Tin sulfide nano paper self-assembly microsphere production method and optical detector of microsphere film

A photodetector and nanopaper technology, which is applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of no photodetector, etc., and achieve easy-to-obtain raw materials, simple and practical production, and fast response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

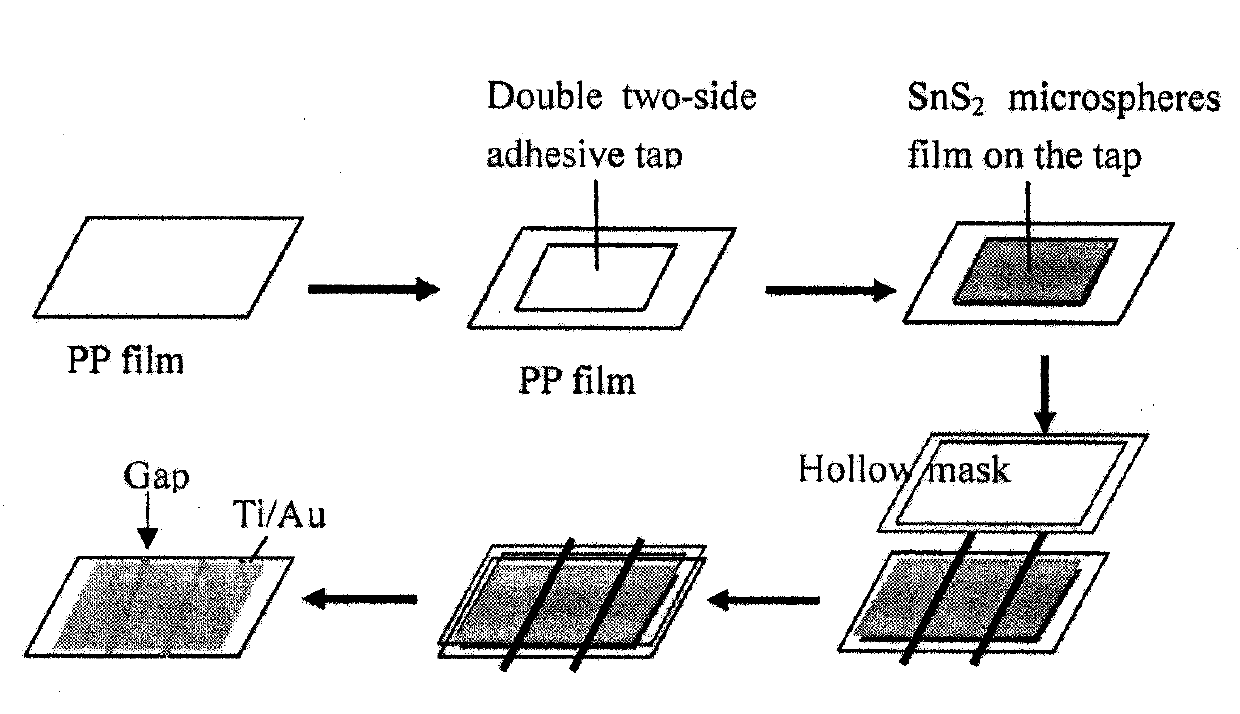

[0012] Example 1. SnS with PP substrate 2 Fabrication of Nanopaper Self-Assembled Microsphere Thin Film Flexible Photodetection Devices

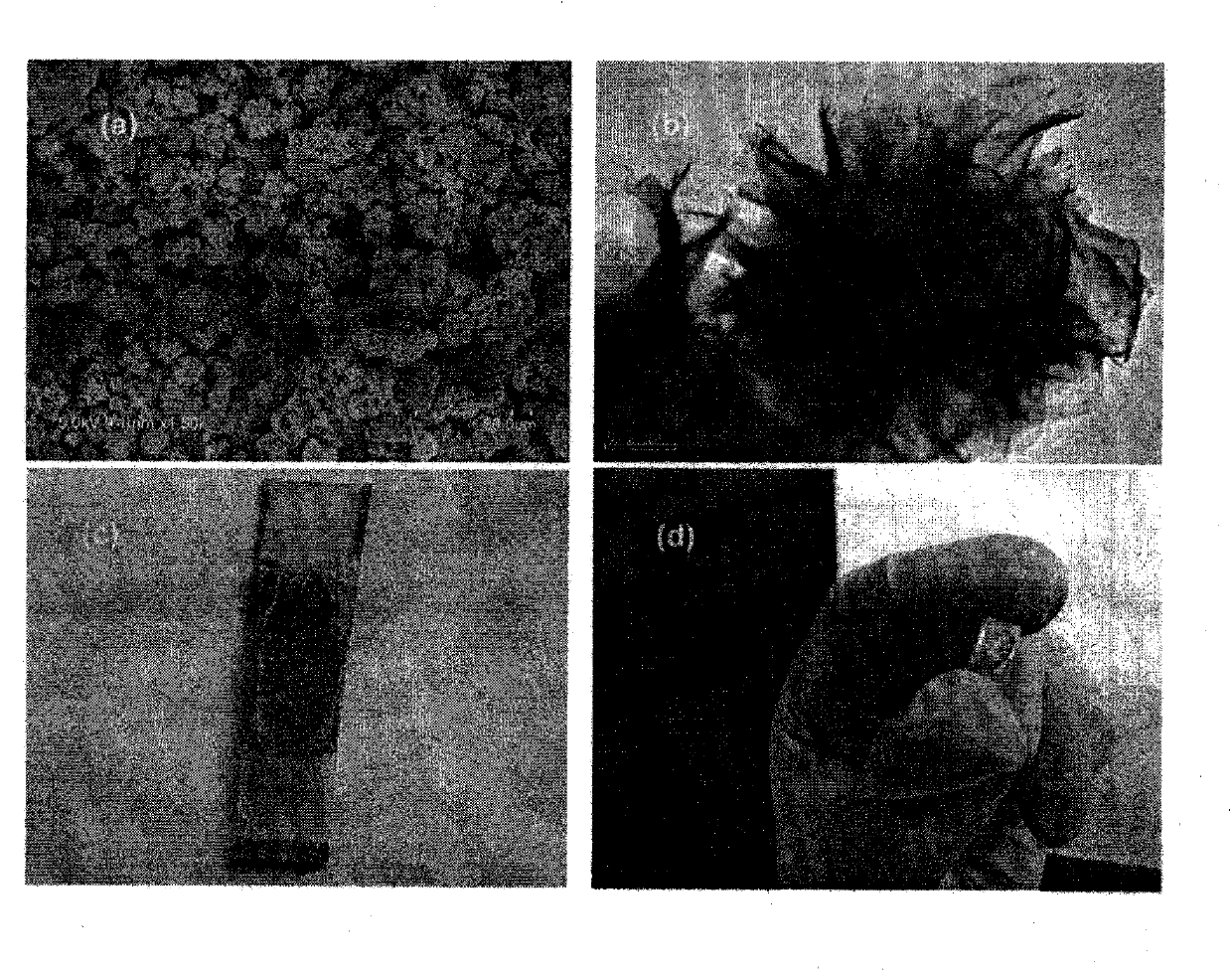

[0013] A. Add 1.7525g SnCl 4 ·5H 2 O(CP), 1.609g thioacetamide (TAA) and 40mL ethanol were placed in a 100mL beaker and stirred for 30 minutes, then transferred to a 50mL stainless steel reaction vessel with polytetrafluoroethylene and sealed. After 24 hours of constant temperature at 180°C, centrifuge, wash with ethanol and pure water three times alternately and centrifuge, dry at 60°C for 3 hours, and collect the product. The structure is confirmed by XRD, and the appearance is as follows: figure 2 (a) and 2(b)

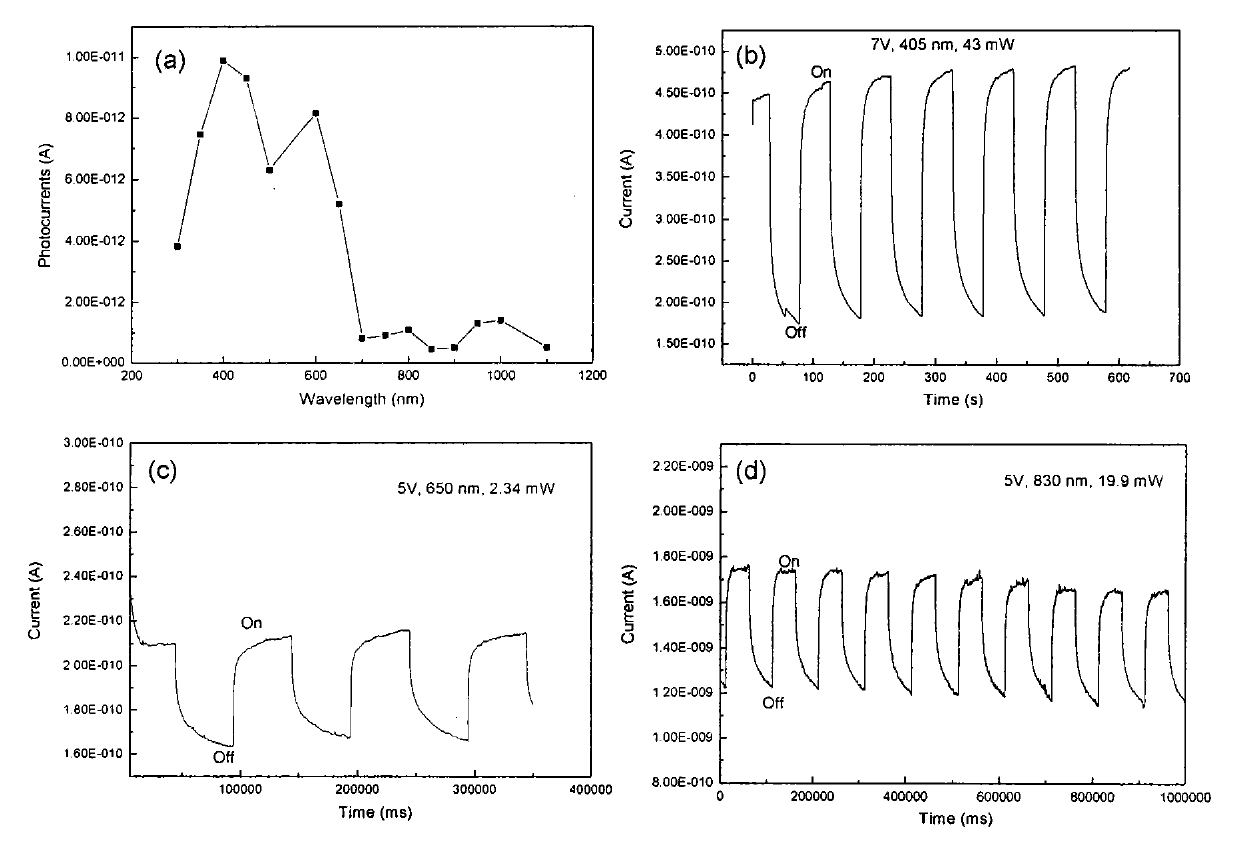

[0014] B. Select a PP flexible substrate with a size of 0.5cm×2cm×0.2mm and paste a 0.5cm×1cm double-sided tape on one side, then mix ethanol with the SnS prepared above 2 The microsphere suspension was evenly coated on the double-sided adhesive tape and dried naturally. Then, in SnS 2 Two enamelled copper wires with a diam...

Embodiment 2

[0016] Example 2. SnS with paper substrate 2 Fabrication of Nanopaper Self-Assembled Microsphere Thin Film Flexible Photodetection Devices

[0017] A. SnS 2 The preparation method of nanopaper self-assembled microspheres is the same as part A of Example 1.

[0018] B. Select a paper substrate with a size of about 0.5cm×2cm×0.2mm and paste a double-sided tape (about 0.5cm×1cm in size) on this side, then mix ethanol with the SnS prepared above 2 The microsphere suspension was evenly coated on the double-sided adhesive tape and dried naturally. Then, in SnS 2 Two enamelled copper wires with a diameter of 70 microns are placed in parallel on the thin film of the microspheres as electrode partitions, and a frame mask is cut to cover the edge of the device. Then vacuum ion sputtering Ti (50nm) / Au (100nm) conductive film, tear off the mask and enameled wire to obtain the device 2 .

Embodiment 3

[0019] Example 3. SnS with PET substrate 2 Fabrication of Nanopaper Self-Assembled Microsphere Thin Film Flexible Photodetection Devices

[0020] A. SnS 2 The preparation method of nanopaper self-assembled microspheres is the same as Part A of Example 1 o

[0021] B. Select a PET substrate with a size of about 0.5cm×2cm×0.2mm and paste a double-sided tape (about 0.5cm×1cm) on this side, and then mix ethanol with the SnS prepared above 2 The microsphere suspension was evenly coated on the double-sided adhesive tape and dried naturally. Then, in SnS 2 Two enamelled copper wires with a diameter of 70 microns are placed in parallel on the thin film of the microspheres as electrode partitions, and a frame mask is cut to cover the edge of the device. Then vacuum ion sputtering Ti (50nm) / Au (100nm) conductive film, tear off the mask and enameled wire to obtain device 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com