Preparation method of copper zinc tin sulfide/graphene oxide composite semiconductor photocatalyst

A graphene composite, copper-zinc-tin-sulfur technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of catalytic activity decline and achieve improved resistance to photodissolution and photocorrosion effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

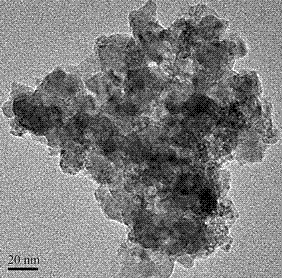

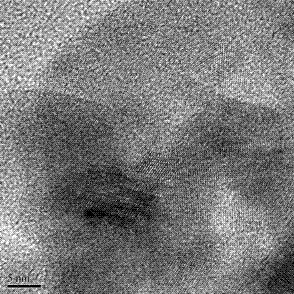

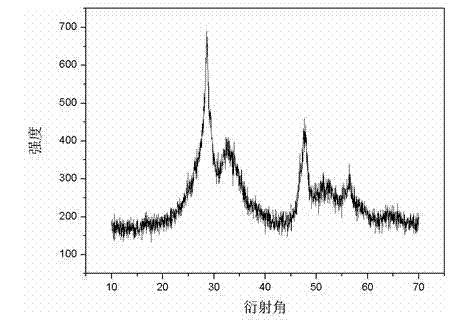

Image

Examples

Embodiment 1

[0030] A preparation method of a copper-zinc-tin-sulfur compound includes the following steps:

[0031] (1) 0.4g copper acetate, 0.18g zinc acetate, 0.24g tin acetate, 0.30g thiourea and 0.012g graphene oxide were mixed and dispersed in 200ml ethylene glycol solution to form a precursor solution;

[0032] (2) Put the precursor solution into a hydrothermal reaction kettle for heating, react at a constant temperature of 200 degrees Celsius for 20 hours and then stop the reaction. After completion, a mixture of copper, zinc, tin and sulfur / graphene oxide composite compound and reaction solution will be obtained;

[0033] (3) After the above mixed liquid is naturally cooled, it is filtered under reduced pressure and dried in a vacuum for 20 hours at a temperature of 40°C during drying to obtain a copper zinc tin sulfur / graphene oxide composite compound semiconductor photocatalyst.

[0034] In this example, a test was conducted on the photocatalytic performance of copper, zinc, tin and sulf...

Embodiment 2

[0038] A preparation method of a copper-zinc-tin-sulfur compound includes the following steps:

[0039] (1) 0.4g copper nitrate, 0.18g zinc nitrate, 0.24g tin nitrate, 0.30g thiourea and 0.024g graphene oxide are mixed and dispersed in 50ml of aqueous solution to form a precursor solution;

[0040] (2) Put the precursor solution into a hydrothermal reaction kettle for heating, react at a constant temperature of 180 degrees Celsius for 24 hours and then stop the reaction. After completion, a mixture of copper, zinc, tin and sulfur / graphene oxide composite compound and reaction solution will be obtained;

[0041] (3) After the above mixed liquid is naturally cooled, it is filtered under reduced pressure and dried in a vacuum for 20 hours at a temperature of 40°C during drying to obtain a copper zinc tin sulfur / graphene oxide composite compound semiconductor photocatalyst.

[0042] Take 20 mg of the prepared copper-zinc-tin-sulfur / graphene oxide composite semiconductor photocatalyst and c...

Embodiment 3

[0044] A preparation method of a copper-zinc-tin-sulfur compound includes the following steps:

[0045] (1) 0.4g copper chloride, 0.18g zinc chloride, 0.24g tin chloride, 0.30g thiourea and 0.036g graphene oxide are uniformly mixed and dispersed in 50ml of aqueous solution to form a precursor solution;

[0046] 2) Put the precursor solution into the hydrothermal reactor for heating, and stop the reaction after a constant temperature reaction at 160 degrees Celsius for 28 hours. After completion, a mixed solution of the copper zinc tin sulfur / graphene oxide composite compound and the reaction solution will be obtained;

[0047] (3) After the above-mentioned mixed liquid is naturally cooled, it is filtered under reduced pressure and dried in a vacuum for 24 hours at a temperature of 50° C. to obtain a copper zinc tin sulfur / graphene oxide composite compound semiconductor photocatalyst.

[0048] Take 20 mg of the prepared copper-zinc-tin-sulfur / graphene oxide composite semiconductor photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com