Method for preparing nano metal or metal oxide/carbon nano-tube composite material

A technology of carbon nanotubes and composite materials, applied in the field of nanomaterials, can solve the problems of carbon nanotube electronic structure damage, low efficiency, cumbersome steps, etc., and achieve the effects of low cost, short process flow and huge application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

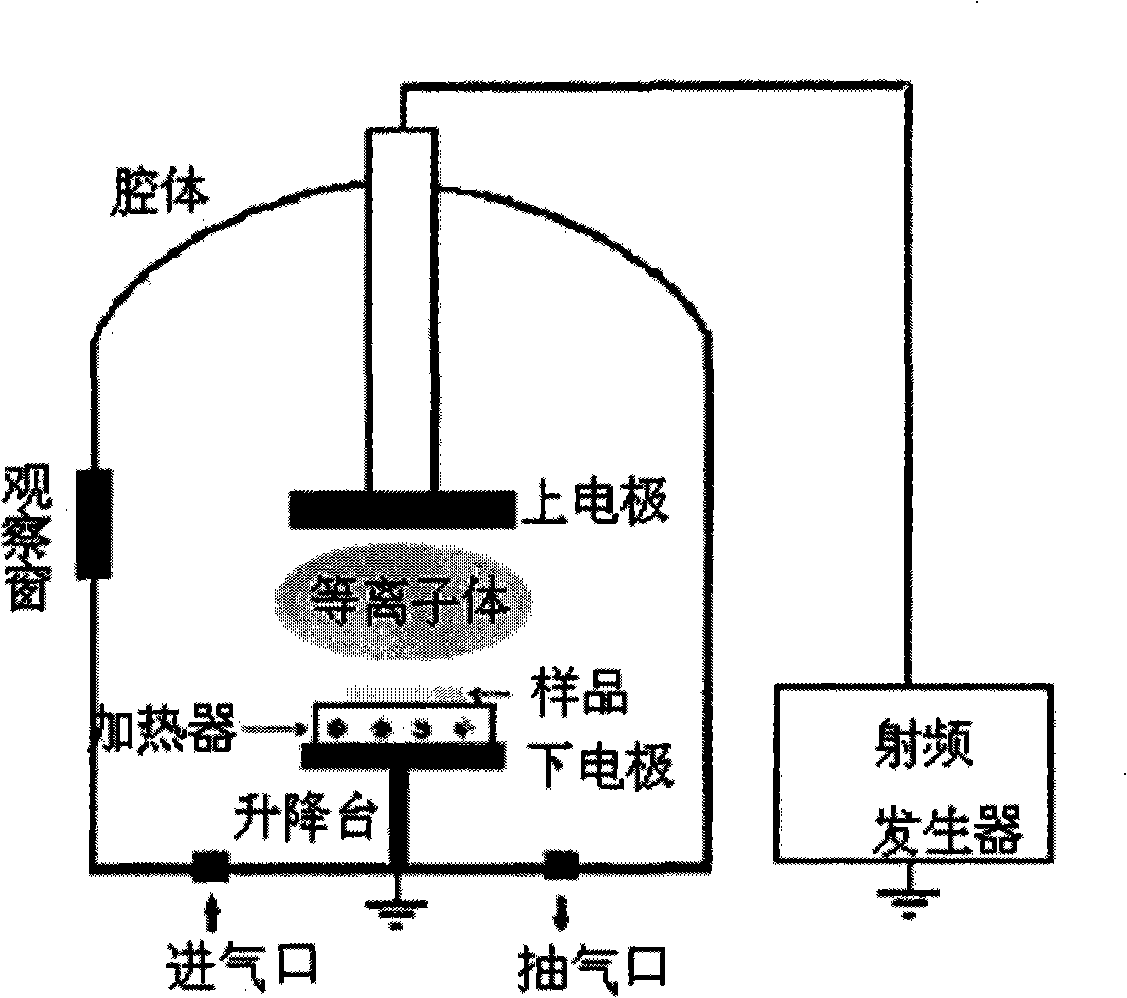

Method used

Image

Examples

Embodiment 1

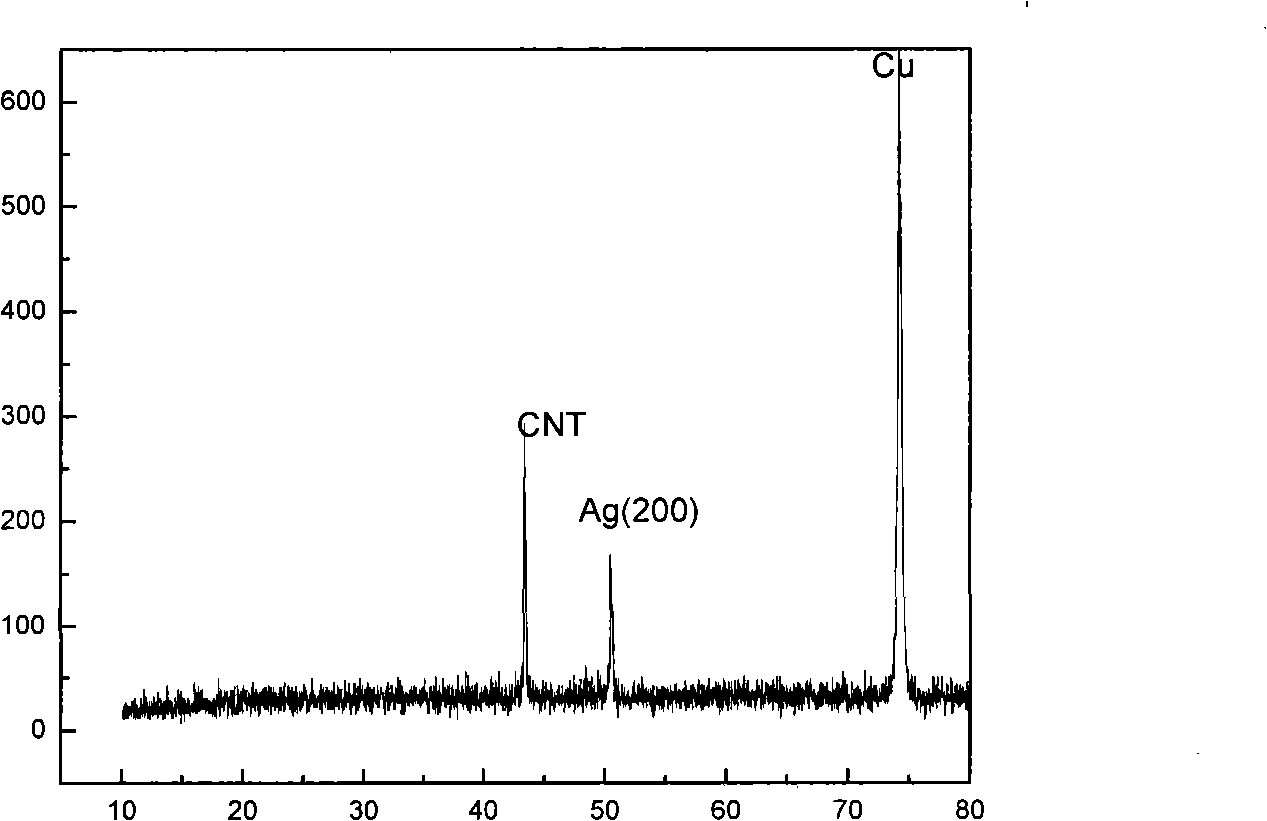

[0032] Carbon nanotubes were prepared by chemical vapor phase method. Pure carbon nanotubes were activated with hydrogen plasma in a radio frequency sputtering deposition furnace for 1 h. Then put the carbon nanotubes dispersed and deposited on the Cu grid in a thermal evaporation furnace, and use the thermal evaporation method to evacuate to 5×10 -3 Pa, the evaporation time is 2min. The Ag / CNT nanocomposite material with Ag nanoparticles deposited on the surface was obtained. figure 2 , image 3 , Figure 4 They are SEM pictures, XRD pictures and TEM pictures of Ag / CNT nanocomposites, respectively. Experiments have shown that a large number of strongly bonded Ag nanoparticles are deposited on the surface of carbon nanotubes.

Embodiment 2

[0034] The preparation and treatment of the carbon nanotubes were the same as in Example 1, and nano Cu was deposited on the carbon nanotubes by the radio frequency sputtering deposition method. The target material is made of high-purity Cu disk, and the vacuum is evacuated to 5×10 -3 Pa, argon gas was introduced, and the flow rate was 20 sccm. After the pressure in the reaction chamber was stabilized at 2 Pa, the RF power was turned on and the power was adjusted to 200 W to generate plasma. The coating time was 7 minutes. After cooling to room temperature, the samples were taken out, and part of the samples were placed in the air for heat treatment for 2 hours, the heat treatment temperature was 400°C, and the condition was air.

[0035] Figure 5 , Figure 6 SEM photos and TEM photos of Cu and carbon nanotube composites obtained by vapor deposition for 7 minutes. The results show that a large number of Cu particles are wrapped around the surface of the carbon nanotubes to...

Embodiment 3

[0037]15 mg of carbon nanotubes activated by hydrogen plasma as described in Example 1 were ultrasonically dispersed in 80 ml of absolute ethanol aqueous solution (volume ratio 1:1), and 20 ml of zinc acetate solution (0.02 mol / l) was added, and magnetically stirred Finally, add 50% ammonia water until the pH value of the solution is 8-11, filter after fully stirring, disperse the solid phase in 100ml water, and adjust the pH value of the solution with ammonia water. The above reactant was sealed in a polytetrafluoroethylene-lined reaction kettle, stood at 200°C for 10h, and then rapidly cooled to room temperature, the product was washed and filtered with deionized water, and dried at 80°C. In the absence of carbon nanotubes, nano-zinc oxide particles were prepared in the same process with 10 ml of the above-mentioned zinc acetate solution, as Figure 9 . The prepared samples were then subjected to alkaline blue photocatalytic degradation experiments, such as Figure 10 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com