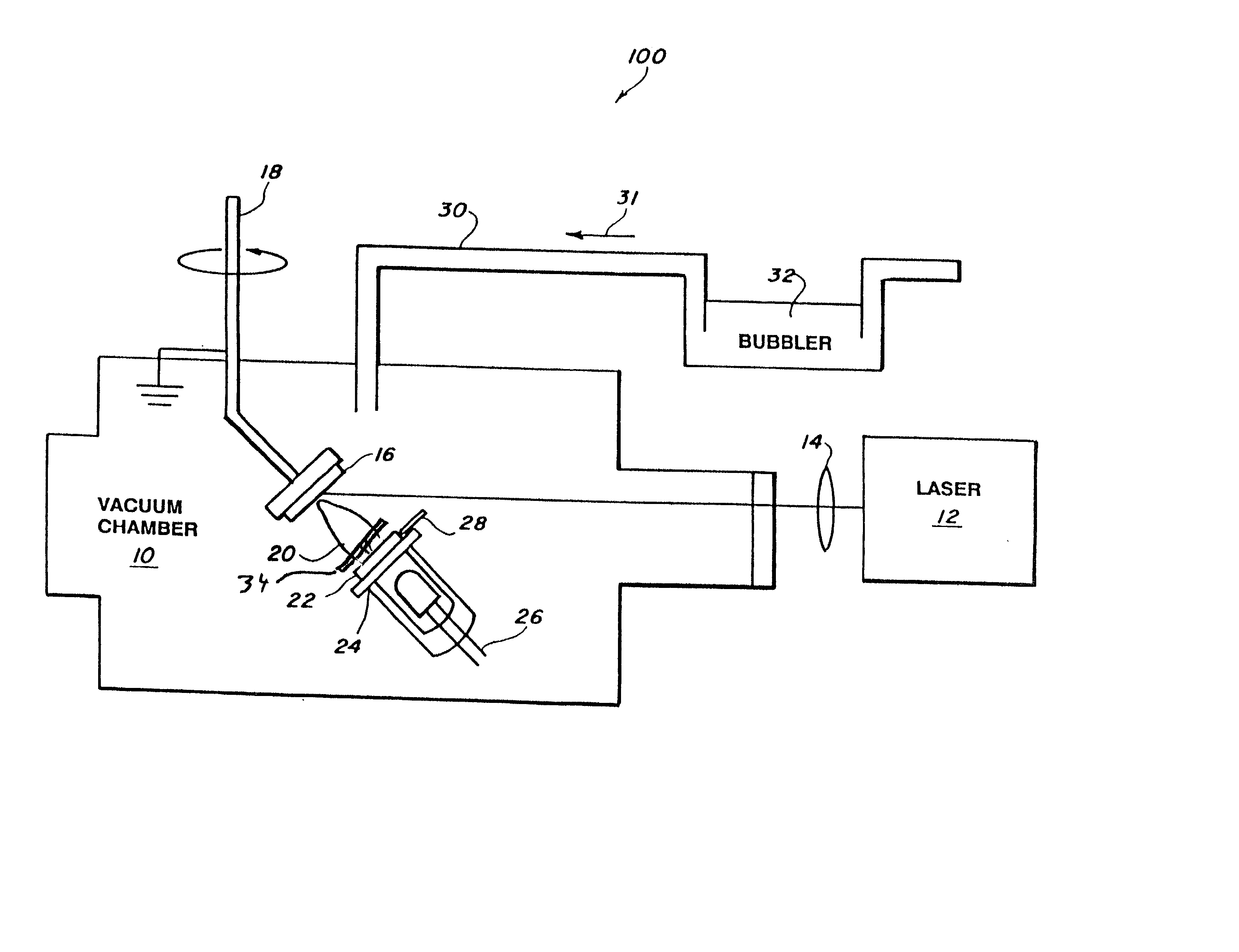

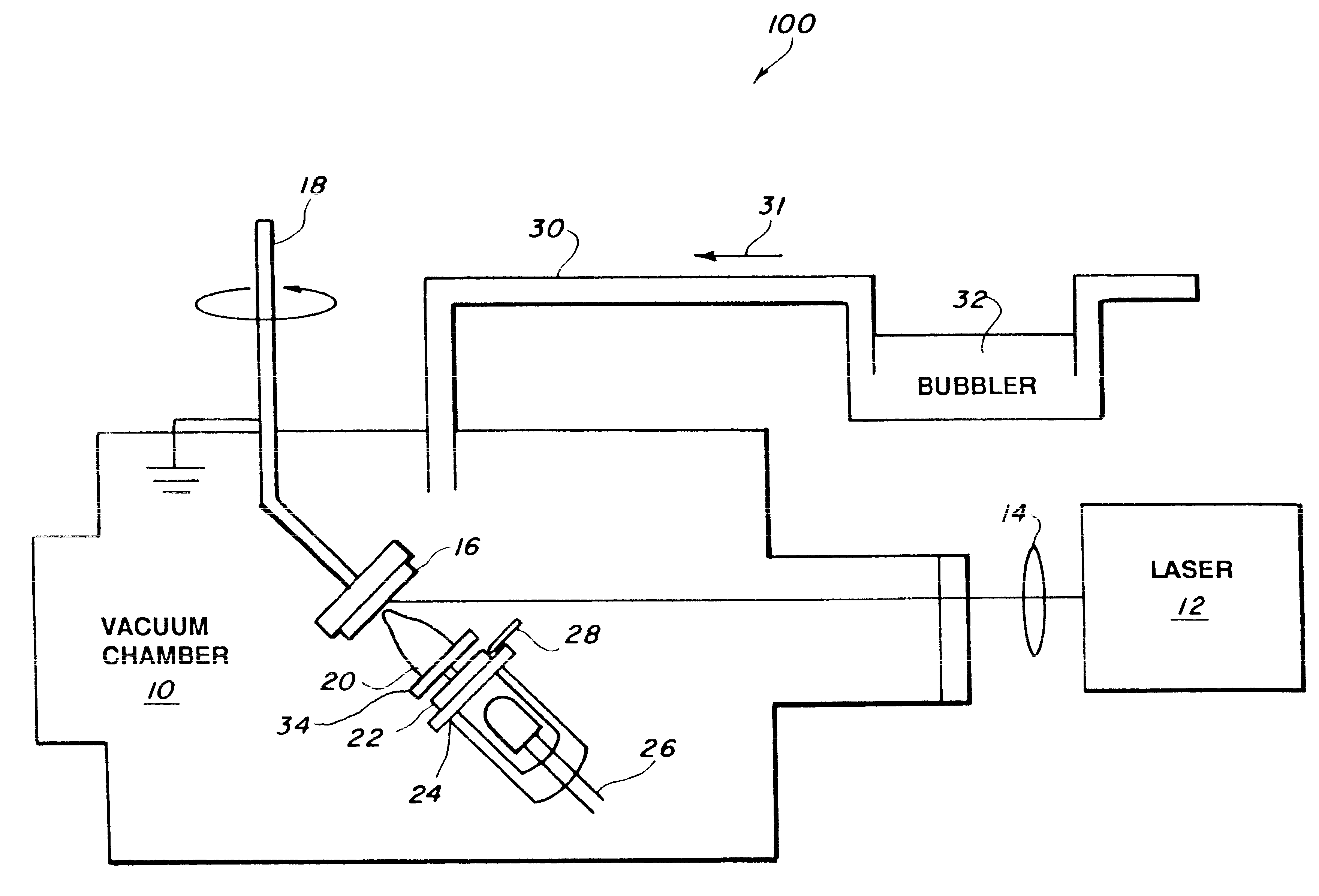

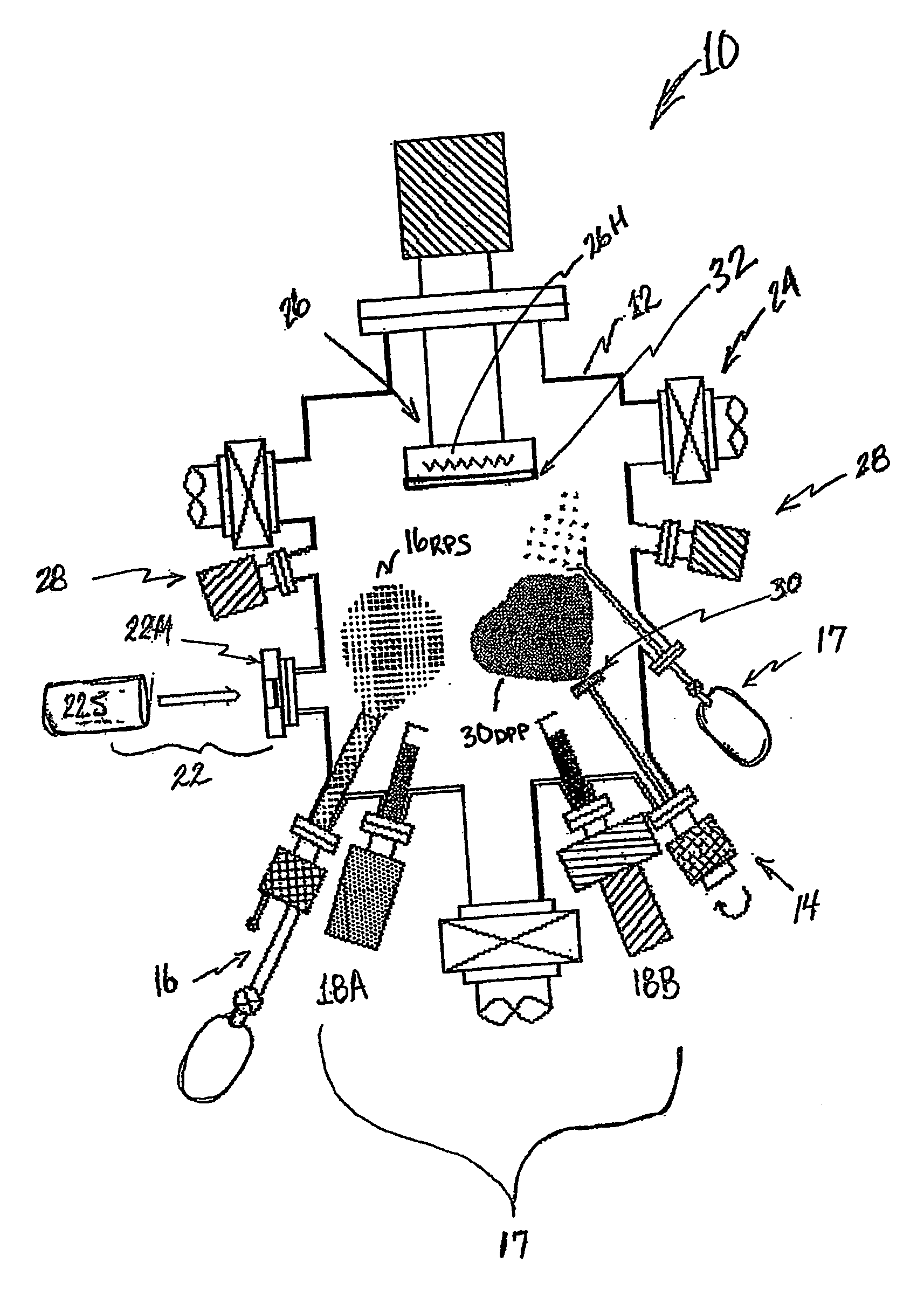

Method and system for fabricating an OLED

InactiveUS20040132228A1Solid-state devicesVacuum evaporation coatingOrganic light emitting deviceErbium lasers

A method and system for fabricating a layer of an organic light emitting device using pulsed laser deposition is provided. A pulsed laser source is used in the method for depositing an organic or coordination complex solid sample on a substrate. A plurality of coherent light wavelengths tuned at different frequencies from the laser and directed through an optical inlet of a vacuum chamber strike a sample to form a volatized sample for depositing on a substrate. Pulsed laser sources used in the method and system include YAG, excimer, alexandrite or combinations thereof. The system includes a pulsed laser source, a vacuum chamber, and an optical inlet for receiving at least two coherent light wavelengths tuned at different frequencies from a pulsed laser source. Alternative methods of deposition may also be performed within the same vacuum chamber.

Owner:HONEYWELL INT INC

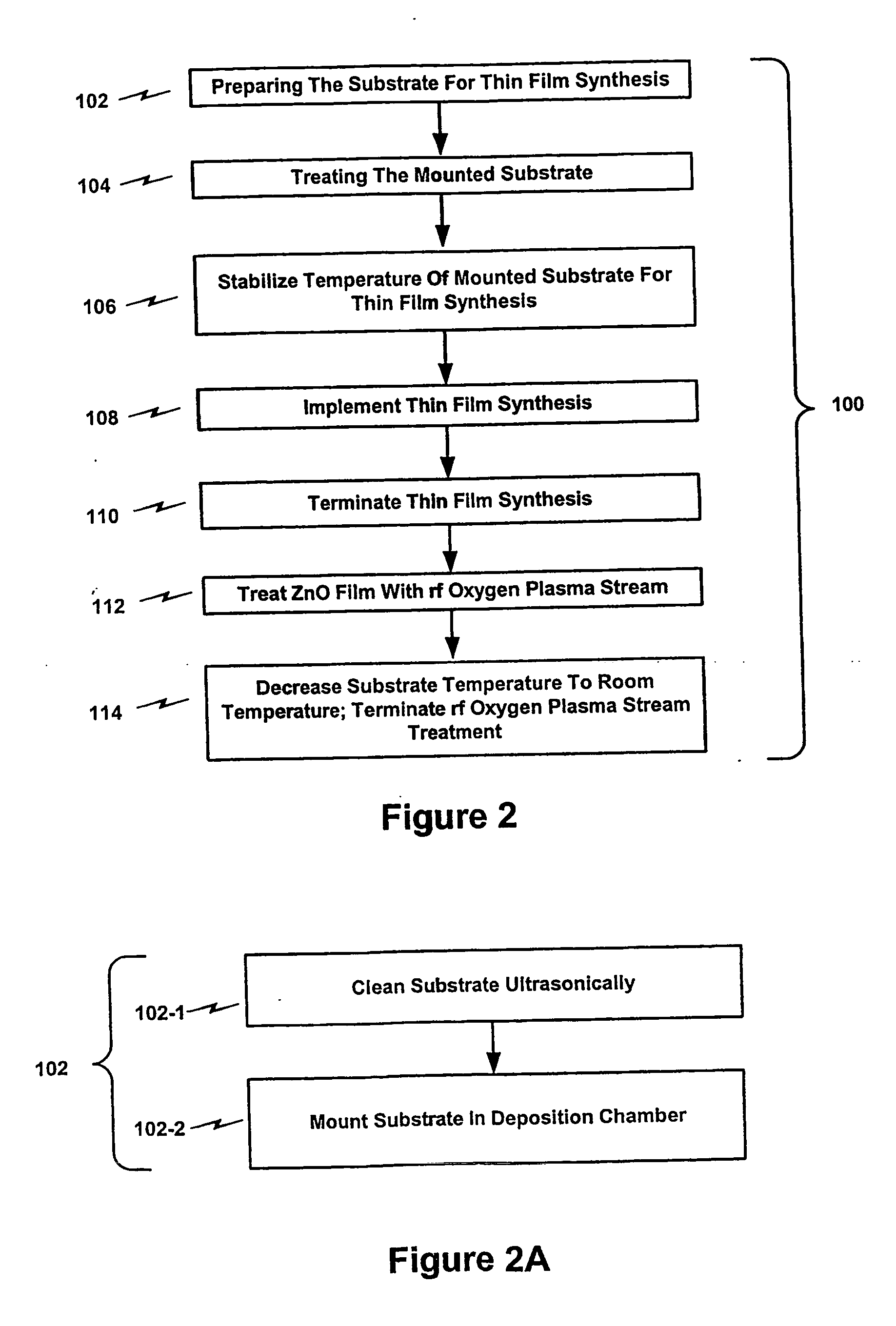

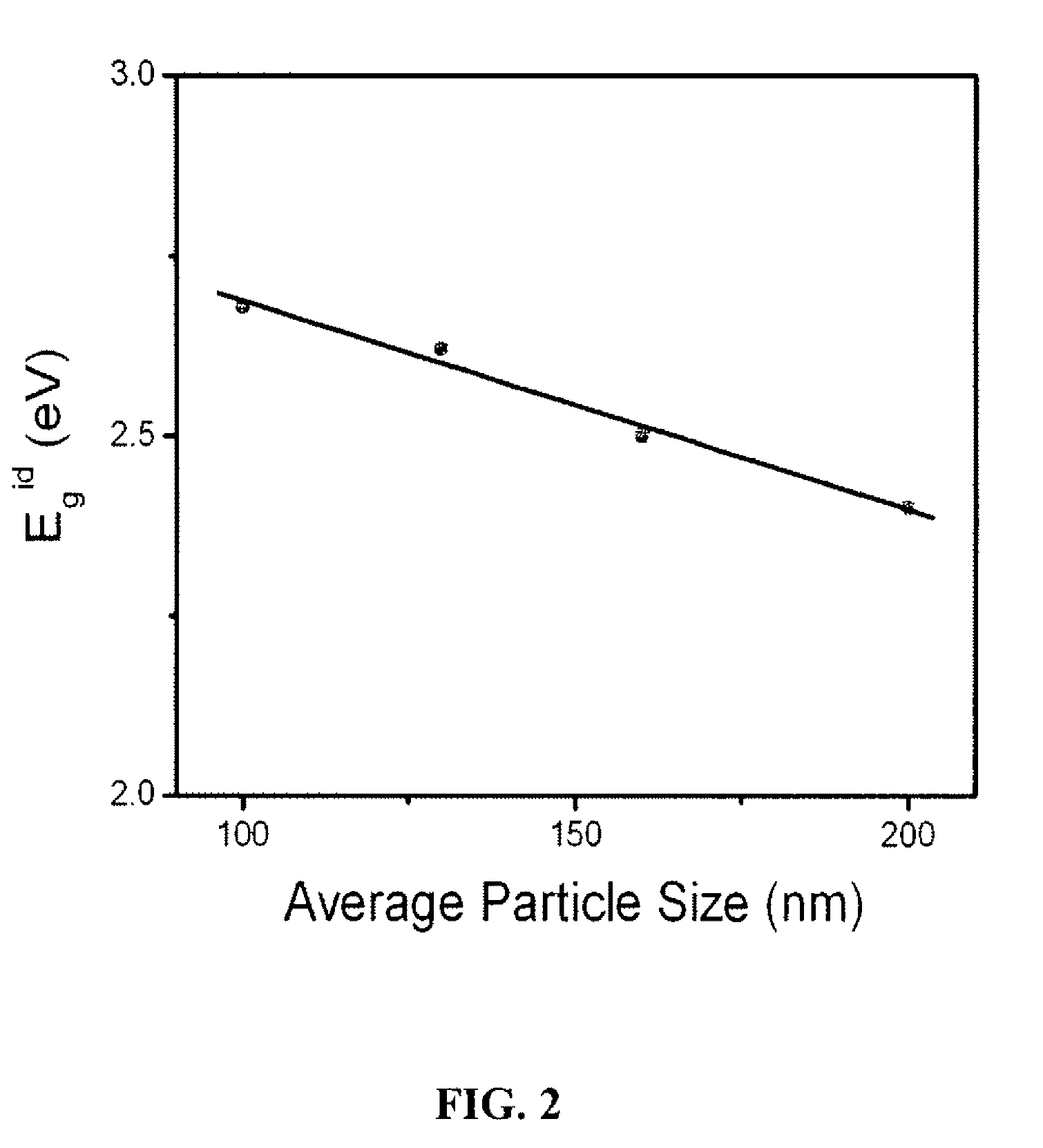

Hybrid beam deposition system and methods for fabricating metal oxide-zno films, p-type zno films, and zno-based II-VI compound semiconductor devices

InactiveUS20060233969A1Increase flux densityVacuum evaporation coatingSputtering coatingSource materialAlloy thin film

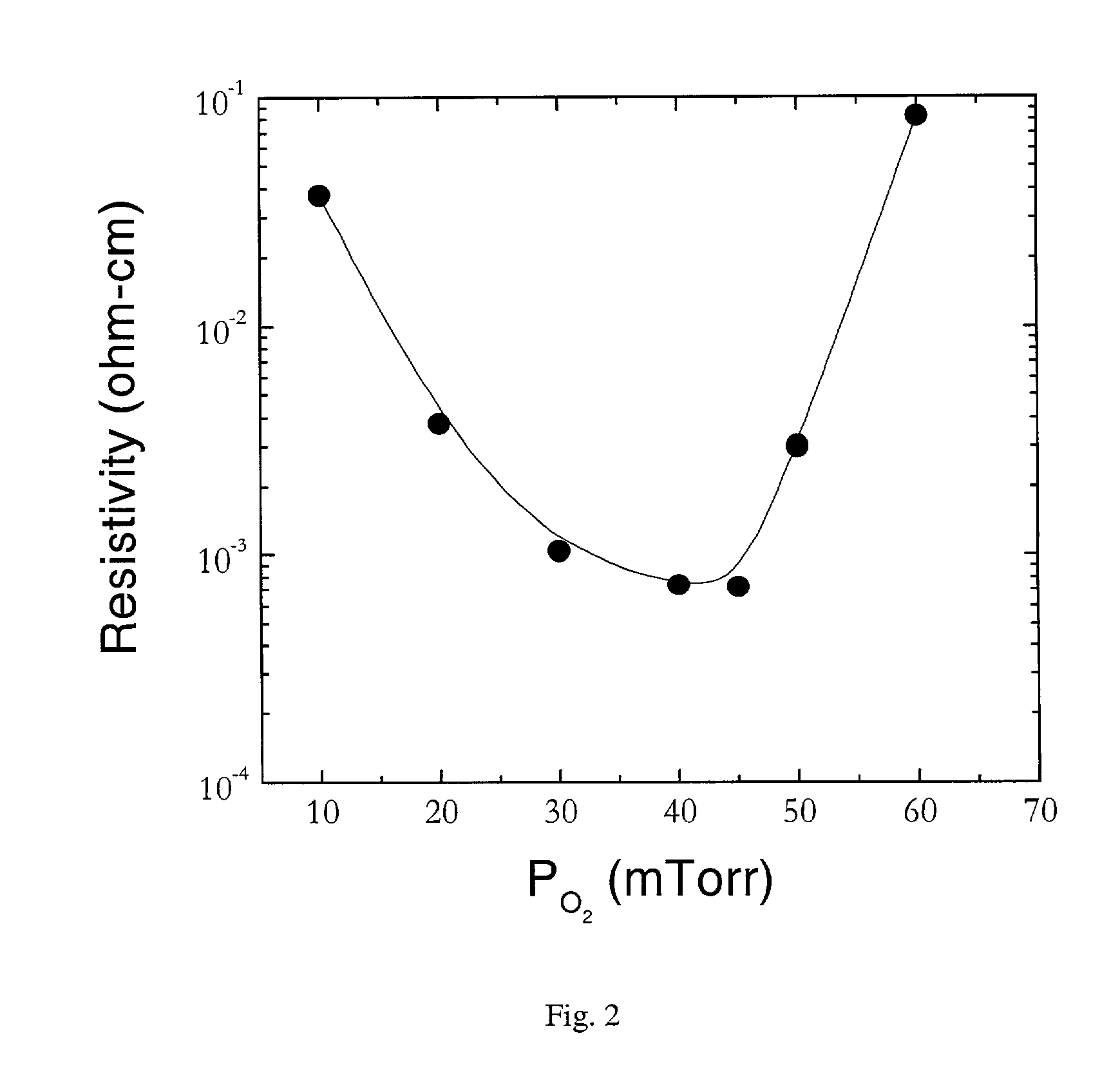

A hybrid beam deposition (HBD) system and methods according to the present invention utilizes a unique combination of pulsed laser deposition (PLD) technique and equipment with equipment and techniques that provide a radical oxygen rf-plasma stream to effectively increase the flux density of available reactive oxygen at a deposition substrate for the effective synthesis of metal oxide thin films. The HBD system and methods of the present invention further integrate molecular beam epitaxy (MBE) and / or chemical vapor deposition (CVD) techniques and equipment in combination with the PLD equipment and technique and the radical oxygen rf-plasma stream to provide elemental source materials for the synthesis of undoped and / or doped metal oxide thin films as well as synthesis of undoped and / or doped metal-based oxide alloy thin films.

Owner:MOXTRONICS

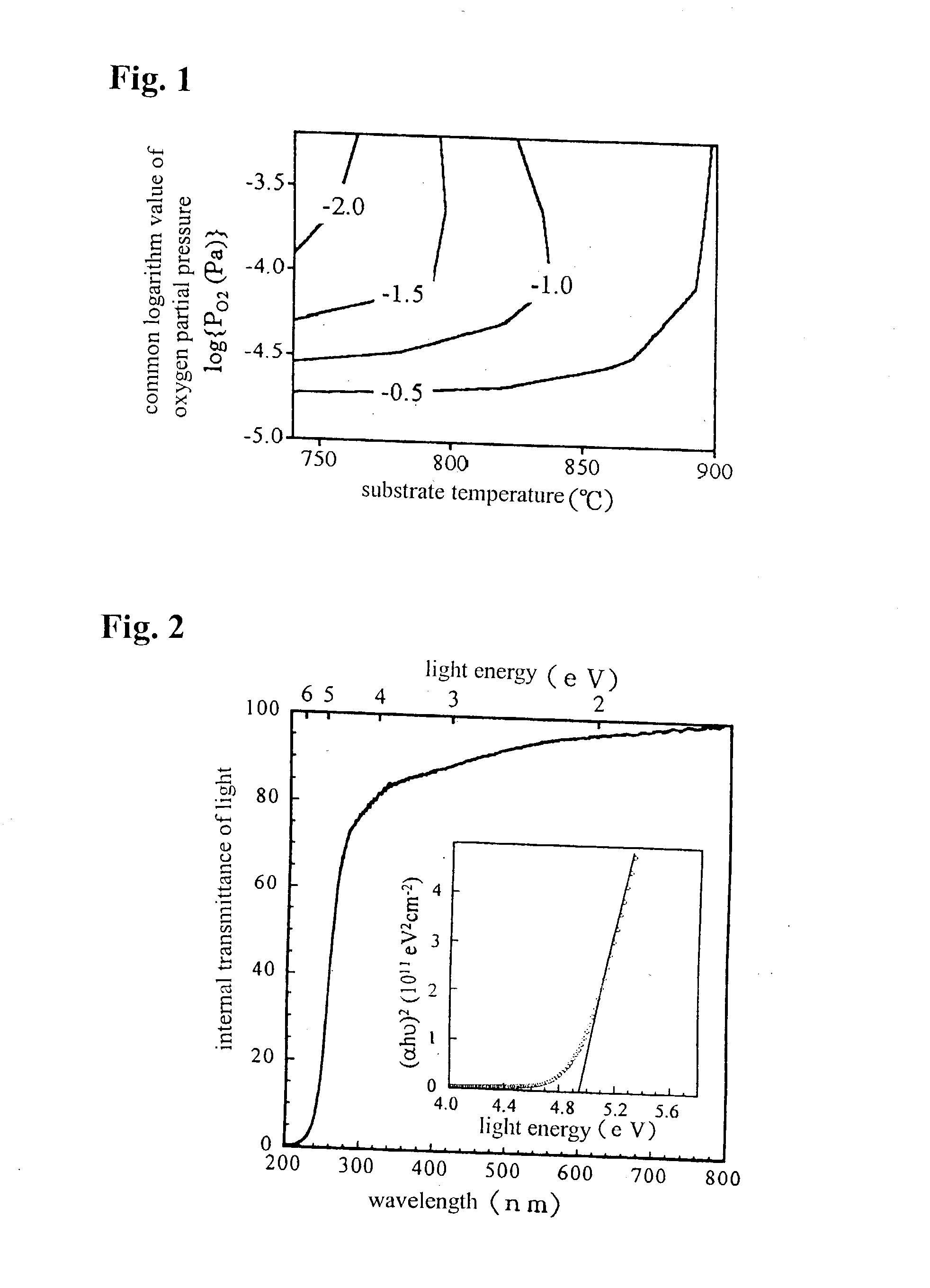

Ultraviolet-transparent conductive film and process for producing the same

The present invention provides an ultraviolet-transparent conductive film comprising a Ga2O3 crystal. The film has a transparency in the wavelength range of 240 to 800 nm, or 240 to 400 nm, and an electric conductivity induced by an oxygen deficiency or dopant in the Ga2O3 crystal. The dopant includes at least one element selected from the group consisting of the Sn, Ge, Si, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo and W. The ultraviolet-transparent conductive film is formed through either one of a pulsed-laser deposition method, sputtering method, CVD method and MBE method, under the conditions with a substrate temperature of 600 to 1500° C. and an oxygen partial pressure of 0 to 1 Pa.

Owner:HOYA CORP +1

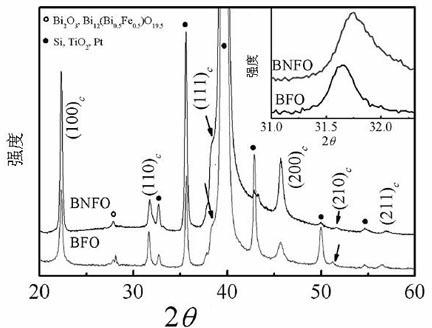

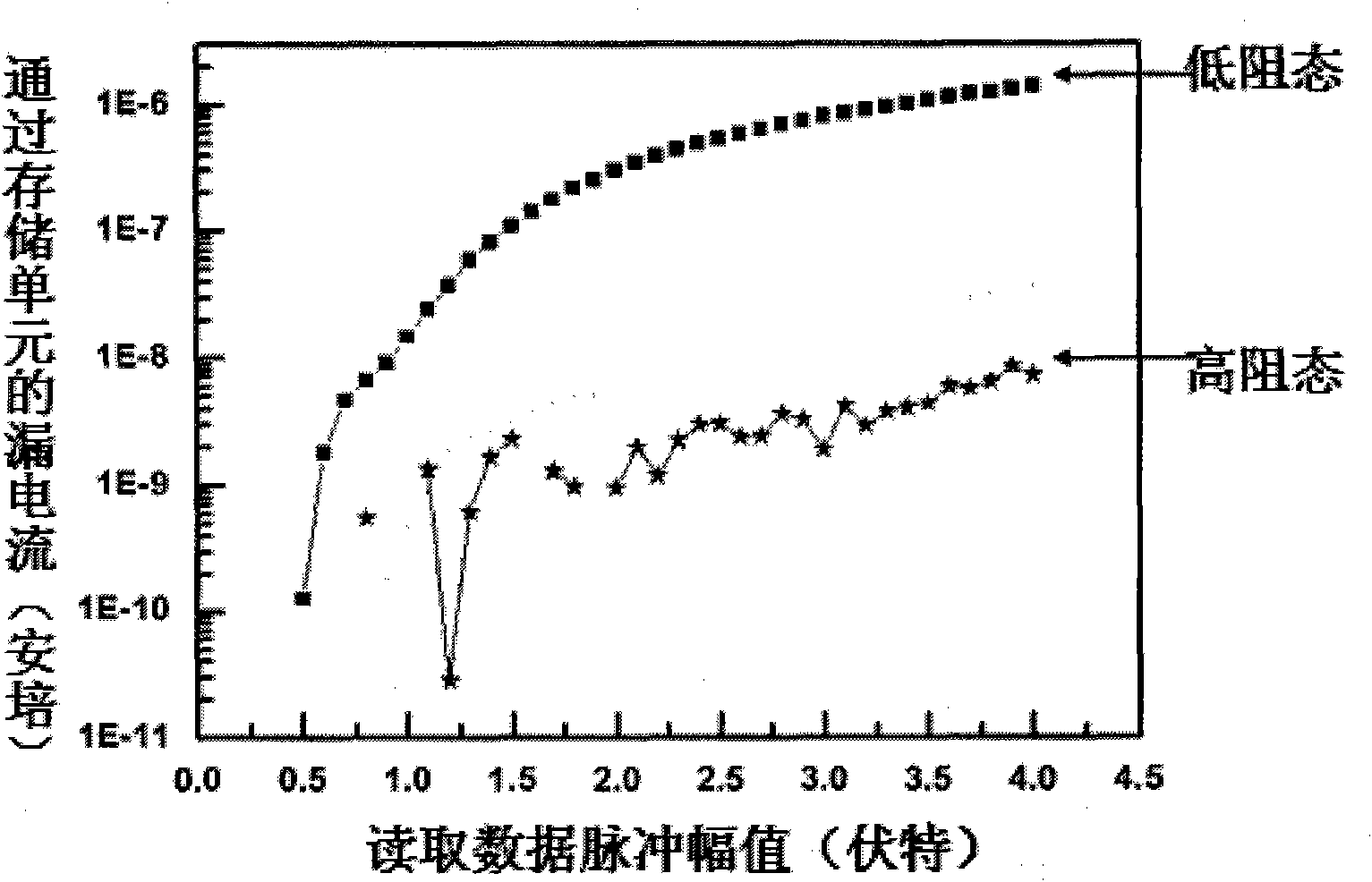

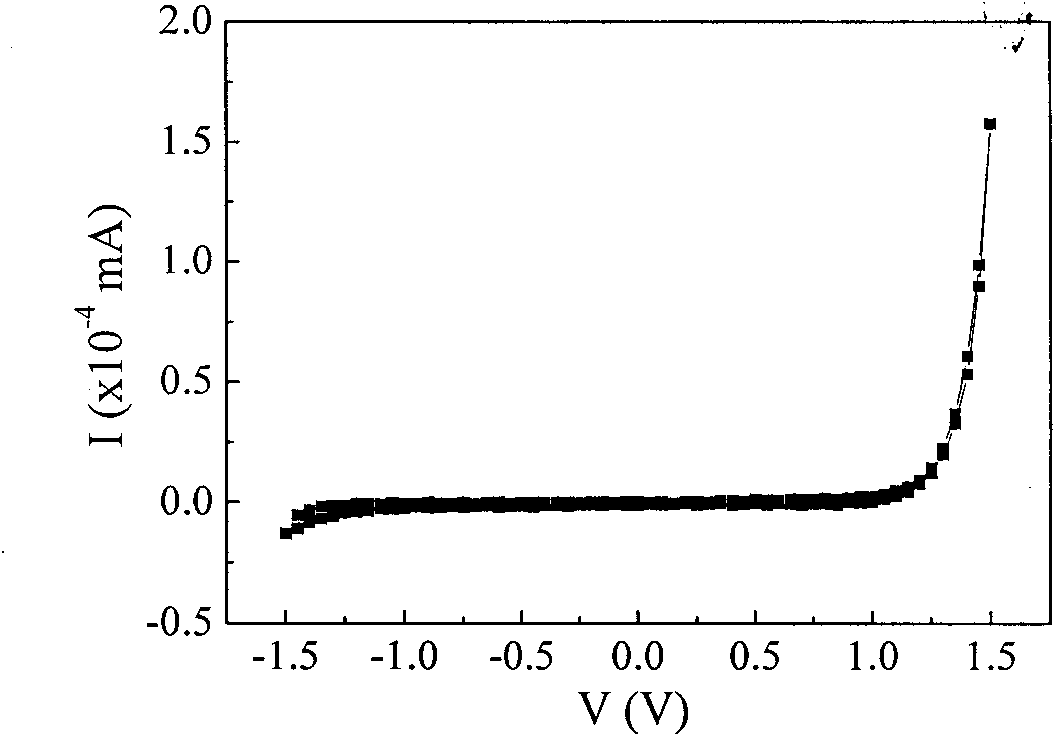

One-phase ferroelectric film and preparing method thereof as well as effective resistance regulation mode

InactiveCN102157682AWith ferroelectricityWith semiconductor performanceElectrical apparatusVacuum evaporation coatingLead zirconate titanateSputtering

The invention discloses a one-phase ferroelectric film capable of regulating effective resistance by ferroelectric polarization, a preparing method of the one-phase ferroelectric film and an effective resistance regulation mode. The one-phase ferroelectric film comprises B-bit-doped Bal-xSrxTil-yByO3, Pb(Fe1-yBy)O3, Pb(Co1-yBy)O3, (Pb1-xAx)(ZryTi1-y)O3, A-bit-doped Y1-xAxMnO3, Bil-xAxFeO3, and Bi4-xAxTi3O12. The one-phase ferroelectric film is prepared by using film preparing methods, such as pulsed laser deposition (PLD), laser molecular beam epitaxy (LMBE) and magnetron sputtering. The prepared ferroelectric film is 0.4-1000 nanometer in the thickness and has larger conductance and leakage current, as well as ferroelectricity and semiconductor performance. The invention provides a method for improving the antifatigue performance of the one-phase ferroelectric film. Turning frequency (x) of the ferroelectric polarization in the method can be increased to 102-1010; and the ferroelectric polarization is turned to regulate the effective resistance of the one-phase ferroelectric film.

Owner:NANJING UNIV OF SCI & TECH

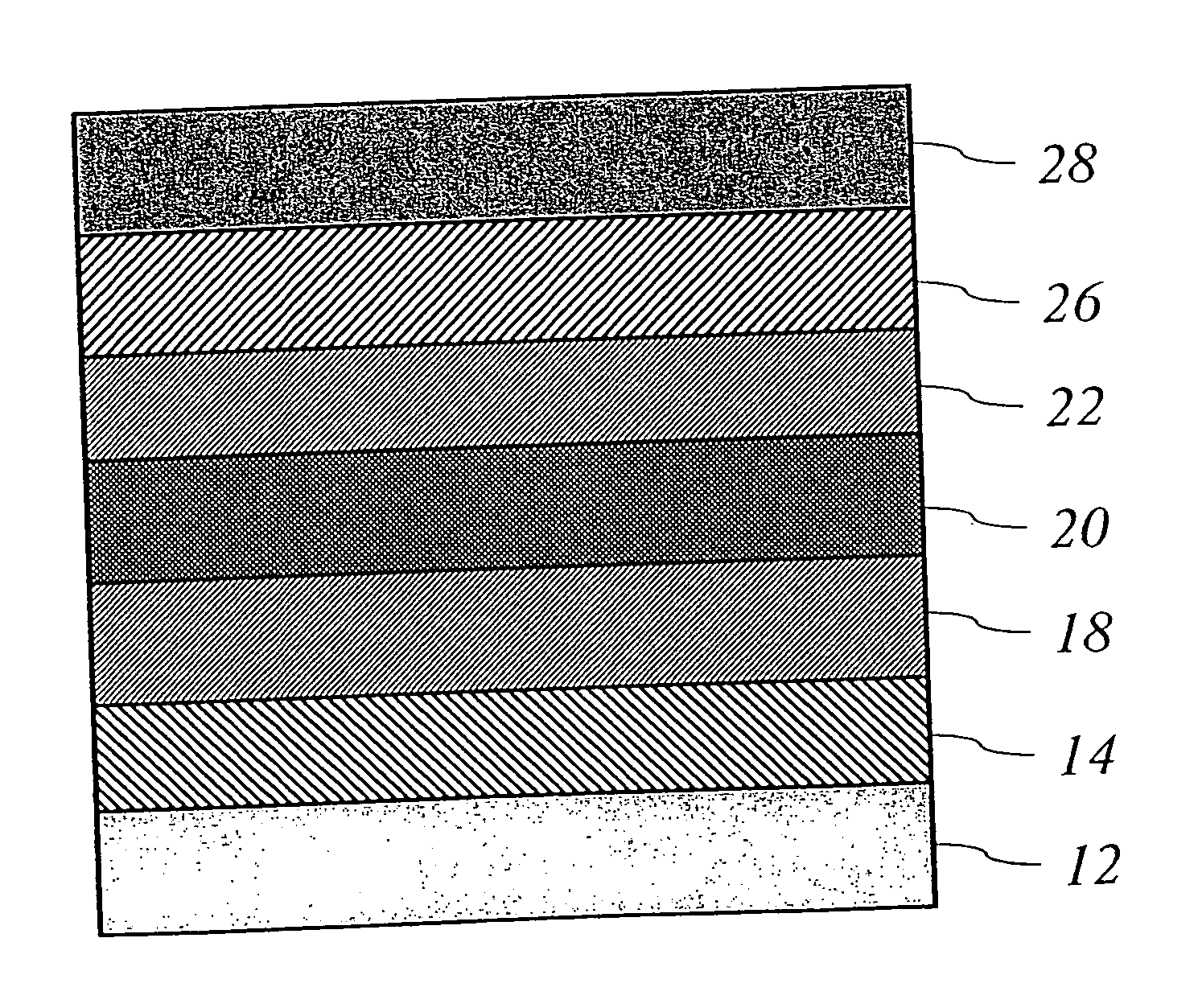

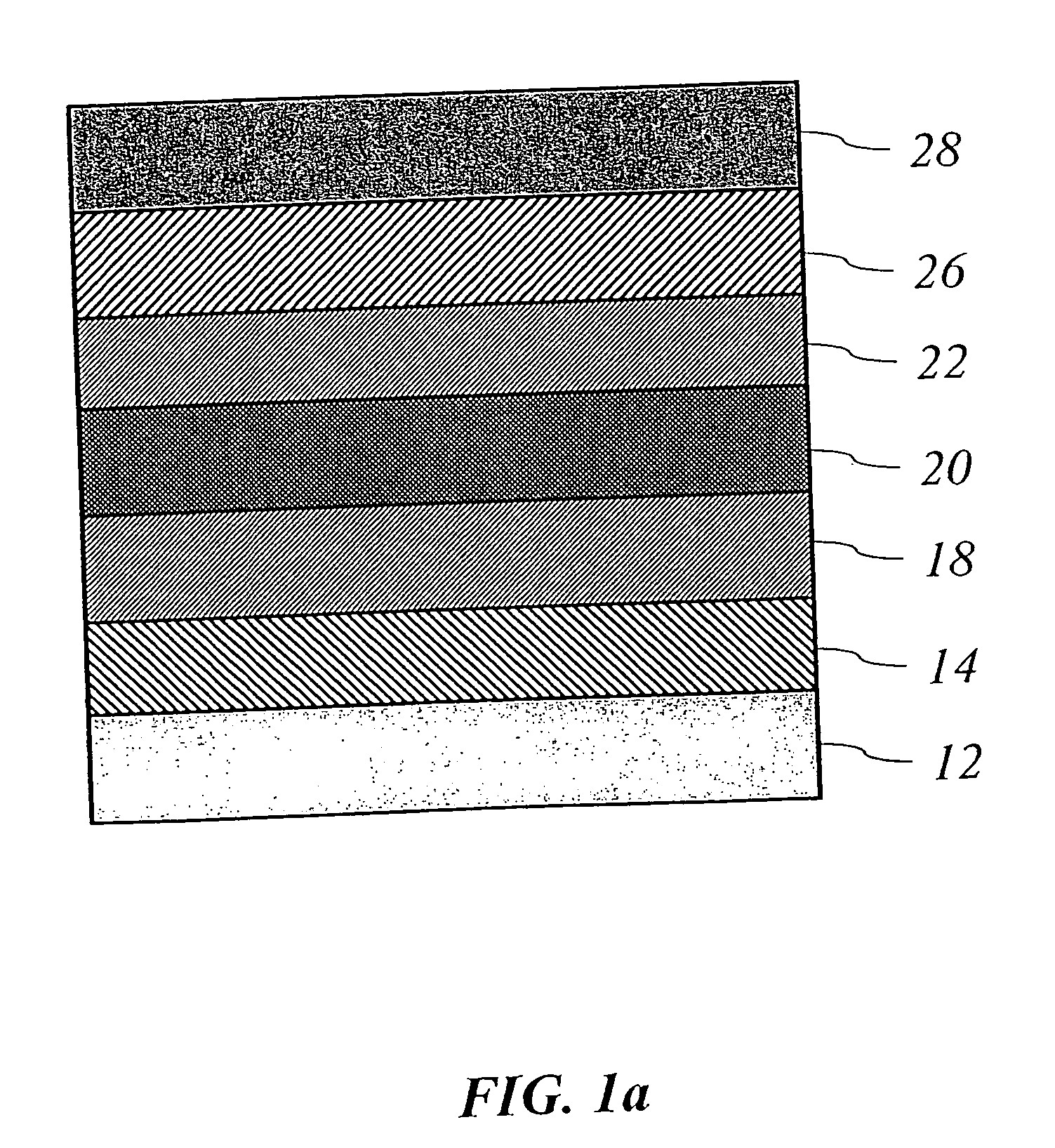

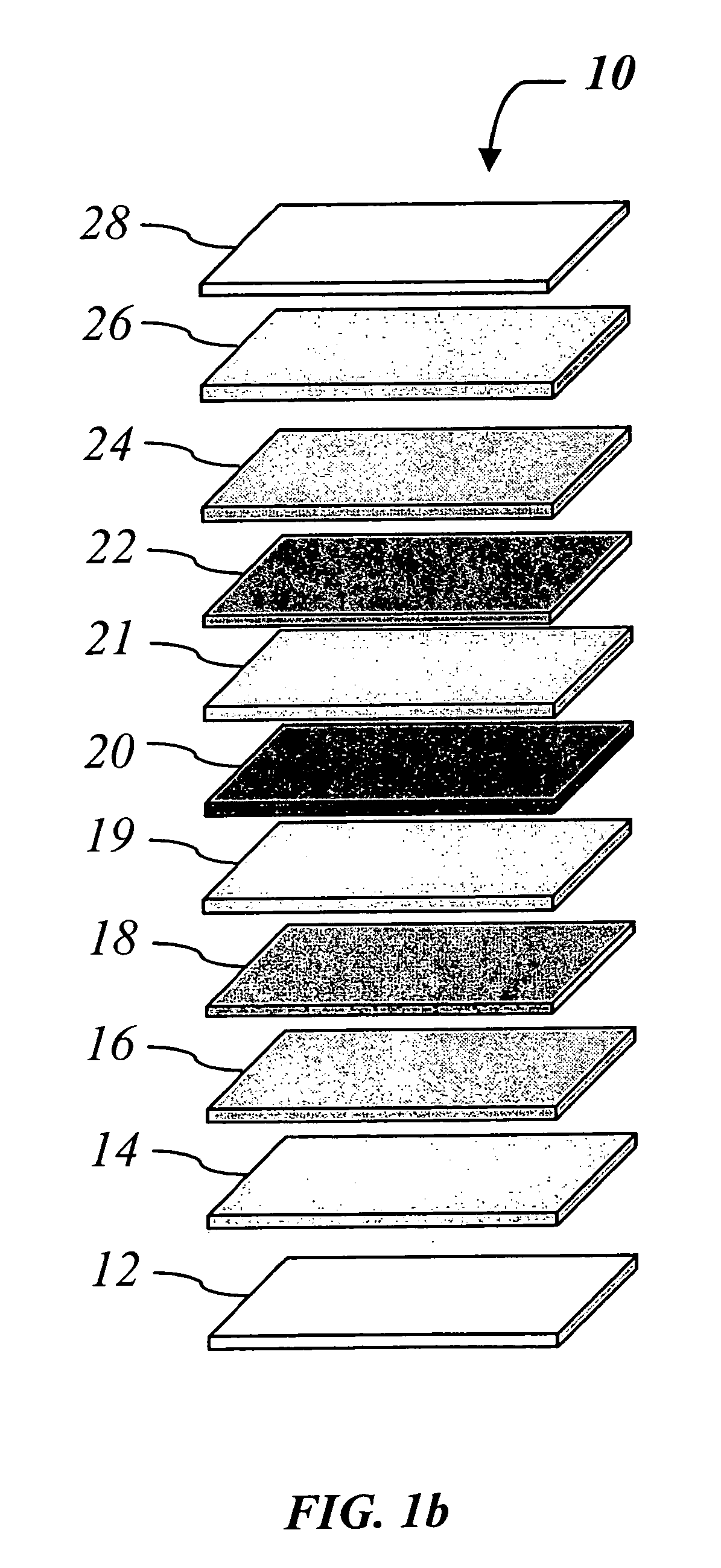

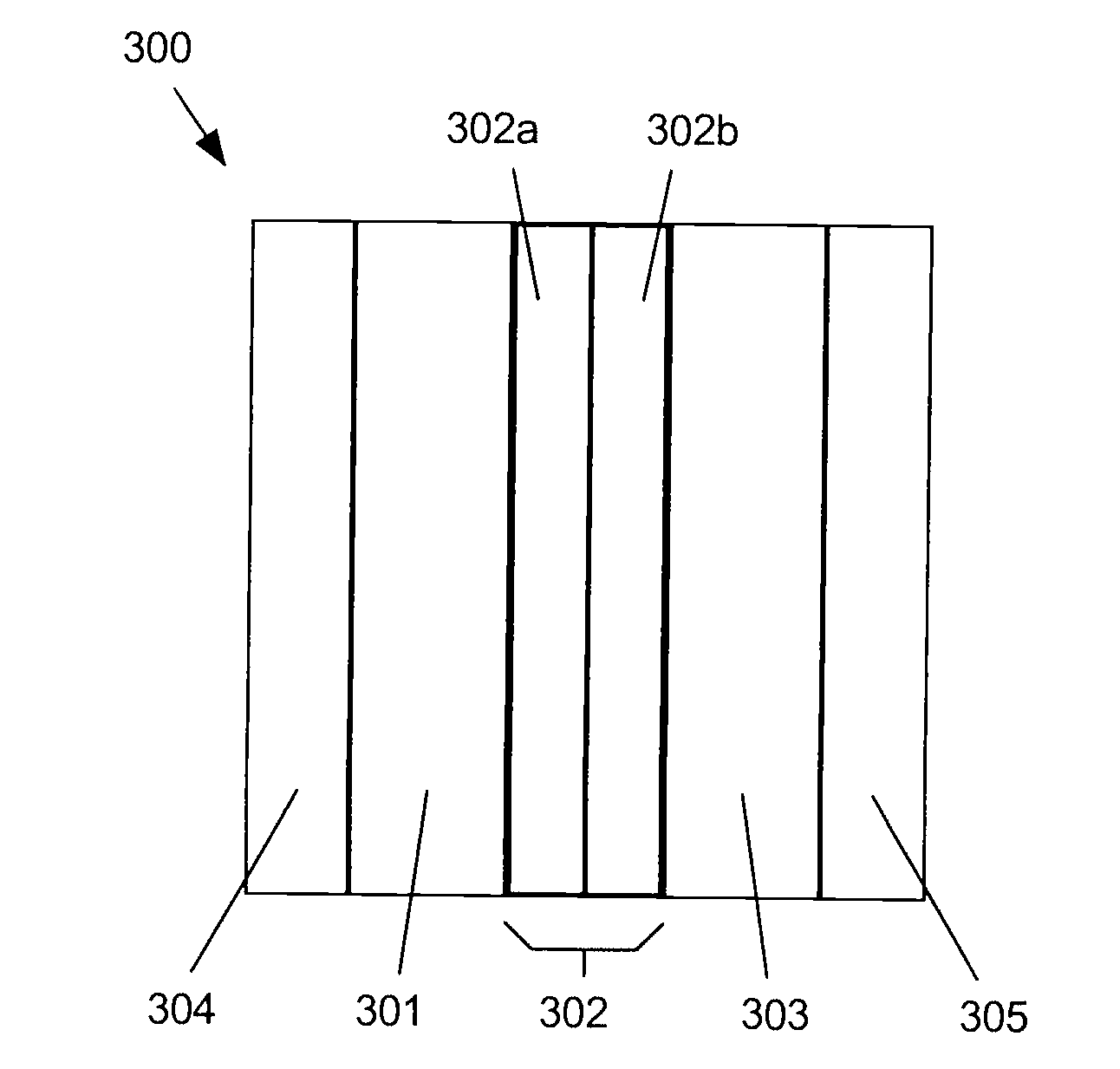

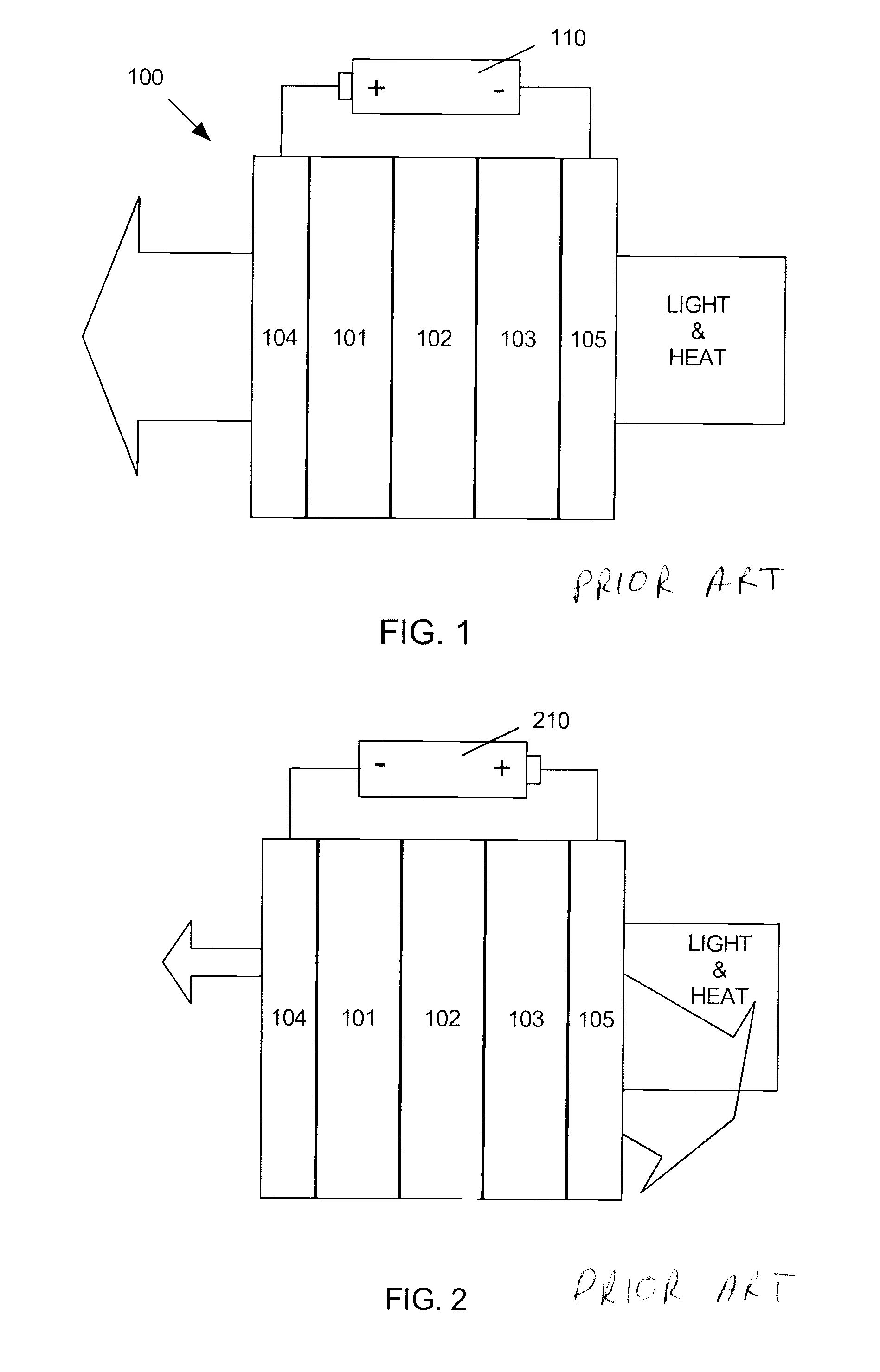

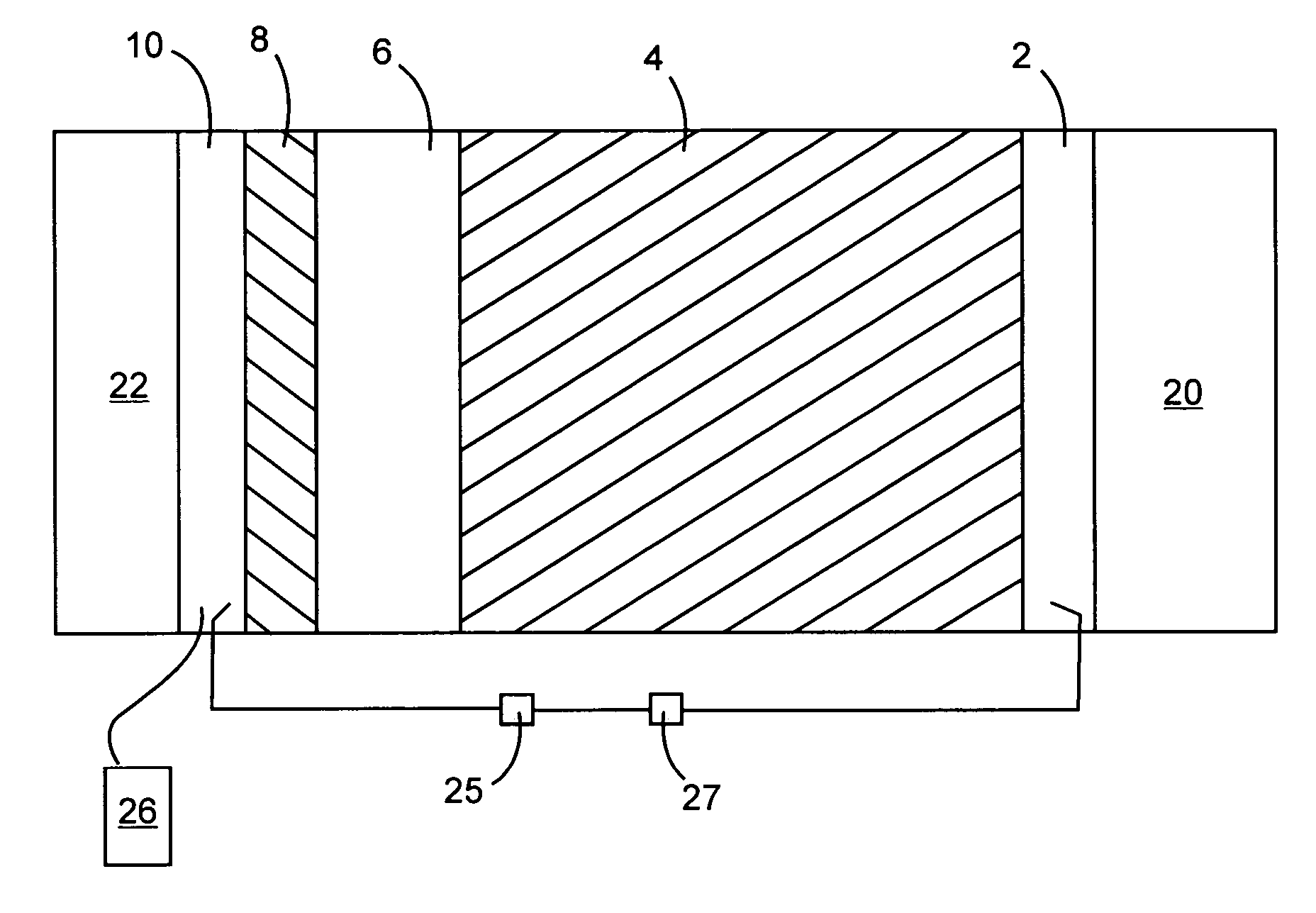

Electrochromic devices and fabrication methods

InactiveUS20080304131A1Radiation applicationsVacuum evaporation coatingElectricityElectrical conductor

An electrochromic device includes a first conductive layer, a single-layer or dual-layer ion conductor layer, and a second conductive layer. The layers are deposited using PVD, CVD, PECVD, atomic layer deposition, pulsed laser deposition, plating, or sol-gel techniques.

Owner:VIEW INC

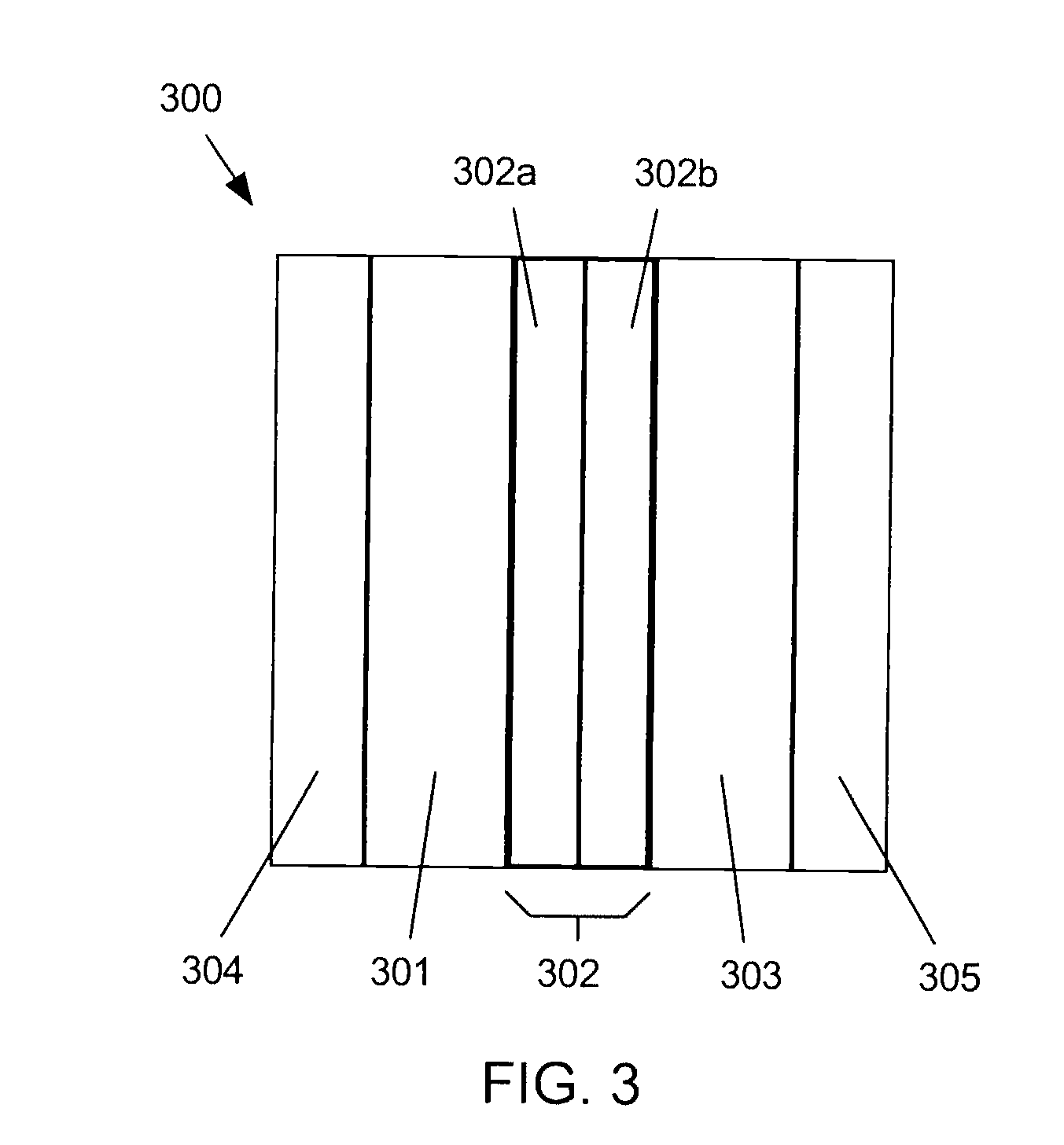

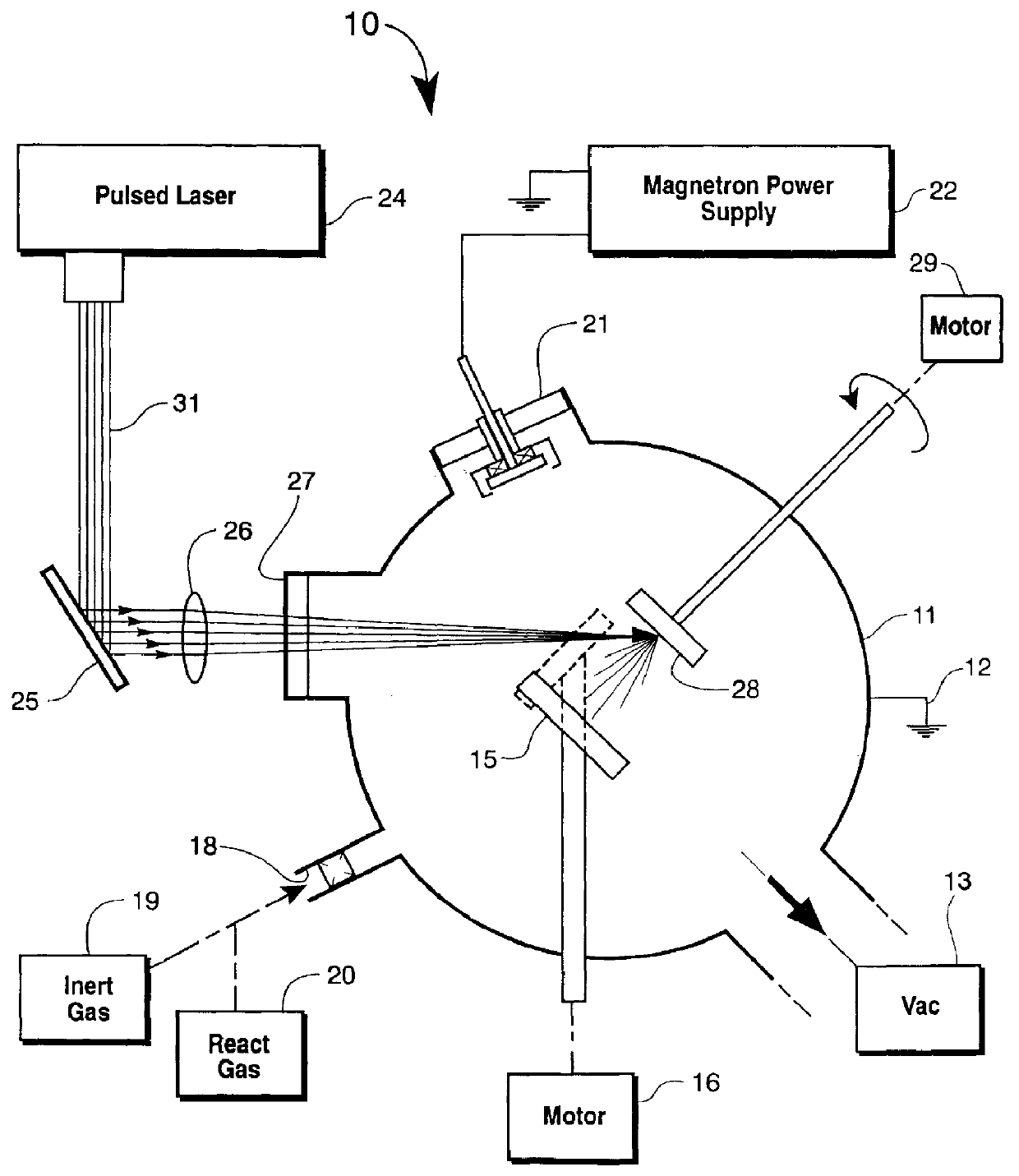

Magnetron sputter-pulsed laser deposition system and method

InactiveUSH1933H1Increase deposition rateImprove performanceCellsVacuum evaporation coatingSputteringDiamond-like carbon

System and method for high vacuum sputtering combining magnetron sputtering and pulsed laser plasma deposition are described wherein simultaneous or sequential magnetron sputtering and pulsed laser deposition operations in a single ultra-high vacuum system provides high deposition rates with precise control of film morphology, stoichiometry, microstructure, composition gradient, and uniformity, in the deposition of high performance coatings of various metal, ceramic and diamond-like carbon materials.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE +1

Copper delafossite transparent p-type semiconductor thin film devices

InactiveUS20100175755A1TransistorElectrolysis componentsPulsed laser depositionSemiconductor thin films

Methods for fabrication of copper delafossite materials include a low temperature sol-gel process for synthesizing CuBO2 powders, and a pulsed laser deposition (PLD) process for forming thin films of CuBO2, using targets made of the CuBO2 powders. The CuBO2 thin films are optically transparent p-type semiconductor oxide thin films. Devices with CuBO2 thin films include p-type transparent thin film transistors (TTFT) comprising thin film CuBO2 as a channel layer and thin film solar cells with CuBO2 p-layers. Solid state dye sensitized solar cells (SS-DSSC) comprising CuBO2 in various forms, including “core-shell” and “nano-couple” particles, and methods of manufacture, are also described.

Owner:APPLIED MATERIALS INC

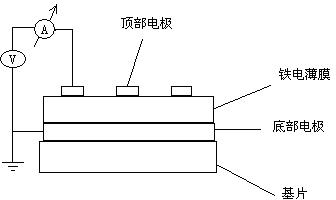

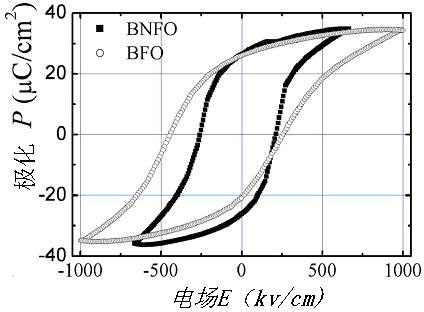

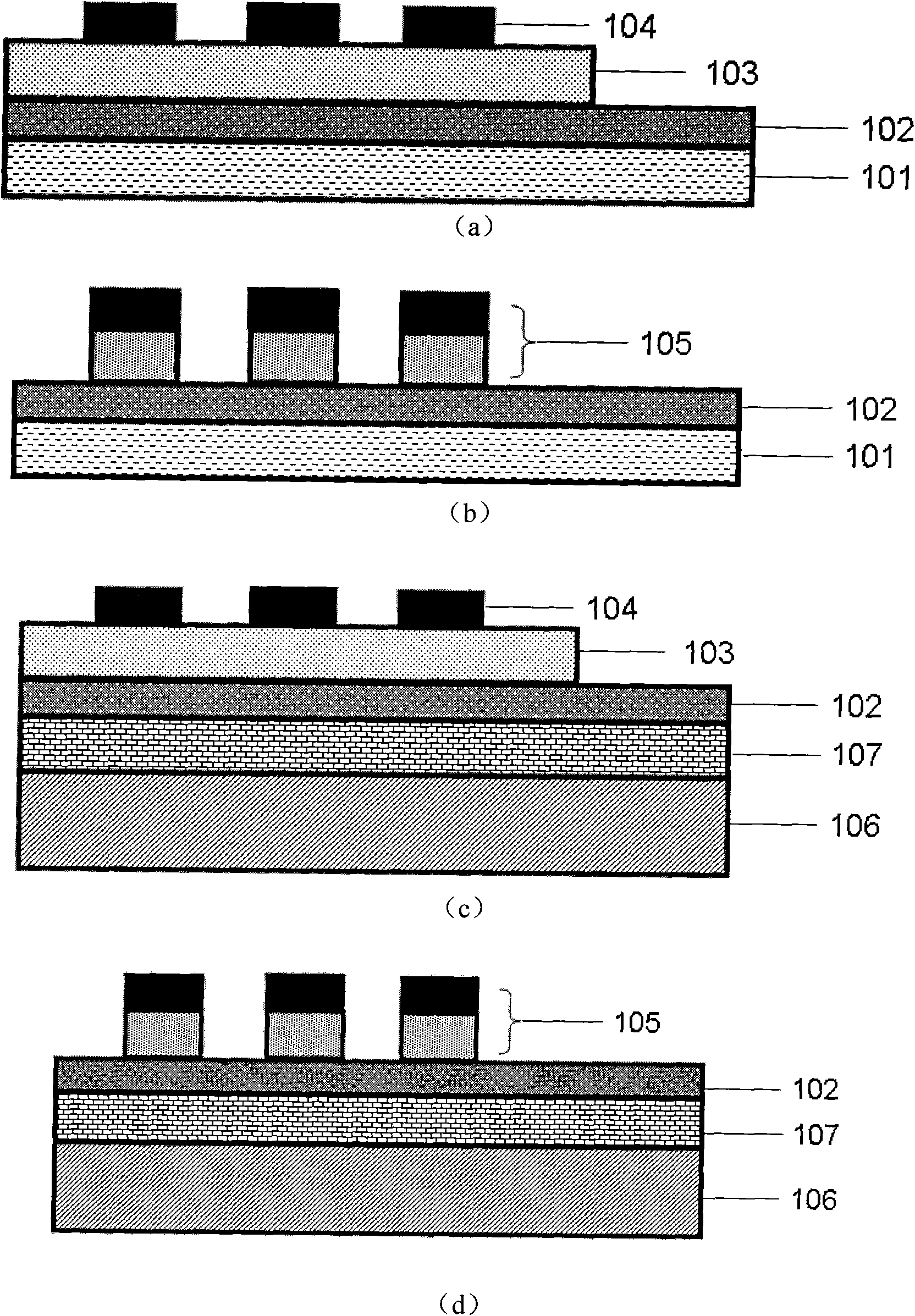

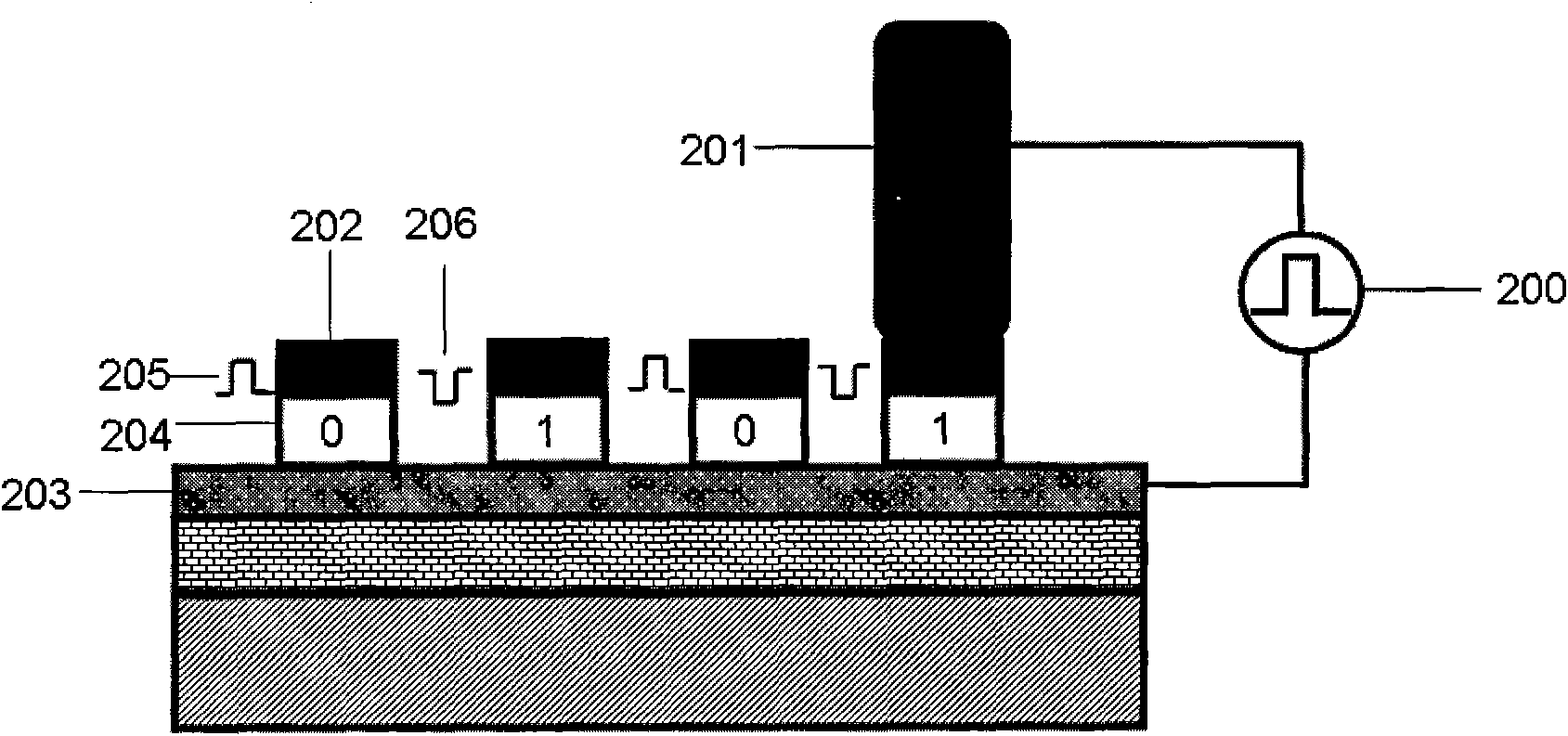

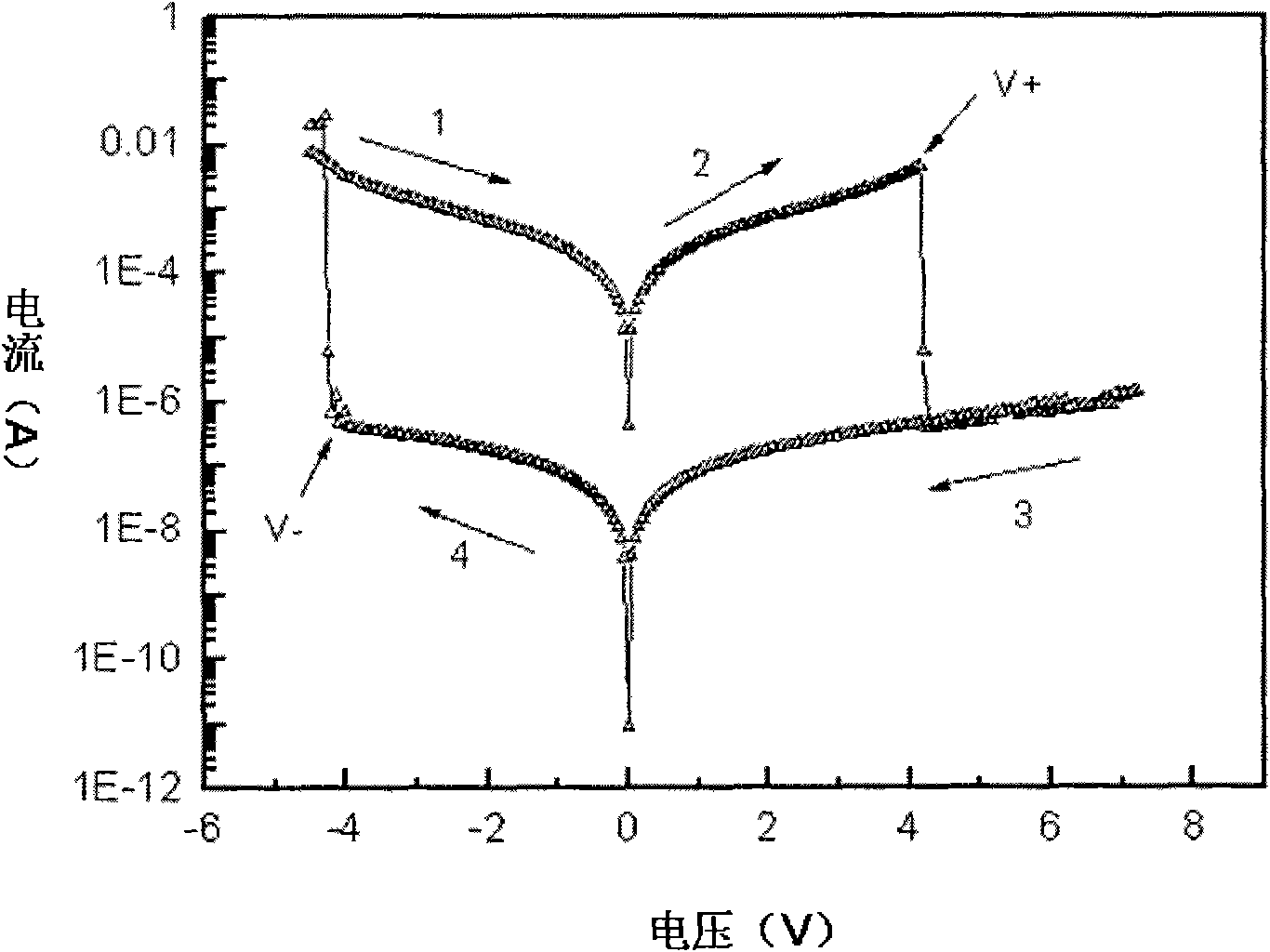

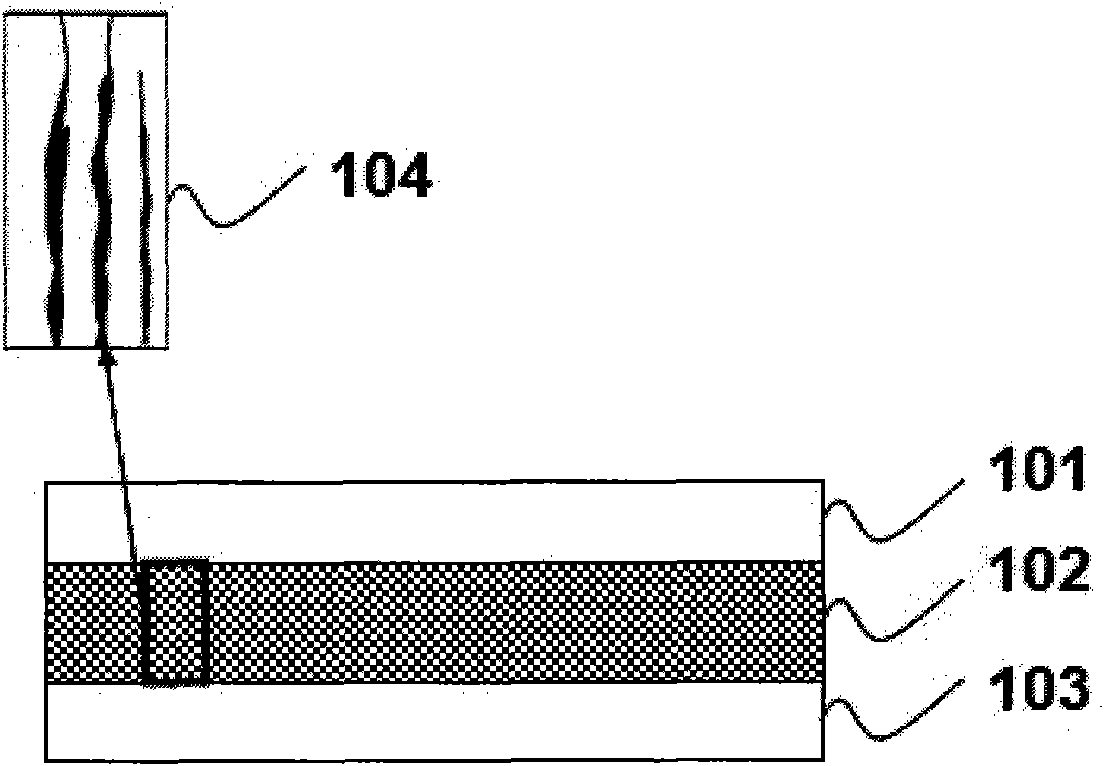

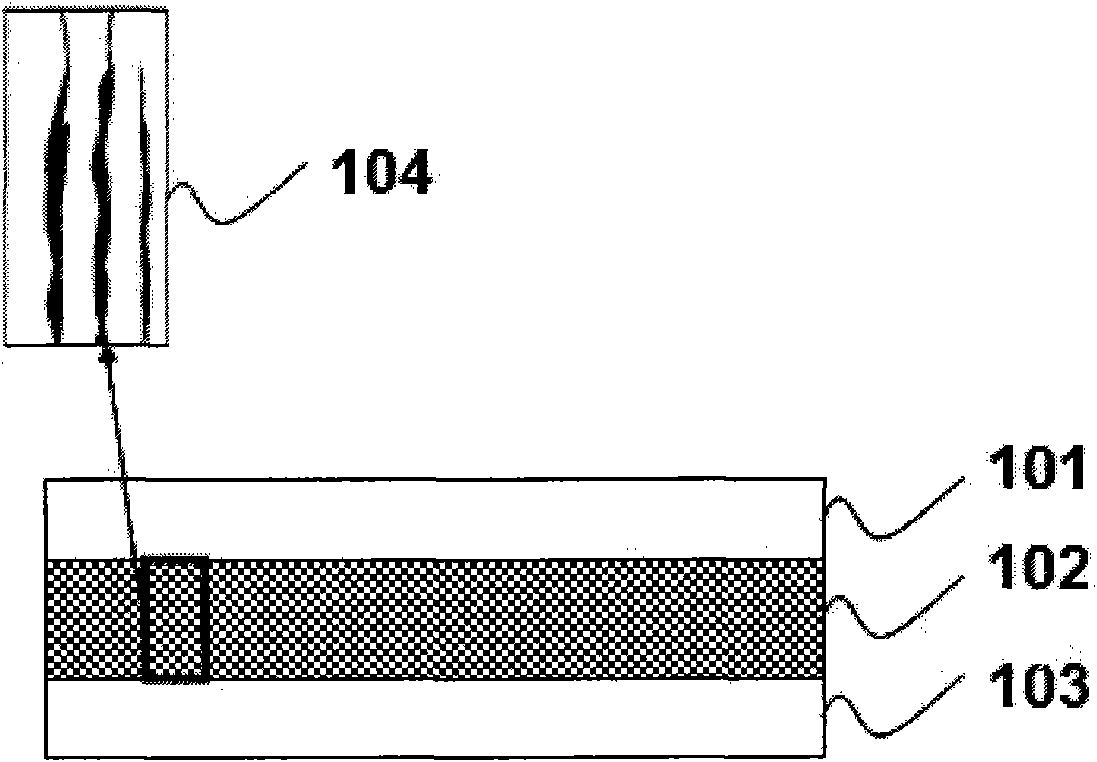

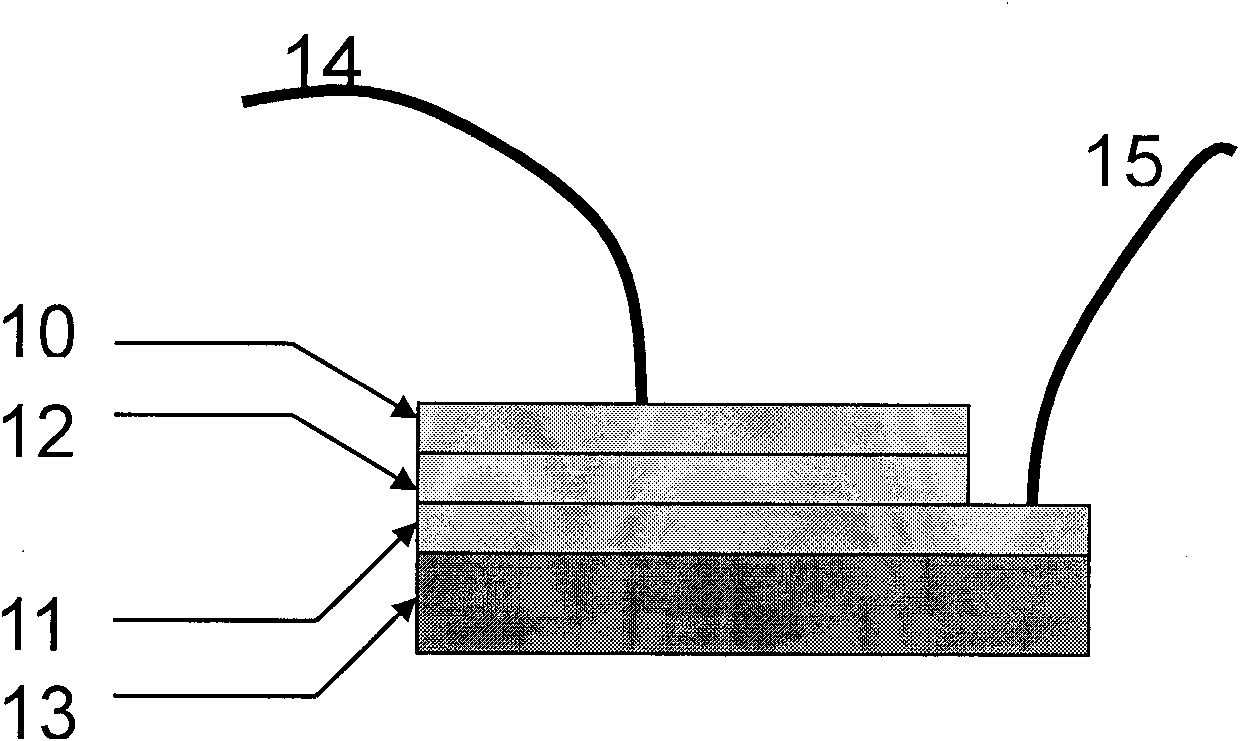

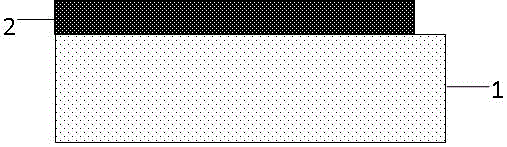

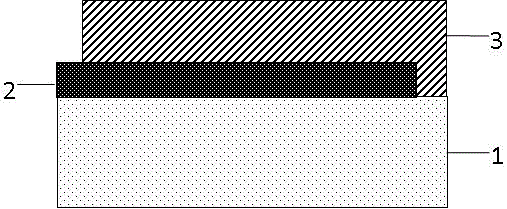

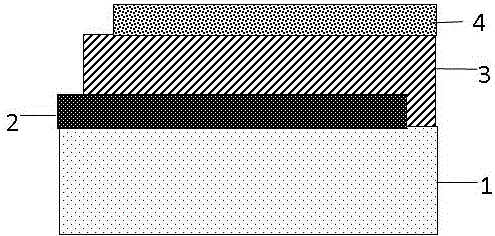

Resistive random access memory based on bismuth iron thin film system and manufacturing method thereof

ActiveCN101587936AHigh and low resistance state resistance value is stableWith magnetoelectric coupling effectElectrical apparatusDigital storageSputteringStatic random-access memory

The invention relates to a resistive random access memory based on bismuth iron thin film system and manufacturing method thereof. The memory comprises an insulating substrate (101) layer as the first layer, a lower electrode (102) as the second layer, a bismuth iron thin film (103) as the third layer, an upper electrode (104) as the fourth layer; the manufacturing method utilizes the method thermal evaporation or magnetron sputtering to grow the lower electrode on the insulating substrate layer, utilizes the method of magnetron sputtering, pulsed laser deposition or colloidal sol-gel to grow the bismuth iron thin film on the lower electrode, finally utilizes the method of thermal evaporation or magnetron sputtering to grow the upper electrode on the bismuth iron thin film, and utilizes the method of ultraviolet lithography, electron beam or ion beam etching to obtain the electrode pattern. The memory provided by the invention has excellent electroluminescent resistance effect and good stability, and has simple manufacturing method, low cost and is easy for manufacturing in large scale and commercial process.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

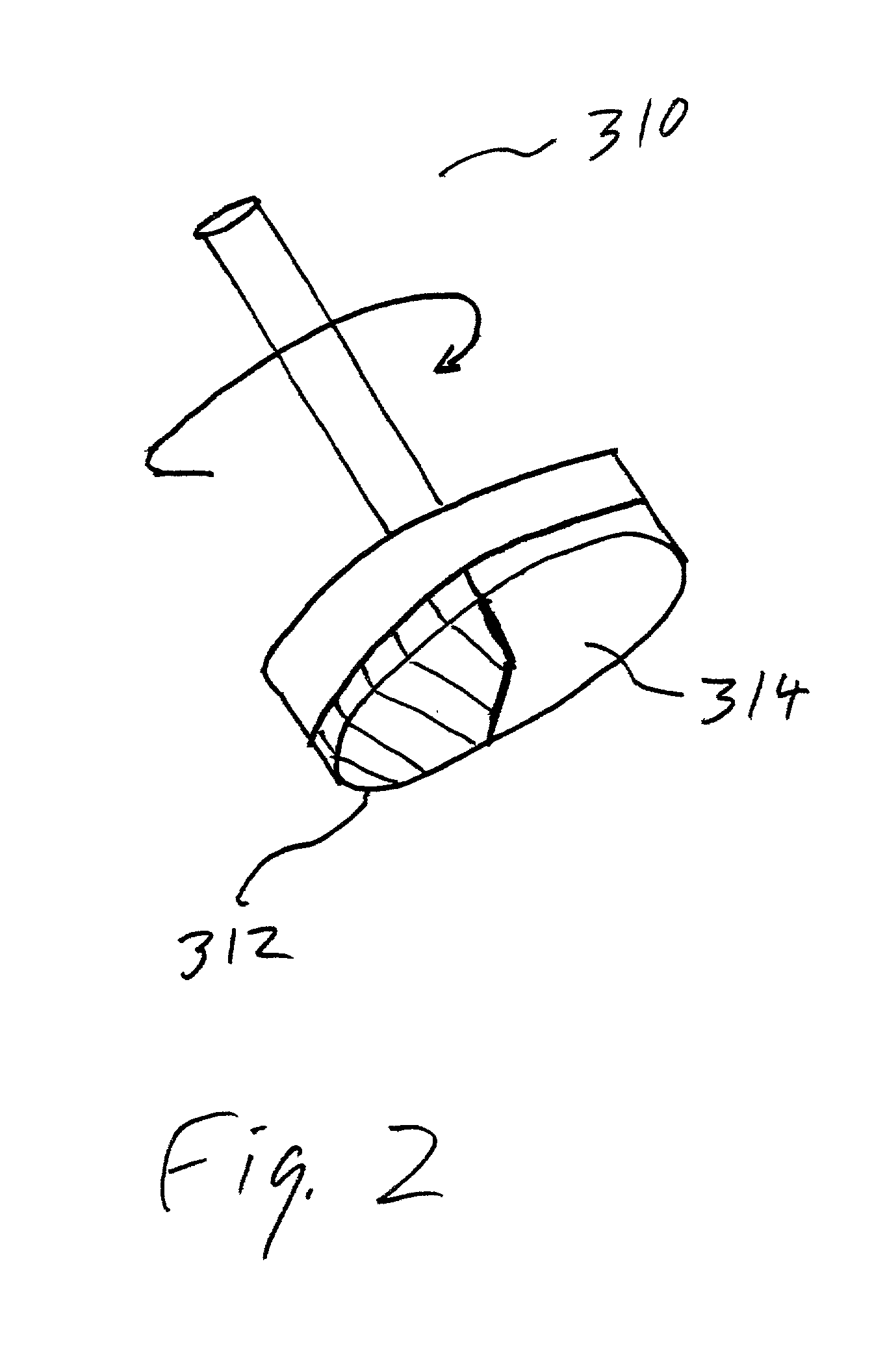

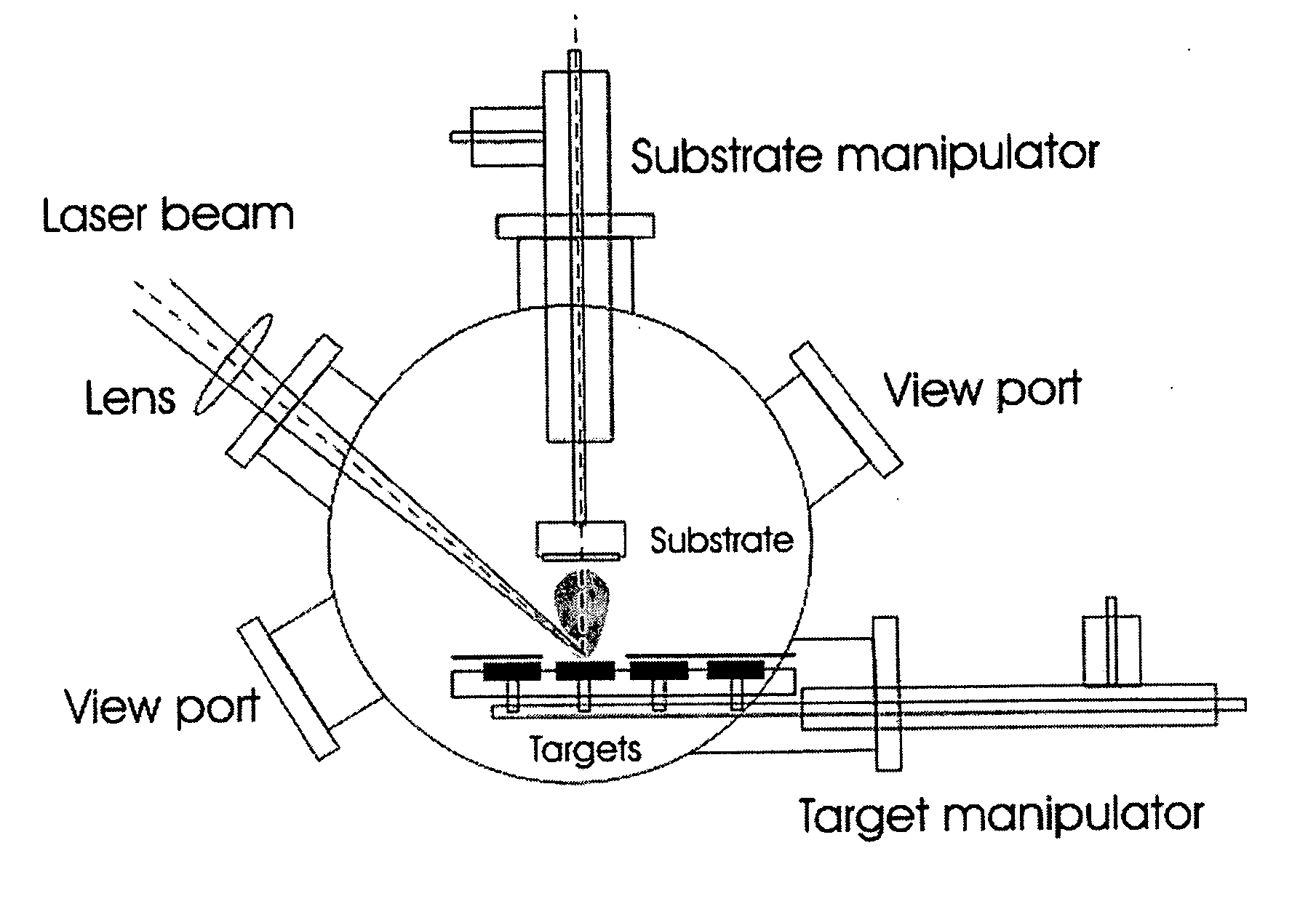

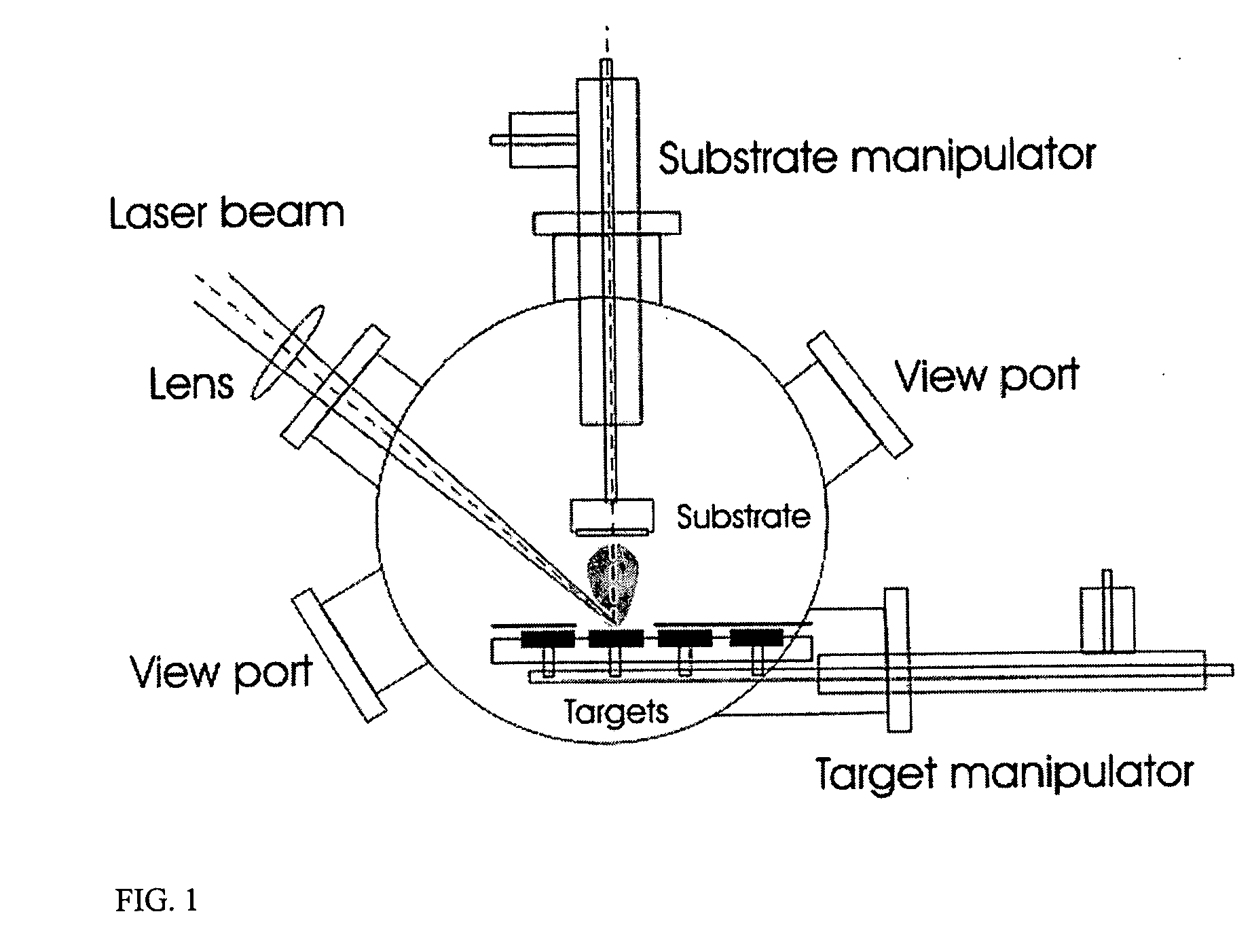

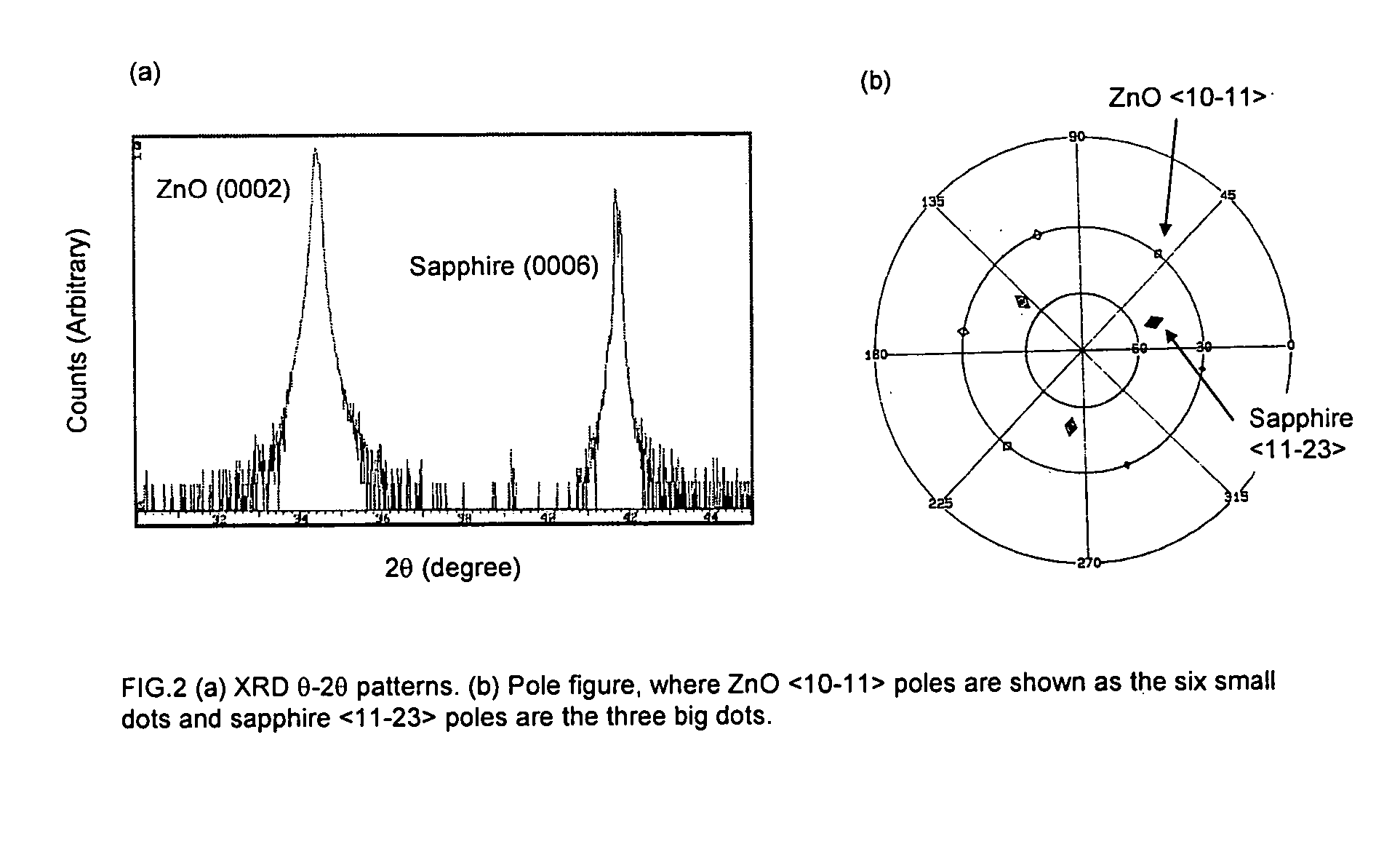

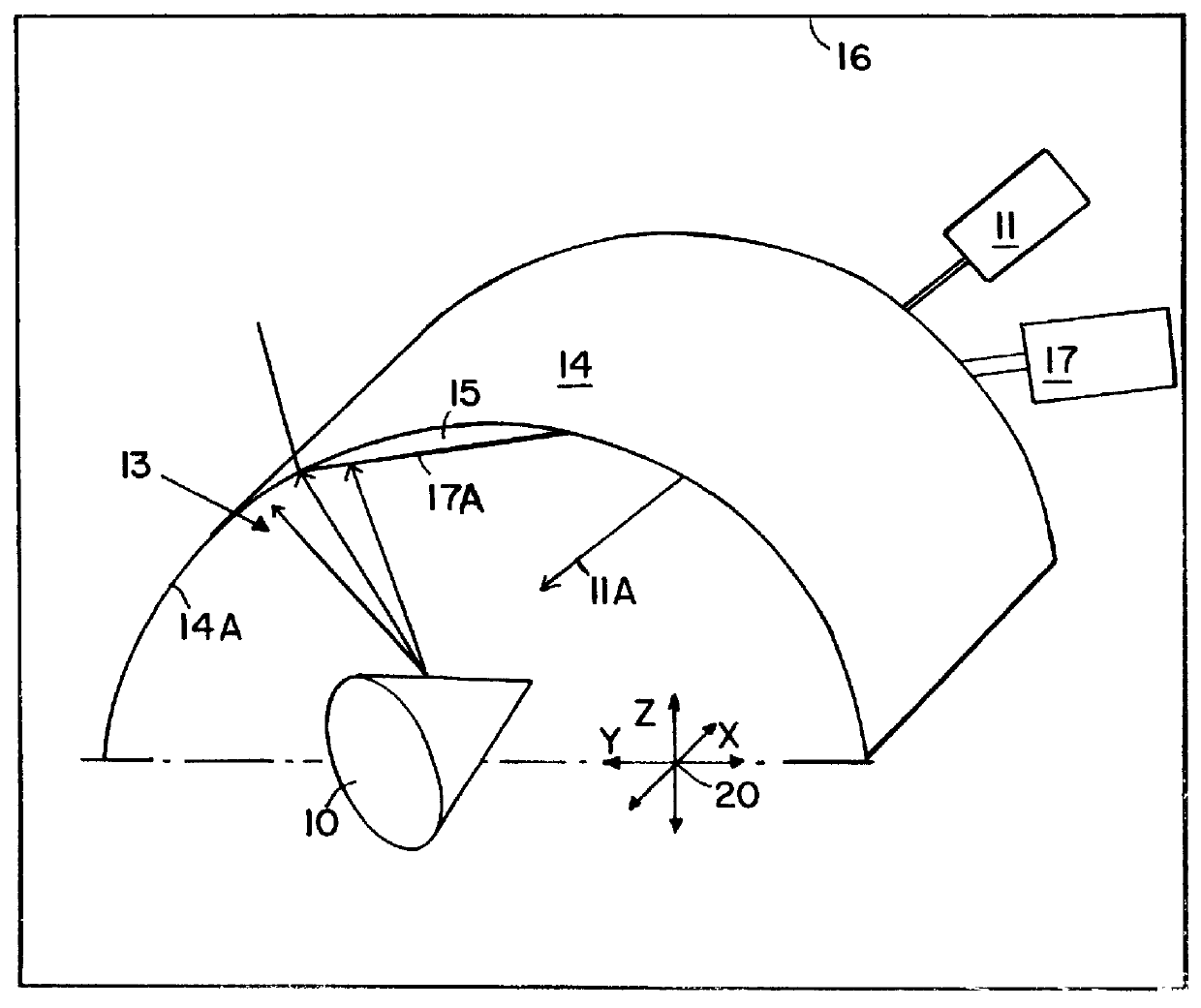

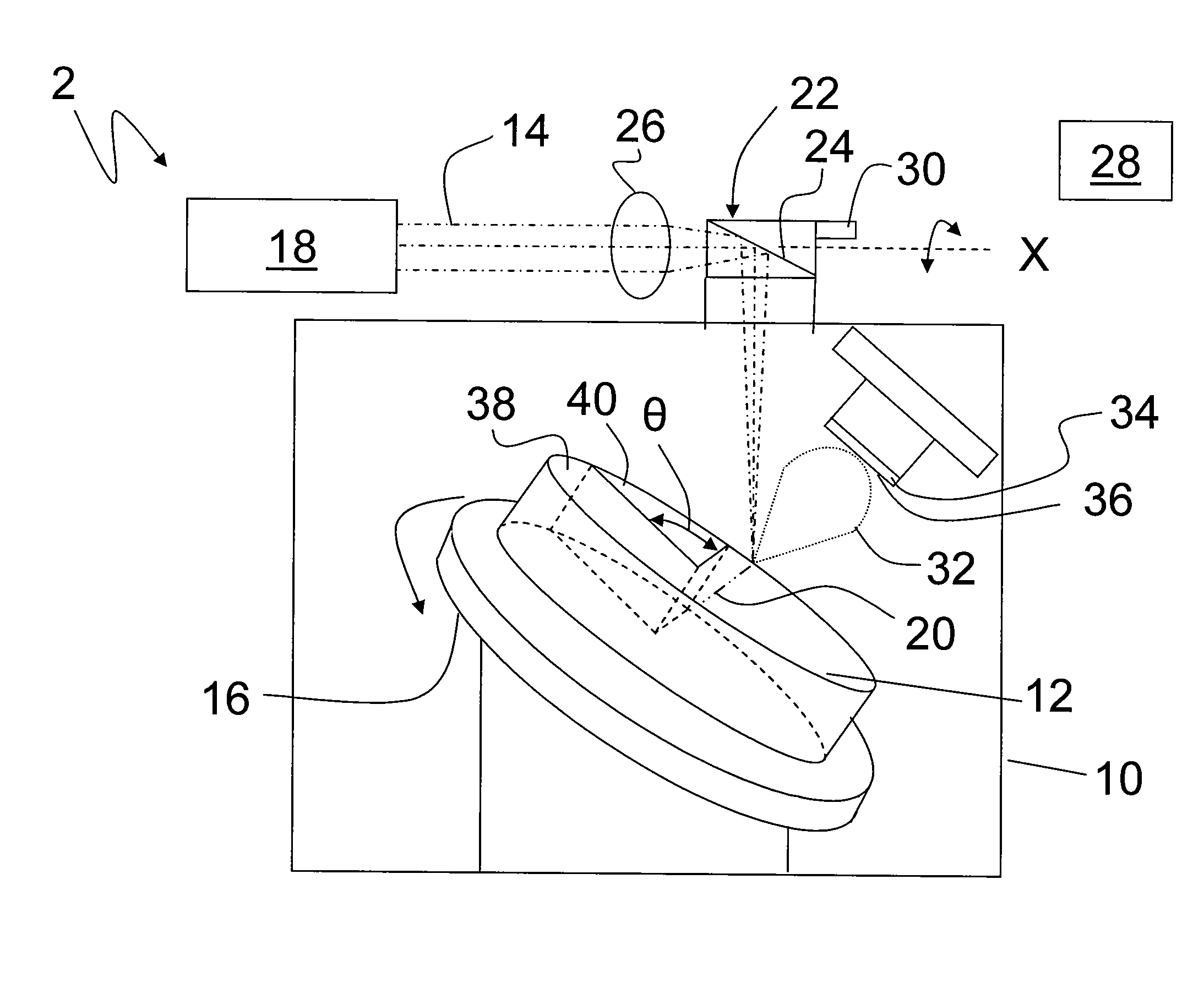

P-type semiconductor zinc oxide films process for preparation thereof, and pulsed laser deposition method using transparent substrates

InactiveUS20070243328A1High concentrationImprove conductivityElectric discharge heatingVacuum evaporation coatingPulsed laser depositionLaser source

A p-type semiconductor zinc oxide (ZnO) film and a process for preparing the film are disclosed. The film is co-doped with phosphorous (P) and lithium (Li). A pulsed laser deposition scheme is described for use in growing the film. Further described is a process of pulsed laser deposition using transparent substrates which includes a pulsed laser source, a substrate that is transparent at the wavelength of the pulsed laser, and a multi-target system. The optical path of the pulsed laser is arranged in such a way that the pulsed laser is incident from the back of the substrate, passes through the substrate, and then focuses on the target. By translating the substrate towards the target, this geometric arrangement enables deposition of small features utilizing the root of the ablation plume, which can exist in a one-dimensional transition stage along the target surface normal, before the angular width of the plume is broadened by three-dimensional adiabatic expansion. This can provide small deposition feature sizes, which can be similar in size to the laser focal spot, and provides a novel method for direct deposition of patterned materials.

Owner:IMRA AMERICA

Electrochromic material

InactiveUS7333258B2Increased durabilityImprove stabilityConductive materialMetal/alloy conductorsOptoelectronicsElectrochromism

An electrochromic material having improved durability and more pleasing color characteristics is composed of a single-phase compound of formula W1−xTaxO3−x / 2, x having a value in a range of from about 0.15 to about 0.5. Thin films of the electrochromic material can be manufactured by pulse laser deposition (PLD). Thin films of the electrochromic material are useful in the fabrication of electrochromic devices, such as “smart” windows, mirrors, information displays and variable emittance surfaces.

Owner:NAT RES COUNCIL OF CANADA

LED epitaxial wafer grown on Si substrate and preparation method thereof

ActiveCN104037287ALight in massGood growth templateSemiconductor/solid-state device manufacturingSemiconductor devicesGas phaseQuantum well

The invention discloses an LED epitaxial wafer grown on an Si substrate and a preparation method thereof. The LED epitaxial wafer grown on the Si substrate is prepared through the following preparation method: using the Si substrate, enabling the surface (111) of the Si substrate to deviate from (100) by 0.5 to 1 degree, growing a first AlN buffer layer, and growing a second AlN buffer layer, an AlGaN step buffer layer, a u-GaN layer, an n-GaN layer, an InGaN / GaN quantum well layer and a p-GaN layer in sequence. The LED epitaxial wafer grown on the Si substrate uses Si as the substrate, the preparation method combines a metal organic chemical vapor deposition technique and a pulsed laser deposition technique, a procedure of pre-paving Al for using the metal organic chemical vapor deposition technique to grow the AlN is omitted, the problem that Si is diffused to the AlN buffer layer under a high temperature to damage the surface shape is avoided, and the LED epitaxial wafer is good in performance, high in crystal quality and suitable for LED devices.

Owner:广州市众拓光电科技有限公司

Cutting fool boron nitride composite coating layer and its preparation method

InactiveCN1514039AReduce internal stressImprove bindingTurning toolsChemical vapor deposition coatingBoron nitrideCemented carbide

A coated composite boron nitride layer on the surface of cutting tool is composed of a substrate layer which is TiCxOyNz layer directly deposited on the hard alloy cutter, an intermediate binding layer which is made of Ni, Ni-contained compound, or N or B contained compound, and a boron nitride layer prepared from cubic boron nitride. Said coated layer is prepared by plasma intensified pulse laser deposition method, or hot wire added RE plasma CVD method, or their combination.

Owner:XIANGTAN UNIV

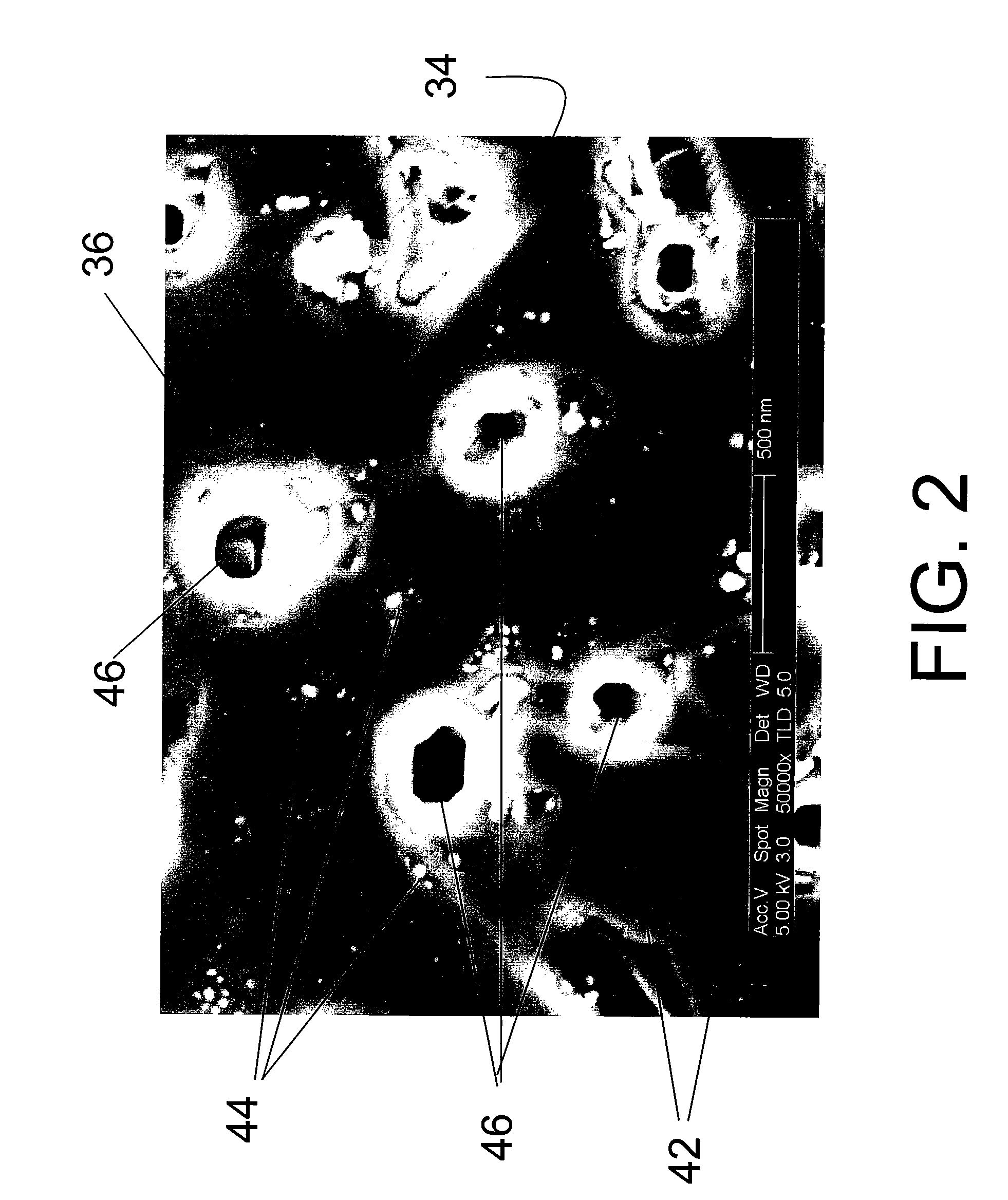

method and apparatus to prepare a substrate for molecular detection

InactiveUS20110194106A1Enhanced coherent anti-Stokes Raman spectroscopyPromote absorptionMaterial nanotechnologyRadiation pyrometrySurface-enhanced Raman spectroscopyEngineering

An device for Raman spectroscopy such as surface enhanced Raman spectroscopy (SERS) is disclosed herein. Various embodiments may be utilized to prepare a SERS substrate using several deposition techniques such as pulsed laser deposition. Some embodiments optimize coverage, volume, or elements of SERS active metals. The method is a single step inexpensive method for preparing a SERS active substrate. In some embodiments a coating layer underneath the SERS active metals is utilized for additional enhancements.

Owner:IMRA AMERICA

Method of forming metal, ceramic or ceramic/metal layers on inner surfaces of hollow bodies using pulsed laser deposition

InactiveUS6146714AElectric discharge heatingRadiation applicationsCoating systemConductive materials

A pulsed laser deposition (PLD) process is used for forming a functional metal, ceramic, or ceramic / metal layer on an inner wall of a hollow body. Simultaneously with the deposition process, a thin-film laser treatment is carried out, whereby a laser beam impinges on the coating layer as it is being formed to achieve a rapid heating followed by a rapid cooling and solidification of the deposited coating layer. In this context, the energy and material flux densities are prescribed and controlled as a function of the spacing of the condensation region from the substrate surface. Laser pulses having an energy of 1 to 2 Joules and a pulse repetition rate of 10 to 50 Hz are used. The pulse duration as well as the residual gas atmosphere in the vacuum deposition chamber are controlled so that the generated plasma flux forms the desired layered grain structure, namely a glassy amorphous structure, a columnar structure, or a polycrystalline structure. The coating or target material can be made of a conducting material and / or an insulating material. By continuously or discretely varying process parameters, it is possible to form graded layer coating systems having properties that vary through the thickness of the coating.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV +1

Ferroelectric oxide/semiconductor composite film diode resistance change memory

ActiveCN101789490ARealize rewritable functionIncrease program/erase speedElectrical apparatusDigital storageStrontium titanateComposite film

The invention belongs to the technical field of the information memory and particularly relates to a ferroelectric oxide / semiconductor sequentially composite film diode resistance change memory. The resistance change memory comprises a substrate, a bottom electrode, a ferroelectric oxide / semiconductor composite memory function layer and a top electrode, and is prepared by the following method which comprises the following steps: developing compound electrodes, such as strontium ruthenium, lanthanum nickel and the like, or metal on the monocrystal strontium titanate or SiO2 / Si substrate to serve as the bottom electrode; then developing the ferroelectric oxide / semiconductor composite film function layer by a pulsed laser deposition or radio frequency magnetron sputtering method; and developing the metal top electrode to form a single diode memory unit structure. The polarity of the diode changes with the orientation of the electric domain. The ferroelectric oxide / semiconductor composite film diode resistance change memory has the advantages of high memory density, good information retentivity and low power consumption.

Owner:FUDAN UNIV

P-type semiconductor zinc oxide films process for preparation thereof, and pulsed laser deposition method using transparent substrates

InactiveUS7608308B2High concentrationImprove conductivityElectric discharge heatingVacuum evaporation coatingPulsed laser depositionLaser source

A p-type semiconductor zinc oxide (ZnO) film and a process for preparing the film are disclosed. The film is co-doped with phosphorous (P) and lithium (Li). A pulsed laser deposition scheme is described for use in growing the film. Further described is a process of pulsed laser deposition using transparent substrates which includes a pulsed laser source, a substrate that is transparent at the wavelength of the pulsed laser, and a multi-target system. The optical path of the pulsed laser is arranged in such a way that the pulsed laser is incident from the back of the substrate, passes through the substrate, and then focuses on the target. By translating the substrate towards the target, this geometric arrangement enables deposition of small features utilizing the root of the ablation plume, which can exist in a one-dimensional transition stage along the target surface normal, before the angular width of the plume is broadened by three-dimensional adiabatic expansion. This can provide small deposition feature sizes, which can be similar in size to the laser focal spot, and provides a novel method for direct deposition of patterned materials.

Owner:IMRA AMERICA

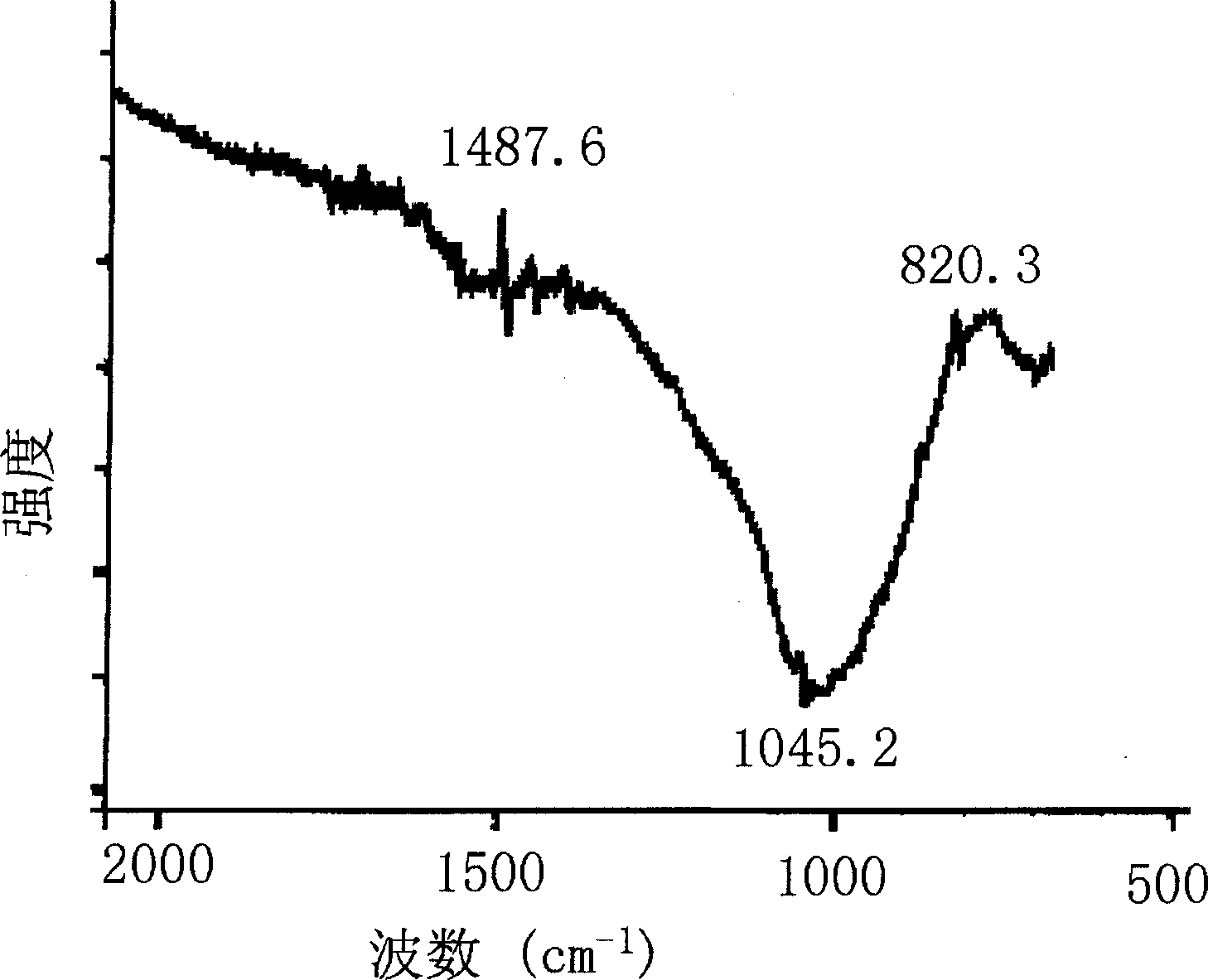

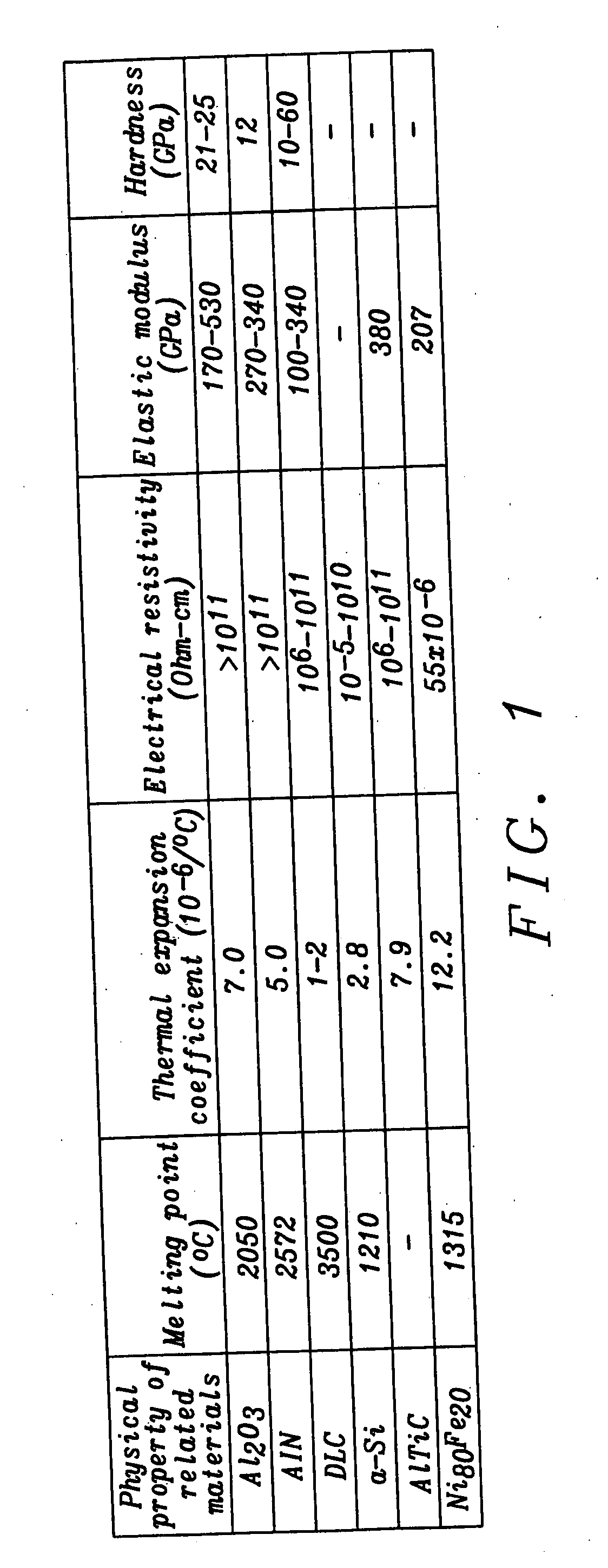

Ultra-hard low friction coating based on AlMgB14 for reduced wear of MEMS and other tribological components and system

InactiveUS20050100748A1Superior protective coatHigh hardnessVacuum evaporation coatingSolid-state devicesMicroelectromechanical systemsAlloy

Performance and reliability of microelectromechanical system (MEMS) components enhanced dramatically through the incorporation of protective thin film coatings. Current-generation MEMS devices prepared by the LIGA technique employ transition metals such as Ni, Cu, Fe, or alloys thereof, and hence lack stability in oxidizing, corrosive, and / or high temperature environments. Fabrication of a superhard, self-lubricating coating based on a ternary boride compound AlMgB14 is described in this letter as a potential breakthrough in protective coating technology for LIGA microdevices. Nanoindentation tests show that hardness of AlMgB14 films prepared by pulsed laser deposition ranges from 45 GPa to 51 GPa, when deposited at room temperature and 573 K, respectively. Extremely low friction coefficients of 0.04-0.05, which are thought to result from a self-lubricating effect, have also been confirmed by nanoscratch tests on the AlMgB14 films. Transmission electron microscopy studies show that the as-deposited films are amorphous, regardless of substrate temperature; however, analysis of FTIR spectra suggests that the higher substrate temperature facilitates formation of the B12 icosahedral framework, therefore leading to the higher hardness.

Owner:IOWA STATE UNIV RES FOUND

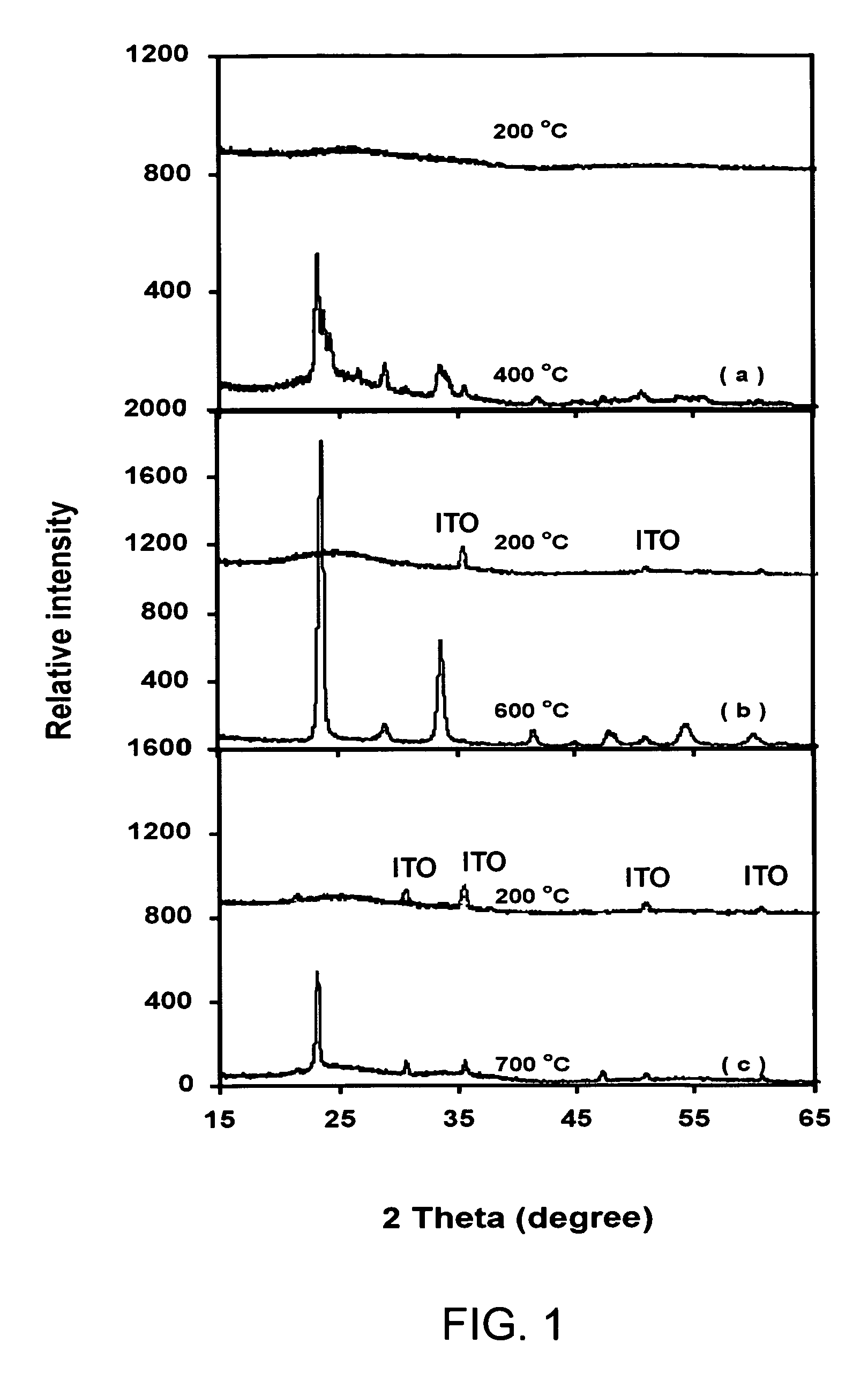

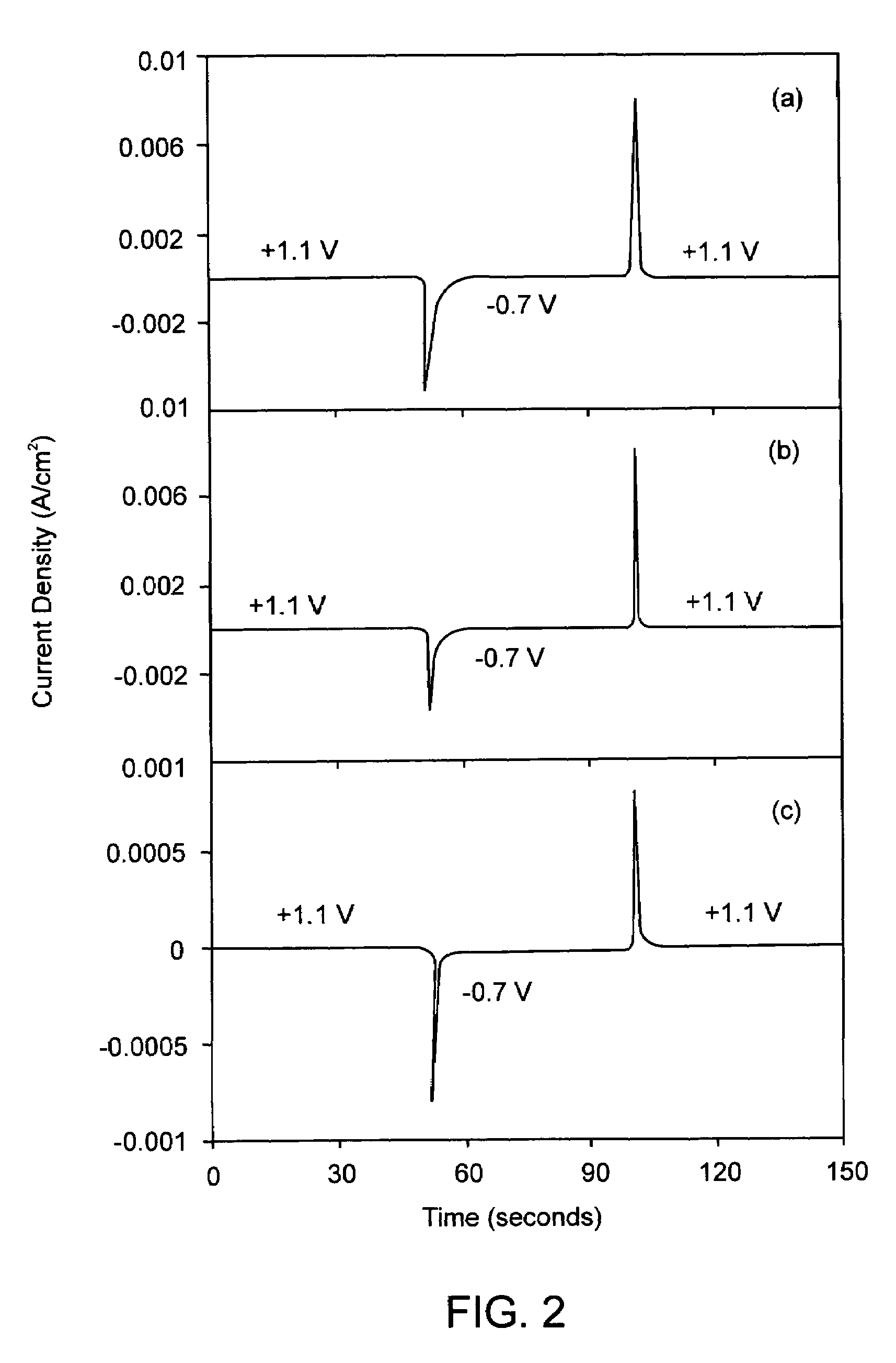

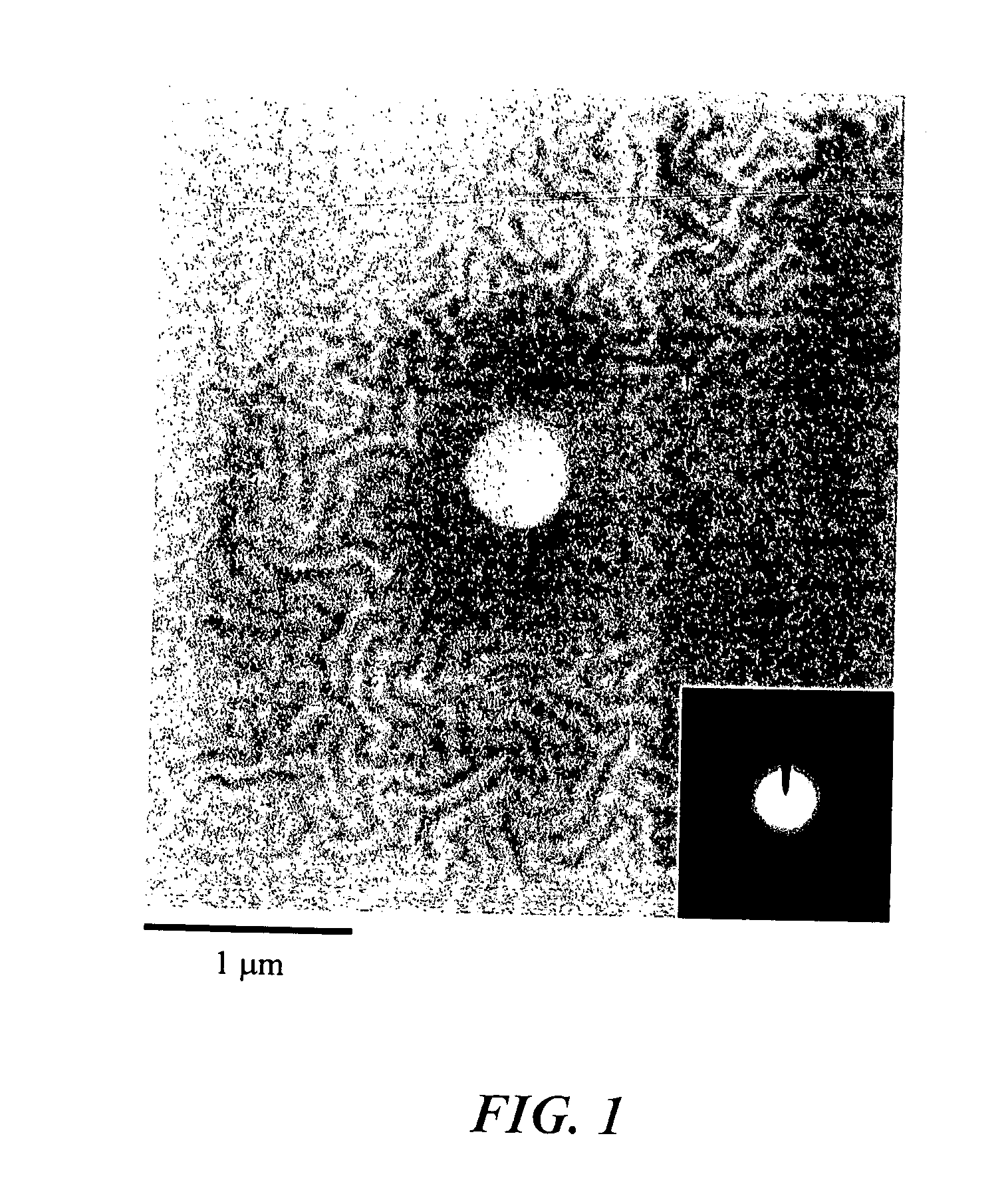

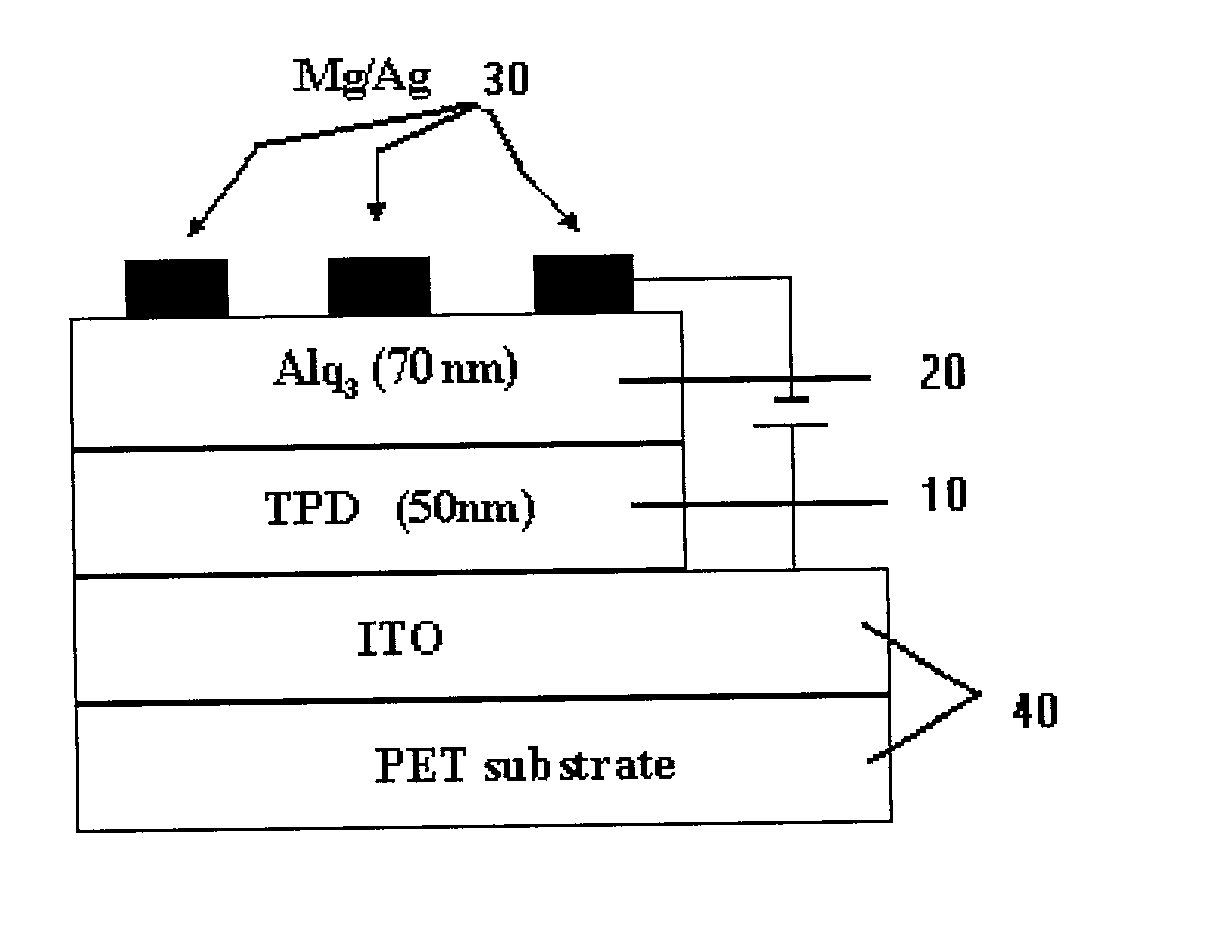

Pulsed laser deposition of transparent conducting thin films on flexible substrates

InactiveUS20020098668A1Flat surfaceGood light transmissionSolid-state devicesSemiconductor/solid-state device manufacturingIndiumAluminum doped zinc oxide

The invention relates to the deposition of transparent conducting thin films, such as transparent conducting oxides (TCO) such as tin doped indium oxide (ITO) and aluminum doped zinc oxide (AZO) on flexible substrates by pulsed laser deposition. The coated substrates are used to construct low cost, lightweight, flexible displays based on organic light emitting diodes (OLEDs).

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

FLUX PINNING ENHANCEMENTS IN SUPERCONDUCTIVE REBa2CU3O7-x (REBCO) FILMS AND METHOD OF FORMING THEREOF

ActiveUS20070129255A1Avoid adverse reactionsSeparationVacuum evaporation coatingSputtering coatingParticulatesFlux pinning

Nanometer-sized non-superconducting particulates in superconductive REBCO films, where RE is a rare earth metal, for flux pinning enhancement and a method of forming are disclosed. A target with a second phase material sector portion and a superconductive material portion is used in a pulse laser deposition process to form films on substrates according to the present invention. The films consist of 10-20 nm-sized precipitates. In a 0.5 μm thick film, a transport critical current density (Jc)>3 MA / cm2 at 77K in self-field was measured. In one embodiment, magnetization Jc at 77 K and 65K showed significant improvements in a composite YBCO films with fine precipitates produced according to the present invention as compared to non-doped (standard) YBCO films (>10 times increase at 9 T, 65 K).

Owner:UNIV OF DAYTON THE

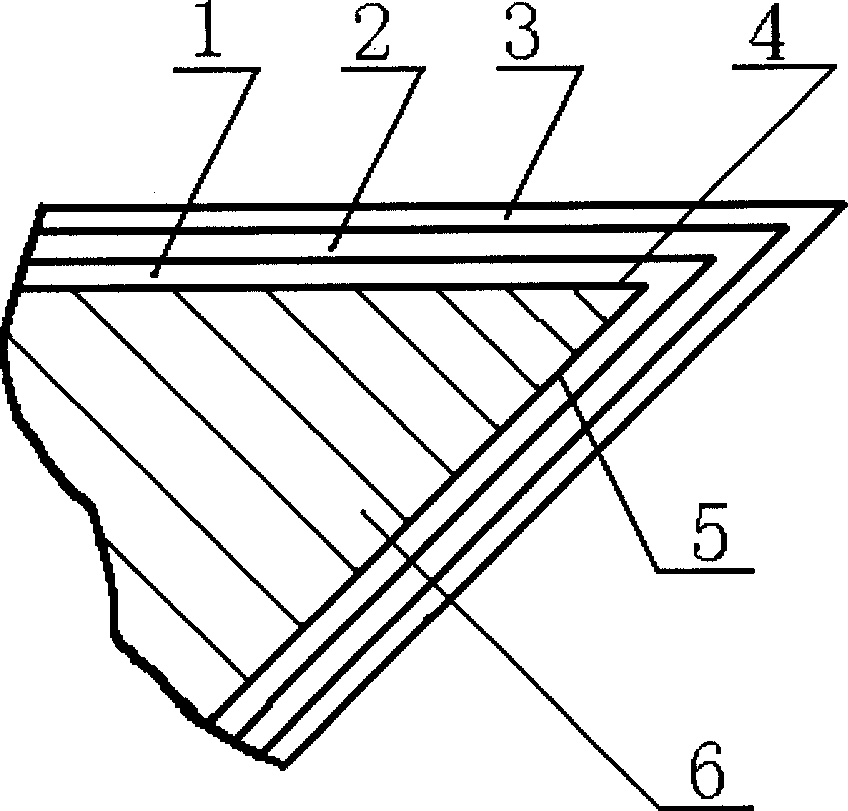

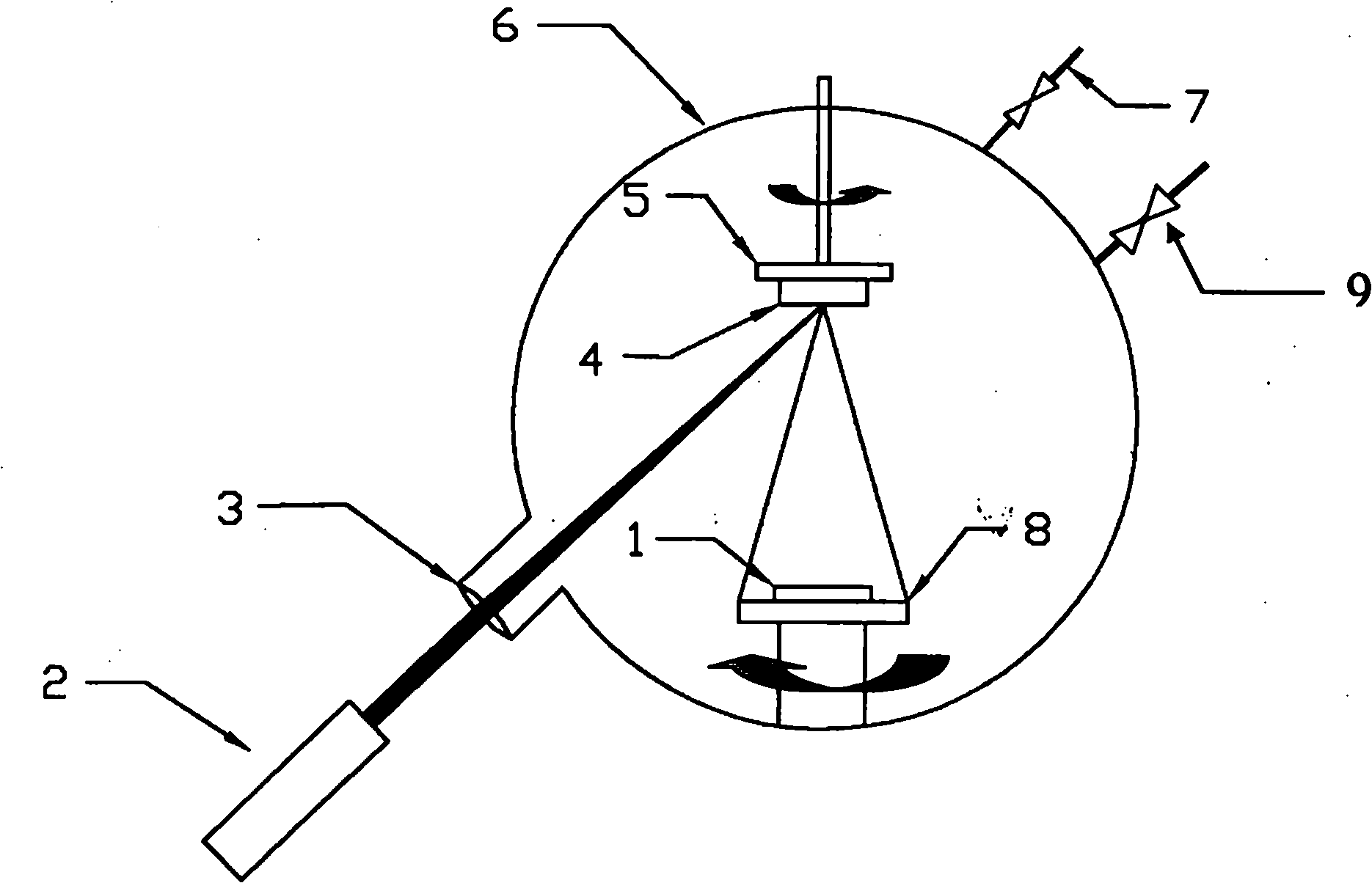

Ferroelectric metal hetero-junction based memristor and preparation method thereof

InactiveCN101864592ASmooth transitionThe periodicity of the resistance state is smallPolycrystalline material growthAfter-treatment detailsOptoelectronicsLithium niobate

The invention relates to a ferroelectric metal hetero-junction based memristor; wherein the memristor material-ferroelectric lithium niobate is prepared by a pulse laser deposition system; monocrystal LN target material (4) is fixed on a target platform (5) of the pulse laser deposition system, and is placed in a growth chamber (6) of a pulse laser deposition film-making system; the vacuum in the growth chamber is pumped to be below 0.8*10-4Pa, oxygen gas flows in, and the oxygen pressure is from 25 to 35Pa, the substrate temperature is heated from 600-650 DEG; a KrF excimer laser is started, and the deposition time is determined according to monopulse energy; in-situ 500-650 DEG annealing is carried out 20-90min; the film has spontaneous polarization and 180-degree domain boundary; the memristor ferroelectric lithium niobate film is clamped between two metal electrode films to form a memristor unit with a miniature sandwich structure; the device can be applied to a high-density low-energy-consumption nonvolatile resistance random access memory.

Owner:NANJING UNIV

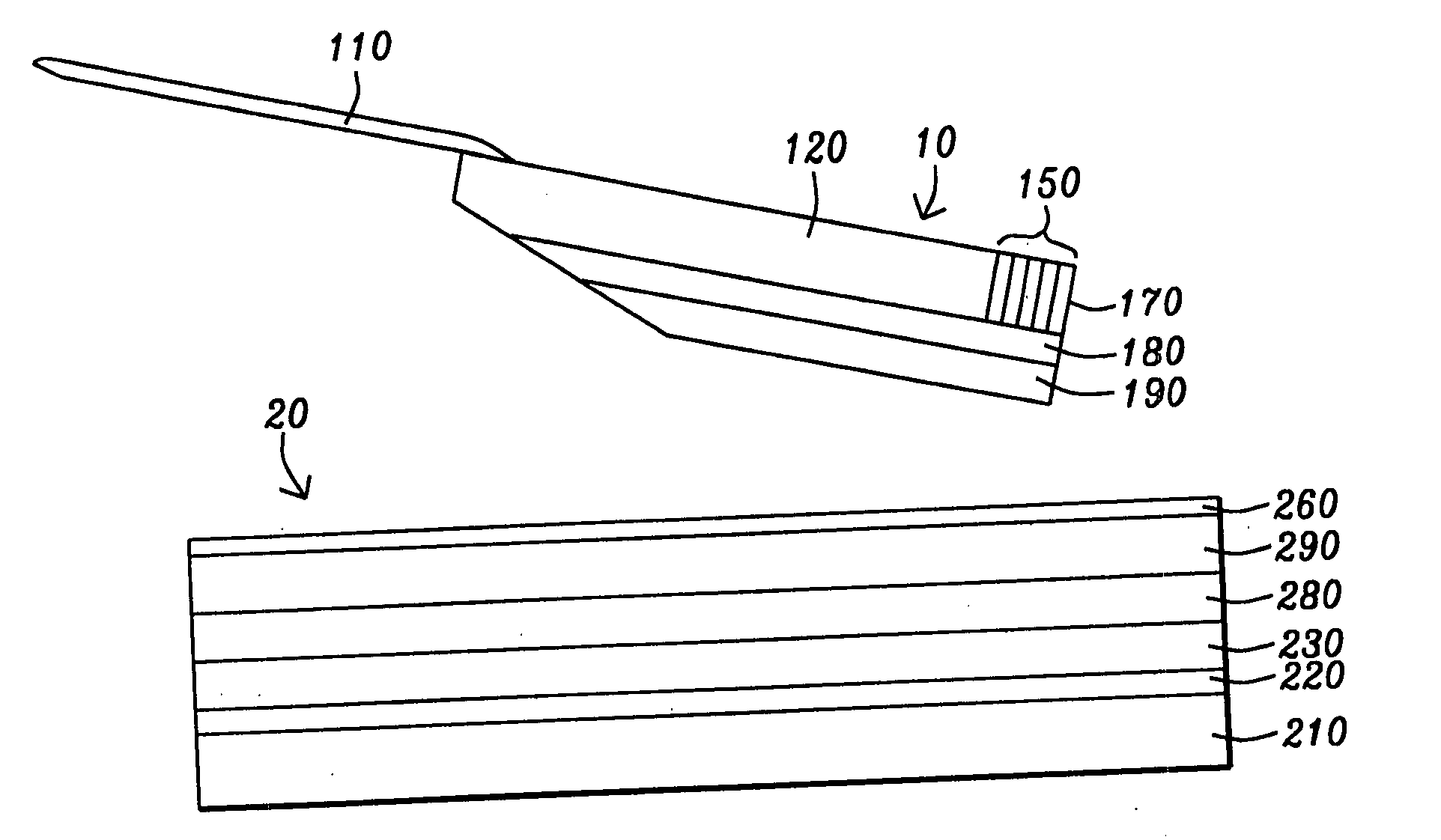

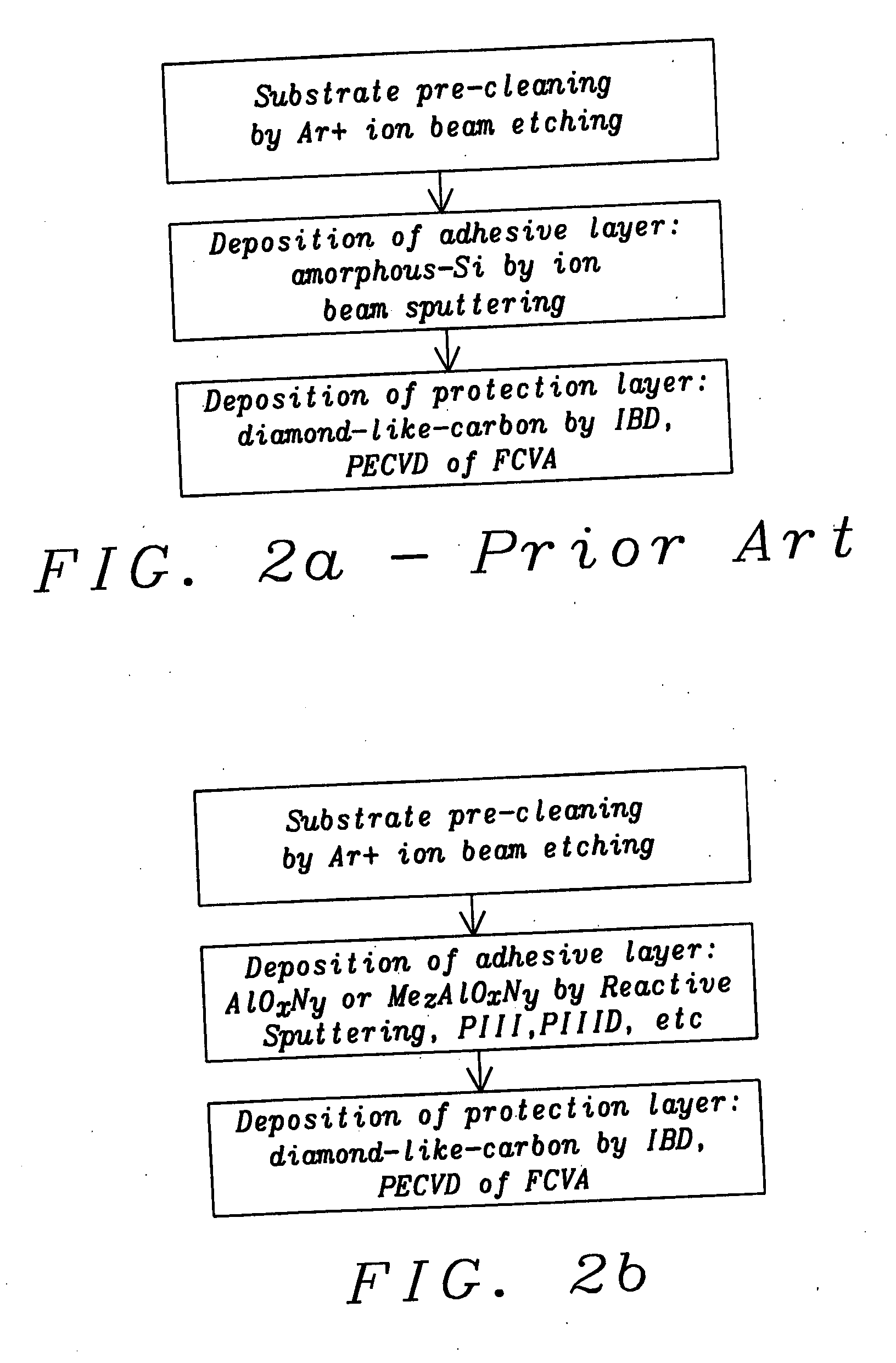

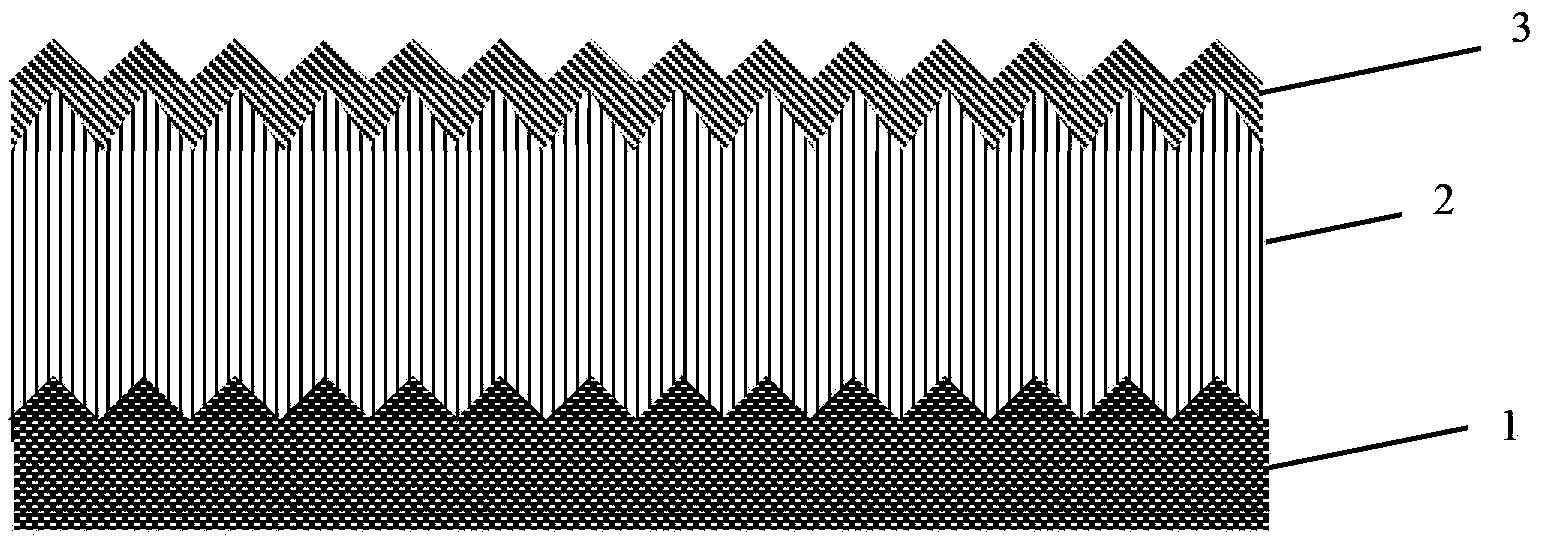

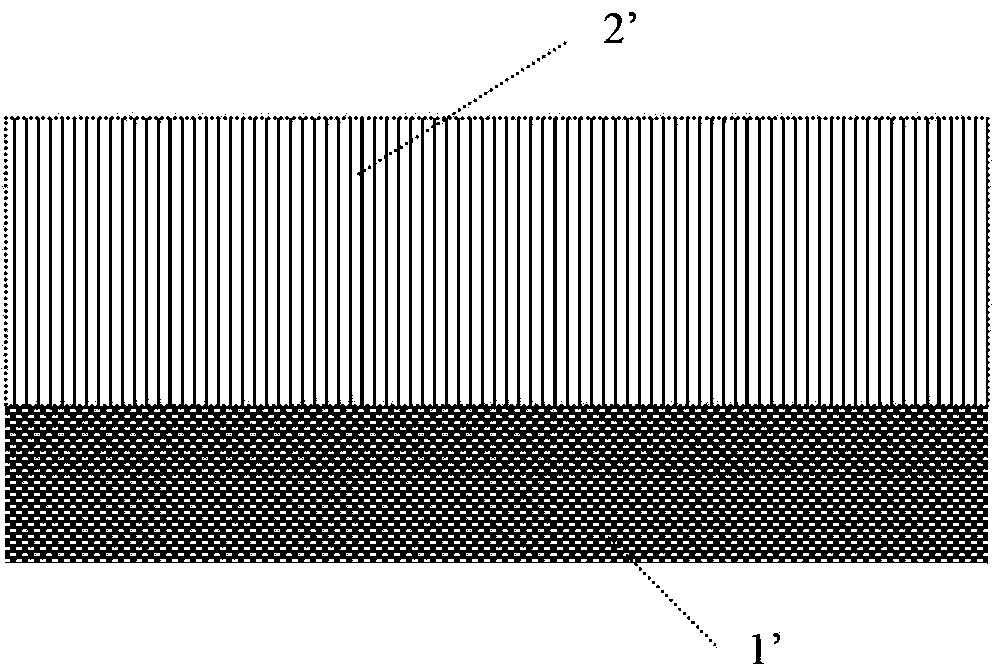

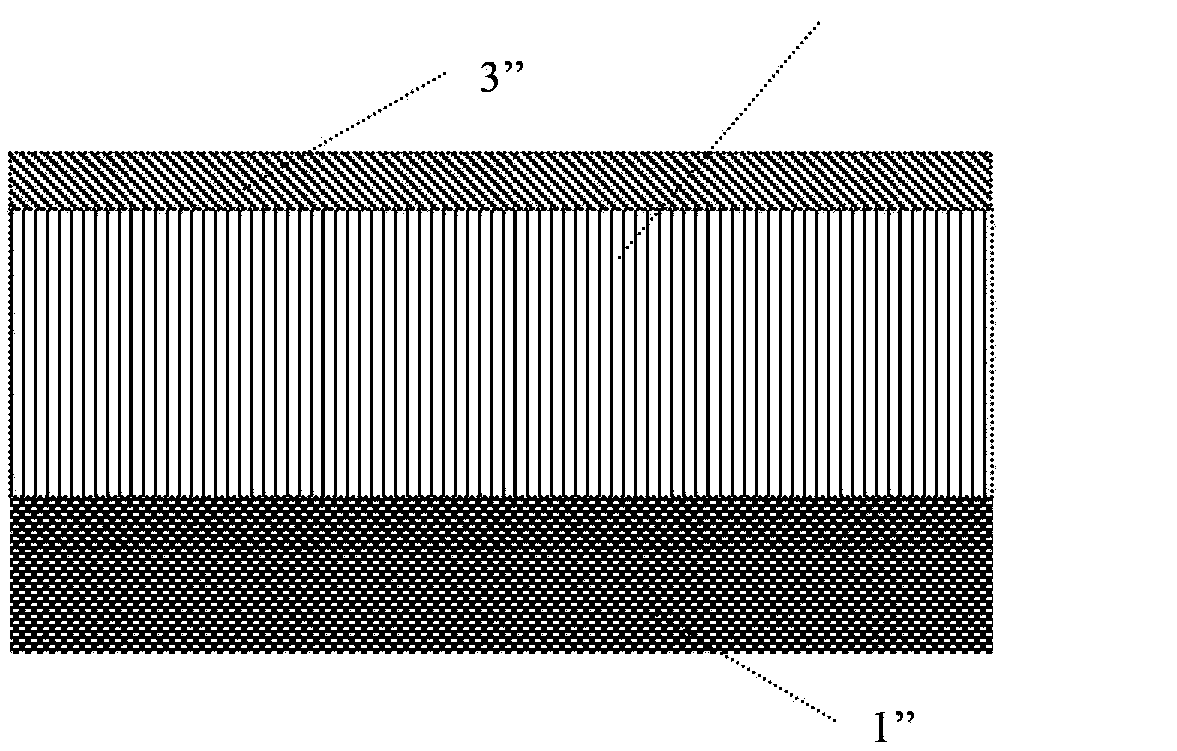

Magnetic recording head and media comprising aluminum oxynitride underlayer and a diamond-like carbon overcoat

ActiveUS20080176108A1Protective layerProvide wear resistanceElectric discharge heatingVacuum evaporation coatingDiamond-like carbonAlloy

A method for forming a protective bilayer on a magnetic read / write head or magnetic disk. The bilayer is formed as an adhesion enhancing underlayer and a protective diamond-like carbon (DLC) overlayer. The underlayer is formed of an aluminum or alloyed aluminum oxynitride, having the general formula AlOxNy or MezAlOxNy where Mez symbolizes Tiz, Siz or Crz and where x, y and z can be varied within the formation process. By adjusting the values of x and y the adhesion underlayer contributes to such qualities of the protective bilayer as stress compensation, chemical and mechanical stability and low electrical conductivity. Various methods of forming the underlayer are provided, including reactive ion sputtering, plasma assisted chemical vapor deposition, pulsed laser deposition and plasma immersion ion implantation.

Owner:SAE MAGNETICS (HK) LTD

Zr-Co-Re thin film getter provided with protection layer, and preparation method thereof

InactiveCN103849835AIncrease speedIncrease inspiratory capacityVacuum evaporation coatingSputtering coatingRare-earth elementHydrogen

The invention relates to a Zr-Co-Re thin film getter provided with a protection layer, and a preparation method thereof. The Zr-Co-Re thin film getter is composed of a getter layer and the protection layer; main components of the getter layer are Zr, Co, and one or more selected form rare earth elements La, Ce, Pr, and Nd; and main component of the protection layer is Ni. Pulsed laser deposition film plating is adopted, and deposition of the double-layer structured thin film getter containing the protection layer and the getter layer on texture monocrystalline silicon is carried out. The texture substrate is capable of increasing effective area of the getter thin film, and so that inspiratory flow rate and inspiratory capacity are increased. The surface of the getter layer is plated with a Ni protection layer; Ni is capable of realizing dissociation of hydrogen, and increasing absorption amount of hydrogen; and the Ni protection layer is capable of inhibiting absorption of oxygen and reducing activation temperature. Activation of the Zr-Co-Re thin film getter can be realized in roasting processes at a temperature of 180 to 350 DEG C; after roasting, the Zr-Co-Re thin film getter possesses excellent inspiration performance at room temperature, can be used for internal gas residue removing of high vacuum microelectronic devices.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Preparation method for copper zinc tin sulfide thin film material

InactiveCN102496659AFlat and dense surfaceReduce usageFinal product manufactureSemiconductor devicesEvaporationCopper foil

The invention discloses a preparation method for a copper zinc tin sulfide thin film material. The preparation method comprises the following steps of: performing oil removal, electrochemical polishing and activation pretreatment on the surface of a copper foil substrate; depositing metallic zinc and tin by using one of a magnetron sputtering method, an evaporation method, a pulsed laser deposition method and an electrodeposition method to form a metallic preformed layer; annealing the metallic preformed layer in a sulfur-containing protective atmosphere at high temperature; and placing the annealed metallic preformed layer in an alkaline KCN solution for etching. By the preparation method, a copper belt is adopted as a flexible substrate and a back contact conductive material, so that the usage of expensive metallic molybdenum is greatly reduced, and production cost is decreased; and a Cu-S phase formed by excessive copper is favorable for the growth of copper zinc tin sulfide crystal grains, reduces charge carrier recombination centers and improves photoelectric conversion efficiency. The copper zinc tin sulfide thin film material prepared by the method is easy to produce in large scale, and can be popularized and applied in a thin film solar cell industry.

Owner:CENT SOUTH UNIV

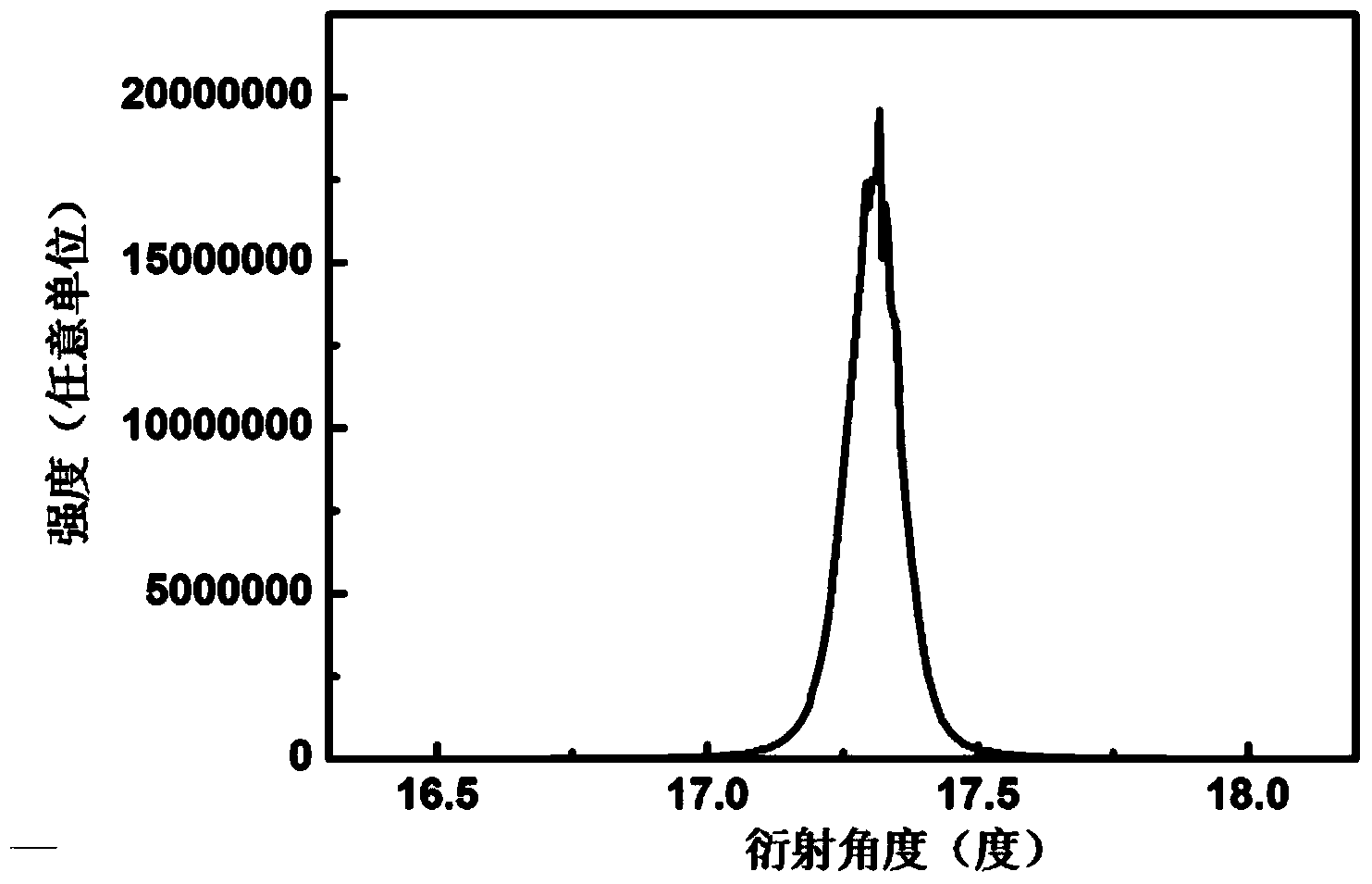

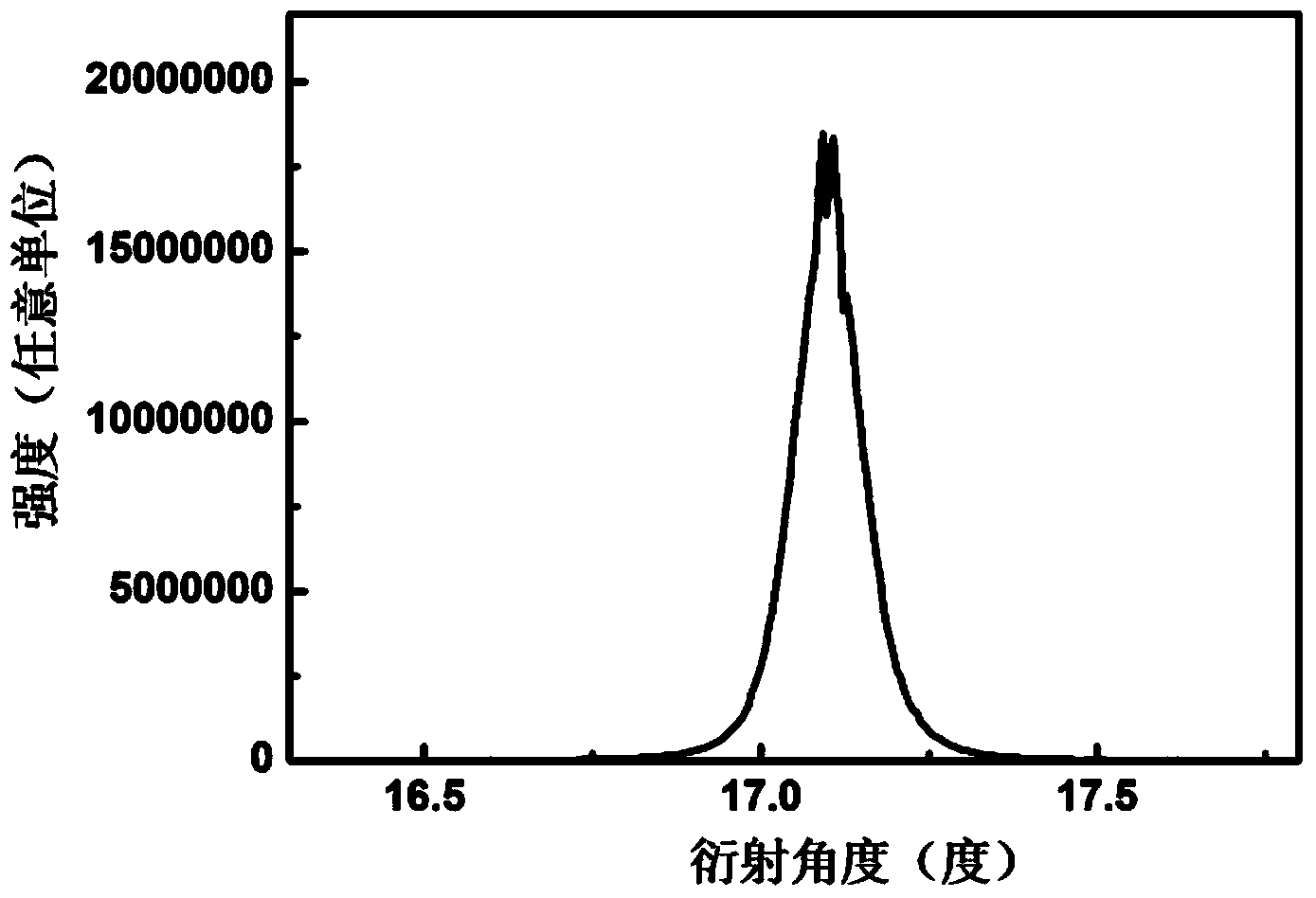

Method for preparing film bulk acoustic wave resonator on the basis of monocrystal AlN

InactiveCN105703732AHigh c-axis orientationAvoid lossImpedence networksThin-film bulk acoustic resonatorElectromechanical coupling coefficient

The invention discloses a method for preparing film bulk acoustic wave resonator on the basis of a monocrystal AlN. The method comprises the following steps of: growing (111) an oriented monocrystal Al film on a preparation substrate by using a molecular beam epitaxial growth method; growing (002) an oriented monocrystal AlN film on the oriented monocrystal Al film by using a pulse laser deposition growth method; and depositing a layer of metallic film on the AlN film to form a Al / AlN / metal sandwich piezoelectric stack structure. The piezoelectric stack structure based on monocrystal AlN prepared by the method can be used for preparing the film bulk acoustic wave resonator. The piezoelectric performance of the monocrystal AlN film is superior to that of a polycrystal AlN piezoelectric film applied to film bulk acoustic wave resonator so that the quality factor and a valid electromechanical coupling factor of a device are increased.

Owner:FOSHAN AIFO LIGHT FLUX TECH CO LTD

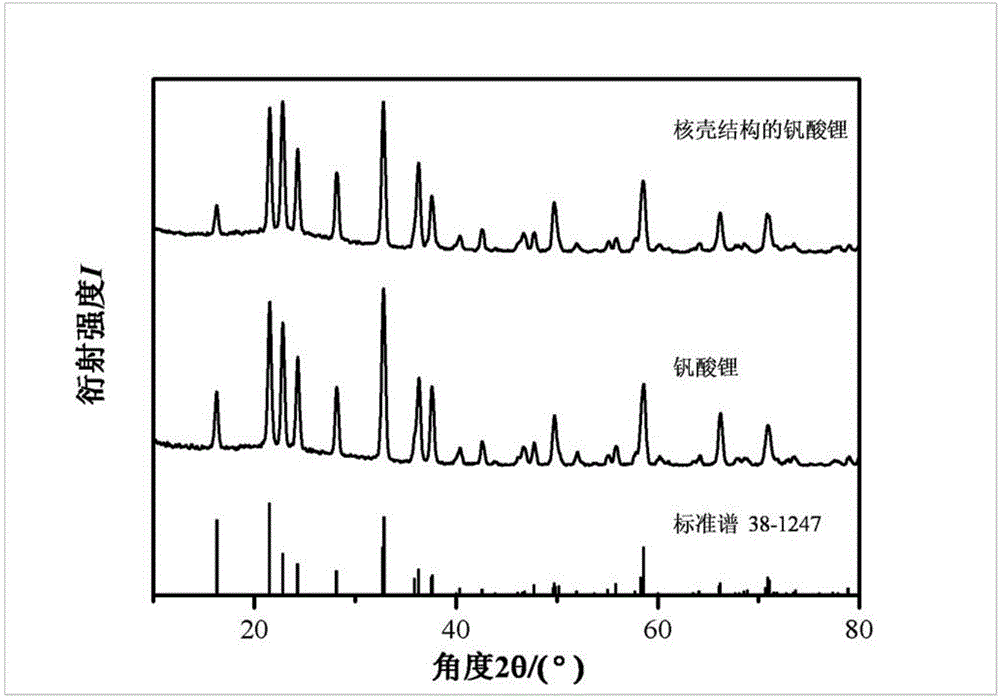

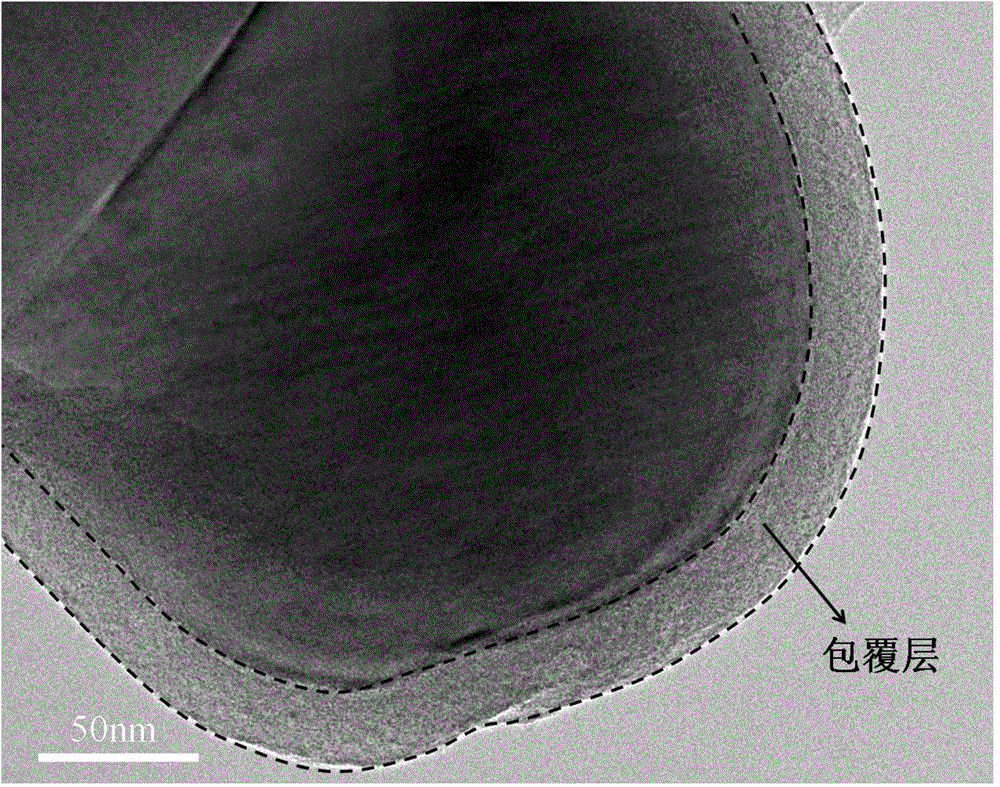

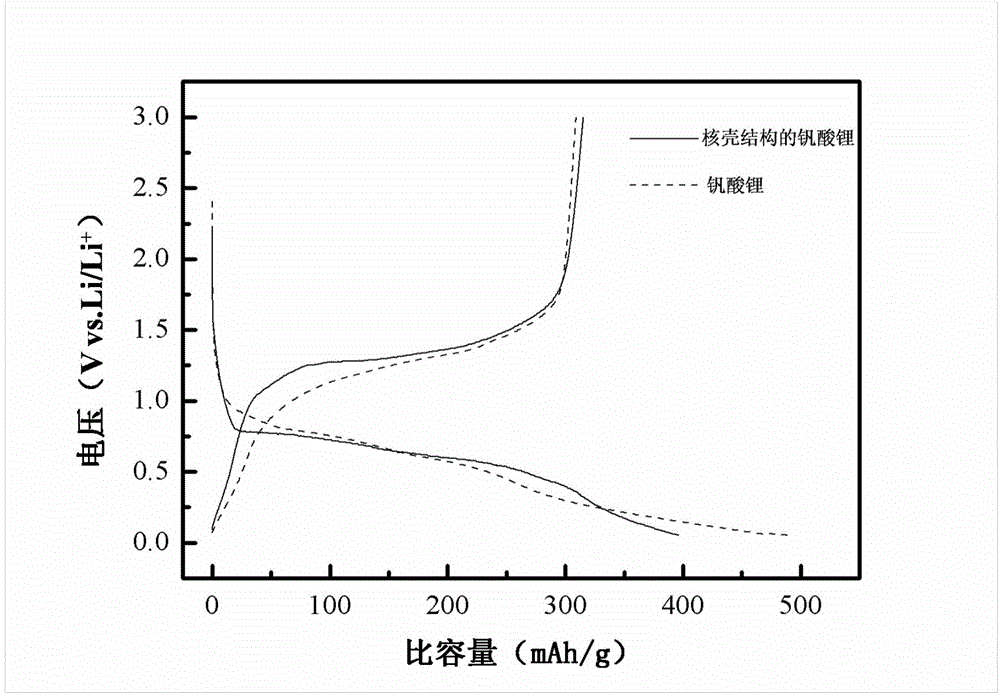

Lithium vanadate anode material, anode, battery and anode material preparation method

The invention discloses a lithium vanadate anode material, an anode, a battery and an anode material preparation method, and belongs to the field of batteries. The lithium vanadate anode material is of a core-shell structure, the core is lithium vanadate, the shell is a coating layer, lithium vanadate is nanometer granules or micrometer level secondary granules formed by nanometer granules, the thickness of the coating layer is 2-30nm, and the coating layer comprises a conductive coating layer or / and a stable coating layer. An organic carbon source is introduced into a high temperature reactor with an inert gas as a carrier by using a chemical vapor deposition method, in order to from the conductive coating layer of amorphous carbon or graphitic carbon on the surface of the core. The conductive coating layer and the stable coating layer are prepared by using a vacuum coating method, a magnetron sputtering method, a pulsed laser deposition method or an atomic layer deposition method. Lithium vanadate is used as an active anode material to obtain high coulombic efficiency, large specific capacity and good rate capability, and the proper embedded escape potential and the considerable volume of lithium vanadate are fully utilized.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com