Preparation of rare earth metal-tin sulfide/grapheme negative electrode material for lithium ion batteries

A lithium-ion battery, graphene negative electrode technology, applied in battery electrodes, circuits, inorganic chemistry and other directions, can solve the problems of reducing electrode cycle life, irreversible capacity increase, poor cycle performance, etc., to avoid capacity decay too fast, The effect of considerable capacity and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) SnCl with a molar ratio of 2:0.1:6:0.1 4 ·5H 2 O: Ce(NO 3 ) 3 ·6H 2 O: CH 3 CSNH 2 : CTAB is dissolved in a mixed solution of water and ethanol;

[0025] (2) In the mixed solution, add an aqueous solution containing 0.06 g of graphene oxide, and continue to stir until it is completely dissolved;

[0026] (3) Transfer the mixture to a polytetrafluoroethylene-lined hydrothermal reactor and react at 180°C for 36 hours;

[0027] (4) Centrifuge the product, wash it, put it into an oven, and dry it at 60°C to obtain a precursor;

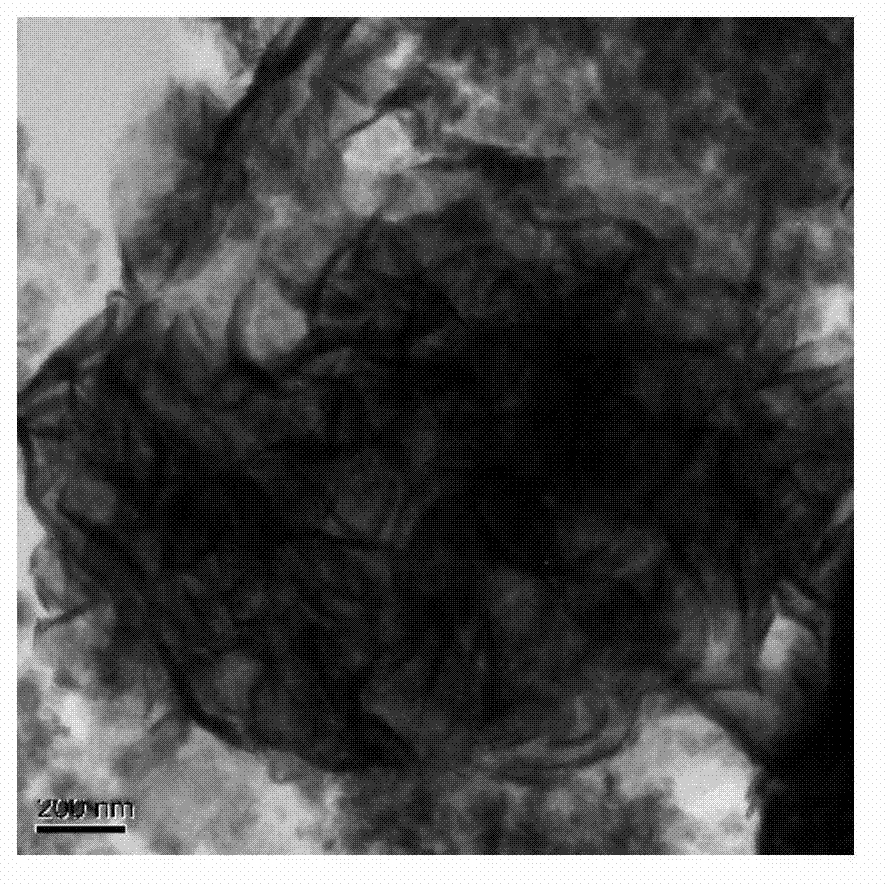

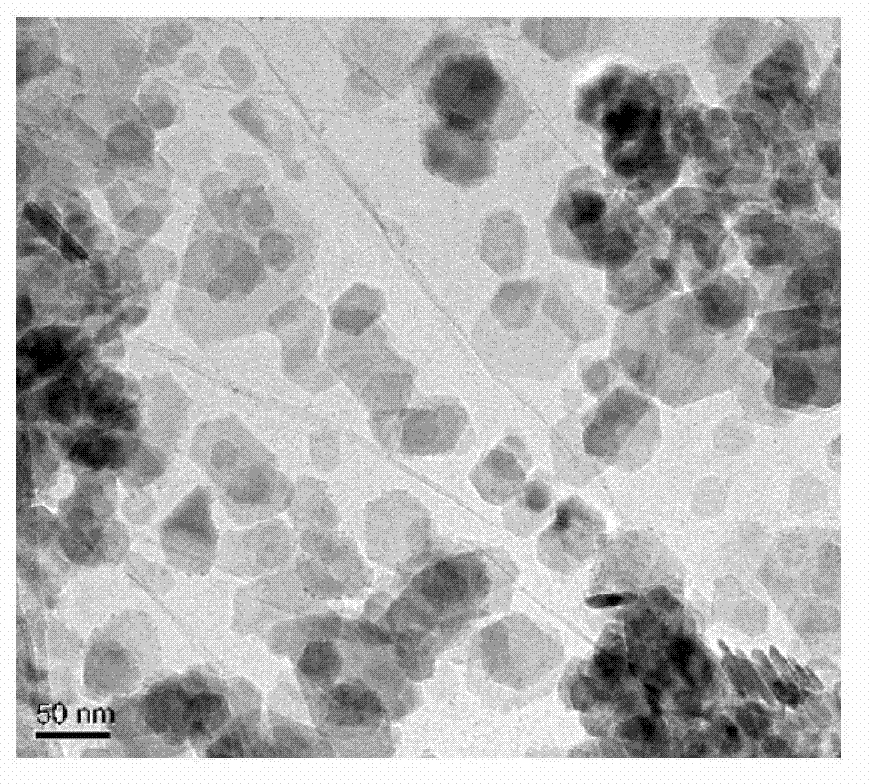

[0028] (5) Heat treatment process: the precursor was sintered in a tube furnace at 500°C for 2h under the protection of argon to obtain Ce-SnS 2 / graphene material.

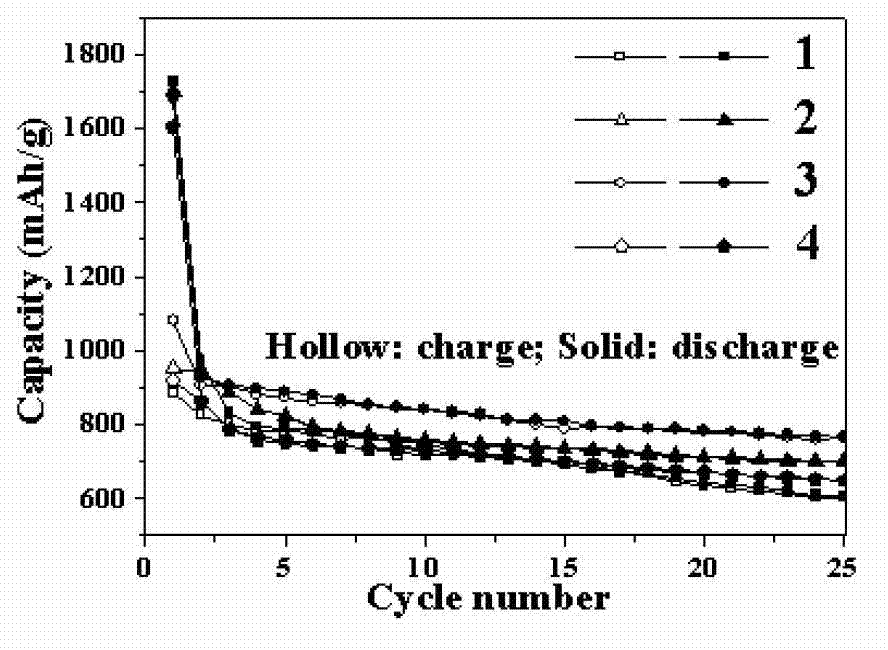

[0029] The product in Example 1 was assembled into a CR2016 button battery, with a lithium sheet (Φ=16 purity>99.9%) as the counter electrode, a polypropylene porous membrane (Φ=18) as the separator, and a LiPF 6 A mixed solution of ethylene carbonate (EC) and dimethyl ca...

Embodiment 2

[0031] (1) SnCl with a molar ratio of 2:0.1:6:0.1 4 ·5H 2 O: Ce(NO 3 ) 3 ·6H 2 O: CH 3 CSNH 2 : CTAB is dissolved in a mixed solution of water and ethanol;

[0032] (2) In the mixed solution, add an aqueous solution containing 0.12 g of graphene oxide, and continue stirring until it is completely dissolved;

[0033] (3) Transfer the mixture to a polytetrafluoroethylene-lined hydrothermal reactor and react at 180°C for 36 hours;

[0034] (4) Centrifuge the product, wash it, put it into an oven, and dry it at 60°C to obtain a precursor;

[0035] (5) Heat treatment process: the precursor was sintered in a tube furnace at 500°C for 2h under the protection of argon to obtain Ce-SnS 2 / graphene material.

[0036] The product in Example 2 was assembled into a CR2016 button battery (the method is the same as in Example 1). Under the condition of current density 0.1C, the charge and discharge performance test is carried out, the charge and discharge voltage range is 0-2.0V, a...

Embodiment 3

[0038] (1) SnCl with a molar ratio of 2:0.1:6:0.1 4 ·5H 2 O: Ce(NO 3 ) 3 ·6H 2 O: CH 3 CSNH 2 : CTAB is dissolved in a mixed solution of water and ethanol;

[0039] (2) In the mixed solution, add an aqueous solution containing 0.24 g of graphene oxide, and continue to stir until it is completely dissolved;

[0040] (3) Transfer the mixture to a polytetrafluoroethylene-lined hydrothermal reactor and react at 180°C for 36 hours;

[0041] (4) Centrifuge the product, wash it, put it into an oven, and dry it at 60°C to obtain a precursor;

[0042] (5) Heat treatment process: the precursor was sintered in a tube furnace at 500°C for 2h under the protection of argon to obtain Ce-SnS 2 / graphene material.

[0043] The product in Example 3 was assembled into a CR2016 button battery (the method is the same as in Example 1). Under the condition of current density 0.1C, the charge and discharge performance test is carried out, the charge and discharge voltage range is 0-2.0V, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com