Preparation method and application of tin sulfide material

A technology of tin sulfide and preparation steps, applied in chemical instruments and methods, nanotechnology for materials and surface science, tin compounds, etc., to achieve the effects of easy industrial production, simple process, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) First, 8mmolSnCl 2 2H 2 O and 16mmolNa 2 S·9H 2 Dissolve O in 40mL and 20mL solvents respectively, and sonicate until dissolved, then add 0.9026g polyvinylpyrrolidone into 20mL solvent, sonicate until dissolved;

[0032] (2) The above SnCl 2 2H 2 O solution, Na 2 S·9H 2 O solution and polyvinylpyrrolidone solution were added dropwise into a hydrothermal reactor (150mL) in sequence, and 20mL of solvent was added, and after magnetic stirring for 20min, the temperature of the hydrothermal reactor was set at 160°C for reaction, and the reaction time was 24h;

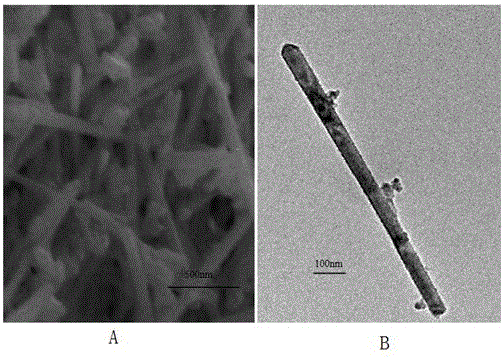

[0033] (3) The precipitate obtained in step (2) was taken out and washed three times with deionized water and ethanol respectively until the filtrate was clear; the obtained product was dried at 50°C for 12 hours to obtain SnS nanorods with controllable morphology. The average diameter of nanorods is 25~100nm, and the length is about 1μm, such as image 3 shown.

Embodiment 2

[0035] (1) First, 8mmolSnCl 2 2H 2 0.0 and 8mmol of thiourea were dissolved in 40mL and 20mL of solvent respectively, and ultrasonicated until dissolved respectively; secondly, 0.9026g of polyvinylpyrrolidone was added to 20mL of solvent, and ultrasonicated until dissolved;

[0036] (2) Add the above solution dropwise into a hydrothermal reaction kettle (150mL) in sequence, and add 20mL of solvent, and after magnetic stirring for 15 minutes, set the temperature of the hydrothermal reaction kettle at 120°C for reaction, and the reaction time is 17h;

[0037] (3) The precipitate obtained in step (2) was taken out and washed four times with deionized water and ethanol, respectively, until the filtrate was clear, and the obtained product was dried at 45°C for 12 hours to obtain rod-shaped SnS with controllable morphology. The average diameter of rod-shaped SnS is about 1 μm, and the length is about 4.5~5 μm, such as Figure 4 shown; Figure 8 It is shown that the smaller particle...

Embodiment 3

[0039] (1) First, 3mmolSnCl 2 2H 2 0 and 12mmol of thioacetamide TAA were dissolved in 40mL and 20mL solvents respectively, and ultrasonicated until dissolved; secondly, 0.6770g cetyltrimethylammonium bromide was added to 20mL solvent, and ultrasonicated until dissolved;

[0040] (2) Add the above solution dropwise into the hydrothermal reaction kettle (150mL) one by one, and add 20mL of solvent. After magnetically stirring for 10 minutes, set the temperature of the hydrothermal reaction kettle at 120°C for reaction, and the reaction time is 24h;

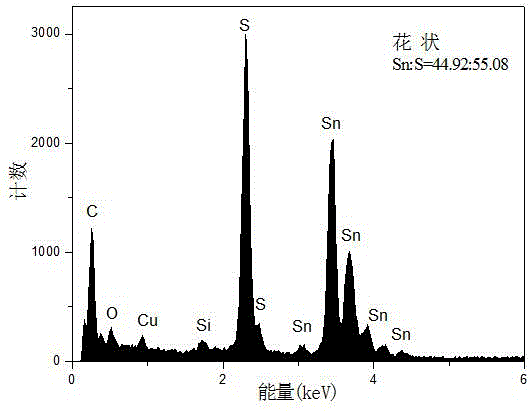

[0041] (3) Take out the precipitate obtained in step (2) and wash it with deionized water and ethanol for 5 times until the filtrate becomes clear; dry the obtained product at 40°C for 12 hours to obtain flower-like SnS with controllable morphology. Its average diameter is about 600nm, such as figure 1 , 2 , 5, it can be seen from the figure that the prepared SnS material is consistent with the standard card, and its lattice para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com