Application method of binary metal sulfides in chargeable magnesium battery

A technology of binary metal and application method, applied in secondary batteries, battery electrodes, non-aqueous electrolyte storage batteries, etc., can solve the problems of cumbersome steps and harsh preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Grind nickel sulfide finely, add 1.5 parts of acetylene black as conductive agent and 1 part of polyvinylidene fluoride to 7.5 parts of nickel sulfide, stir evenly, coat on copper foil, and dry in an oven at 80°C. Use a punch with a diameter of 12mm to punch into a pole piece, press it under a pressure of 1MPa, and dry it in a vacuum oven at 100°C for 4 hours to obtain a positive pole piece, then transfer it to an argon glove box, and use metal magnesium as the negative pole , 0.25mol L -1 Mg(AlCl 2 BuEt) 2 / Tetrahydrofuran is used as the electrolyte to make a button-type rechargeable magnesium battery.

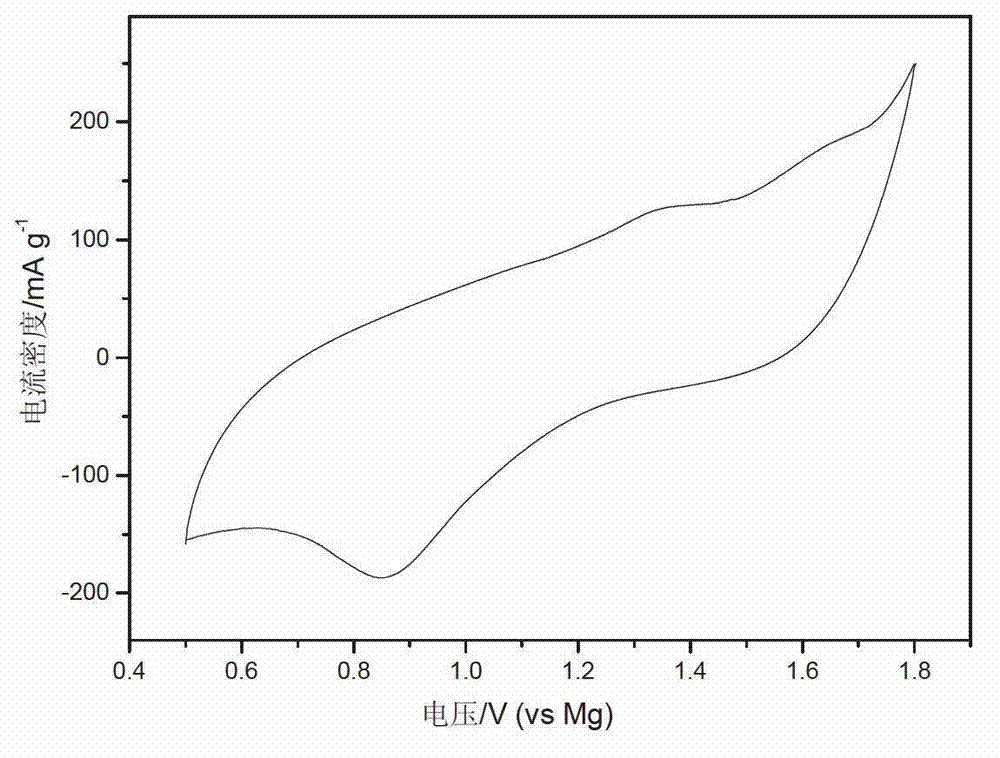

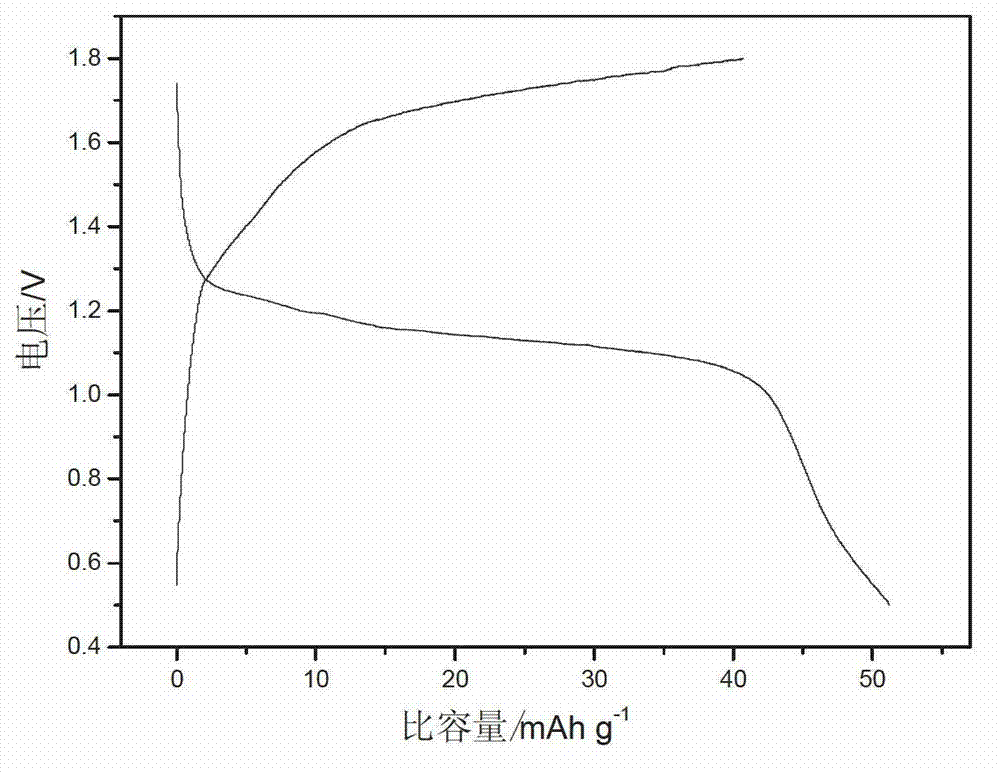

[0028] The cyclic voltammetry curve of the button-type rechargeable magnesium battery is as follows: figure 1 As shown, it can be seen that nickel sulfide is electrochemically active. The charging and discharging test results are as follows: figure 2 As shown, the test charge and discharge current density is 1.534mA·g -1 , the discharge capacity is 51.2mAh·g -...

Embodiment 2

[0030] Grind manganese sulfide finely, add 1.5 parts of acetylene black as conductive agent and 1 part of polyvinylidene fluoride to 7.5 parts of manganese sulfide, stir evenly, coat on copper foil, and dry in an oven at 80°C. Use a punch with a diameter of 12mm to punch into a pole piece, press it under a pressure of 1MPa, and dry it in a vacuum oven at 100°C for 4 hours to obtain a positive pole piece, then transfer it to an argon glove box, and use metal magnesium as the negative pole , 0.25mol L -1 Mg(AlCl 2 BuEt) 2 / Tetrahydrofuran is used as the electrolyte to make a button-type rechargeable magnesium battery.

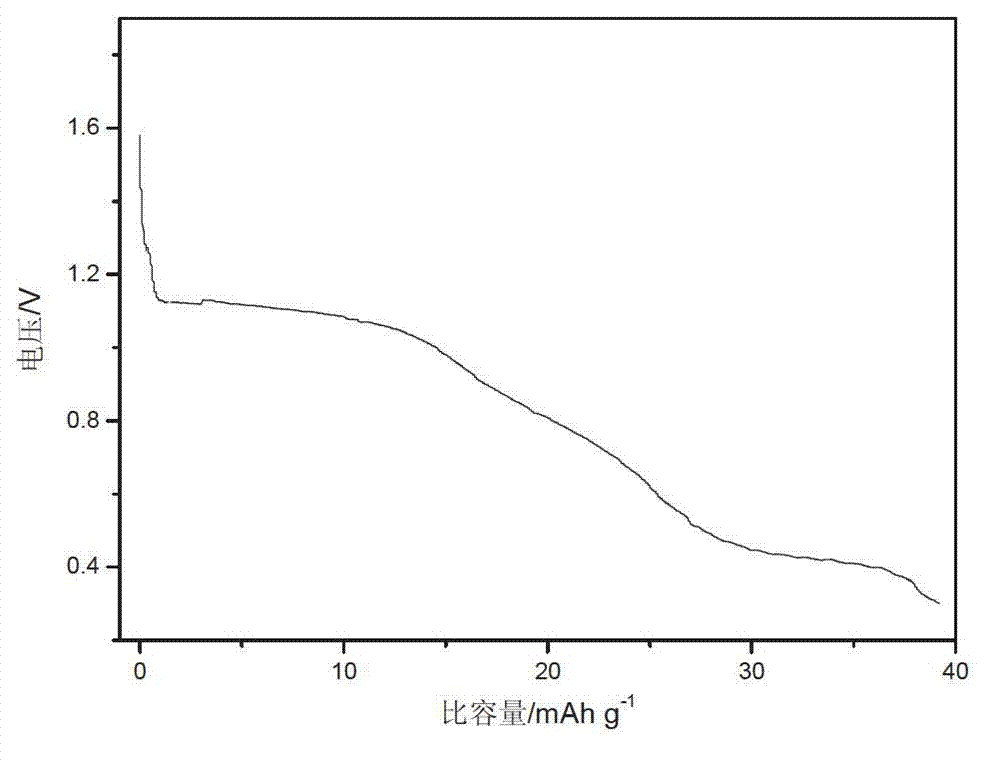

[0031] The discharge test results of the button-type rechargeable magnesium battery are as follows: image 3 As shown, the test discharge current density is 2mA·g -1 , the discharge capacity is 39.2mAh·g -1 .

Embodiment 3

[0033] Grind tin sulfide finely, add 1.5 parts of acetylene black as a conductive agent and 1 part of polyvinylidene fluoride to 7.5 parts of tin sulfide, mix well, coat on copper foil, and put it in an oven at 80°C for drying. Use a punch with a diameter of 12mm to punch into a pole piece, press it under a pressure of 1MPa, and dry it in a vacuum oven at 100°C for 4 hours to obtain a positive pole piece, then transfer it to an argon glove box, and use metal magnesium as the negative pole , 0.25mol L -1 Mg(AlCl 2 BuEt) 2 / Tetrahydrofuran is used as the electrolyte to make a button-type rechargeable magnesium battery.

[0034] The discharge capacity of the button-type rechargeable magnesium battery can reach 100mAh·g -1 . Compared with comparative example 1, the rechargeable magnesium battery prepared by tin sulfide as positive electrode material in this embodiment can provide 6 S 8 High discharge capacity of rechargeable magnesium batteries prepared as cathode materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Discharge current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com