Preparation method of ethanediamine intercalation tin sulfide compound

A technology of tin disulfide and ethylenediamine, applied in tin compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high equipment requirements, achieve high purity, expand the application range, and expand the effect of layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

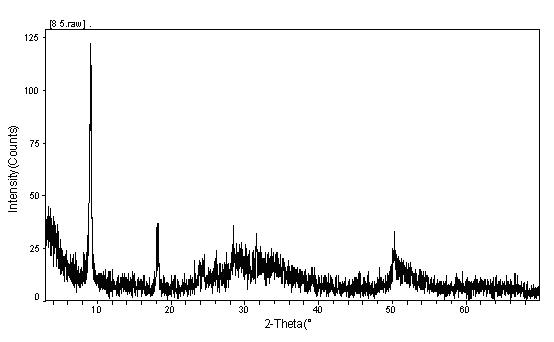

Image

Examples

Embodiment 1

[0017] a. Weigh 0.5035g tin disulfide and transfer it to a 50ml polytetrafluoroethylene inner cylinder;

[0018] b. Measure 25ml of absolute ethanol, pour it into the reaction kettle, then slowly add 5ml of anhydrous ethylenediamine, and stir evenly;

[0019] c. Tighten the reaction kettle, put the reaction kettle into the muffle furnace, adjust the temperature to 180°C, and the time is 20 hours;

[0020] d. After the reaction, centrifuge to obtain a solid sample, then use absolute ethanol to filter and wash several times, and dry the obtained sample naturally at room temperature.

Embodiment 2

[0022] a. Weigh 0.5020g of tin disulfide and transfer it to a 50ml polytetrafluoroethylene inner cylinder;

[0023] b. Measure 25ml of absolute ethanol, pour it into the reaction kettle, then slowly add 5ml of anhydrous ethylenediamine, and stir evenly;

[0024] c. Tighten the reaction kettle, put the reaction kettle into the muffle furnace, adjust the temperature to 170°C, and the time is 22 hours;

[0025] d. After the reaction, centrifuge to obtain a solid sample, then use absolute ethanol to filter and wash several times, and dry the obtained sample naturally at room temperature.

Embodiment 3

[0027] a, take by weighing 0.5250g tin disulfide, transfer in the polytetrafluoroethylene inner tube of 50ml;

[0028] b. Measure 20ml of absolute ethanol, pour it into the reaction kettle, then slowly add 10ml of anhydrous ethylenediamine, and stir evenly;

[0029] c. Tighten the reaction kettle, put the reaction kettle into the muffle furnace, adjust the temperature to 160°C, and the time is 24 hours;

[0030] d. After the reaction, centrifuge to obtain a solid sample, then use absolute ethanol to filter and wash several times, and dry the obtained sample naturally at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com