Nano zinc oxide-graphite-graphene composite material and its preparation method and application

A technology of nano-zinc oxide and composite materials, which is applied in the field of nano-zinc oxide-graphite-graphene composite materials and its preparation and application, can solve the problems of reduced electrode cycle life, low charge and discharge capacity, and easy "agglomeration" The effect of initial irreversible capacity, alleviating volume change, and avoiding rapid attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

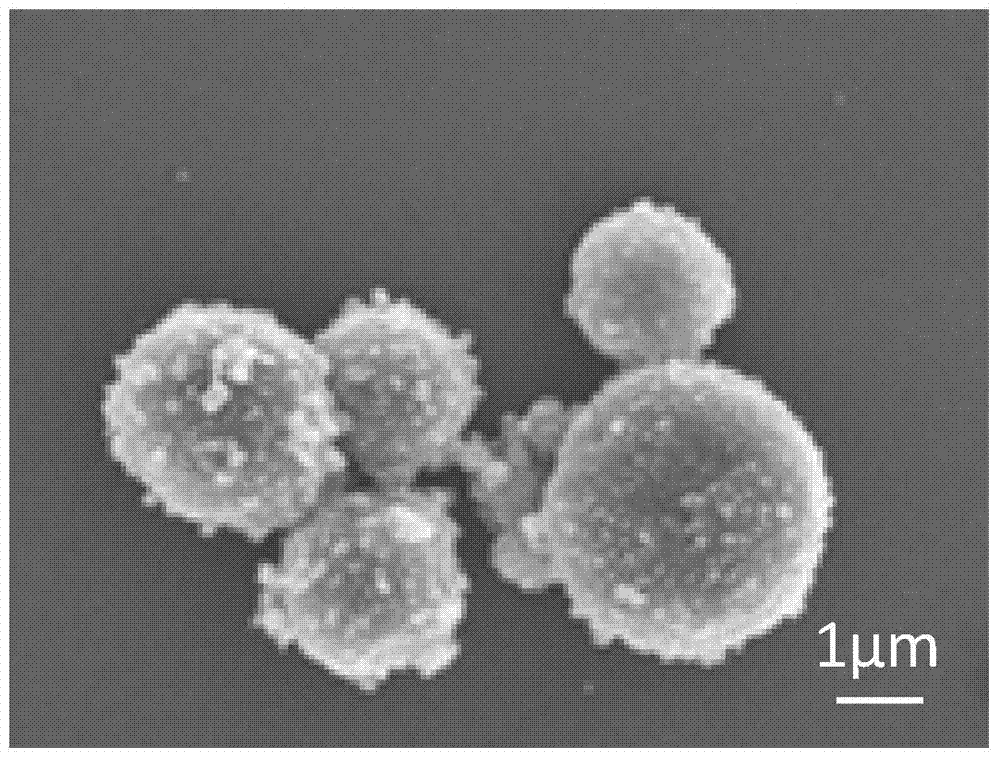

[0046] Weigh 10g tetraamminezinc sulfate (Zn(NH 3 ) 4 SO 4) and 10g of petroleum pitch were dissolved in 300ml of ethanol and stirred to obtain solution A. Add 100 g of natural spherical graphite (0.5-1 μm in particle size) and 2 g of graphene oxide into a 10% by mass polyethylene glycol (PEG-4000) aqueous solution, and ultrasonically disperse for 30 minutes to obtain a suspension B. After mixing Solution A and Suspension B, add 50g of polyvinylpyrrolidone (weight average molecular weight: 8000-10000), stir well, then add dropwise 300mL of a mixture of ammonia water and ethanol (the volume ratio of ammonia water and ethanol is 1:50) , to obtain the sol-gel system C. Dry the above-mentioned sol-gel system C at 80°C for 3 hours, then raise the temperature to 200°C and dry for 4 hours to obtain precursor D; the precursor D is calcined and heat-treated at 1500°C in nitrogen for 9 hours to obtain nano-oxidized Zinc-graphite-graphene composites.

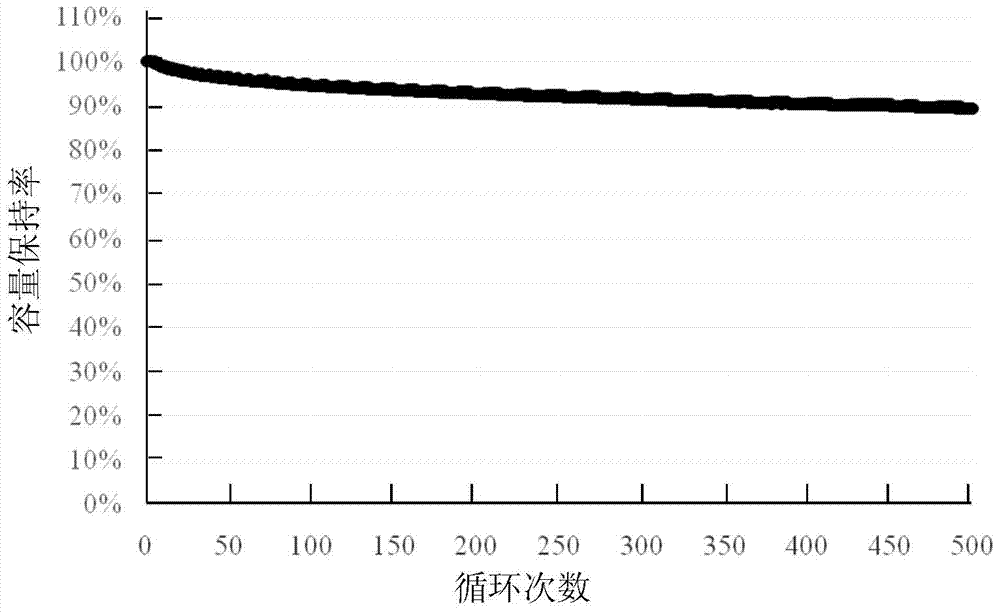

[0047] In the composite materi...

Embodiment 2

[0050] Weigh 10g zinc tetraammonium carbonate (Zn(NH 3 ) 4 CO 3 ) and 20g of coal tar pitch were dissolved in 400ml of methanol and stirred to obtain solution A. Add 80 g of colloidal graphite (0.5-1 μm in particle size) and 1 g of graphene oxide into an aqueous solution of polyethylene glycol (PEG-8000) with a concentration of 5% by mass, and ultrasonically disperse for 50 minutes to obtain a suspension B. After mixing Solution A and Suspension B, add 60g of polyvinylpyrrolidone (weight average molecular weight: 8000-10000), stir well, then add dropwise 500mL of a mixture of ammonia water and ethanol (the volume ratio of ammonia water and ethanol is 1:20) , to obtain the sol-gel system C. The above-mentioned sol-gel system C was dried at 90°C for 3 hours, then heated to 180°C and dried for 6 hours to obtain precursor D; the precursor D was calcined and heat-treated at 2000°C in nitrogen for 6 hours to obtain nano-oxidized Zinc-graphite-graphene composites.

[0051] In th...

Embodiment 3

[0054] Weigh 10g tetraammine zinc dichloride (Zn(NH 3 ) 4 Cl 2 ) and 5g of phenolic resin were dissolved in 200ml of isopropanol and stirred to obtain solution A. Add 50 g of natural spherical graphite (0.5-1 μm in particle size) and 2 g of graphene oxide into a 20% by mass polyethylene glycol (PEG-6000) aqueous solution, and ultrasonically disperse for 40 minutes to obtain a suspension B. After mixing Solution A and Suspension B, add 50g of polyvinylpyrrolidone (weight average molecular weight: 8000-10000), stir well, then add dropwise 200mL of a mixture of ammonia water and ethanol (the volume ratio of ammonia water and ethanol is 1:10) , to obtain the sol-gel system C. The above-mentioned sol-gel system C was dried at 90°C for 3 hours, and then heated to 190°C and dried for 5 hours to obtain precursor D; the precursor D was calcined and heat-treated at 1200°C in helium for 10 hours to obtain nano Zinc oxide-graphite-graphene composites.

[0055] In the composite materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com