Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

297 results about "Tin sulfide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Friction material

InactiveUS20050004258A1Good brake feelingImprove effectivenessBraking element arrangementsOther chemical processesMohs scale of mineral hardnessHardness

A friction material is made by molding and curing a composition containing a fibrous base that includes stainless steel fibers but not other steel fibers, a binder, and a friction modifier that includes at least two types of hard particles having a large Mohs hardness, bronze powder and a specific amount of tin sulfide. The friction material has a excellent balance of properties, including a high strain linearity that provides a excellent brake feel, a high torque linearity and a excellent effectiveness, and also minimizes disc rotor attack, disc pad wear and metal pickup. Such friction materials are particularly suitable for automotive applications, such as disc pads.

Owner:NISSHINBO INDDUSTRIES

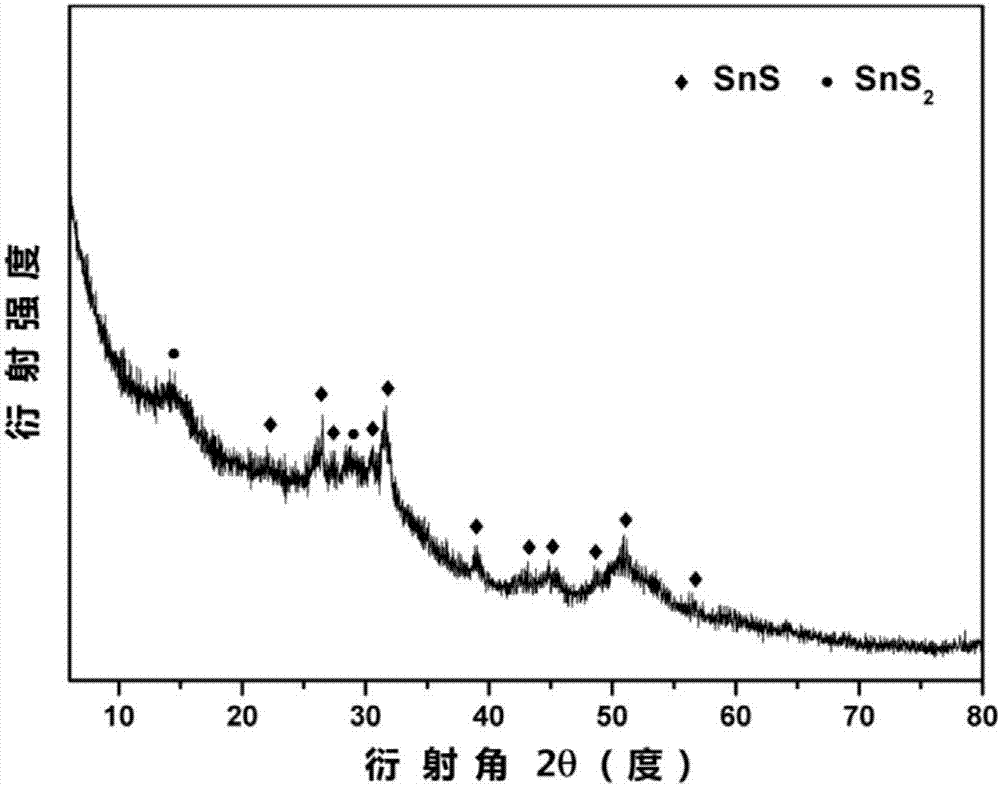

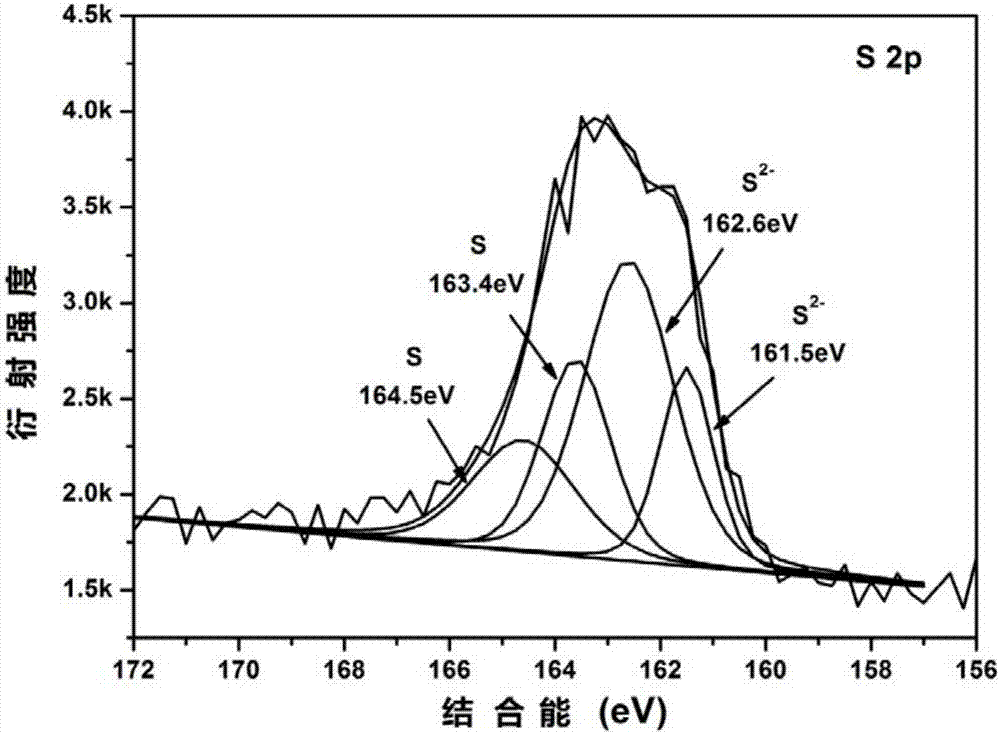

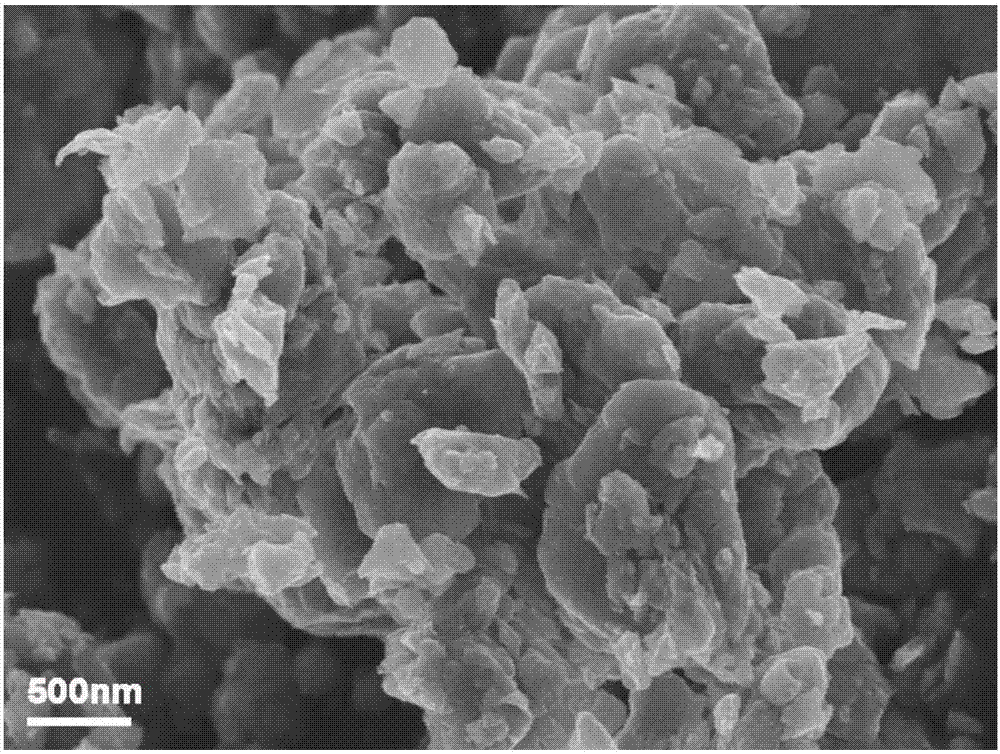

Preparation method and application of tin sulfide material

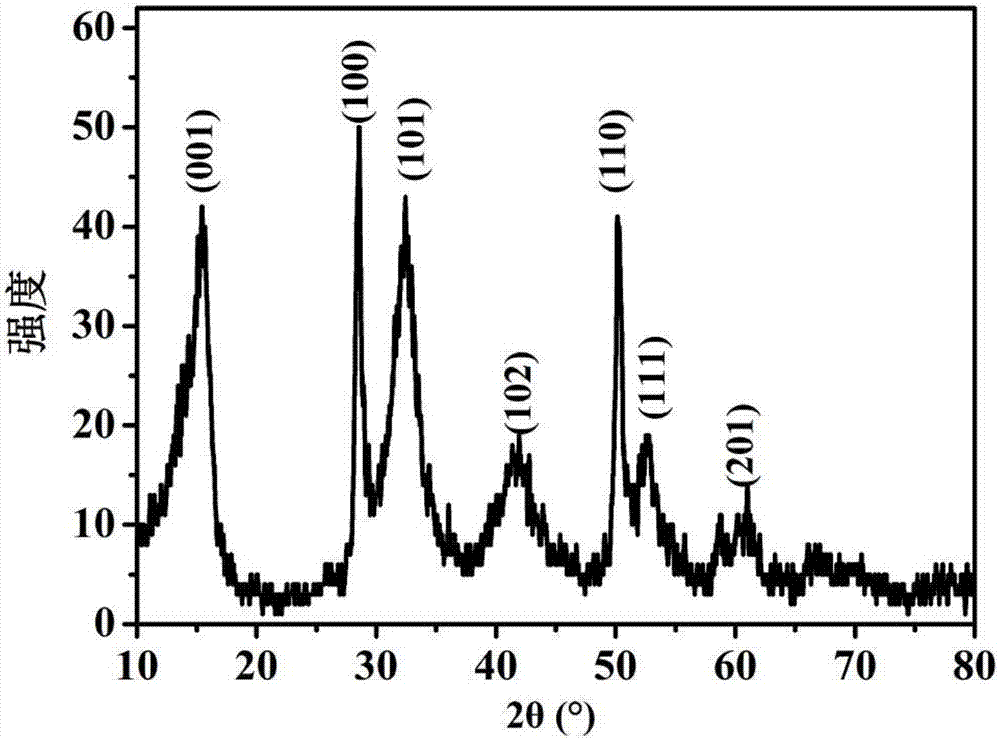

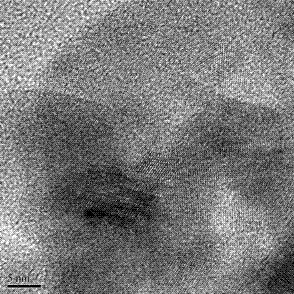

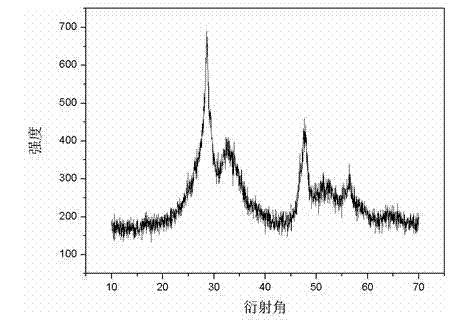

ActiveCN105800674ASimple methodMild reaction conditionsMaterial nanotechnologyPhysical/chemical process catalystsActive agentReaction temperature

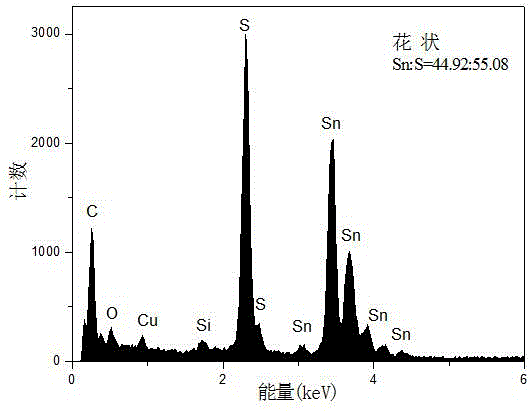

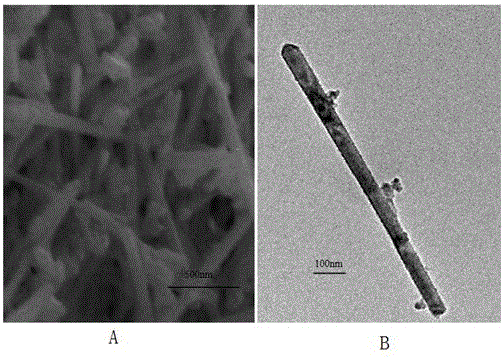

The invention discloses a preparation method of a tin sulfide material. A solvothermal method is adopted, dehydrate-stannous chloride is used as a tin source, the morphology and particle size of the synthetic material are controlled by controlling a sulfur source, the reaction temperature, reaction time, the solvent variety and the surfactant variety, and the SnS photocatalytic material with controllable morphology and high quality is prepared. The method is simple in preparation and easy to carry out, the yield is high, consumed time is short, cost is low, reaction conditions are mild, good development prospects are achieved, industrial production is easy to achieve, and the prepared material has high photocatalytic activity and has good industrial application prospects when serving as the photocatalytic material.

Owner:KUNMING UNIV OF SCI & TECH

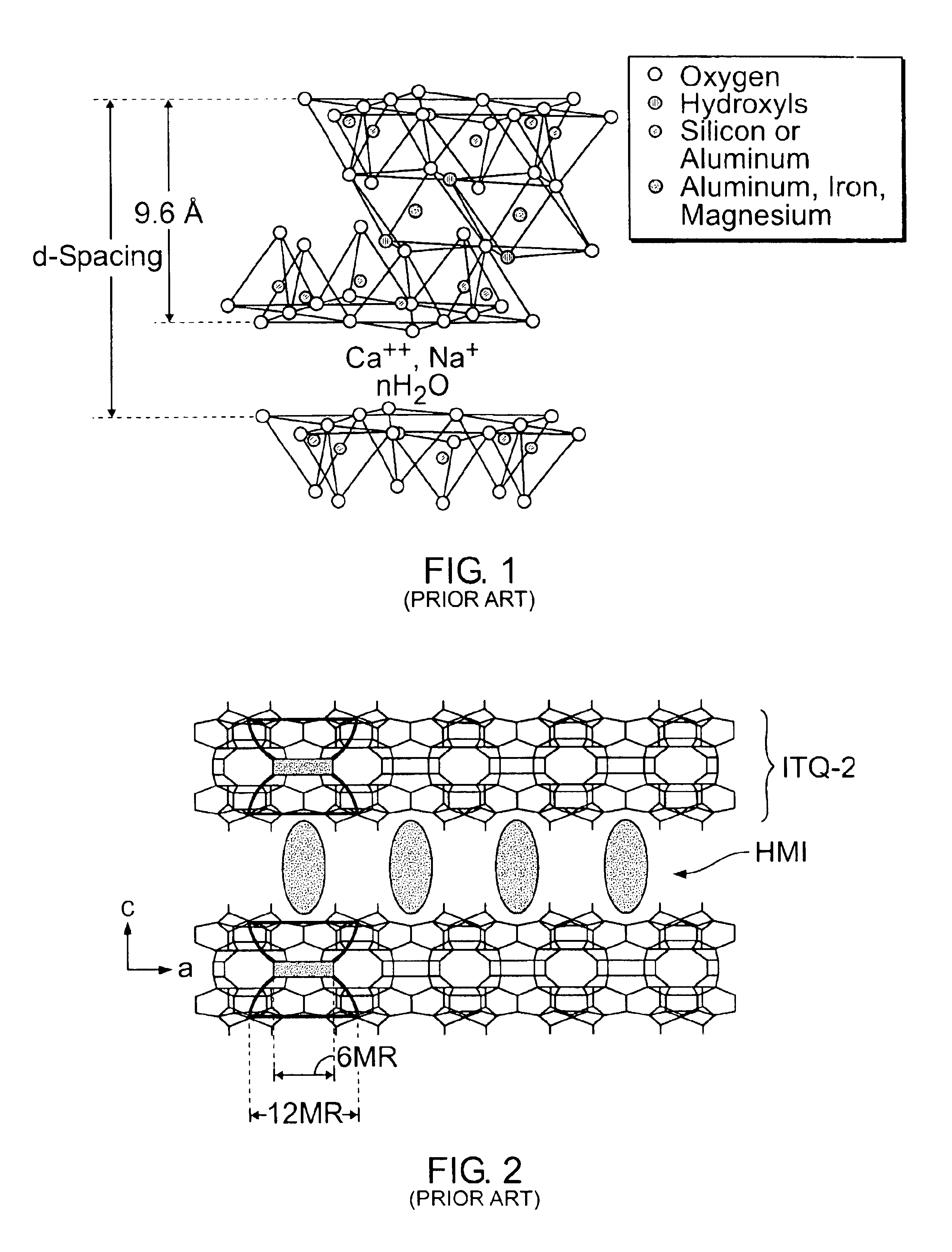

Layered silicate material and applications of layered materials with porous layers

InactiveUS6863983B2High porosityImprove propertiesMaterial nanotechnologyRecord information storagePorous layerMaterials science

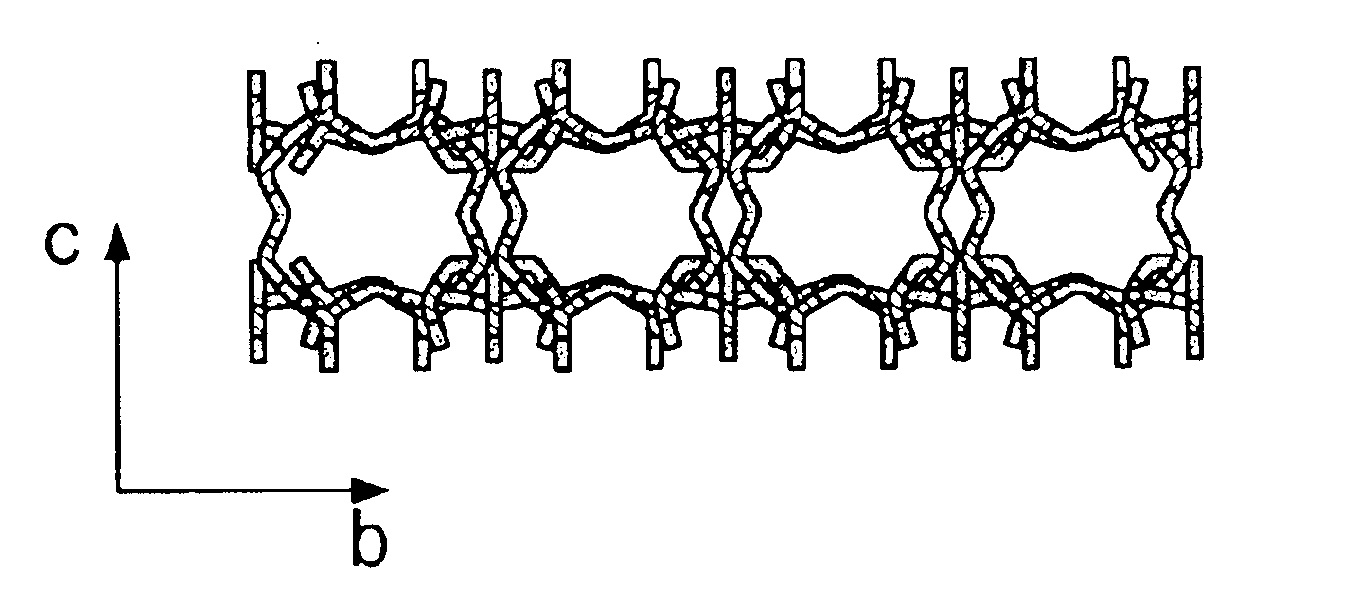

Layered silicate materials and applications are disclosed. In one aspect, the invention features layered silicate materials having pores that run generally perpendicular to the layers. In another aspect, the invention features composite materials including layered framework materials (e.g., layered silicate materials, layered Aluminophosphate materials, layered tin sulfides) having pores or openings that run generally perpendicular to the layers.

Owner:UNIV OF MASSACHUSETTS

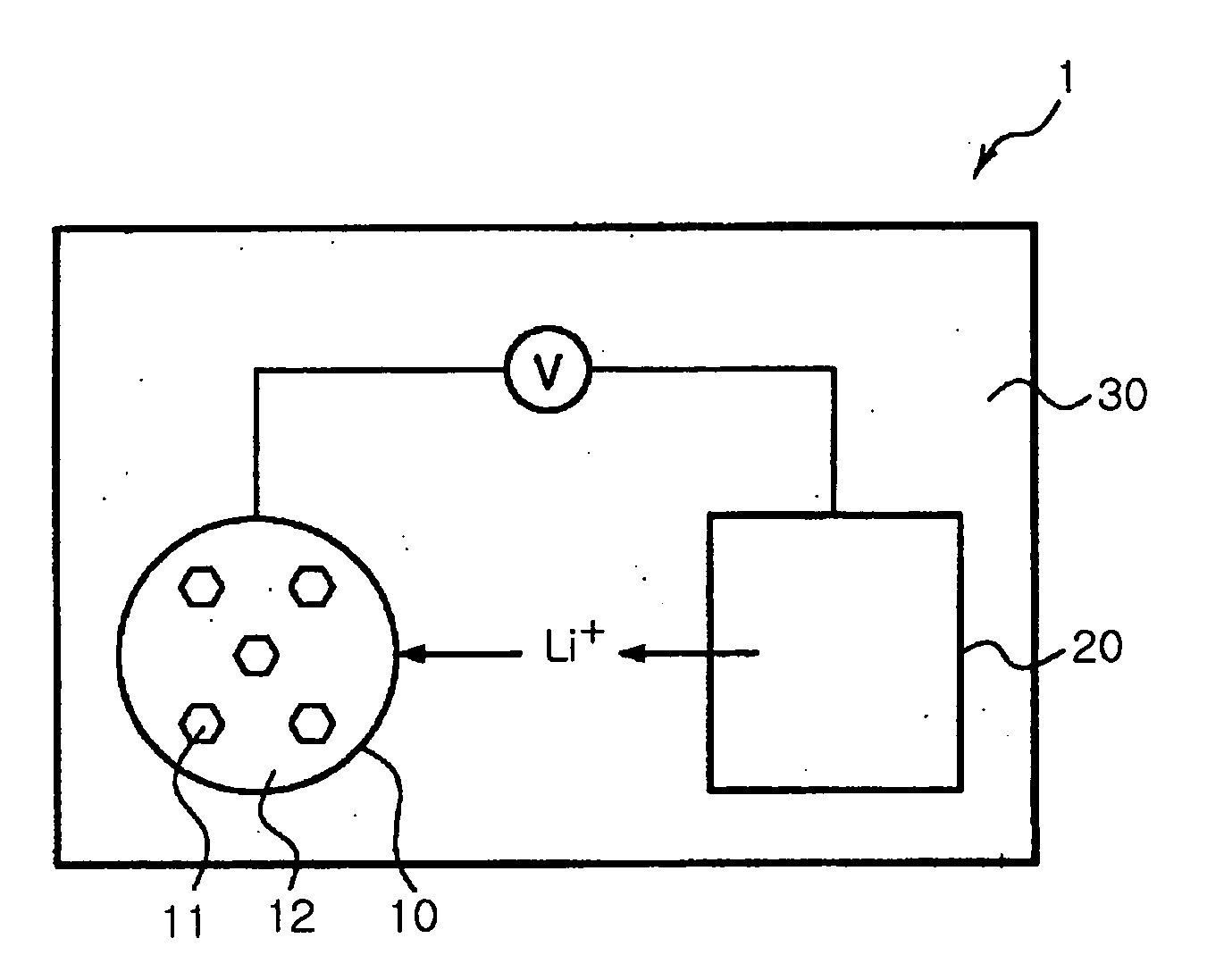

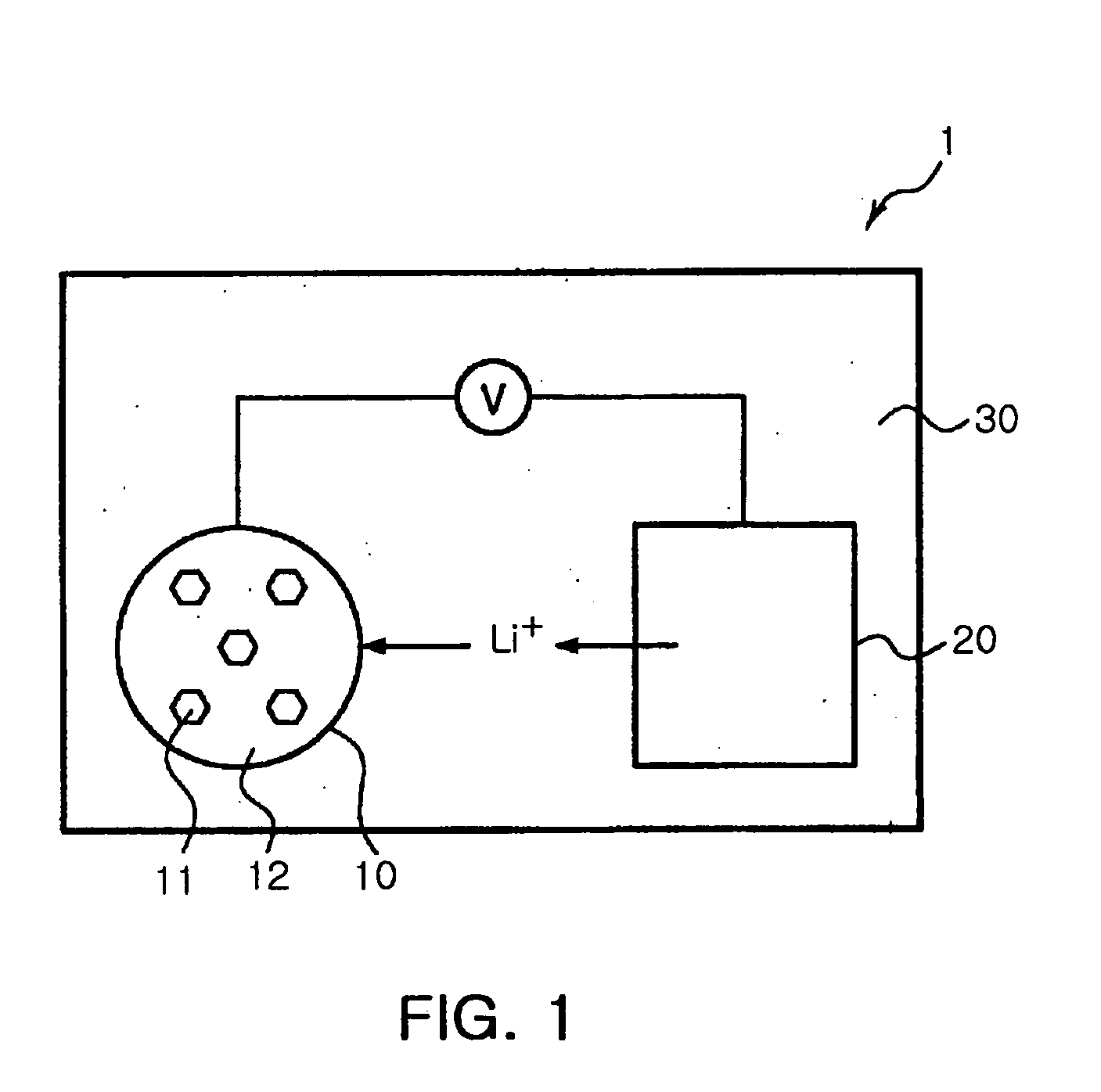

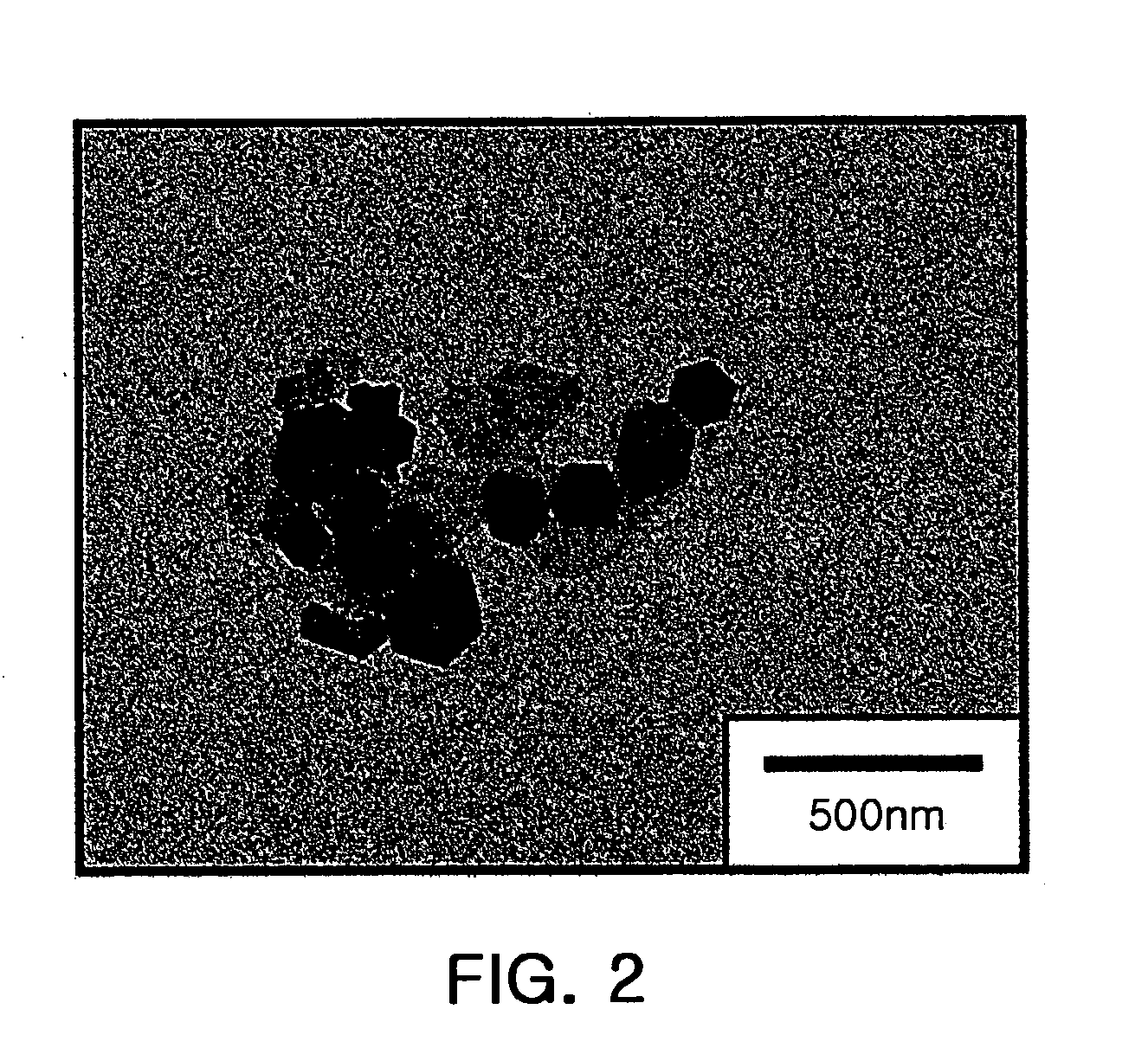

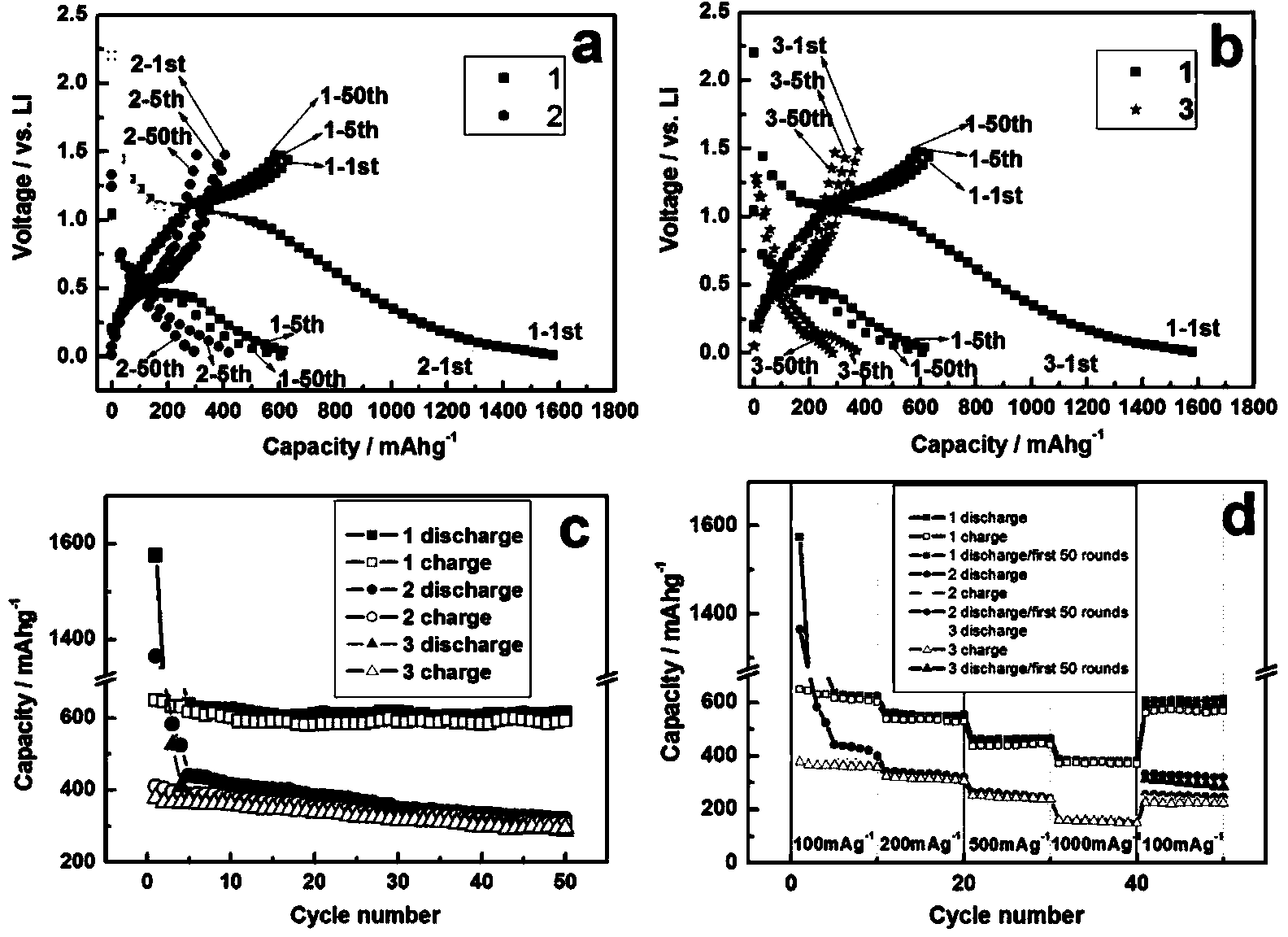

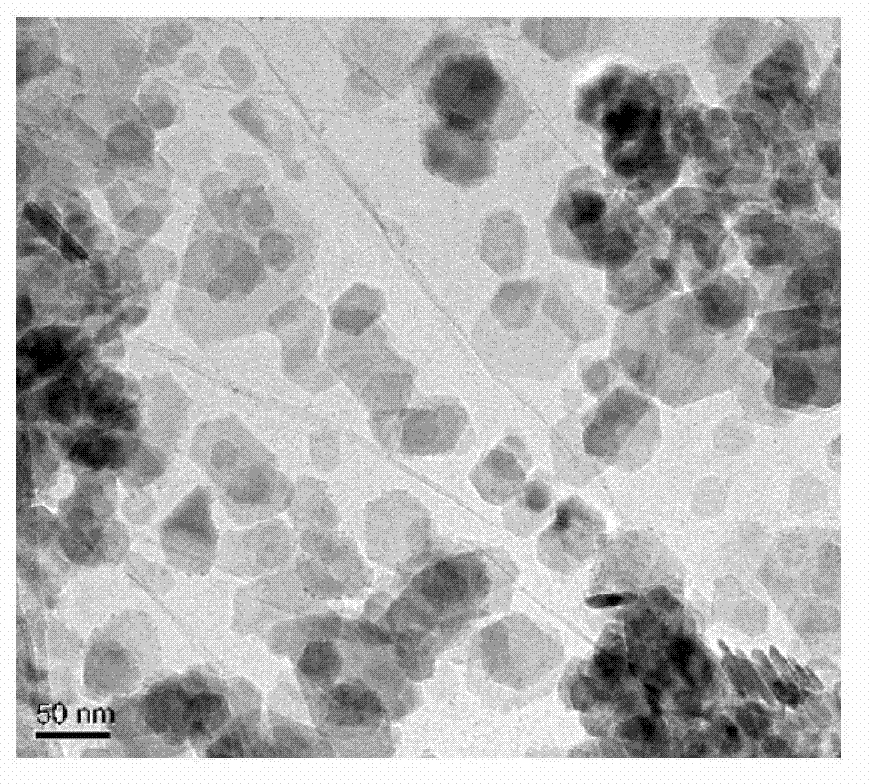

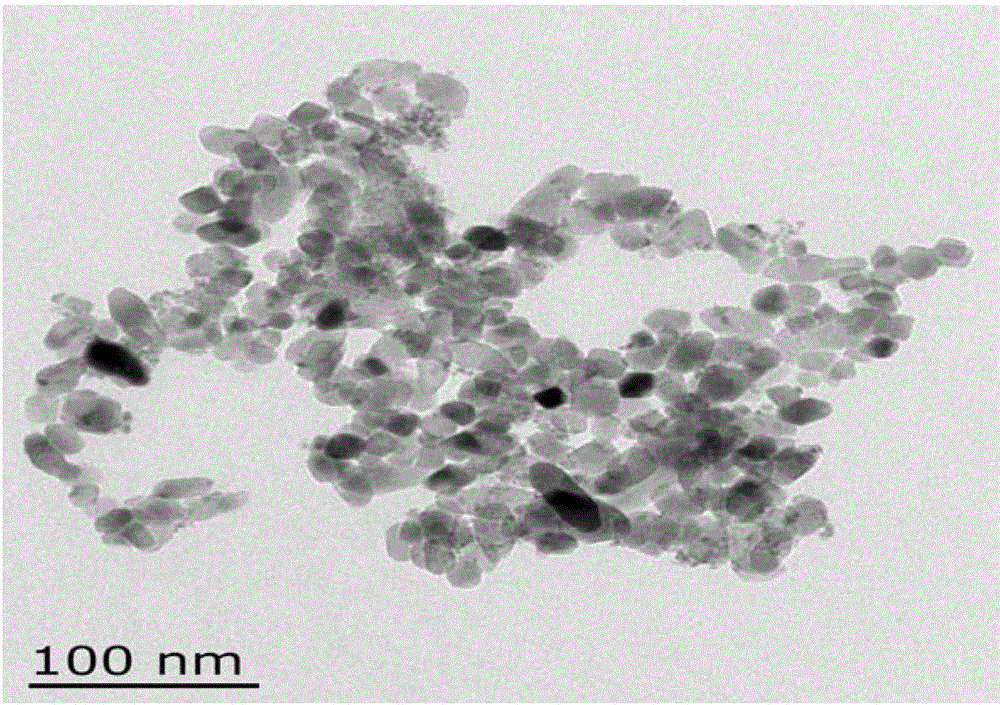

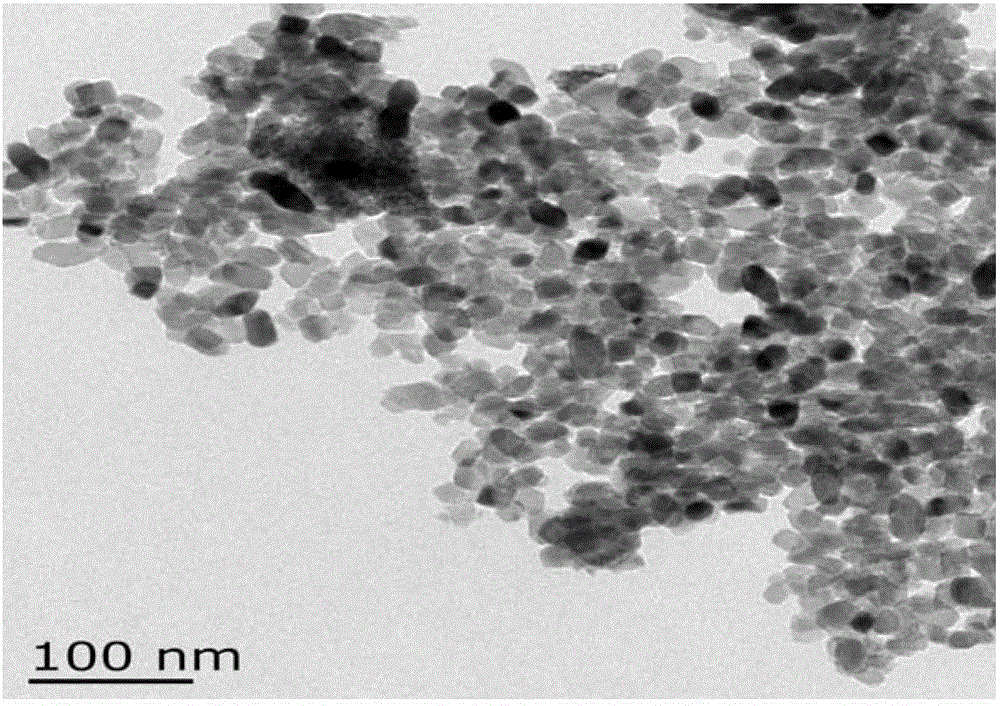

Preparing method of tin sulfide nanoparticles and manufacturing method of lithium ion battery using the same

InactiveUS20090029258A1Small sizeEasily controlled in size and morphologyMaterial nanotechnologyTin compoundsNanoparticleSodium-ion battery

There is provided a method of preparing tin sulfide nanoparticles, in which tin sulfide particles are prepared selectively, easily controlled in size and morphology and can be massively produced more easily through a simpler process. The method includes: mixing a tin sulfide precursor with at least one surfactant into a mixture; and heating the mixture.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

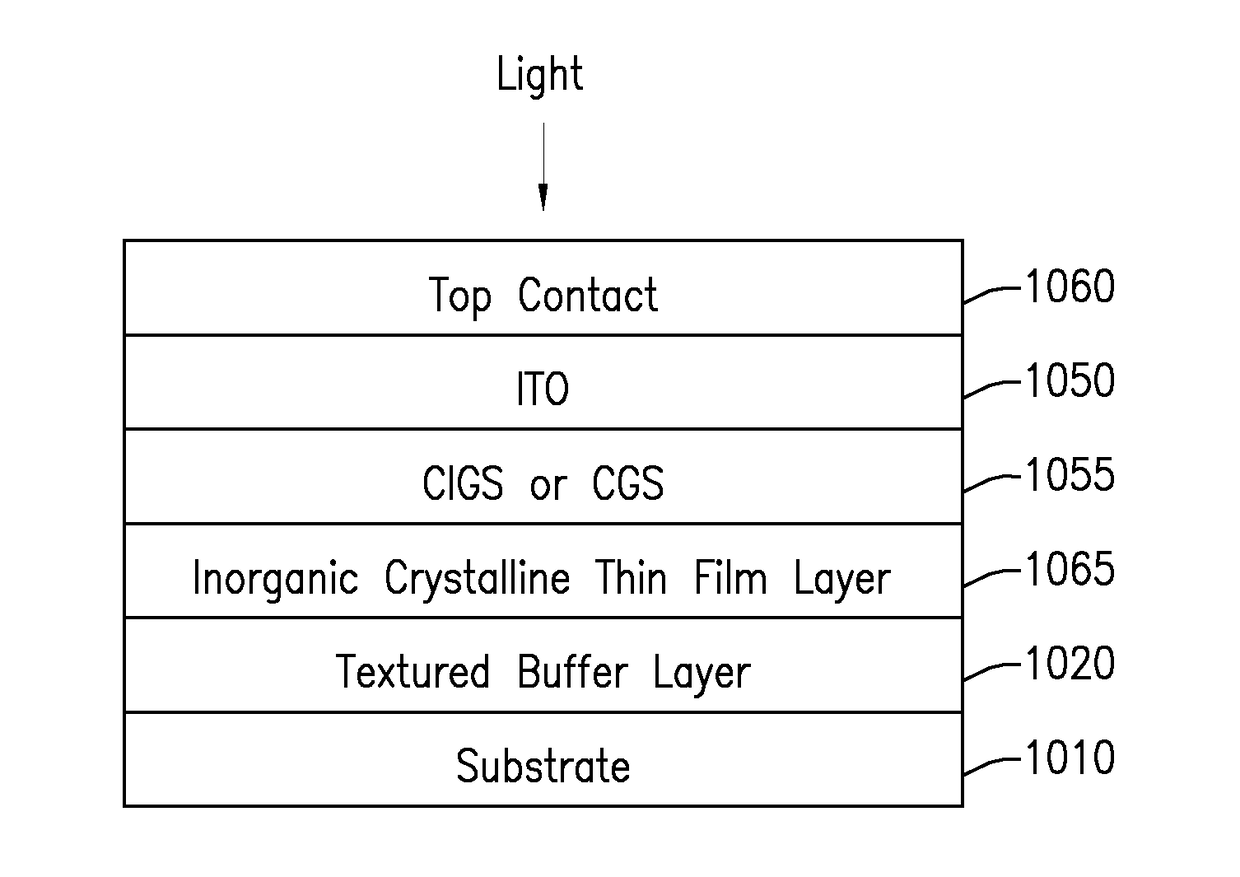

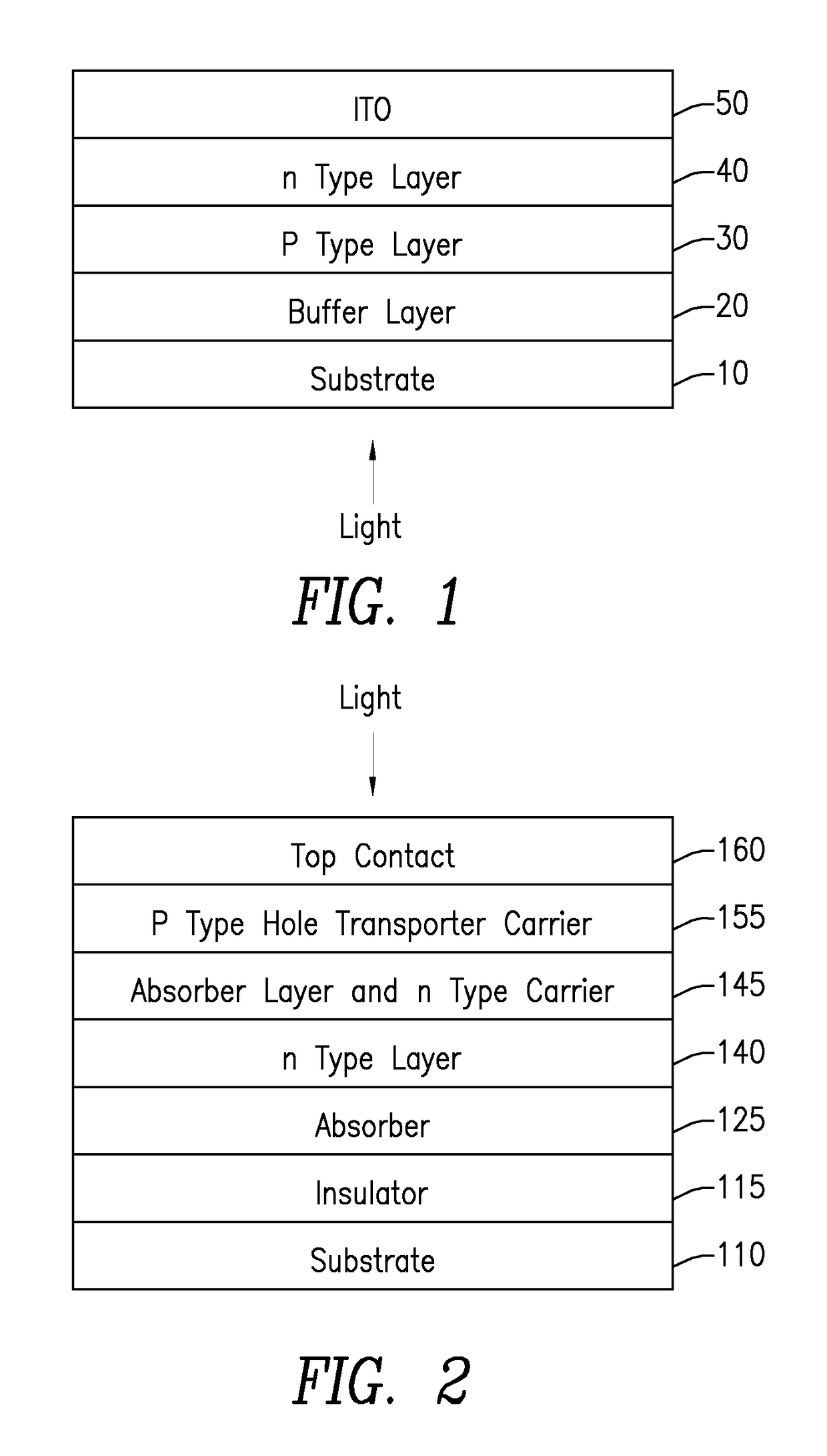

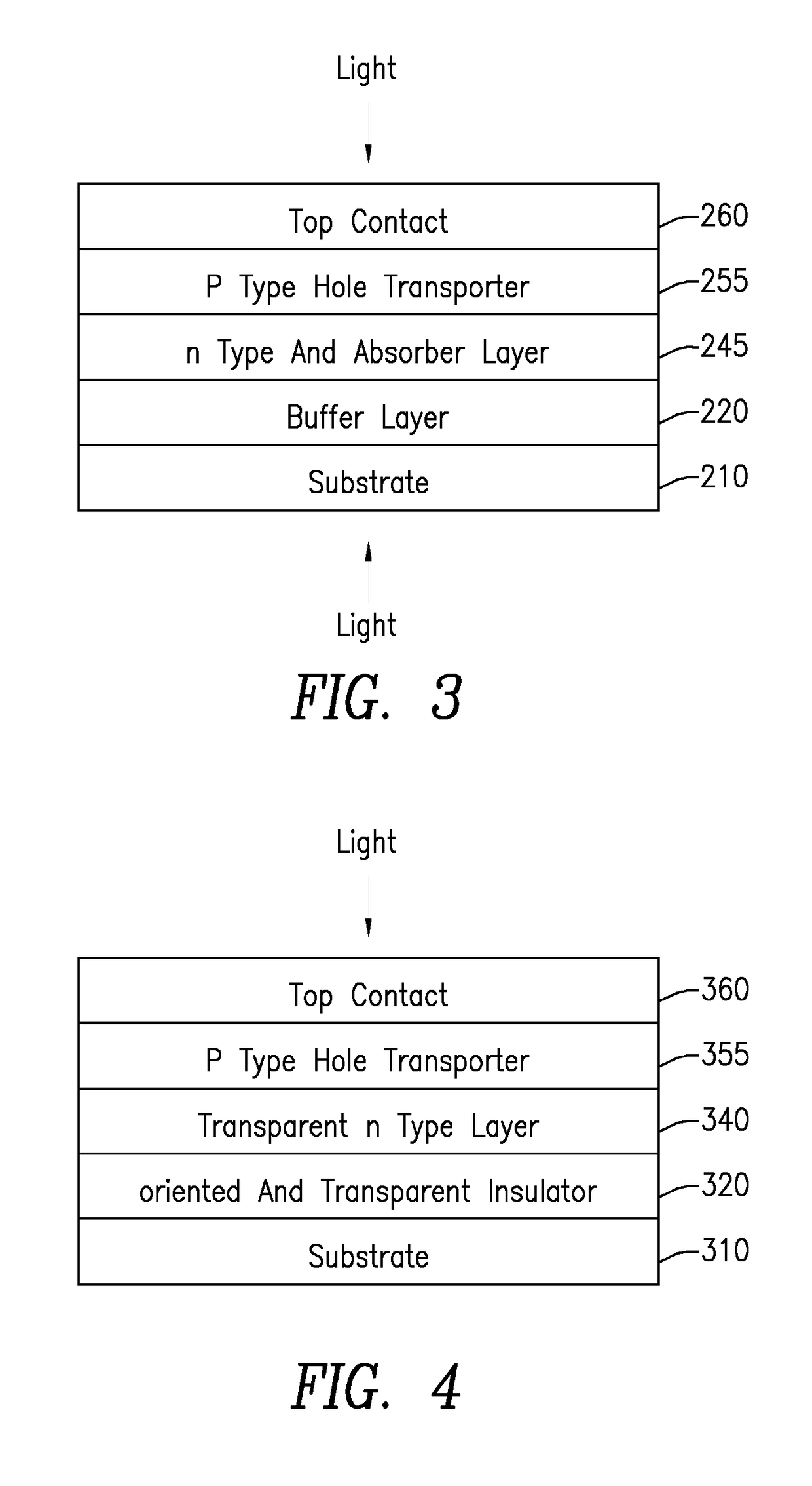

High efficiency thin film tandem solar cells and other semiconductor devices

InactiveUS20170271622A1Layer is highTransistorSolid-state devicesElectrical conductorTandem solar cell

Architectures for tandem solar cell including two thin films forming a top layer and a bottom layer. Such cells can be bi-facial. Exemplary materials used for the top layer are CIGS (CGS), perovskites (Sn and Ge), amorphous silicon (a-Si), copper oxide, tin sulfide, CZTS and III-V materials. For the bottom layer an inorganic film such as either silicon or germanium may be used. In general, the architecture includes of a glass, plastic or metal substrate and a buffer layer, either an oxide insulator or nitride conductor.

Owner:SOLAR TECTIC

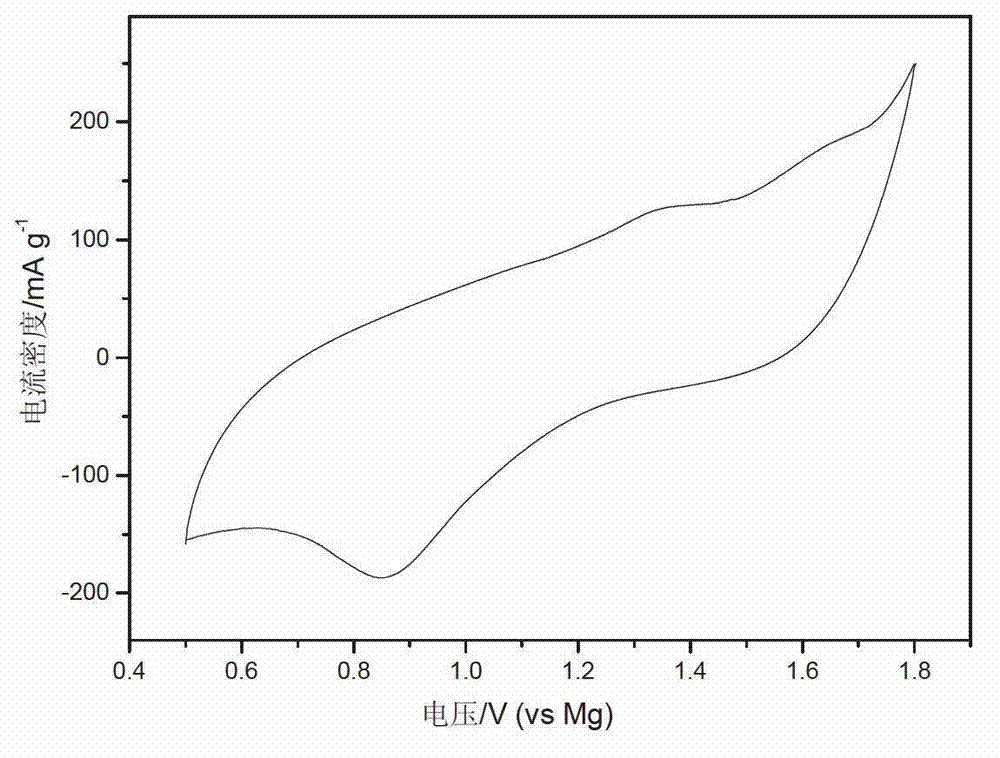

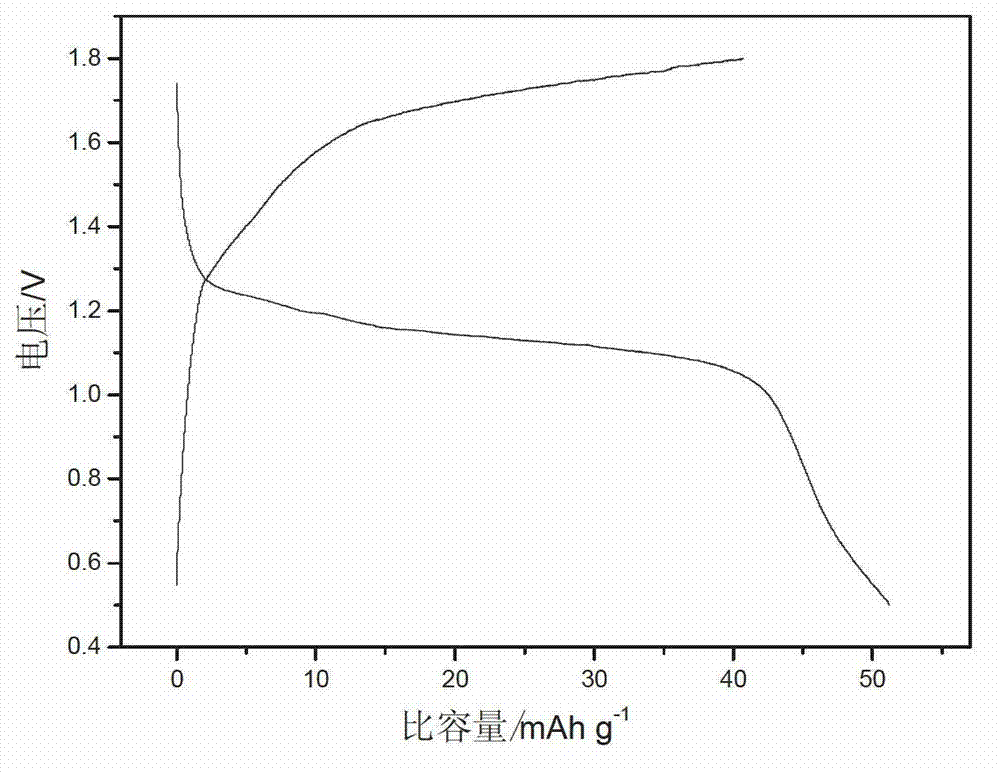

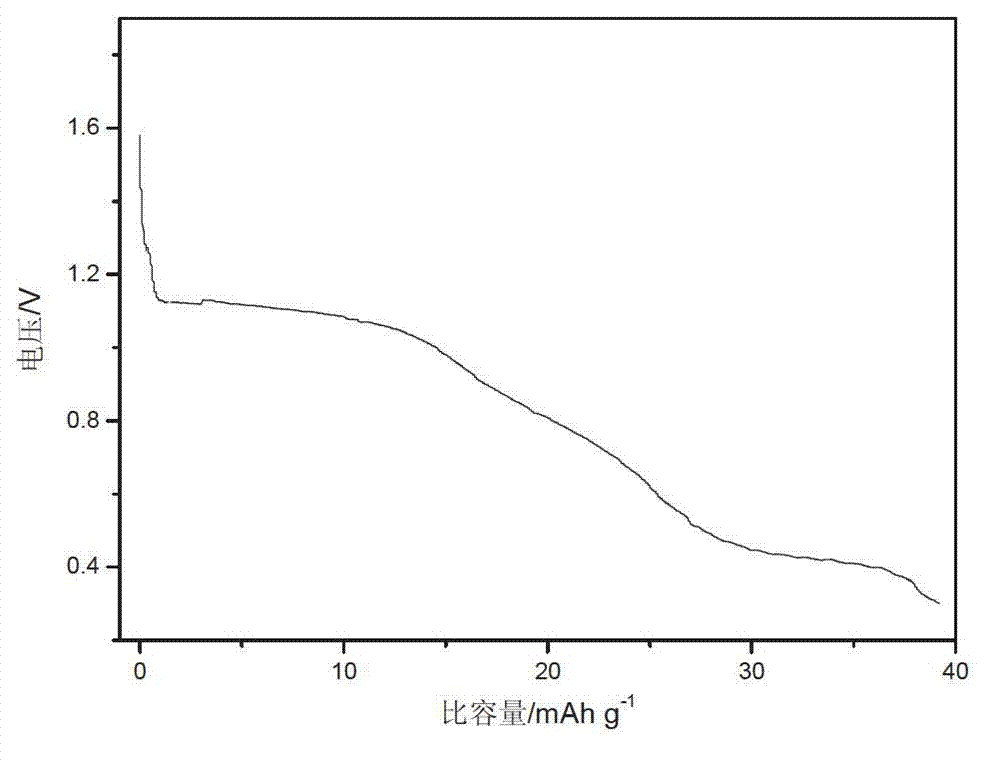

Application method of binary metal sulfides in chargeable magnesium battery

InactiveCN102969501AUnderstand the purposeLearn about featuresCell electrodesFinal product manufactureNickel sulfideCobalt sulfide

The invention discloses an application method of binary metal sulfides in a chargeable magnesium battery. The binary metal sulfides comprise nickel sulfide, manganese sulfide, cobalt sulfide, ferric sulfide, tin sulfide, tungsten sulfide, zinc sulfide, vanadic sulfide and the like. The preparation method for preparing the chargeable magnesium battery with the binary metal sulfides as an anode material specifically comprises the steps of: grinding the binary metal sulfides; adding a conductive agent and a bonding agent into the binary metal sulfides, and agitating uniformly and coating on a current collector; placing the current collector in an oven to dry, punching into a pole piece by a punch, tabletting and placing into a vacuum oven to dry so as to obtain the anode material; and using magnesium as a cathode, adding an electrolyte and assembling the chargeable magnesium battery. The chargeable magnesium battery prepared by the method provided by the invention has the advantages of simpleness in preparation, abundance in materials, low cost, and easiness in mass production. The chargeable magnesium battery has a great advantage as a large energy storing battery and has a good application prospect as a green energy resource.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method for copper zinc tin sulfide thin film material

InactiveCN102496659AFlat and dense surfaceReduce usageFinal product manufactureSemiconductor devicesEvaporationCopper foil

The invention discloses a preparation method for a copper zinc tin sulfide thin film material. The preparation method comprises the following steps of: performing oil removal, electrochemical polishing and activation pretreatment on the surface of a copper foil substrate; depositing metallic zinc and tin by using one of a magnetron sputtering method, an evaporation method, a pulsed laser deposition method and an electrodeposition method to form a metallic preformed layer; annealing the metallic preformed layer in a sulfur-containing protective atmosphere at high temperature; and placing the annealed metallic preformed layer in an alkaline KCN solution for etching. By the preparation method, a copper belt is adopted as a flexible substrate and a back contact conductive material, so that the usage of expensive metallic molybdenum is greatly reduced, and production cost is decreased; and a Cu-S phase formed by excessive copper is favorable for the growth of copper zinc tin sulfide crystal grains, reduces charge carrier recombination centers and improves photoelectric conversion efficiency. The copper zinc tin sulfide thin film material prepared by the method is easy to produce in large scale, and can be popularized and applied in a thin film solar cell industry.

Owner:CENT SOUTH UNIV

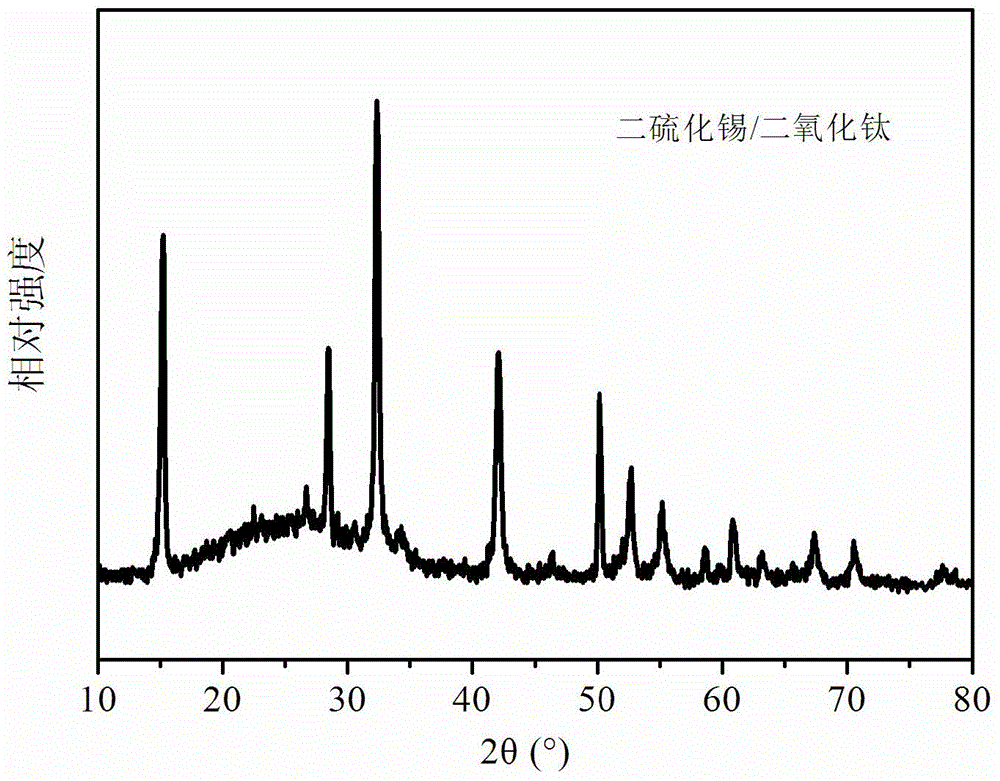

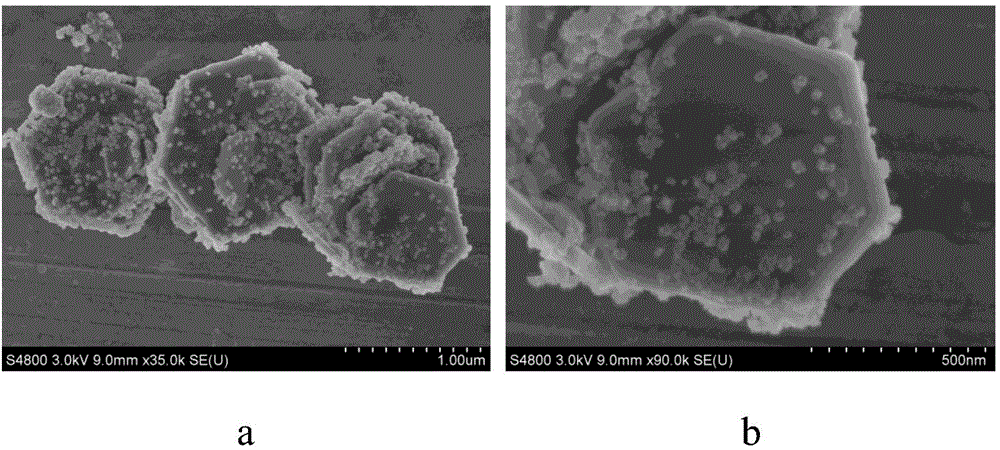

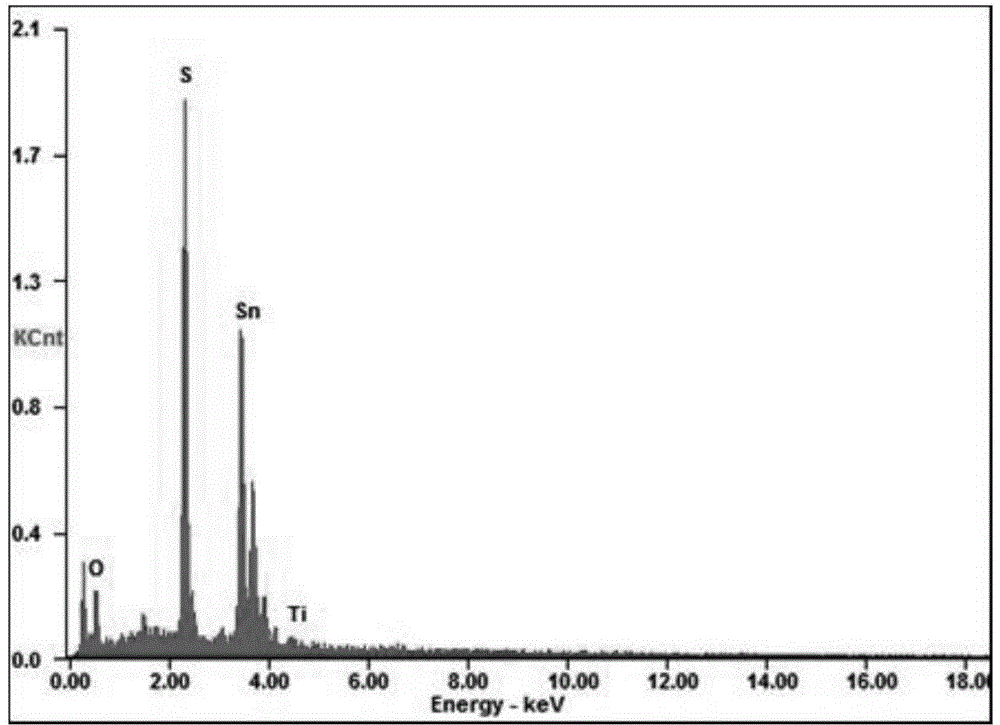

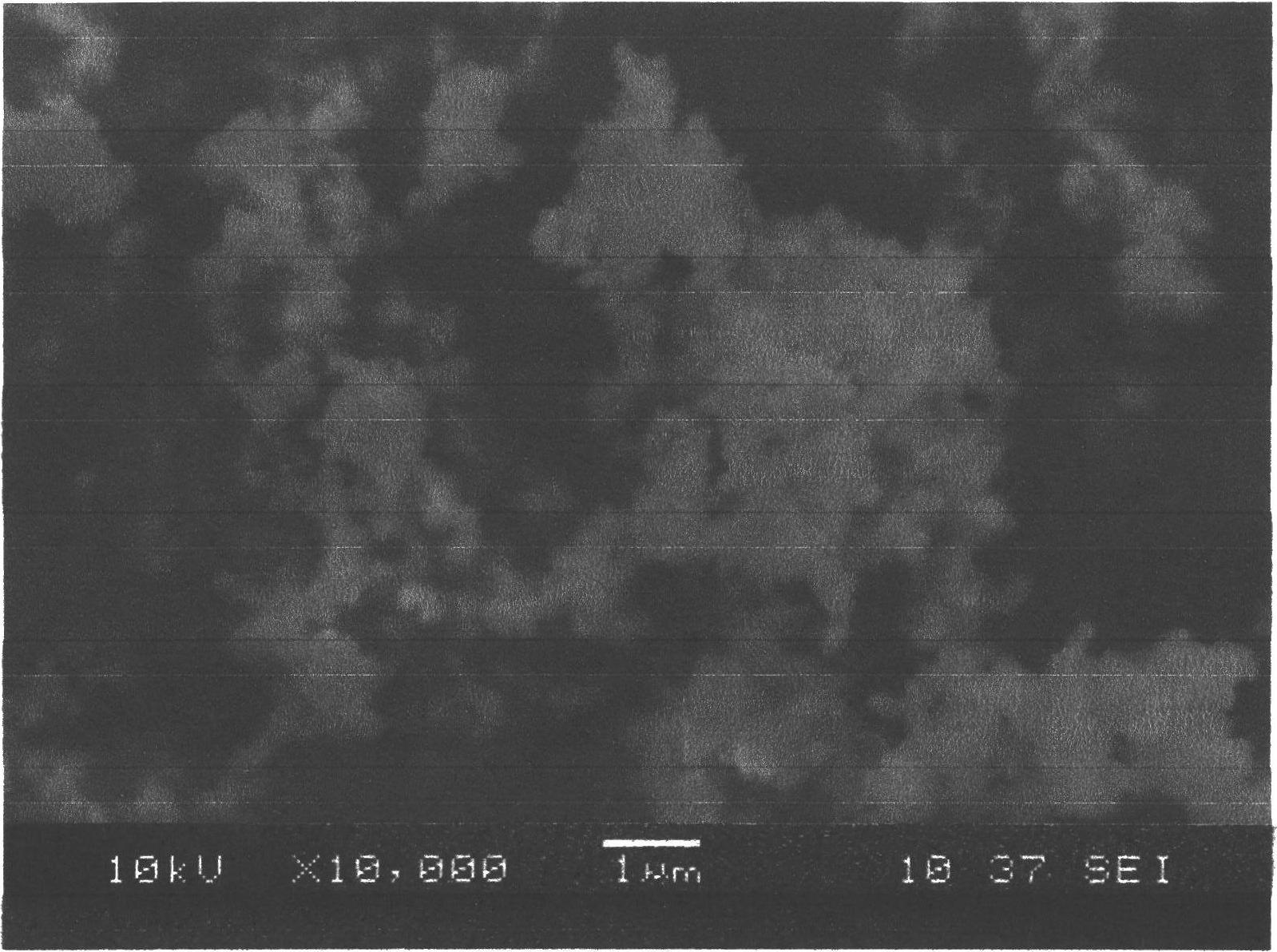

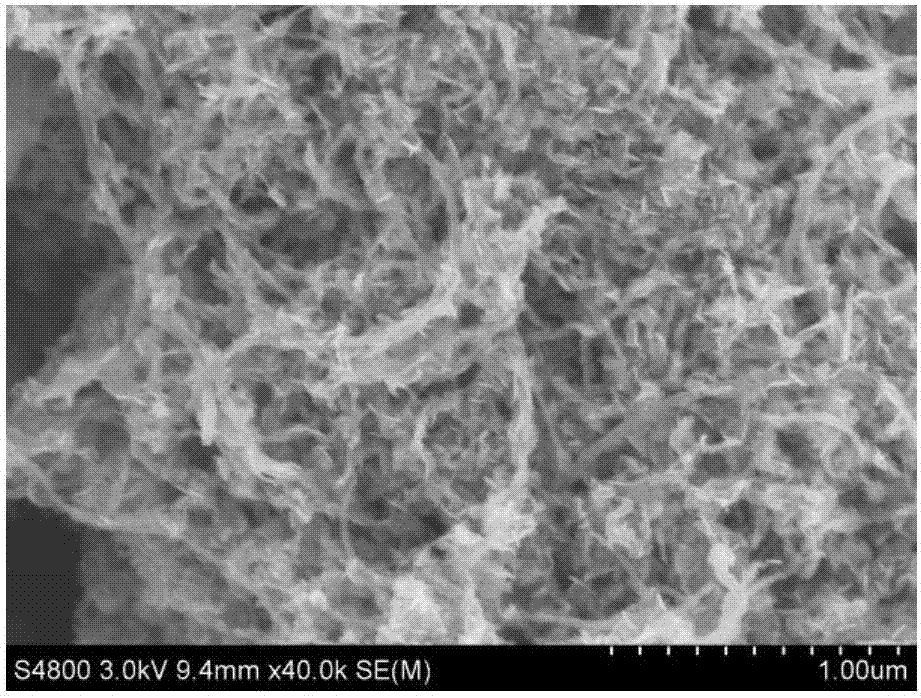

Tin disulfide/titanium dioxide compound photocatalyst and preparation method thereof

ActiveCN104888753AUniform sizeRegular shapeMaterial nanotechnologyWater/sewage treatment by irradiationThioureaPotassium dichromate

The invention discloses a tin disulfide / titanium dioxide compound photocatalyst which is prepared from a precursor solution through hydrothermal reaction, wherein the precursor solution is prepared from tin disulfide powder and butyl titanate in the mass ratio of 1:(20-100). The compound photocatalyst has controllable size, tin disulfide is of a hexagonal nanoscale flake shape, titanium dioxide nano-particles are uniformly loaded on tin disulfide, and the photocatalyst material has high photocatalytic reduction efficiency on potassium dichromate in a water body. The invention also discloses a preparation method of the compound photocatalyst. The preparation method comprises the following steps: a. preparing tin disulfide powder from tin chloride pentahydrate and thiourea; b. mixing the tin disulfide powder and butyl titanate to prepare the precursor solution; and c. hydrothermally heating the prepared precursor solution to prepare the compound photocatalyst. The preparation steps are simplified greatly, the control difficulty of technological parameters is lowered, and the large-scale preparation of the tin disulfide / titanium dioxide compound photocatalyst is realized.

Owner:澄城县海泰电子材料有限责任公司

Friction material

InactiveUS7297728B2Improve effectivenessExcellent brake feelBraking element arrangementsOther chemical processesMohs scale of mineral hardnessShell molding

A friction material is made by molding and curing a composition containing a fibrous base that includes stainless steel fibers but not other steel fibers, a binder, and a friction modifier that includes at least two types of hard particles having a large Mohs hardness, bronze powder and a specific amount of tin sulfide. The friction material has a excellent balance of properties, including a high strain linearity that provides a excellent brake feel, a high torque linearity and a excellent effectiveness, and also minimizes disc rotor attack, disc pad wear and metal pickup. Such friction materials are particularly suitable for automotive applications, such as disc pads.

Owner:NISSHINBO INDDUSTRIES

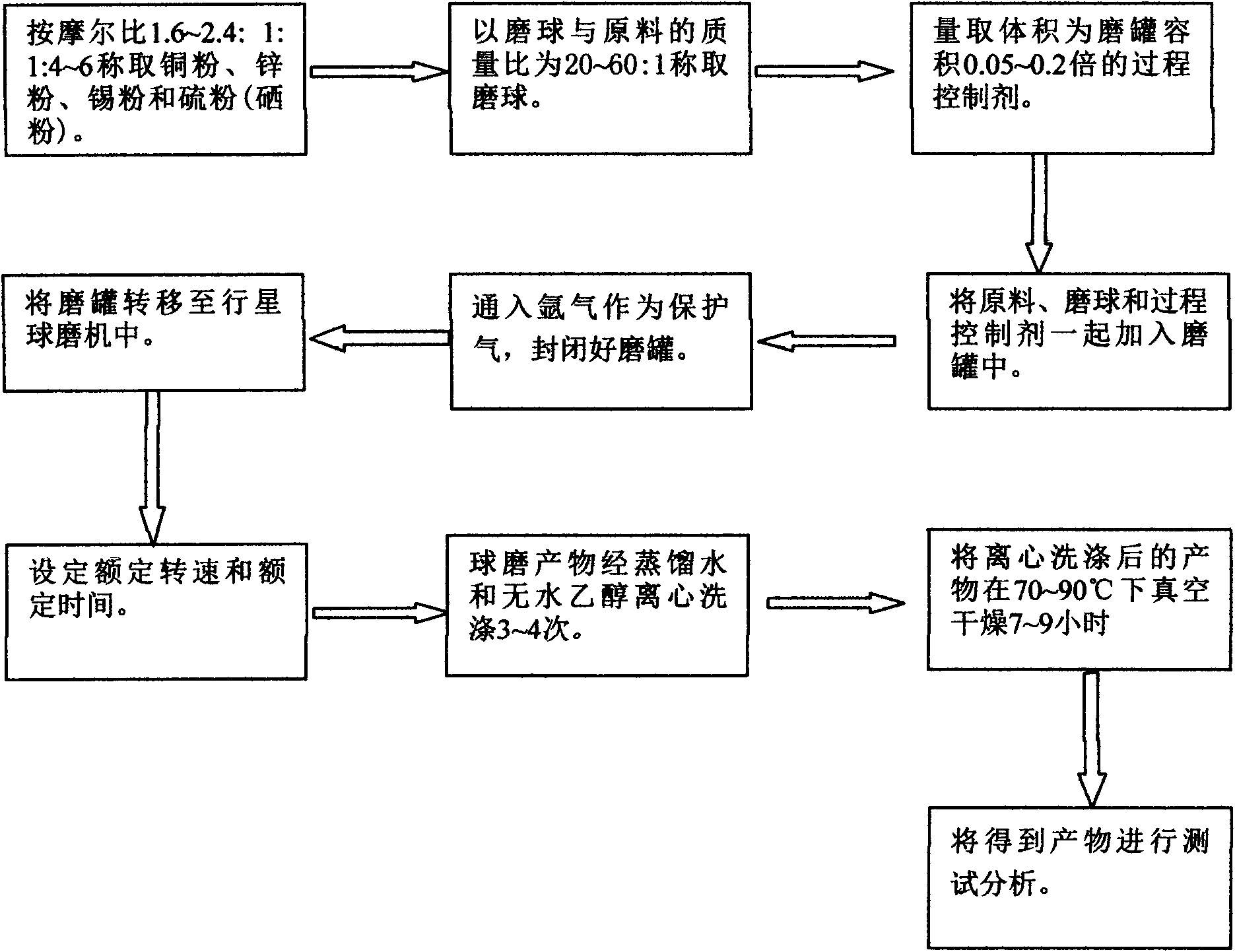

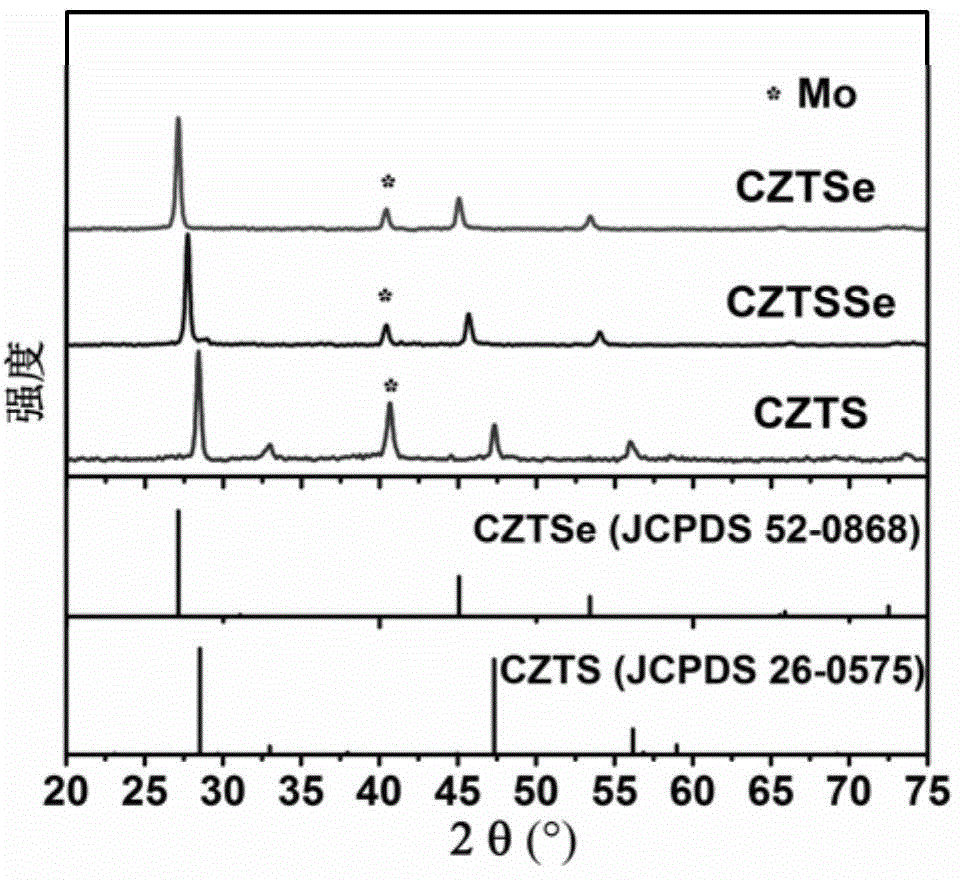

Method for preparing CZTS (Copper Zinc Tin Sulfide) (Se) series nanometer powder by low-temperature mechanical alloying

InactiveCN102642818AAvoid introducingReaction raw materials are readily availableTin compoundsSelenium/tellurium compundsIsobutanolHexamethylenediamine

The invention discloses a method for preparing CZTS (Copper Zinc Tin Sulfide) (Se) series nanometer powder by low-temperature mechanical alloying. Elementary substances Cu powder, Zn powder, Sn powder and S (Se) powder are added into a ball-milling tank according to a certain mole ratio, an alcohol and amine mixed liquor is used as a process control agent, ball milling is carried out according to a rated ratio of grinding media to material, a set rotational speed and ball milling time, and a ball-milled product is centrifugally washed and dried to obtain a target product. In the raw materials, elementary substances sulfur powder and selenium powder can be exchanged in any mole ratio; and the process control agent is the mixed liquor of alcohol and amine with the volume ratio of 1-20:1, the alcohol is one of ethanol, ethylene glycol, normal butanol, isobutanol, isoamylol, tertiary amyl alcohol and glycerol, and the amine is one of ethanediamine, iso-butylamine, diisopropylamine, hexamethylenediamine and triethylamine. The method disclosed by the invention has the advantages of easy obtainment of raw materials, pure products, low energy consumption, easy control in product shape and appearance, simple process and the like, and is suitable for industrial production.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

High-temperature wear-resisting ceramic composite fiber brake block

InactiveCN103122959AInhibition of devitrification changesImprove adhesionOther chemical processesFriction liningCeramic compositeBarium titanate

The invention relates to a high-temperature wear-resisting ceramic composite fiber brake block which is manufactured by processing framework materials and auxiliary materials through material mixing, mould pressing, hot press molding and solidification procedures, wherein the framework materials comprise bismaleimide modified phenolic resin, short aramid fiber, high-purity ceramic fiber, potassium titanate fiber, mineral fiber, barium titanate and nickel; the auxiliary materials comprise molybdenum sulfide and / or tin sulfide, graphite and / or coke, acrylonitrile-butadiene rubber, mica, zinc oxide, stearic acid, barium sulfate and 4010-type antiager. The high-temperature wear-resisting ceramic composite fiber brake block solves the problems existing in the prior brake blocks, can well avoid high-speed decay and high-temperature decay, has the advantages of being good in staibility and long in service life, and is a high-temperature wear-resisting ceramic composite fiber brake block which is low in noise, high in intensity and low in pollution.

Owner:山东金山汽配有限公司

Vibration-damping, denoising and yaw low-speed braking pad and fabrication method thereof

ActiveCN103256325AStable coefficient of frictionGood high temperature friction performanceFriction liningLow speedCarbon fibers

The invention relates to a braking pad, in particular to a vibration-damping, denoising and yaw low-speed braking pad for a yaw braking device of a wind generating set and a fabrication method of the braking pad. The vibration-damping, denoising and yaw low-speed braking pad comprises a steel backing and an abrasive layer attached to the steel backing, wherein the abrasive layer is fabricated by taking PTS (Phenolic Thermospheres) suspension method phenolic resin as a gluing agent, taking graphite, tin sulfide and copper sulfide as a lubricant, taking antimony trisulfide, zirconium silicate, silicon carbide and silicon dioxide as an abradant, taking potassium titanate whiskers, ceramic fibers, aramid fibers, carbon fibers, steel fibers and copper fibers as reinforced fibers, taking calcium carbonate, mica, vermiculite and foam ferrous powder as an inorganic filler, and taking cashew nut shell oil friction powder and rubber powder as an organic filler according to a wet method pressing technology. The braking pad has the advantages that component percentages of a friction material and a processing technology are reasonable; the braking sensitivity is high; the braking vibration is small; the friction noise is low; and the braking pad is provided with a pad abrasion alarm line.

Owner:JIAOZUO LICHUANG BRAKE

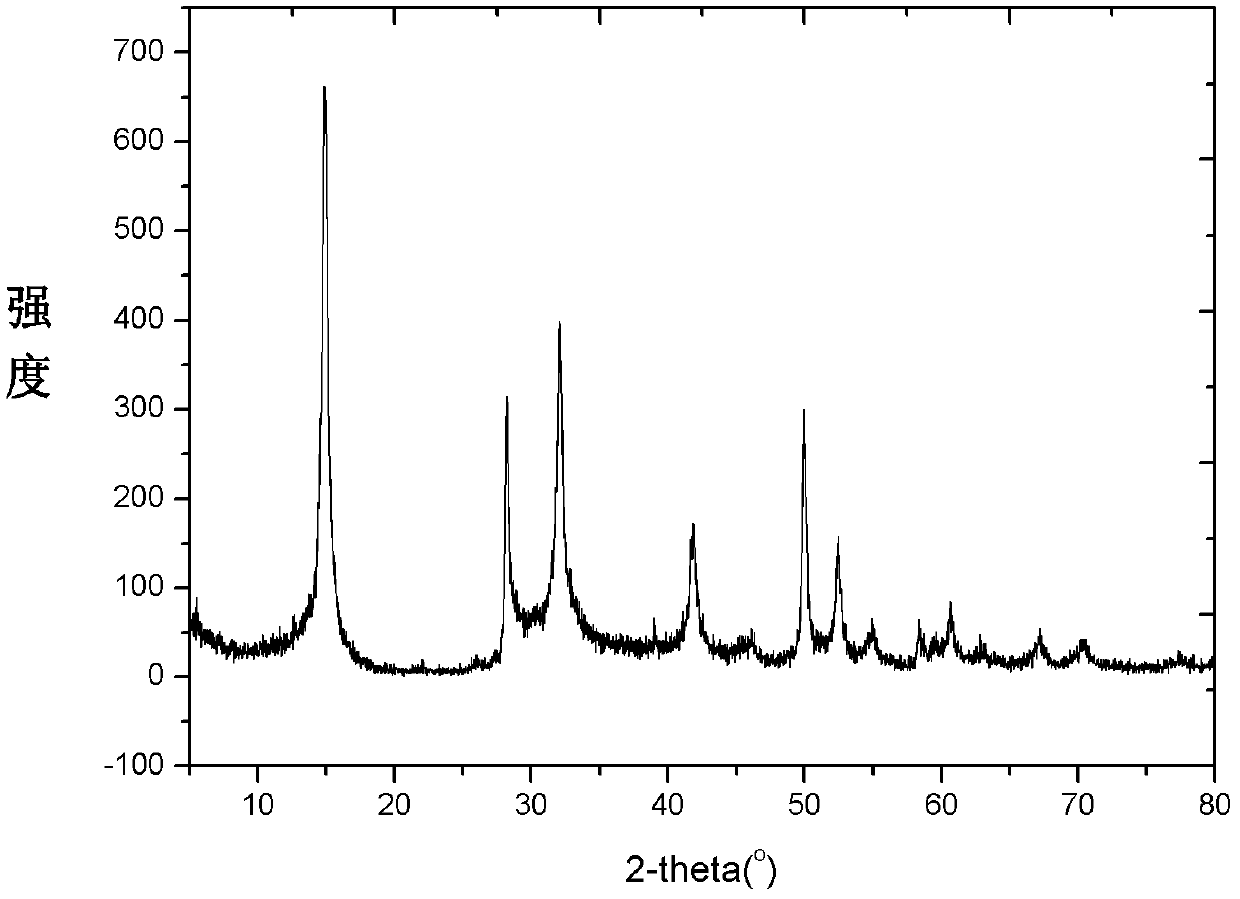

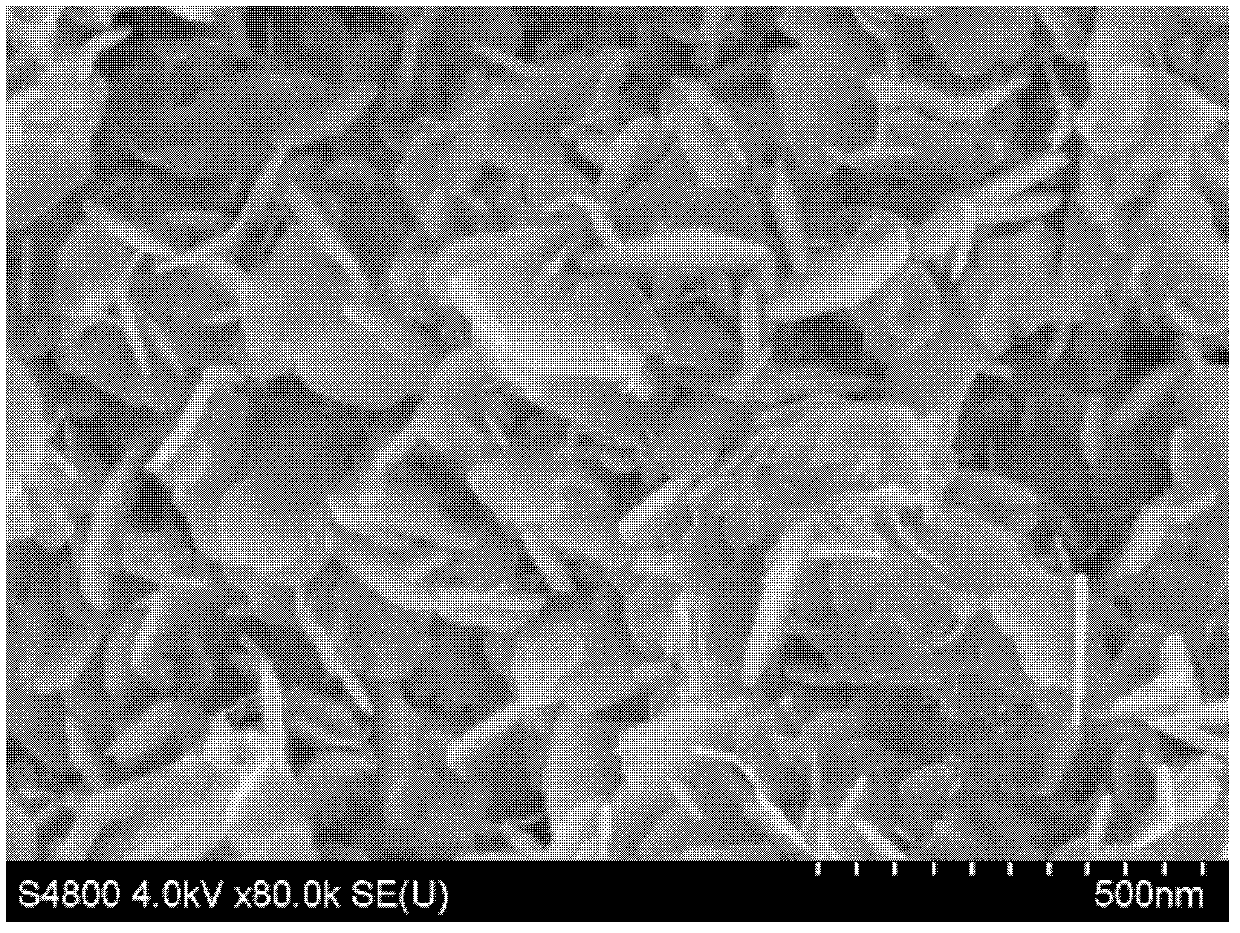

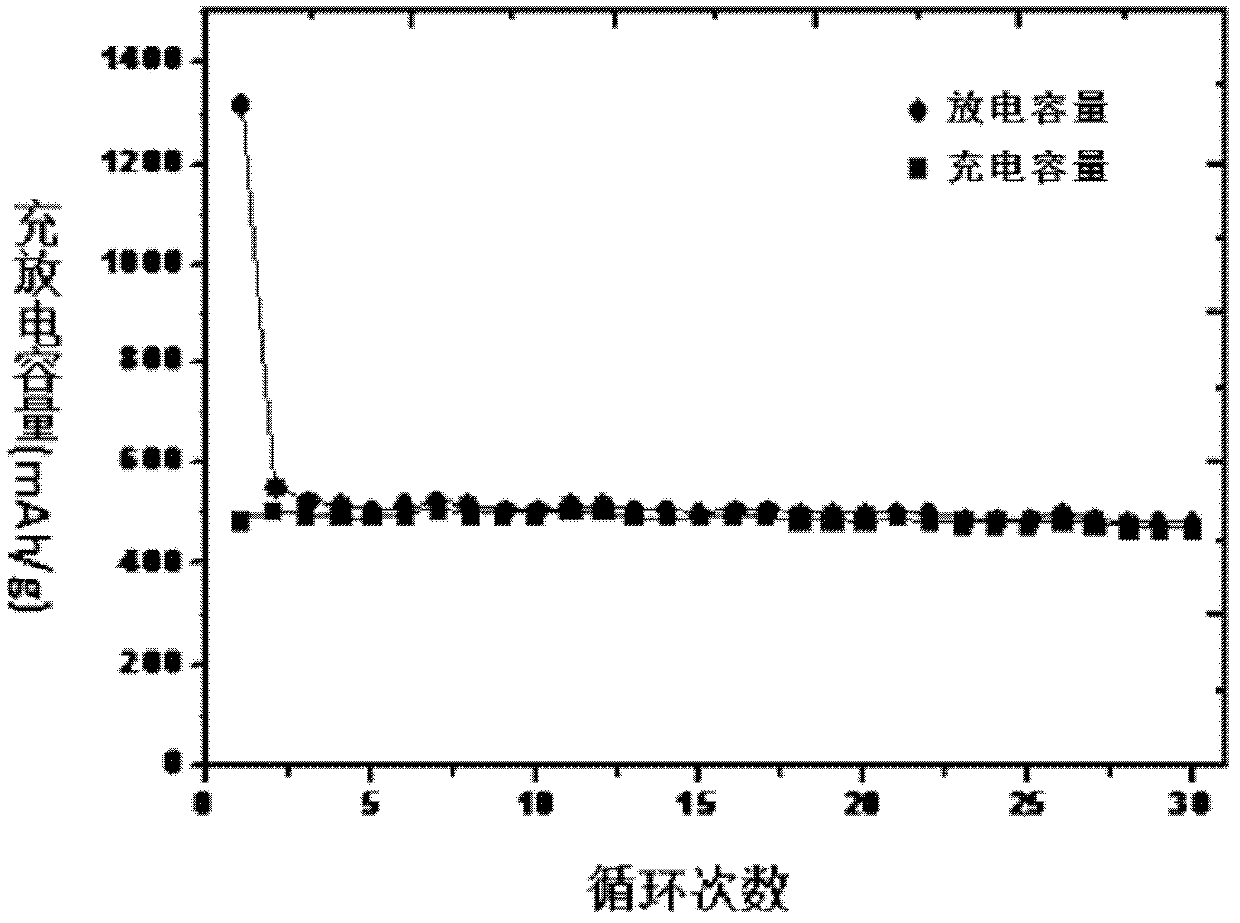

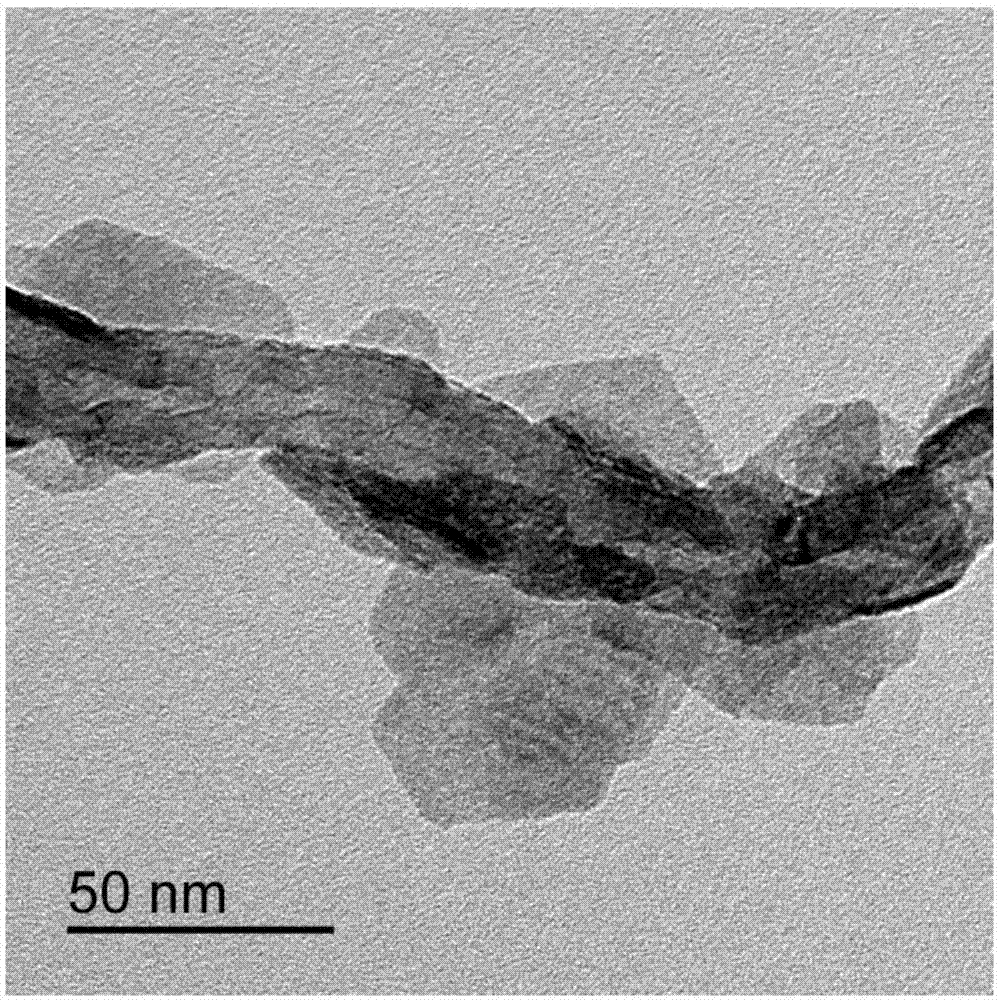

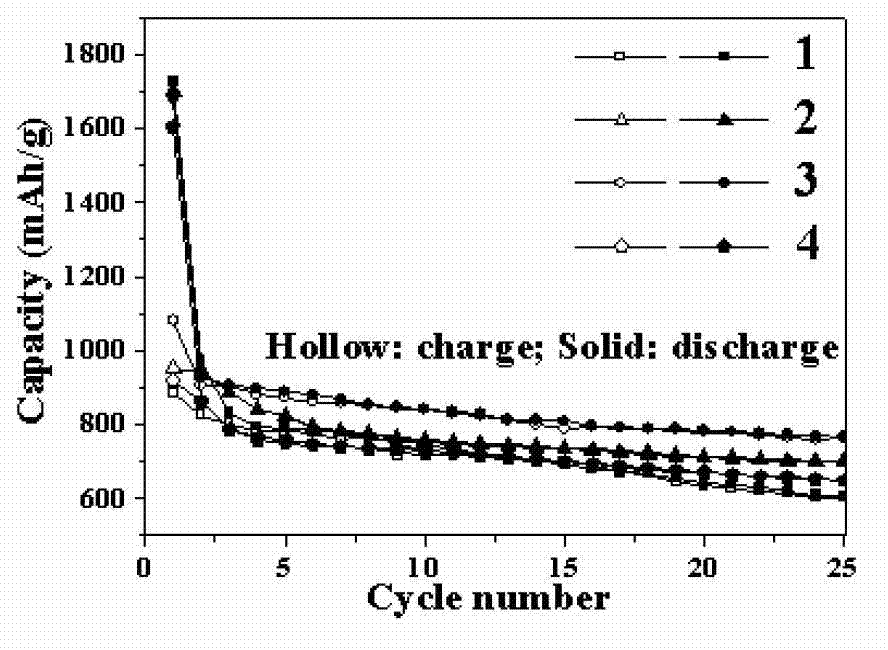

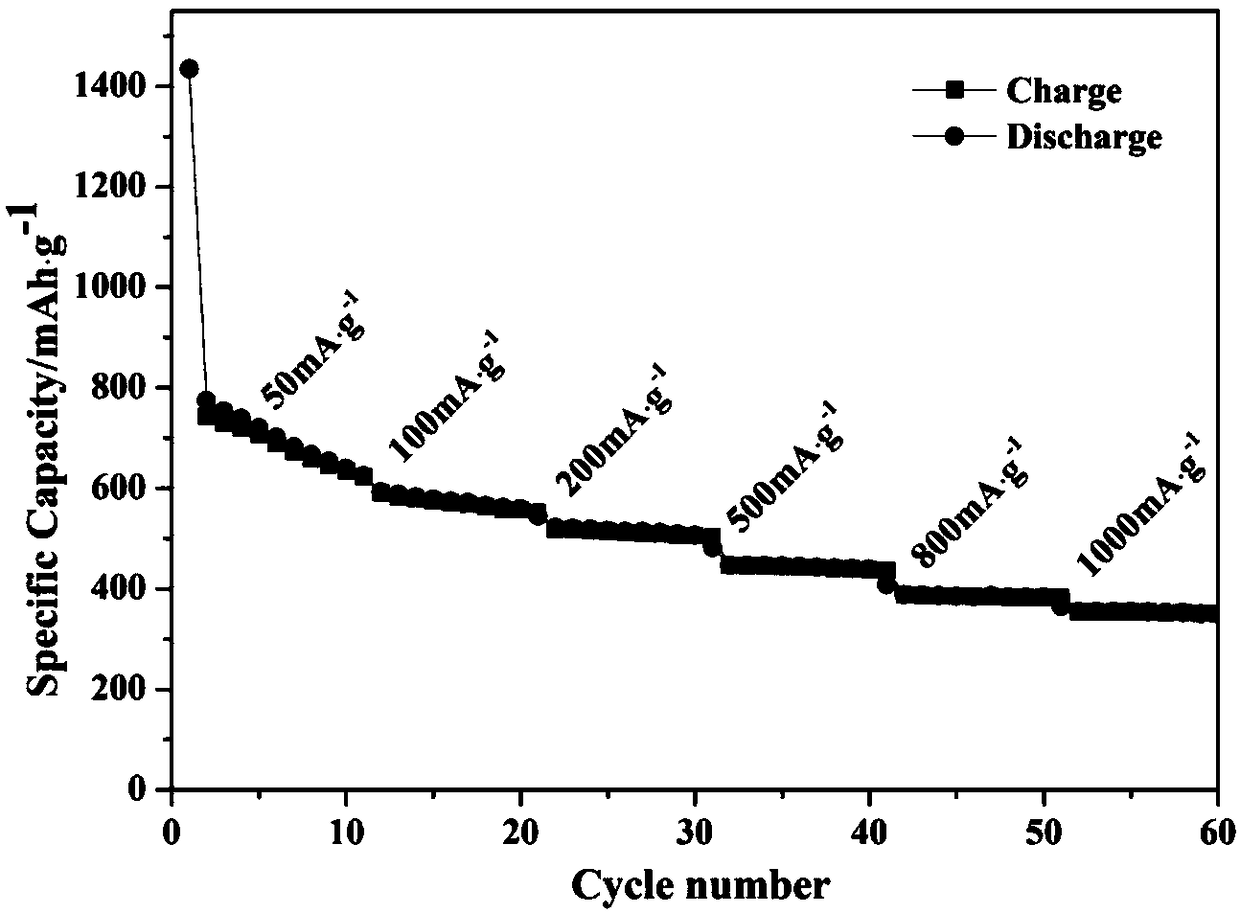

Lithium ion battery cathode active material, preparation method of the lithium ion battery cathode active material, cathode material and cathode

The invention provides a lithium ion battery cathode active material. The lithium ion battery cathode active material is characterized in that the lithium ion battery cathode active material comprises tin sulfide nano-sheets and graphene nano-sheets; the thickness of the graphene nano-sheet is in a range of 1 to 20nm; the thickness of the tin sulfide nano-sheet is in a range of 5 to 50nm; and the lithium ion battery cathode active material has a porous structure. The invention also provides a preparation method of the lithium ion battery cathode active material, a cathode material containing the lithium ion battery cathode active material, and a cathode prepared from the cathode material. The lithium ion battery cathode active material has a high reversible capacity, good fast charging-discharging cycling stability and a low cost.

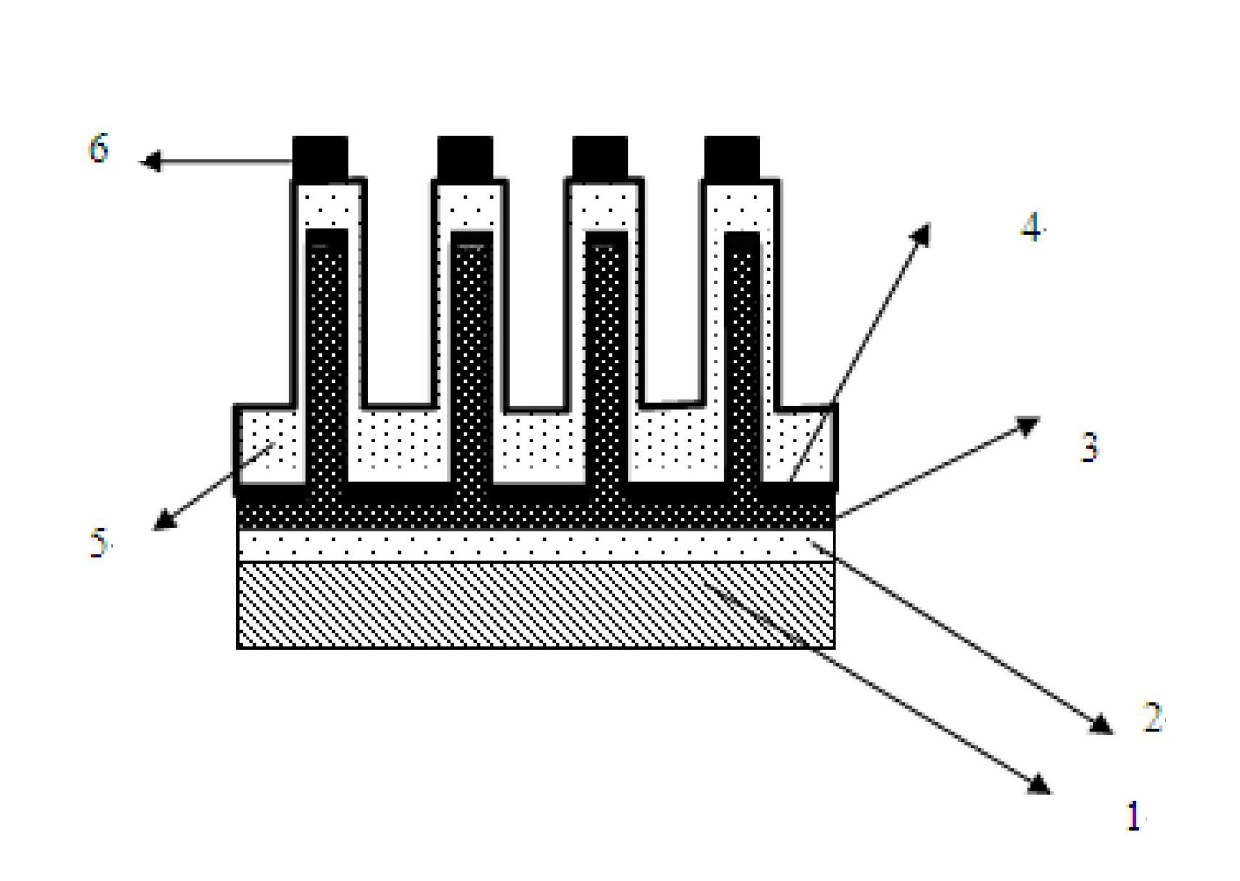

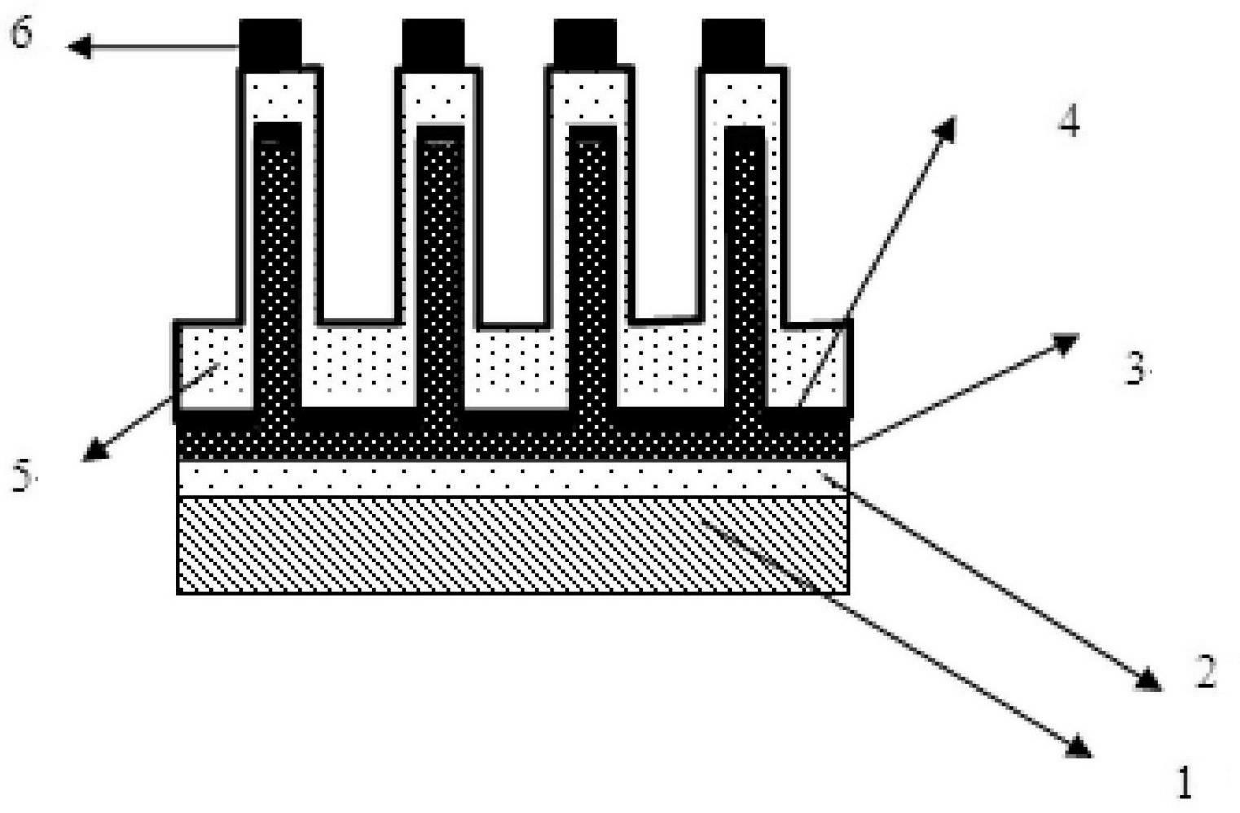

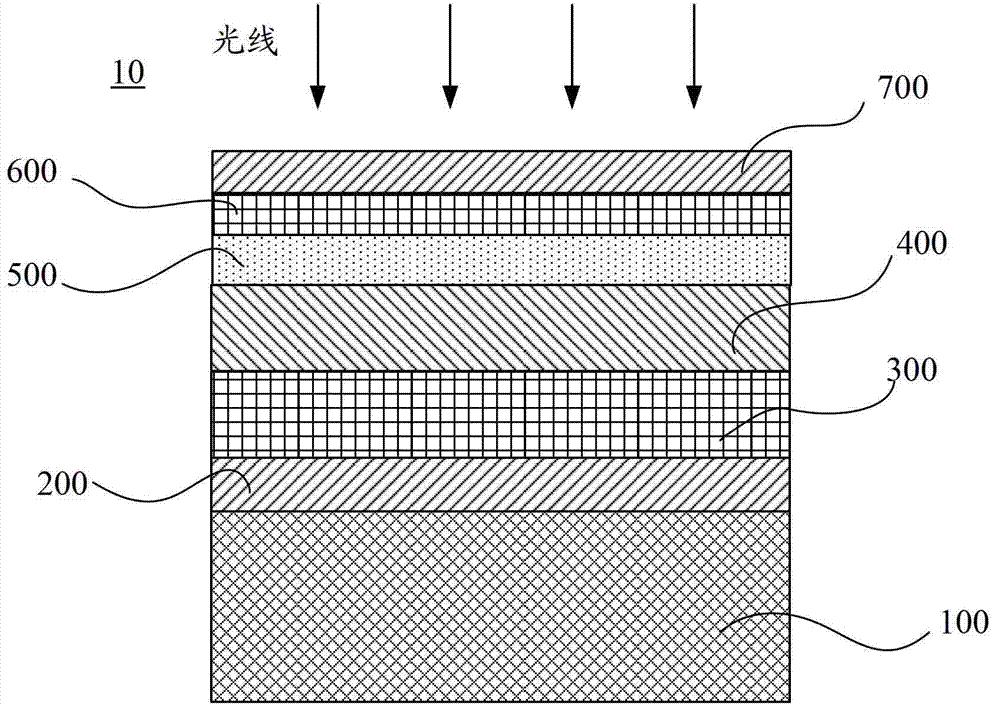

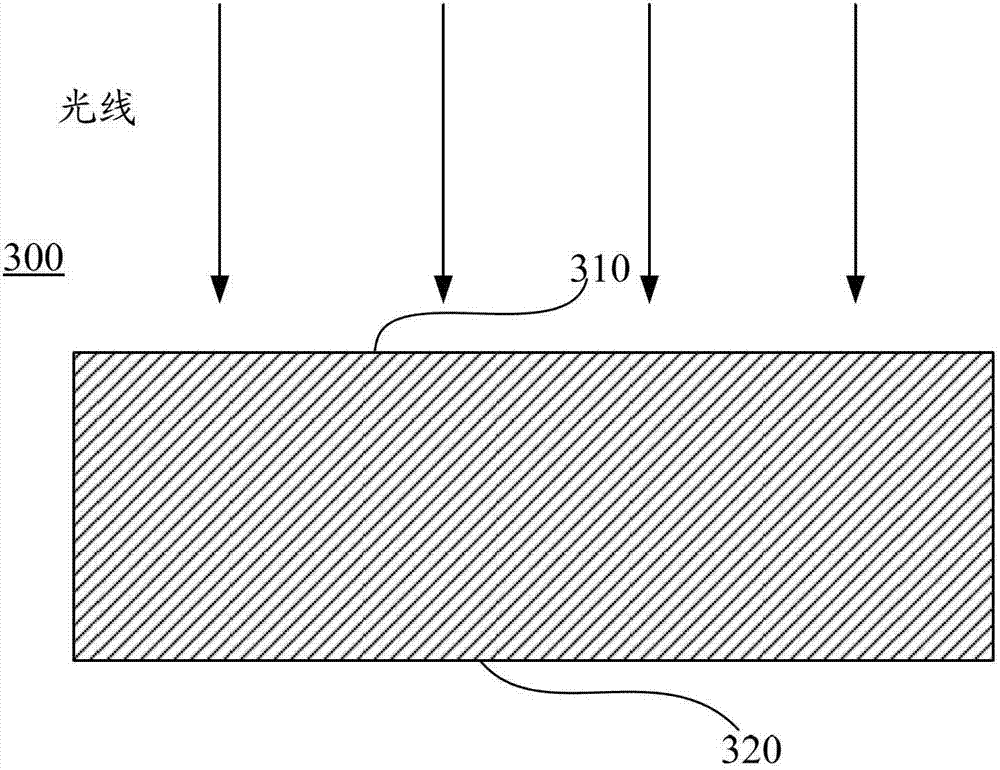

Nanometer structure copper zinc tin sulfide (CZTS) film photovoltaic cell and preparation method of nanometer structure CZTS film photovoltaic cell

InactiveCN102637755AImprove efficiencyLow costFinal product manufacturePhotovoltaic energy generationNanowireTe element

The invention discloses a nanometer structure copper zinc tin sulfide (CZTS) film photovoltaic cell, which sequentially consists of a substrate, a back electrode, a p type semiconductor nanometer wire array, an n type semiconductor thin layer, a window layer and a metal grid electrode, wherein the p type semiconductor nanometer wire array consists of semiconductor alloy (CuxB<1-x>)2Cy(DzS<1-z>), wherein x is greater than 0 but is smaller than or equal to 1, y is greater than or equal to 0 but smaller than or equal to 2, z is greater than or equal to 0 but smaller than 1, B is silver and / or gold, C is more than one kind of materials of aluminum, zinc or tin, D is selenium and / or tellurium. Through the subsequent processes of controlling the deposition element types, the deposition element sequence, the heat treatment mode and the like, the ingredients, the phase structure and the energy band structure of the absorption layer nanometer wire array are regulated, so the solar photovoltaic cells with different structures and performance can be prepared. The nanometer structure CZTS film photovoltaic cell provided by the invention has the advantages that the light reflection is reduced, good light capture capability is realized, the band gap regulation is improved, and the great improvement of the photoelectric conversion efficiency is finally realized.

Owner:SUN YAT SEN UNIV

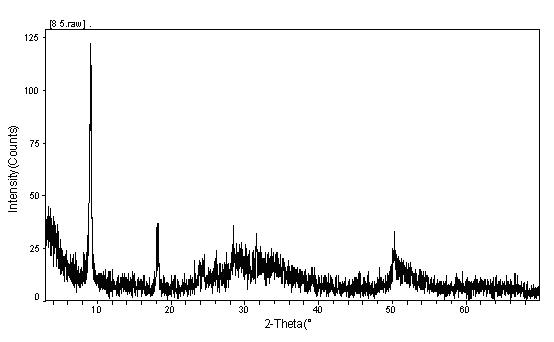

Preparation method of ethanediamine intercalation tin sulfide compound

The invention discloses a preparation method of an ethanediamine intercalation tin sulfide compound. The preparation method comprises the following steps: putting tin sulfide and absolute ethyl alcohol in a polytetrafluoroethylene inner cylinder, slowly adding anhydrous ethanediamine, and then evenly stirring; tightening a reaction kettle, putting the reaction kettle in a muffle furnace, and regulating the temperature to 150-180 DEG C for 20-24 hours; and after the reaction is finished, centrifuging so as to obtain the solid substance ethanediamine intercalation tin sulfide compound. The preparation method is simple, and the obtained product is high in purity; and ethanediamine molecules enter into gaps of tin sulfide, thereby enlarging the interlamellar spacing of a layered material, improving the property of an inorganic material and broadening the application range of the inorganic material.

Owner:EAST CHINA NORMAL UNIV

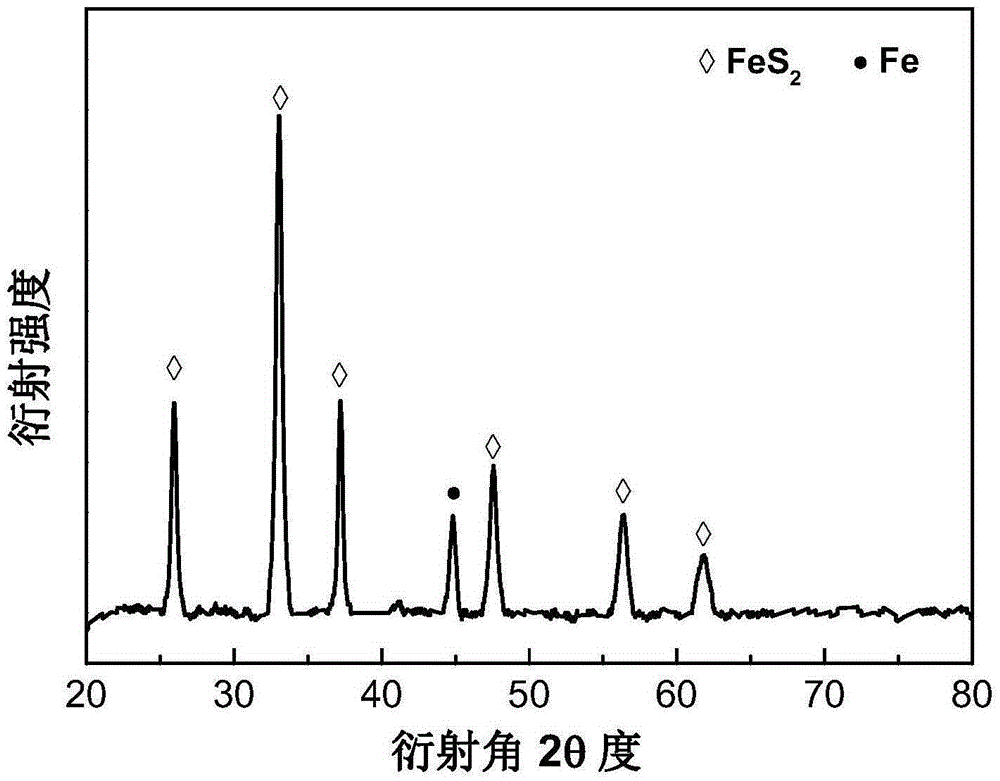

Preparation method for shell-core type carbon-coated metal sulfide nano-composite particles and application of particles

ActiveCN105428618ALow costEasy to makeMaterial nanotechnologyCell electrodesAutomatic controlMetallic sulfide

The invention provides a preparation method for shell-core type carbon-coated metal sulfide nano-composite particles. The obtained composite particles as a lithium ion battery negative electrode material are applied to the field of lithium ion batteries. The method comprises the steps: adding a certain proportion of carbon source-containing substances and inert gases into an automatic control direct-current arc metal nano-powder production device, and evaporating a metal raw material to obtain a carbon-coated metal nanoparticle precursor; and then mixing the precursor with sulfur powder, putting a mixture into a high-pressure sealed reaction kettle to perform heat treatment to obtain carbon-coated metal sulfide nano-composite particles, and making a lithium ion electrode plate by taking a carbon-coated iron sulfide nano-composite material as an active substance. The method has the advantages that low-temperature sulfuration is performed by taking in-situ synthesized carbon-coated iron and tin nanoparticles as precursors to obtain carbon-coated iron sulfide and tin sulfide nano-composite particles; the lithium insertion / extraction capacity density and the cycle stability are relatively high; the raw material cost is low; a process is simple; the large-scale preparation can be realized; and the industrial production requirements are met.

Owner:DALIAN UNIV OF TECH

Method for manufacturing copper-zinc-tin-sulfide absorbing layer thin film and copper-zinc-tin-sulfide solar cell

InactiveCN103762257AImprove conversion efficiencyStable chemical propertiesFinal product manufactureSemiconductor devicesVulcanizationSulfur

The invention discloses a method for manufacturing a copper-zinc-tin-sulfide absorbing layer thin film. A CZTS solar cell absorbing layer is obtained through vulcanization after a CZTS precursor is co-deposited electrochemically. The invention further discloses a method for manufacturing a copper-zinc-tin-sulfide solar cell. The method can be operated at normal temperature and pressure and easy to adjust and control, H2S pollution is avoided, equipment is simple, cost is saved, the surface of the manufactured copper-zinc-tin-sulfide absorbing layer thin film is smooth and very compact, and the efficiency of the manufactured cell is high. The method can be widely used for large-scale industrial production.

Owner:EAST CHINA NORMAL UNIV

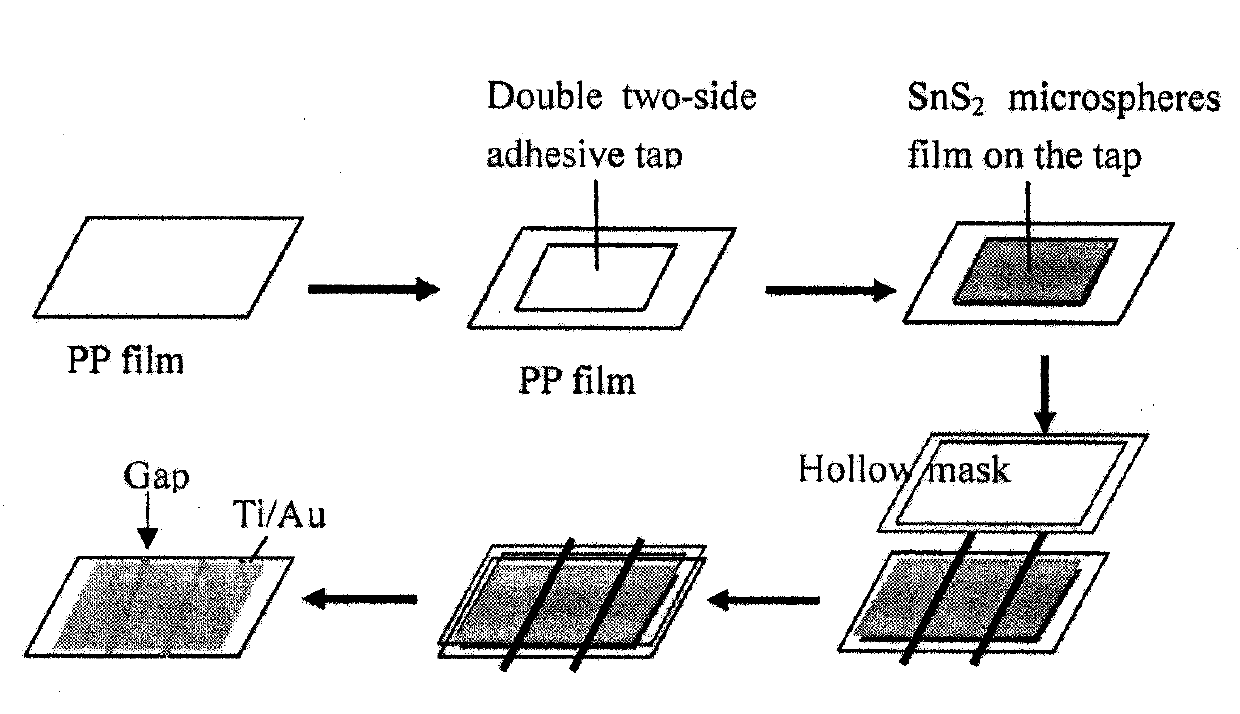

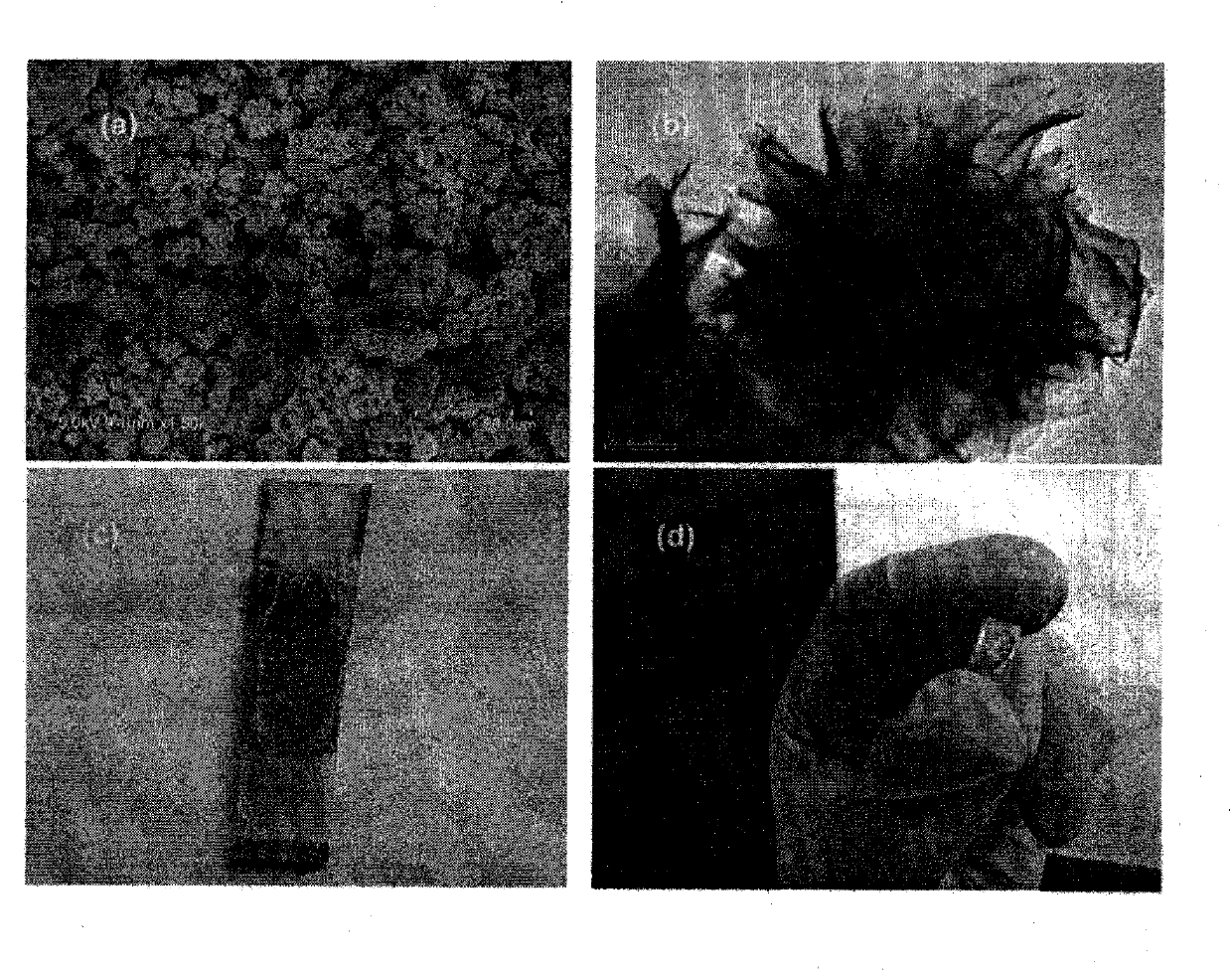

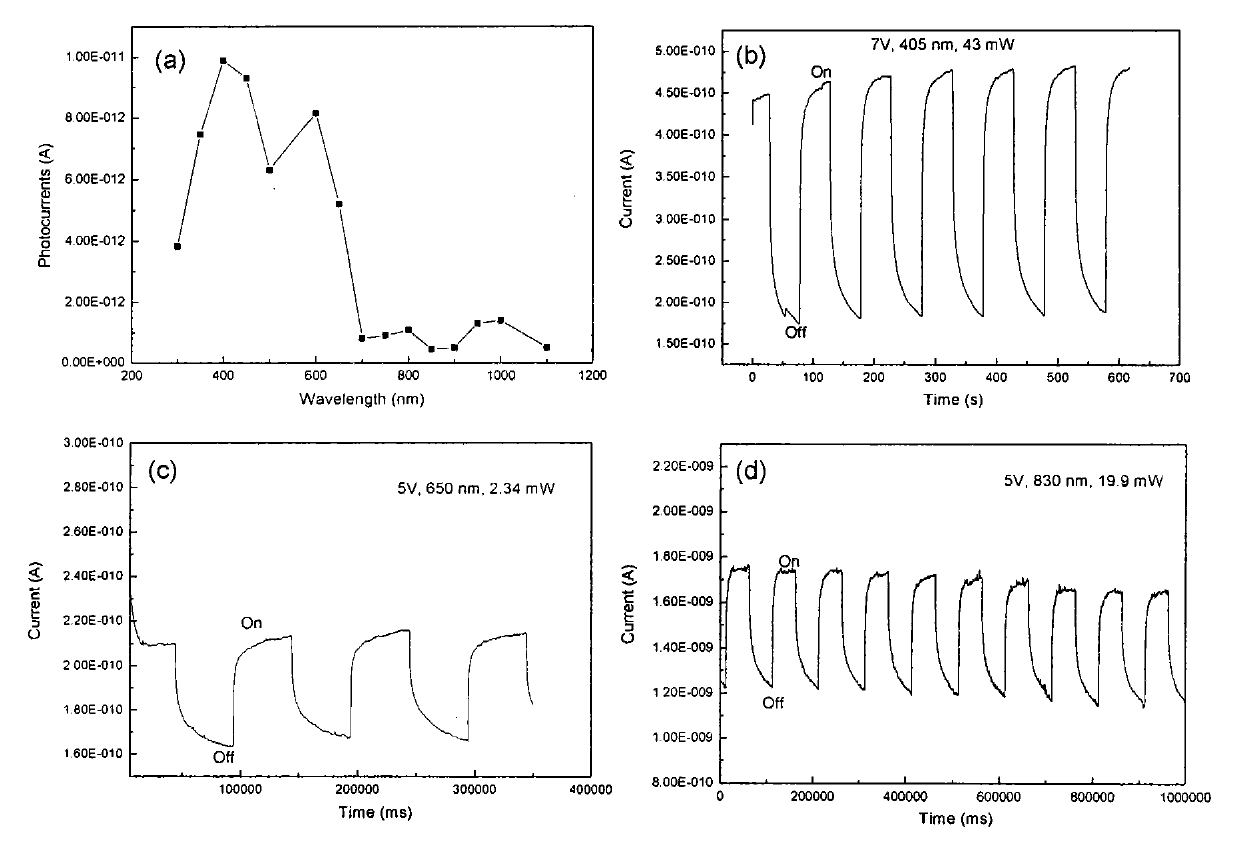

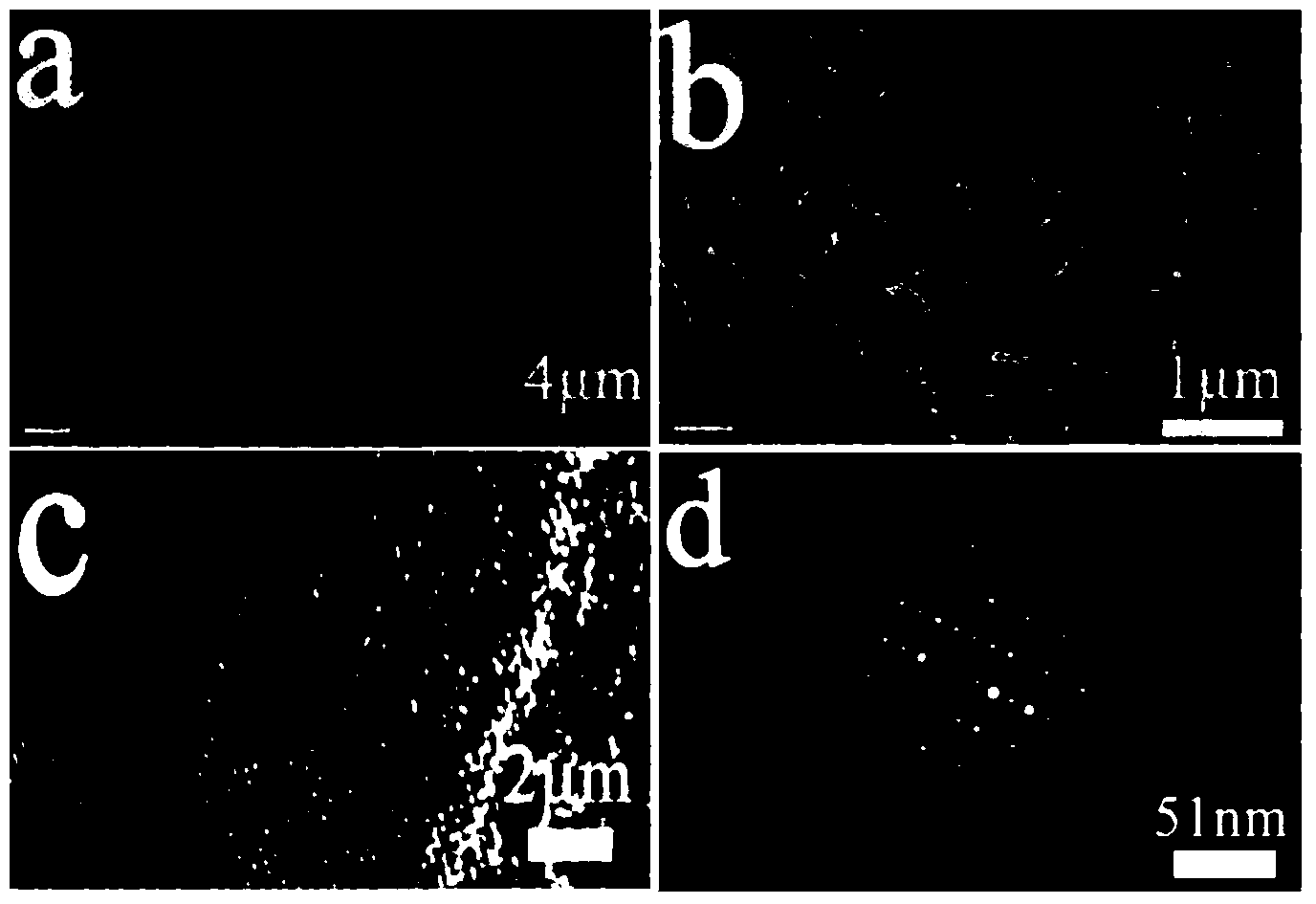

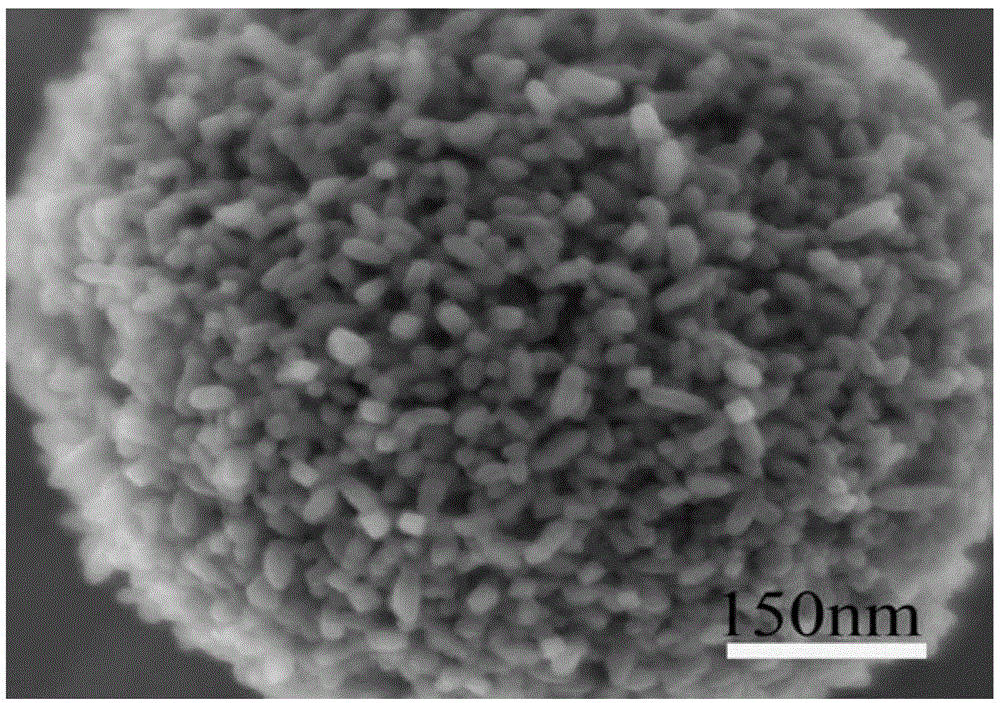

Tin sulfide nano paper self-assembly microsphere production method and optical detector of microsphere film

InactiveCN104201232AQuick responseRaw materials are easy to getFinal product manufactureSemiconductor devicesPolyethylene terephthalate glycolMicrosphere

Discloses are a tin sulfide nano paper self-assembly microsphere production method and an optical detector of a microsphere film. A tin sulfide nano paper microsphere is produced by an ethanol solvent hot method, the tin sulfide nano paper microsphere and ethanol suspension liquid is arranged on a flexible substrate such as PP (Polypropylene), PET (Polyethylene Terephthalate) and paper in a dropwise-added or coating mode, the flexible substrate is pasted through a double sided tape, the film is formed through natural drying, a simple metal wire and a paper frame mask cover the film, three conductive electrodes such as titanium and gold or gold are sputtered through vacuum ions, the independent electrodes are reserved on the tin sulfide nano paper microsphere film after the mask is uncovered, and accordingly the simple optical detector from ultraviolet 300 nm to near infrared 830 nm is formed. The performance is good and reliable according to experimental results. The invention also discloses materials of the tin sulfide nano paper self-assembly microsphere and a machining method of the detector.

Owner:NANJING UNIV

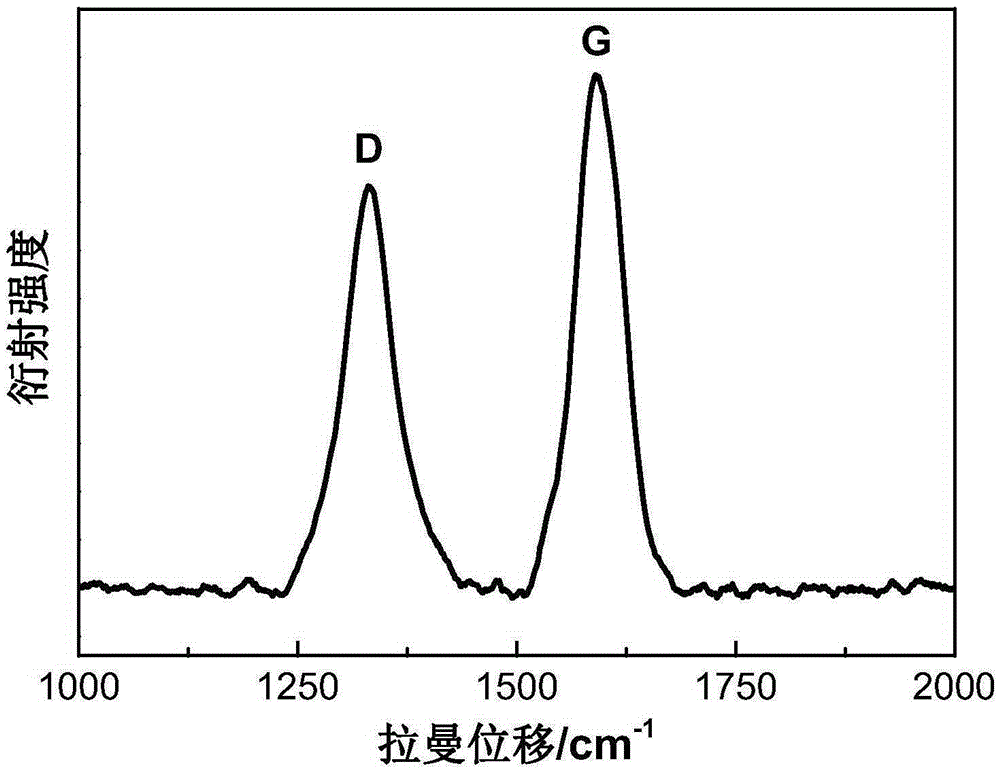

Preparation method of tin sulfide-carbon nanotube composite electrode material

InactiveCN107394129ARaw materials are easy to getImprove conductivityCell electrodesSecondary cellsUltrasonic dispersionVacuum drying

The invention discloses a preparation method of a tin sulfide-carbon nanotube composite electrode material. The preparation method comprises the steps of 1, adding a certain amount of a carboxylation multiwalled carbon nanotube into a certain amount of absolute ethyl alcohol, and performing ultrasonic dispersion for 2.5-3.5 hours to obtain a dispersion liquid A; 2, weighing a certain amount of tin chloride pentahydrate into the dispersion liquid A in the step 1, performing stirring for 10-30 minutes, adding a certain amount of thioacetamide under a stirring state, and performing stirring for 30-40 minutes to obtain a solution B; 3, transferring the solution B obtained in the step 2 to a reaction kettle with a polytetrafluoroethylene lining, performing hydrothermal reaction under a certain temperature, naturally cooling to a room temperature after reaction is completed to obtain a deep green precipitant; and 4, collecting the deep green precipitant obtained in the step 3, sequentially and centrifugally washing the deep green precipitant with deionized water and the absolute ethyl alcohol, and placing the deep green precipitant in a vacuum drying box for drying to obtain the tin sulfide-carbon nanotube composite electrode material. The tin sulfide-carbon nanotube composite electrode material is simple in preparation process.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of copper zinc tin sulfide/graphene oxide composite semiconductor photocatalyst

InactiveCN103611549AImprove solubilityAccelerated corrosionPhysical/chemical process catalystsWater/sewage treatment by irradiationZinc compoundsSulfur

The invention discloses a preparation method of a copper zinc tin sulfide / graphene oxide composite semiconductor photocatalyst. The photocatalyst comprises copper zinc tin sulfide coated by graphene oxide. The preparation method comprises the following steps: step 1) uniformly mixing and dispersing 0.05%-0.2% of graphene oxide, 32%-34% of copper compound, 16%-18% of zinc compound, 21%-23% of tin compound and 26%-29% of sulfur compound in a carrying solution to form a precursor solution; step 2) enabling a reaction precursor to react at high temperature so as to prepare the copper zinc tin sulfide / graphene oxide composite semiconductor photocatalyst. The copper zinc tin sulfide / graphene oxide composite compound photocatalyst prepared by the preparation method disclosed by the invention improves the resistance to light dissolution and the resistance to light corrosion, and enables the photocatalyst to stably degrade organic pollutants in a water body for a long time.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

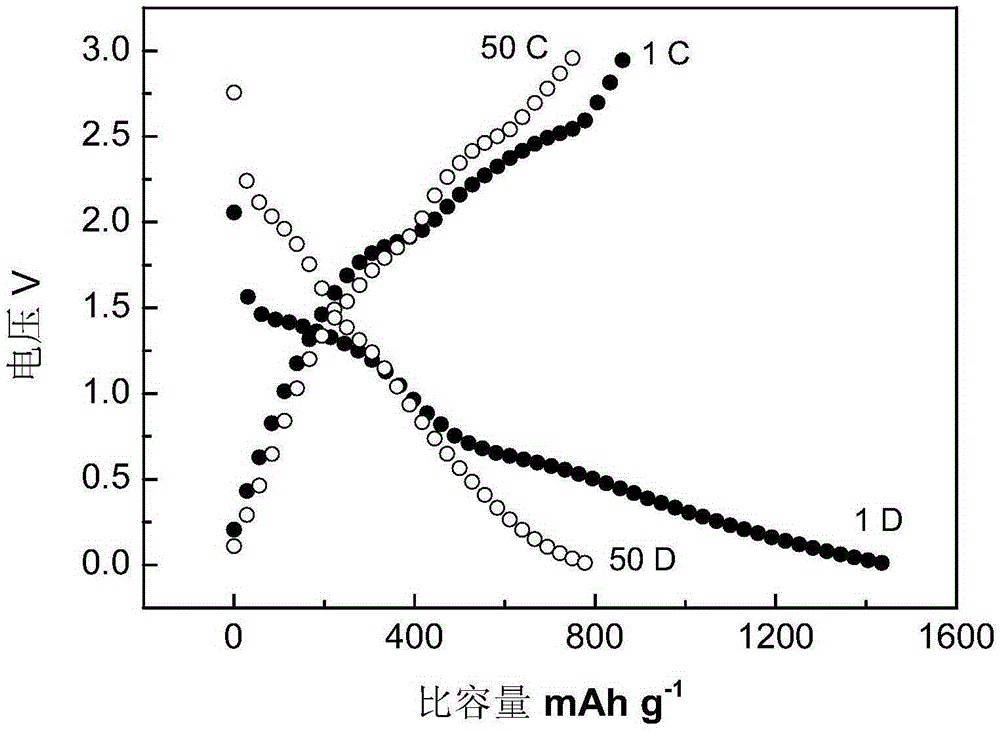

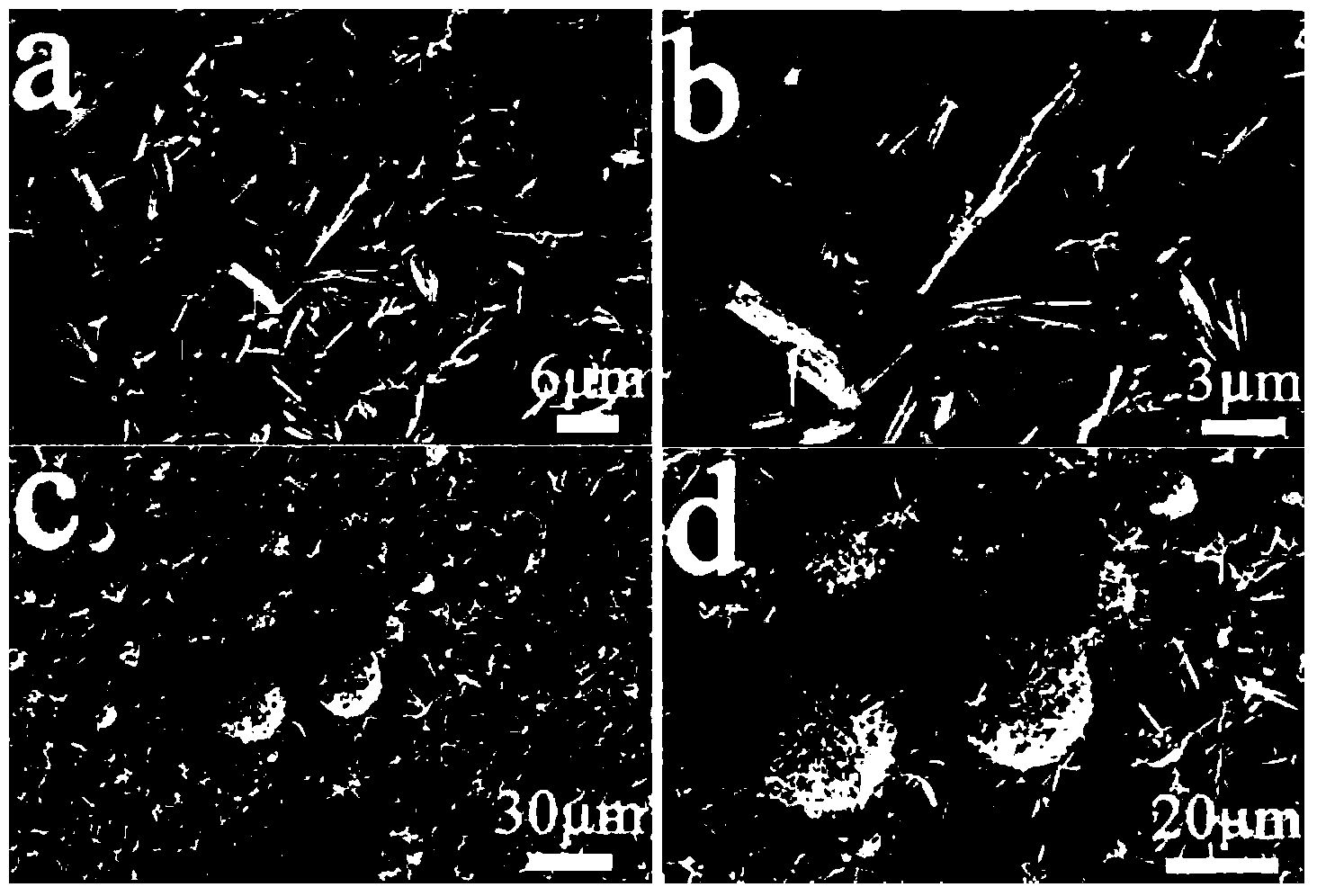

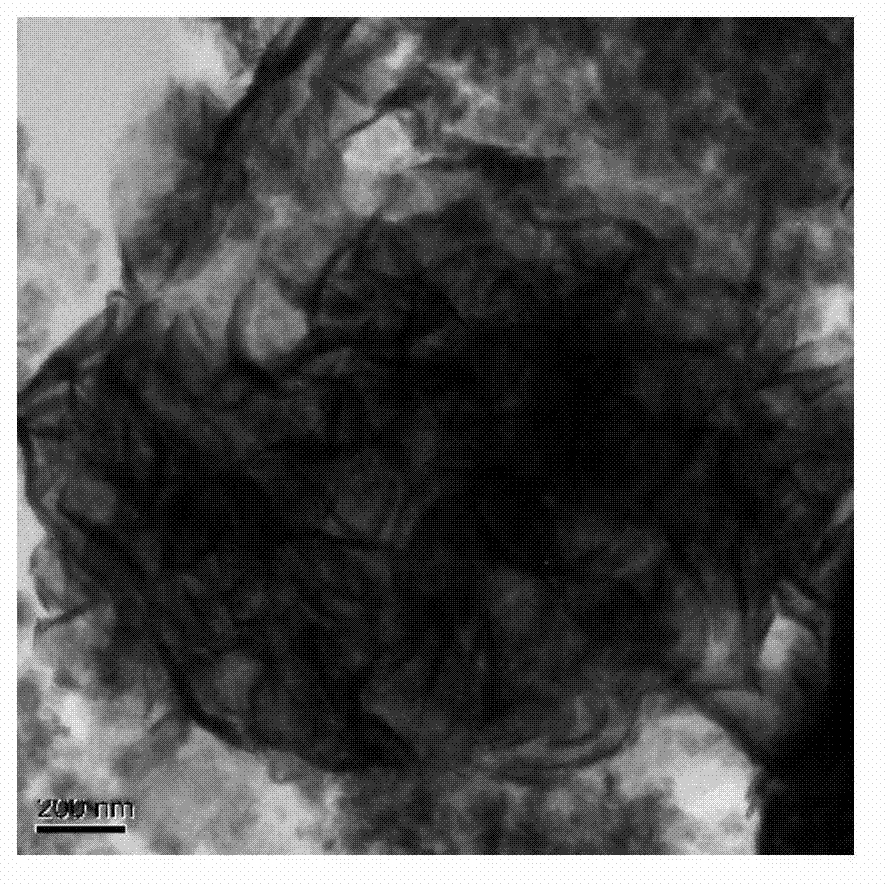

Preparation method and application of spherical tin sulfide consisting of nanorods

InactiveCN103915625ABuffer volume effectWill not cause mutual extrusion pulverizationTin compoundsCell electrodesCyclic processLithium-ion battery

The invention discloses a preparation method and application of spherical tin sulfide consisting of nanorods, belonging to the technical field of lithium ion battery materials. The invention further provides a preparation method of a negative electrode material. The method comprises the following steps: uniformly mixing a sulfur source, a tin source and a surfactant; heating a mixed solution by using a hydro-thermal method; filtering and drying the product to obtain a lithium battery negative electrode material of the spherical tin sulfide consisting of nanorods. Compared with spherical tin sulfide consisting of nanosheets, the spherical tin sulfide consisting of nanorods has the advantages that the cycle performance is improved, the stability of nanorods is higher than that of nanosheets in a circulating process, the volume change of an electrode material is suppressed effectively, the capacity fading of the electrode material is slowed down, and the cycle life of a battery is prolonged effectively.

Owner:JINAN UNIVERSITY

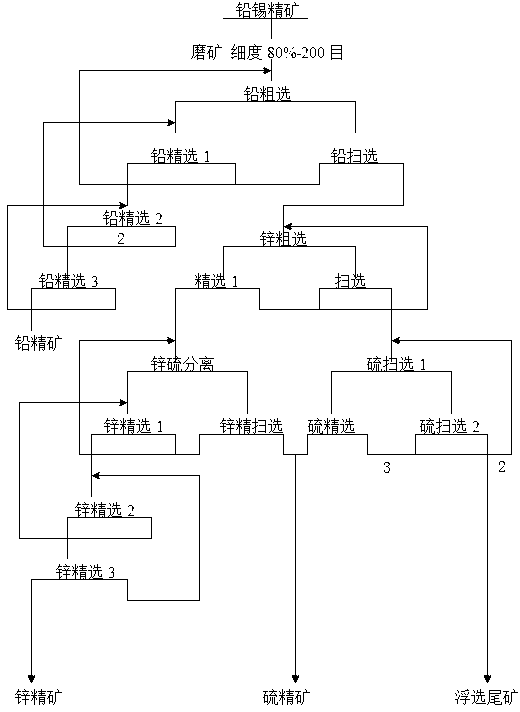

Flotation separation beneficiation method for lead-zinc-tin sulfide ores

The invention discloses a flotation separation beneficiation method for lead-zinc-tin sulfide ores, in particular relates to a beneficiation method for lead-zinc-tin sulfide associated ores complex and difficult to separate, belonging to the technical field of beneficiation. The method comprises the following steps that the procedures of one roughing, one scavenging and two concentration is carried out during grinding lead-zinc-tin ores, and lead concentrate is firstly obtained; secondly concentration and scavenging are performed on the scavenged zinc, sulfur and tin mixtures to obtain zinc-sulfur mixtures and scavenging tailings; thirdly the procedures of three concentration and one scavenging are performed on the zinc-sulfur mixtures to obtain zinc concentrate and a part of sulfur concentrate; and finally sulfur concentrate and flotation tailings are scavenged to be separated from the scavenging tailings, and tin concentrate and gravity tailings are obtained by adopting the prior art for separation. According to the flotation separation beneficiation method, the grade of the obtained plumbum is 50-55%, and the recovery percent is 80-85%; the grade of the obtained zinc concentrate is 45-50%, and the recovery percent is 80-85%; the grade of the obtained sulfur is 35-40%; and the grade of the obtained tin is 40-45%.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing Cu2ZnSn(S,Se)4 solar cell absorbing layer film by using mercaptan-based ink

InactiveCN103560165AIncrease profitSafe preparationFinal product manufacturePhotovoltaic energy generationCarbon.organicSolvent

The invention provides a method for preparing Cu2ZnSn(S,Se)4 solar cell absorbing layer film by using mercaptan-based ink, belonging to the technical field of a solar cell absorbing layer film. The method comprises the steps of (a) stable precursor solution preparation under an air condition, (b) the preparation of a precursor film by using a spinning coating method, (c) drying, (d) multiple times of spinning coating and drying and (e) annealing processing. According to the film preparation method, the use of expensive original materials and devices is not needed, mercaptan which is a volatile, low carbon organic compound is taken as a solvent, and a problem of the introduction of carbon and oxygen elements in the previous copper zinc tin sulfide nanocrystal synthesis process can be overcome. The controllability of each process step is good, the preparation of the absorbing layer film with large grains, density and good photoelectric performance is facilitated, the process is simple, the repeatability is strong, and the large-scale production is easy to realize.

Owner:BEIJING UNIV OF TECH

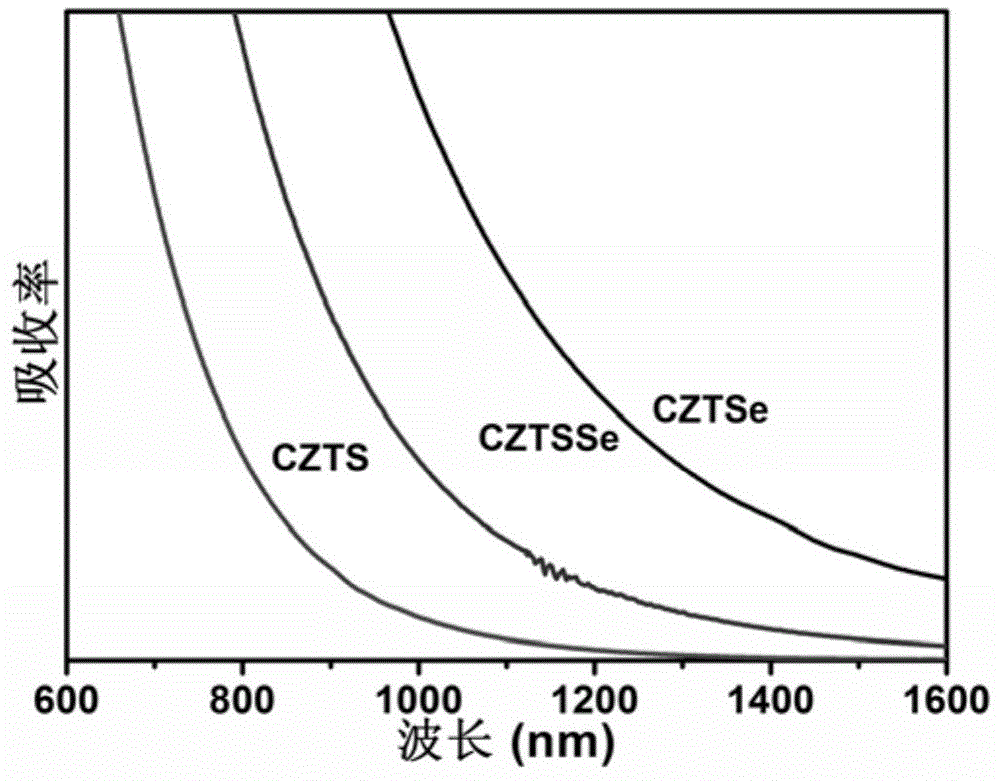

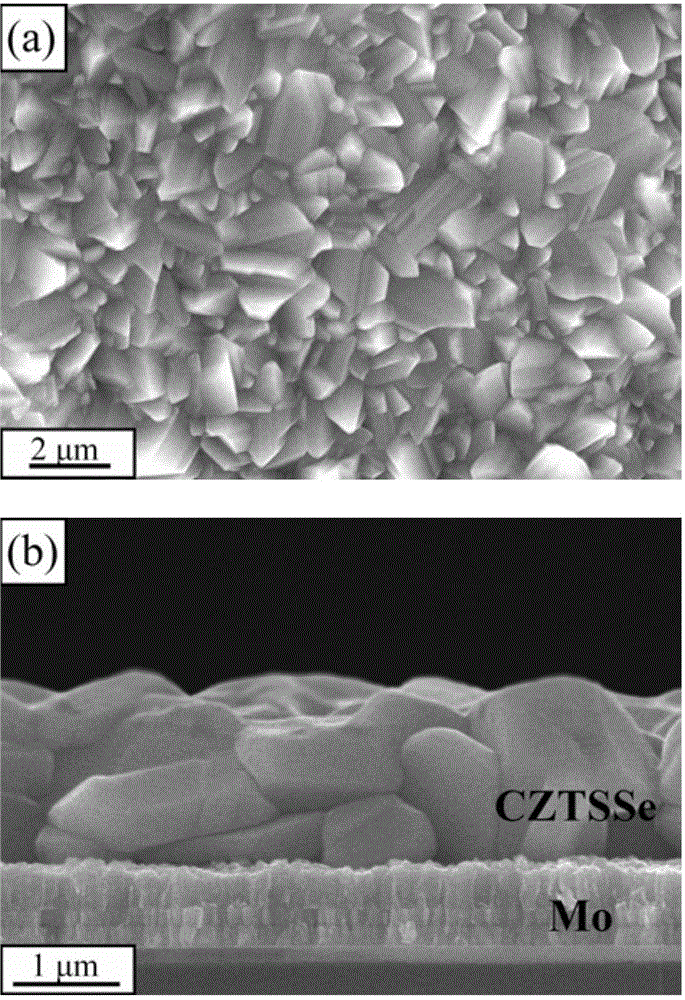

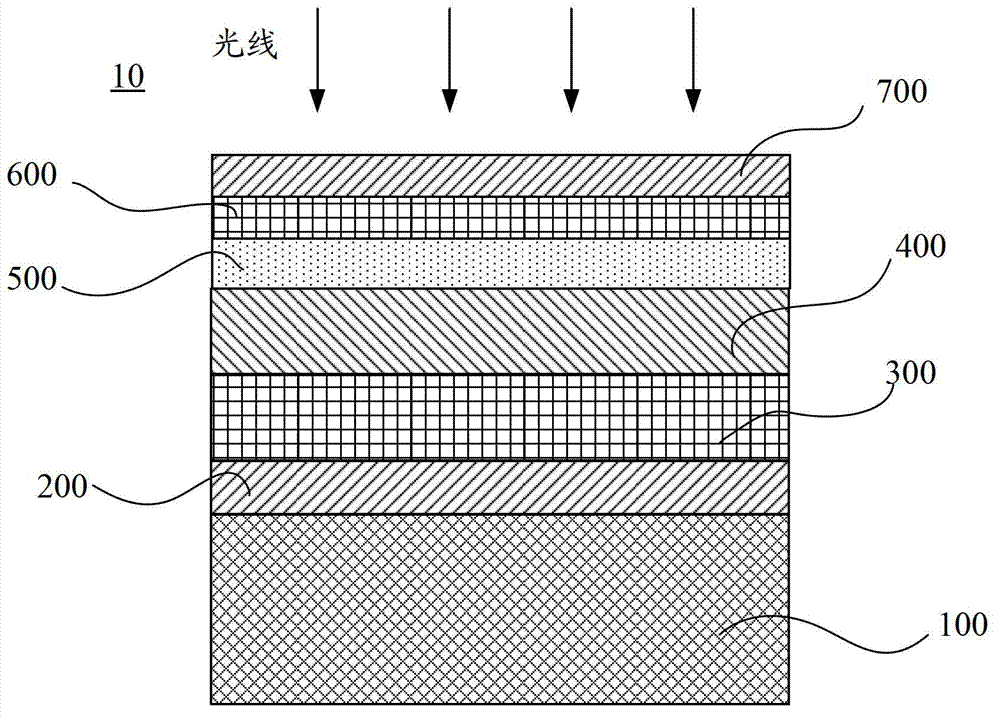

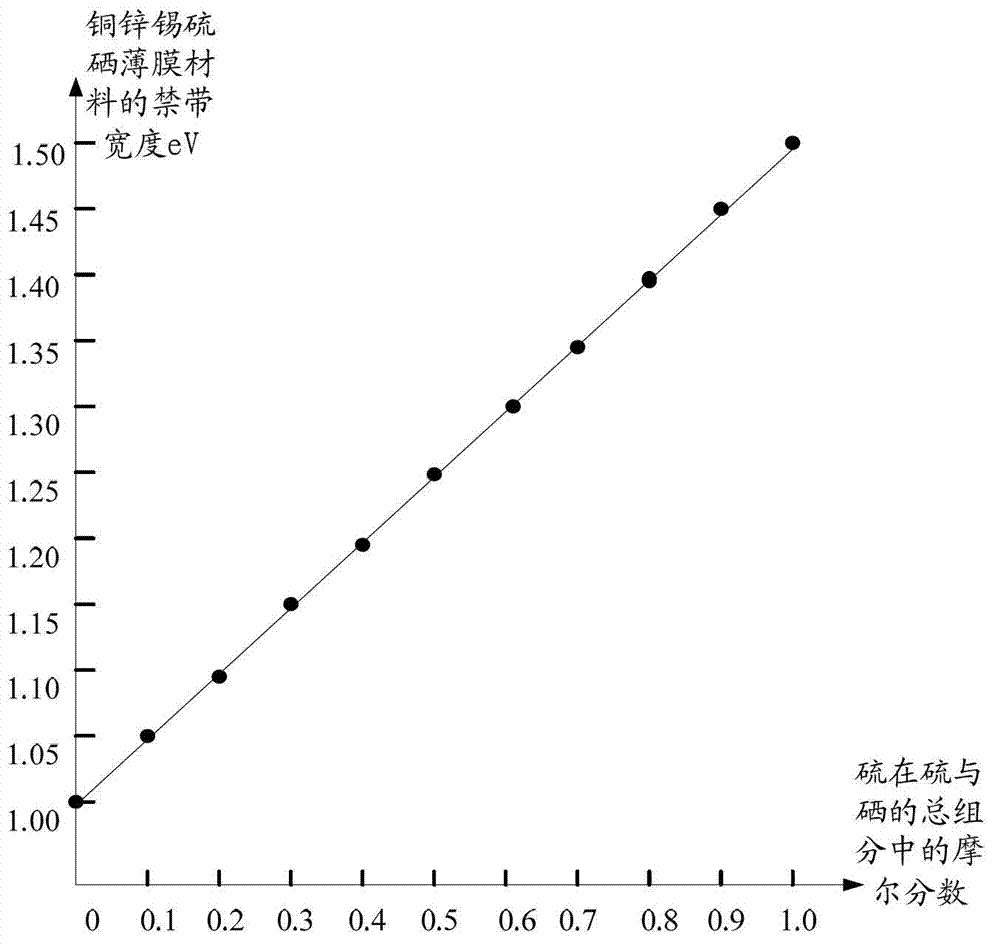

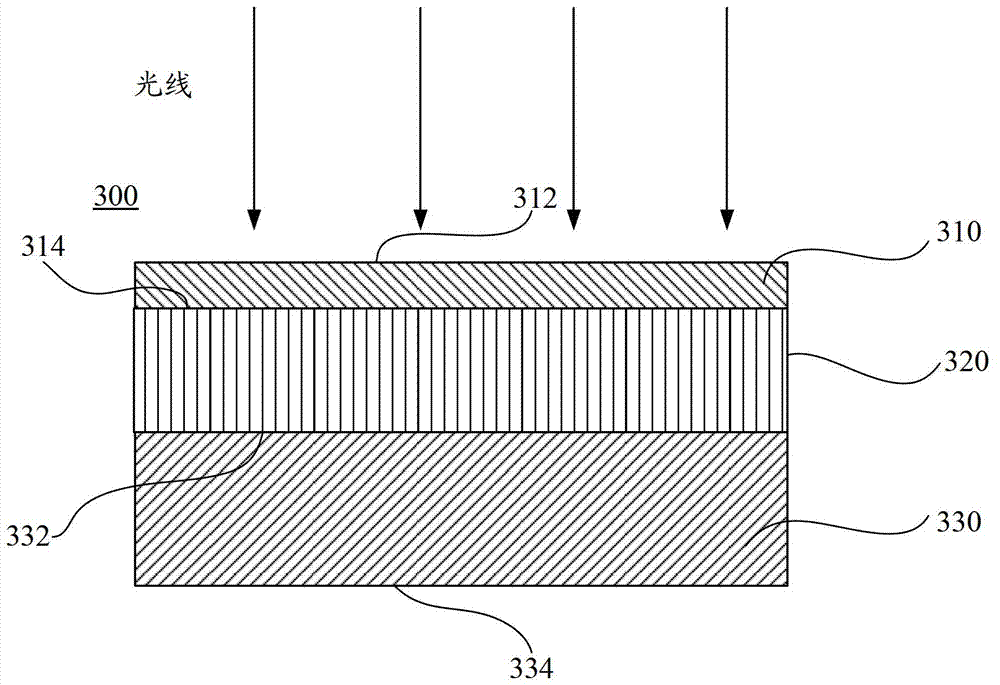

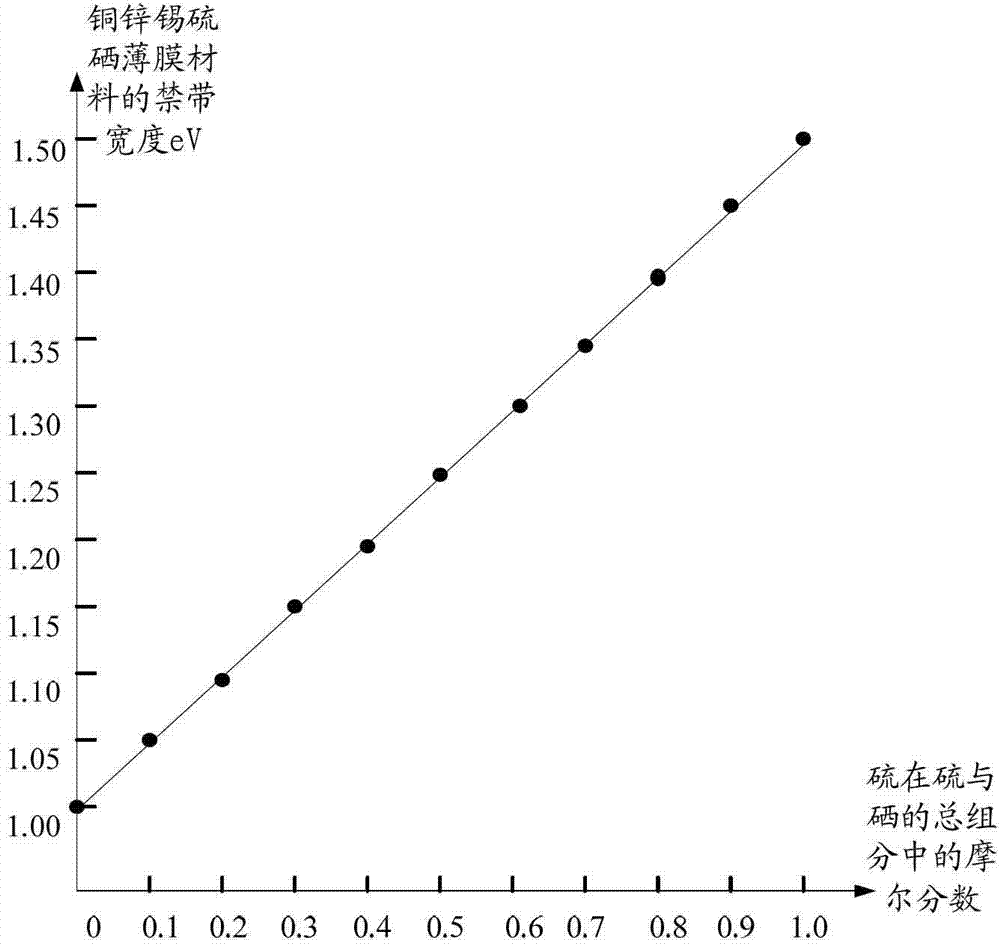

Copper-zinc-tin-sulfide-selenium film and preparation method thereof, as well as copper-zinc-tin-sulfide-selenium film solar cell

The invention provides a copper-zinc-tin-sulfide-selenium (CZTSSe) film, comprising a light-incident layer, an intermediate layer and a backlight layer all which are made from a copper-zinc-tin-selenium material and a copper-zinc-tin-sulfide material, wherein the light-incident layer comprises a first light-incident surface and a first backlight surface, and the molar ratio of sulfide to selenium in the material of the light-incident layer is decreased gradually along the direction from the first light-incident surface to the first backlight surface; the backlight layer comprises a second light-incident surface connected to the intermediate layer and a second backlight surface apart away from the intermediate layer, and the molar ratio of the sulfide to the selenium in the material of the backlight layer is increased gradually along the direction from the second light-incident surface to the second backlight surface; and the molar ratio of the sulfide to the selenium in the material at the first backlight surface is equal to that in the material at the second light-incident surface. The CZTSSe film can improve the collection efficiency of photo-induced carriers, further enhances the photoelectric conversion efficiency of a CZTSSe) film solar cell using the film. The invention also provides a manufacturing method of the CZTSSe film and a CZTSSe film solar cell.

Owner:SHENZHEN INST OF ADVANCED TECH +1

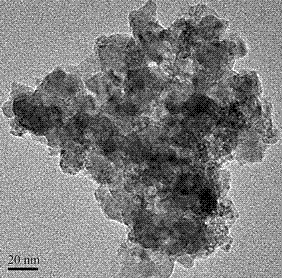

Preparation of rare earth metal-tin sulfide/grapheme negative electrode material for lithium ion batteries

InactiveCN102931402AFast electrode capacityElectrode capacity fades quicklyTin compoundsCell electrodesRare earthLithium-ion battery

The invention relates to preparation of a rare earth metal-tin sulfide / grapheme negative electrode material for lithium ion batteries. A simple hydrothermal method is used to obtain a Ce-SnS2 / grapheme material. The synthesized Ce-SnS2 / grapheme material is mixed with Ce and grapheme, the volume changes caused during charge and discharge can be relieved effectively, the electrode capacity of the material can be prevented from fading too fast, and at the same time, the electrical conductivity is increased, so that the capacity of the Ce-SnS2 / grapheme material is higher than the cycle performance of pure-phase SnS2. According to the synthesized material, the graphite has good electrical conductivity, carriers can be transferred during re-charge and re-discharge conveniently, the volume changes caused during charge and discharge can be relieved effectively, the electrode capacity of the material is prevented from fading too fast, and disadvantages of a single SnS2 electrode is overcome. The material serves the negative electrode material for lithium ion batteries and is provided with considerable capacity and good cycle performances, and the disadvantages of the single SnS2 electrode are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Copper-zinc-tin-sulfide-selenium film and preparation method thereof as well as copper-zinc-tin-sulfide-selenium film solar cell

ActiveCN102769047AAvoid recombinationExtend your lifeFinal product manufactureVacuum evaporation coatingPotential differenceZinc

The invention provides a copper-zinc-tin-sulfide-selenium (CZTSSe) film, which comprises a light-incident surface and a backlight surface opposite to the light-incident surface. The molar ratio of sulfide to selenium in the CZTSSe film is increased gradually along with the direction from the light-incident surface to the backlight surface. The forbidden bandwidth of the CZTSSe film is changed along with the changes of the molar ratio of the sulfide to the selenium in a material. The forbidden bandwidth can cause the generation of potential difference between the light-incident surface and the backlight surface, and photo-induced carriers are driven out of a high recombination area; therefore, recombination among the photo-induced carriers is avoided, and the service liives of the photo-induced carriers are prolonged. The generated potential difference is beneficial to improving the diffusion length of the photo-induced carriers and the collection efficiency of the photo-induced carriers is improved, thus improving the photoelectric conversion efficiency of the cell. The invention further provides a preparation method of the CZTSSe film and a CZTSSe film solar cell.

Owner:SHENZHEN INST OF ADVANCED TECH +1

Titanium dioxide/tin sulfide composite material, preparation method and application thereof

ActiveCN106000422AAchieve the purpose of purificationHigh catalytic activityPhysical/chemical process catalystsDispersed particle separationPhotocatalytic degradationAir purification

The invention relates to a titanium dioxide / tin sulfide composite material, a preparation method and application thereof. The titanium dioxide / tin sulfide composite material includes titanium dioxide particles and tin sulfide particles growing in situ on the surfaces of the titanium dioxide particles by hydrothermal method, the molar mass ratio of SnS2 and TiO2 in the titanium dioxide / tin sulfide composite material is (0.001-0.20):1, preferably (0.09-0.14):1, the particle size of the titanium dioxide particles is 10-50nm, and the particle size of the tin sulfide particles is 5-10nm. The invention adopts hydrothermal method (chemical bath method) to grow tin sulfide particles in situ on the titanium dioxide surface so as to obtain the titanium dioxide / tin sulfide composite material, and the titanium dioxide / tin sulfide composite material is applied to visible light for photocatalytic degradation of formaldehyde, thus reaching the purpose of indoor air purification. At the same time, by adjusting different Sn / Ti molar ratios, a composite coating material with the optimal visible-light catalytic activity can be obtained.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing copper-zinc-tin-sulfide solar cell absorbing layer with homogeneous solution method

InactiveCN103346215AIncrease profitReduce carbon residueFinal product manufactureSemiconductor devicesTechnology developmentSulfur

The invention discloses a method for preparing a copper-zinc-tin-sulfide solar cell absorbing layer with a homogeneous solution method and belongs to the field of functional materials. The method comprises the following steps that (a) a substrate is washed, (b) front-body solution is prepared, (c) a front-body thin film is prepared, and (d) annealing processing is carried out. According to the method for preparing the copper-zinc-tin-sulfide solar thin film, expensive raw materials and equipment are of no need, each technology step can be well controlled, toxic macromolecule solvent is of no need, a large amount of residual carbon in the copper-zinc-tin-sulfide solar thin film preparing process is avoided, large-grained and compact copper-zinc-tin-sulfide solar cell absorbing layer thin film preparing is facilitated, the technology is simple, cost is low, repeatability is high, a new idea is provided for environment-protection low-cost high-conversion-efficiency copper-zinc-tin-sulfide thin-film solar cell technology development, and the potential of large-scale industrial production is achieved.

Owner:BEIJING UNIV OF TECH

Preparation method of nanosheet self-assembled three-dimensional nano flower tin sulfide/graphitized carbon nitride lithium ion battery anode material

ActiveCN109286009AControllable growthUniform size distributionMaterial nanotechnologyCell electrodesVacuum dryingMaterials science

The invention discloses a preparation method of a nanosheet self-assembled three-dimensional nano flower tin sulfide / graphitized carbon nitride lithium ion battery anode material. Melamine is kept at450-650 DEG C for 2-6 hours, is naturally cooled to room temperature, is ground for prepare use, and is dispersed in ethanol to obtain a suspension, the suspension is centrifuged and washed several times with deionized water and absolute ethanol, vacuum drying is conducted to obtain a product g-C3N4, the product g-C3N4 is dissolved in the deionized water, after stirring, the product g-C3N4 is ultrasonically dispersed to form a suspension A, PVP is added to the suspension A, stirring is conducted until the product g-C3N4 is completely dissolved to form a solution B, TAA and SnCl4 2H2O are addedto the solution B, stirring is uniformly conducted to form a solution C, the solution C is subjected to a microwave hydrothermal reaction, after the reaction is completed, a precursor is obtained, the precursor is centrifuged and washed several times with the deionized water and the absolute ethanol, and vacuum drying is conducted to obtain a nanosheet self-assembled three-dimensional nano flowerSnS2 / g-C3N4 battery material.

Owner:SHAANXI UNIV OF SCI & TECH

Tin sulfide/sulfur/less-layer graphene composite material and preparation method and application thereof

ActiveCN107316989AAlleviate volume changesImprove electronic conductivityCell electrodesSecondary cellsLithiumSulfur

The invention discloses a tin sulfide / sulfur / less-layer graphene composite material and a preparation method and application thereof. The preparation method comprises the following steps of adding tine powder, sulfur powder and expanded graphite into a ball-milling tank, performing mixing, and performing ball-milling by employing dielectric barrier discharge plasma assisted with a high-efficiency ball-milling method to obtain the tin sulfide / sulfur / less-layer graphene composite material, wherein in a mixture of the tin powder, the sulfur powder and the expanded graphite, the mass percent of the expanded graphite accounts for 20-80%, the mole ratio of the tin powder and the sulfur powder is (1:1)-(1:4), the ball material ratio of ball milling is (30:1)-(70:1), and the ball-milling time is 10-40 hours. The composite material shows excellent electrochemical performance when used as a lithium / sodium ion battery negative material and has high capacity, excellent cycle property and rate performance. The composite material has the advantages of wide raw material source, low cost and no pollution to an environment, the preparation method is simple, and production on a large scale is easy.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com