Lithium ion battery cathode active material, preparation method of the lithium ion battery cathode active material, cathode material and cathode

A negative electrode active material, lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of flake nanostructures being easily damaged and affecting battery life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention also provides a preparation method of lithium ion battery negative electrode active material, wherein, the method comprises the following steps:

[0020] (1) Under the condition that the temperature is 15-50°C, 1 mass part of flake graphite, 0.5-0.8 mass parts of sodium nitrate, 3-6 mass parts of potassium permanganate and 50-100 mass parts of 98% by weight of concentrated sulfuric acid After carrying out the contact reaction for 75-150 hours, the solid was separated;

[0021] (2) placing the obtained solid in an organic solvent for ultrasonic dispersion to obtain a dispersion;

[0022] (3) Based on 1 part by mass of solid dispersed in an organic solvent, add 1-100 parts by mass of soluble tin salt and 1-1000 parts by mass of water to the dispersion, and continue the reaction at a temperature of 120-180°C After 3-8 hours, filter to obtain a solid; and react the solid in a mixed gas atmosphere of hydrogen sulfide and inert gas at 300-600°C for 2-10...

Embodiment 1

[0050] This example is used to illustrate the preparation of the lithium ion battery negative electrode active material.

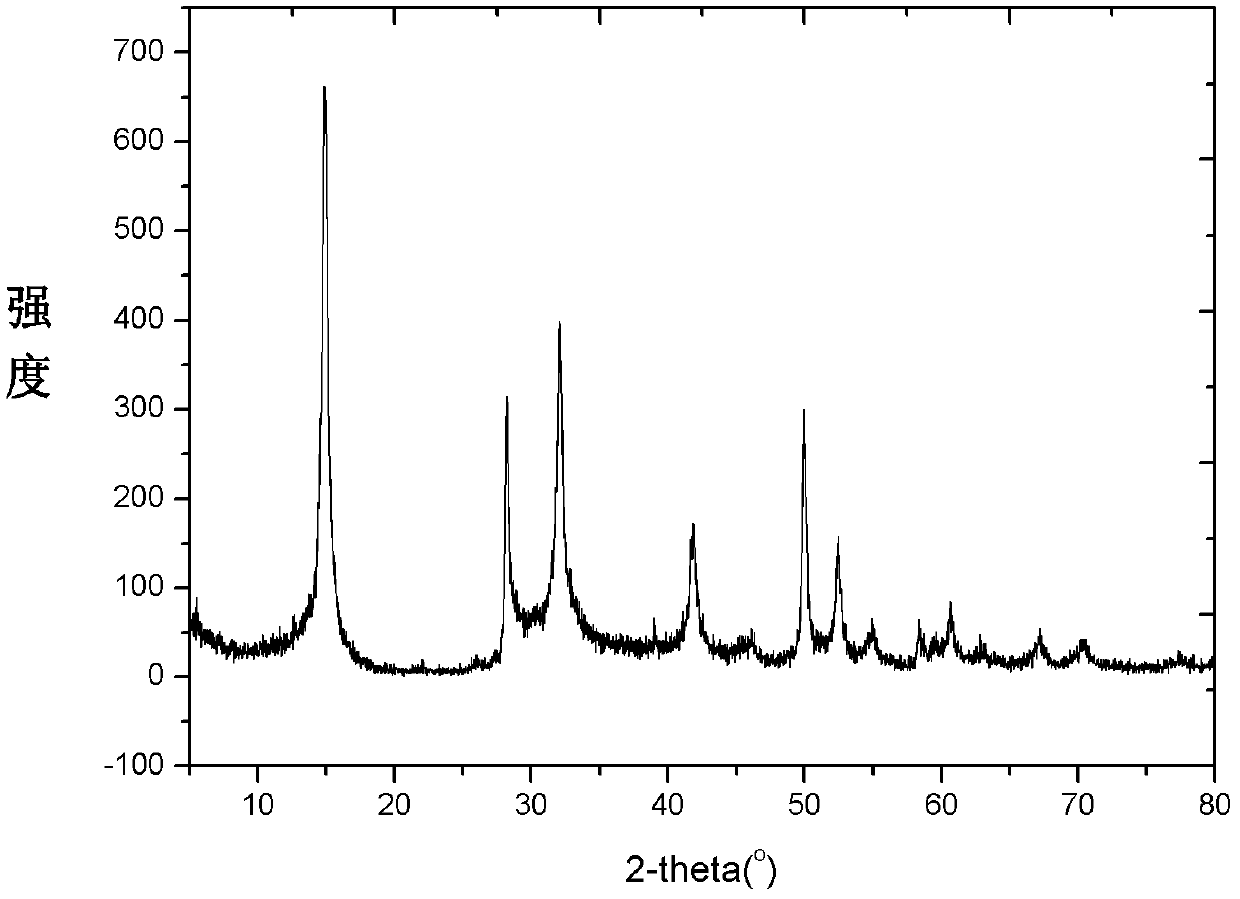

[0051] (1) Preparation of graphene oxide sheet: 1g flake graphite (particle size is 1 micron), 0.5g sodium nitrate and 5g potassium permanganate are added in 100g vitriol oil (concentration is 98% by weight), stirring at room temperature After 150 hours, it was filtered, washed with deionized water, and vacuum-dried at 60° C. for 12 hours to obtain graphene oxide sheets.

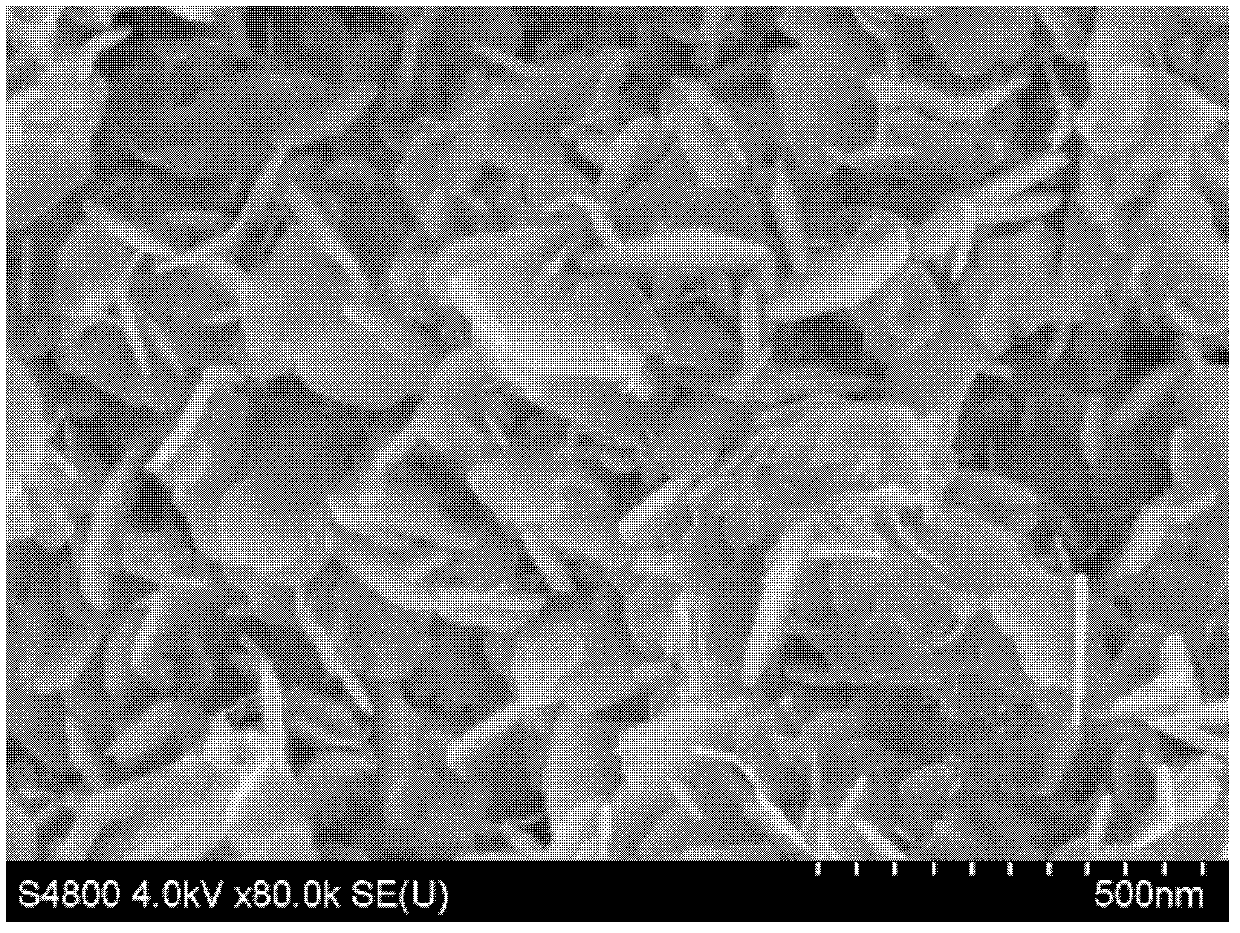

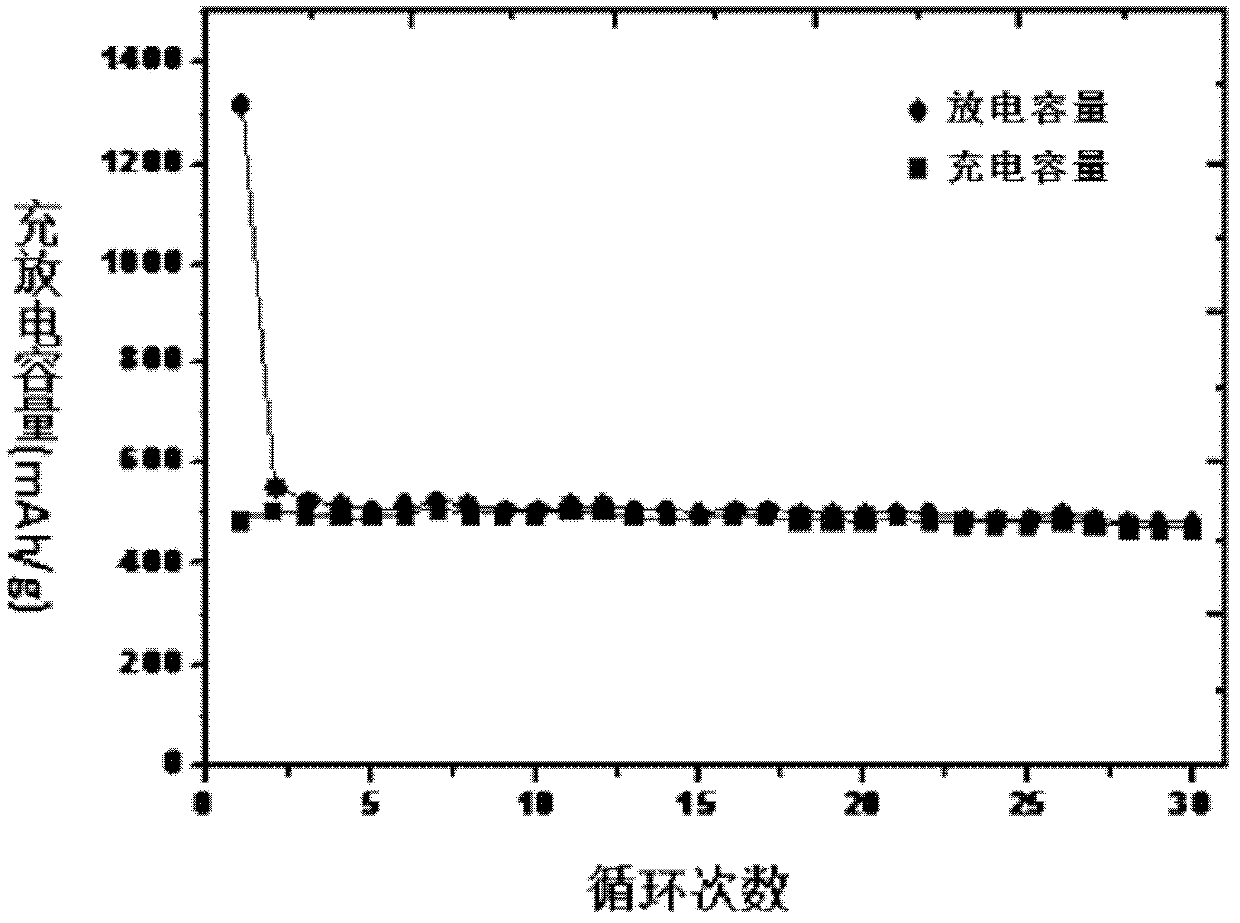

[0052] (2) Preparation of lithium-ion battery negative electrode active material: the graphene oxide sheet of 0.1g obtained in step (1) is ultrasonically dispersed in 100ml ethylene glycol (Beijing Chemical Plant, analytically pure), then add 1g of chlorine dihydrate Sn (Sinopharm Group Chemical Reagent Co., Ltd.) and 10ml of deionized water, the resulting reactant was refluxed and stirred at 120°C for 8h, and was repeatedly centrifuged and washed with ethanol solvent for 5 times, then v...

Embodiment 2

[0055] This example is used to illustrate the preparation of the lithium ion battery negative electrode active material.

[0056] (1) Preparation of graphene oxide: adopt the same method as step (1) of embodiment 1 to carry out, the difference is that the particle diameter of flake graphite is 100 microns, the addition of potassium permanganate is 3g, the addition of vitriol oil The amount was 50 g, and the stirring time at room temperature was 75 hours to obtain graphene oxide sheets.

[0057] (2) Preparation of lithium-ion battery negative electrode active material: Ultrasonic dispersion of 0.1g of graphene oxide sheets obtained in step (1) in 100ml ethylene glycol (Beijing Chemical Plant, analytically pure), then add 0.1g of tetrachloride Chloride tin (Sinopharm Group Chemical Reagent Co., Ltd.) and 0.1ml deionized water, the resulting reactant was refluxed and stirred at 140°C for 6h, and was repeatedly centrifuged and washed with ethanol solvent for 5 times, then vacuum-d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com