Flotation separation beneficiation method for lead-zinc-tin sulfide ores

A mineral processing method, lead-zinc sulfide technology, applied in flotation, solid separation, etc., can solve the problems of ineffective recovery and waste of resources, and achieve the effect of reducing waste and improving mineral recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

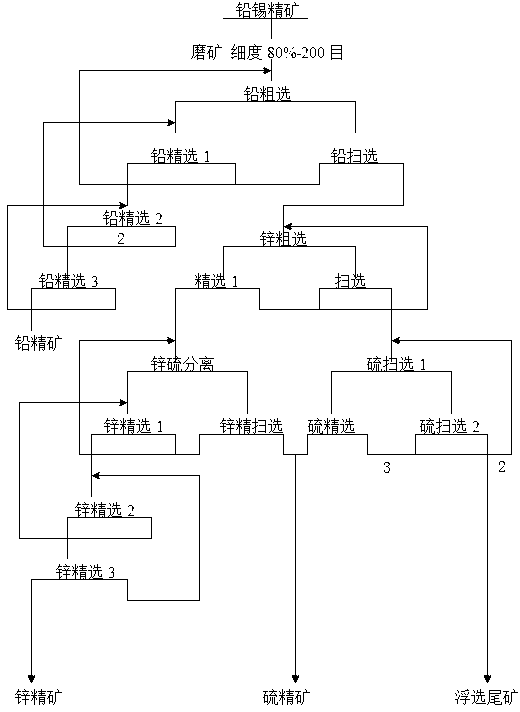

[0023] Embodiment 1: The flotation separation ore dressing method of lead-zinc-tin ore in this embodiment: (such as figure 1 shown)

[0024] (1) First crush the lead-zinc-tin ore (composition and percentage range: 2wt% lead, 3wt% zinc, 9wt% sulfur, 0.4wt% tin, and the rest are impurities) until the particle size is less than 15mm, and then add water to adjust the pulp concentration to 68wt% Finally, grind the ore, and add 20% lead-zinc-tin ore dry base in the process of grinding 200 on a dry basis of ethyl sulfur nitrogen, lead-zinc-tin ore lime to adjust the slurry pH to 11, and then add inhibitors zinc sulfate and sodium sulfite in sequence (the addition of zinc sulfate is 100% of the dry basis of lead-zinc-tin ore , the addition of sodium sulfite is 100% of the dry basis of lead-zinc-tin ore ), lead-zinc-tin ore dry basis 20 The foaming agent 730A is used to keep the pulp pH > 11, and finally the grinding fineness is over 200 mesh sieve to reach more than 80wt%;

...

Embodiment 2

[0031] The flotation separation ore dressing method of the present embodiment lead-zinc-tin sulfide ore: (as figure 1 shown)

[0032] (1) First crush the lead-zinc-tin ore (composition and percentage range: 2.5wt% lead, 3.5wt% zinc, 8wt% sulfur, 0.45wt% tin, and the rest are impurities) until the particle size is less than 15mm, and then add water to adjust the slurry concentration to Grinding after 70wt%, and in the process of grinding, add 100% lead-zinc-tin ore dry basis successively 1000 on a dry basis of ethyl disulfide nitrogen, lead zinc tin ore lime to adjust the pH of the slurry to 12, and then add inhibitors zinc sulfate and sodium sulfite in sequence (the amount of zinc sulfate added is 400% of the dry basis of lead-zinc-tin ore , the addition of sodium sulfite is 400% of the dry basis of lead-zinc-tin ore ), lead-zinc-tin ore dry basis 40 The foaming agent 730A is used to keep the pulp pH > 11, and finally the grinding fineness is over 200 mesh sieve to re...

Embodiment 3

[0039] The flotation separation ore dressing method of the present embodiment lead-zinc-tin sulfide ore: (as figure 1 shown)

[0040] (1) First, crush the lead-zinc-tin ore (composition and percentage range: lead 3wt%, zinc 3.1wt%, sulfur 7wt%, tin 0.6wt%, and the rest are impurities) until the particle size is less than 15mm, and then add water to adjust the slurry concentration to 60wt % after grinding, and in the process of grinding, add 80% lead-zinc-tin ore dry base successively 850 on a dry basis of ethyl disulfide nitrogen, lead zinc tin ore lime to adjust the pH of the slurry to 11.5, and then add inhibitors zinc sulfate and sodium sulfite in sequence (the addition of zinc sulfate is 300% of the dry basis of lead-zinc-tin ore , the addition of sodium sulfite is 200% of the dry basis of lead-zinc-tin ore ), lead-zinc-tin ore dry basis 70 The foaming agent 730A is used to keep the pulp pH > 11, and finally the grinding fineness is over 200 mesh sieve to reach mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com