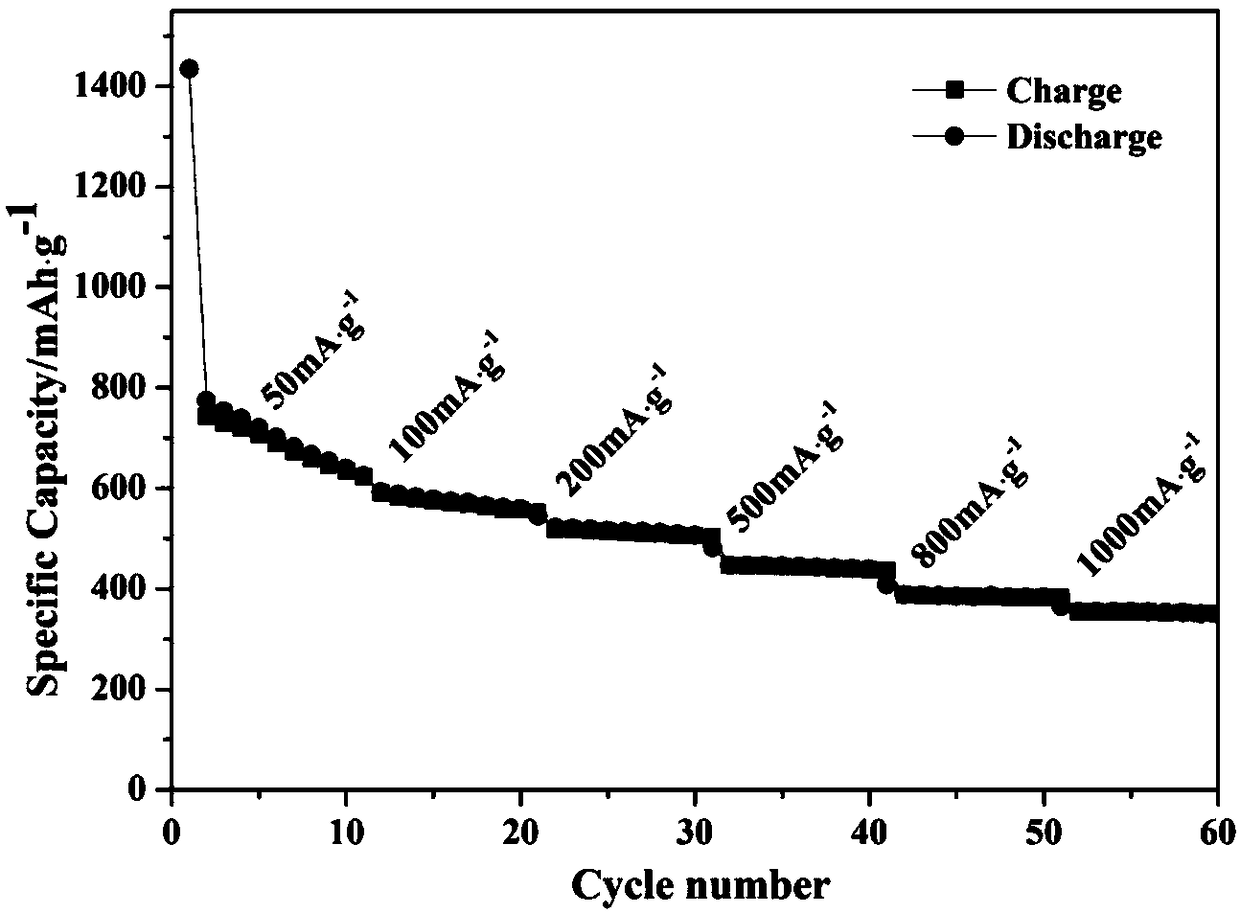

Preparation method of nanosheet self-assembled three-dimensional nano flower tin sulfide/graphitized carbon nitride lithium ion battery anode material

A technology of carbon nitride, three-dimensional nanometer, applied in the field of preparation of negative electrode materials of lithium ion batteries, can solve the problems of large salt consumption, long cycle, polluted ion exchange resin, etc., and achieves low preparation cost, high production efficiency, Controlled effect of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of a nanosheet self-assembled three-dimensional nanoflower tin sulfide / graphitized carbon nitride lithium ion battery negative electrode material, comprising the following steps:

[0029] 1) Put 5-15g of melamine in a crucible with a cover, place it in a muffle furnace at 450-650°C for 2-6 hours, keep the heating rate at 2°C / min, and wait for it to cool down to room temperature naturally. Grind the yellow product finely in a mortar;

[0030] 2) Then disperse it in ethanol for 2 hours under vigorous stirring, and disperse 30-50 mg of the product obtained in step 1) in every 40-60 mL of ethanol. Subsequently, the suspension was centrifuged and washed several times with deionized water and absolute ethanol, and then vacuum-dried at 60-100 °C for 8-14 h. Finally, the yellow product g-C is obtained 3 N 4 .

[0031] 3) Add 30~50mg g-C 3 N 4 Dissolve in 40-60ml of deionized water, vigorously stir for 5 hours, and ultrasonically disperse for 3 hours. ...

Embodiment 1

[0038] 1) Put 5 g of melamine in a crucible with a cover, place it in a muffle furnace at 450°C for 2 hours, and keep the heating rate at 2°C / min. grind in a bowl;

[0039] 2) Then it was dispersed in ethanol for 2 hours under vigorous stirring, and 30 mg of the product obtained in step 1) was dispersed in every 40 mL of ethanol. Subsequently, the suspension was centrifuged and washed several times with deionized water and absolute ethanol, and then dried under vacuum at 60 °C for 8 h. Finally, the yellow product g-C is obtained 3 N 4 .

[0040] 3) Add 30mg g-C 3 N 4 Dissolve in 40ml deionized water, stir vigorously for 5 hours, and disperse ultrasonically for 3 hours. Suspension A is formed;

[0041] 4) Then slowly add 0.4g of PVP (polyvinylpyrrolidone) to the above suspension A, and magnetically stir for 10 minutes until it is completely dissolved to form solution B;

[0042] 5) According to the molar ratio of elements n S :n Sn =2:0.5 TAA (thioacetamide) and SnCl ...

Embodiment 2

[0046] 1) Put 10g of melamine in a crucible with a cover, place it in a muffle furnace at 550°C for 4 hours, and keep the heating rate at 2°C / min. grind in a bowl;

[0047] 2) Then it was dispersed in ethanol for 2 hours under vigorous stirring, and 40 mg of the product obtained in step 1) was dispersed in every 50 mL of ethanol. Subsequently, the suspension was centrifuged and washed several times with deionized water and absolute ethanol, and then dried under vacuum at 80 °C for 12 h. Finally, the yellow product g-C is obtained 3 N 4 .

[0048] 3) 40mg g-C 3 N 4 Dissolve in 50ml deionized water, stir vigorously for 5h, and disperse ultrasonically for 3h. Suspension A is formed;

[0049] 4) Then slowly add 0.5g of PVP (polyvinylpyrrolidone) to the suspension A above, and stir magnetically for 10 minutes until completely dissolved to form solution B;

[0050] 5) According to the molar ratio of elements n S :n Sn= 2:1 TAA (thioacetamide) and SnCl 4 2H 2 O was added ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com