Process for preparing silver tin oxide material

A technology of silver tin oxide and internal oxidation, applied in the field of preparation of silver tin oxide materials, can solve problems such as unfavorable electrical properties of materials, product size, limitation of tin oxide content, etc., and achieve the effects of improved comprehensive performance, firm bonding and sufficient oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

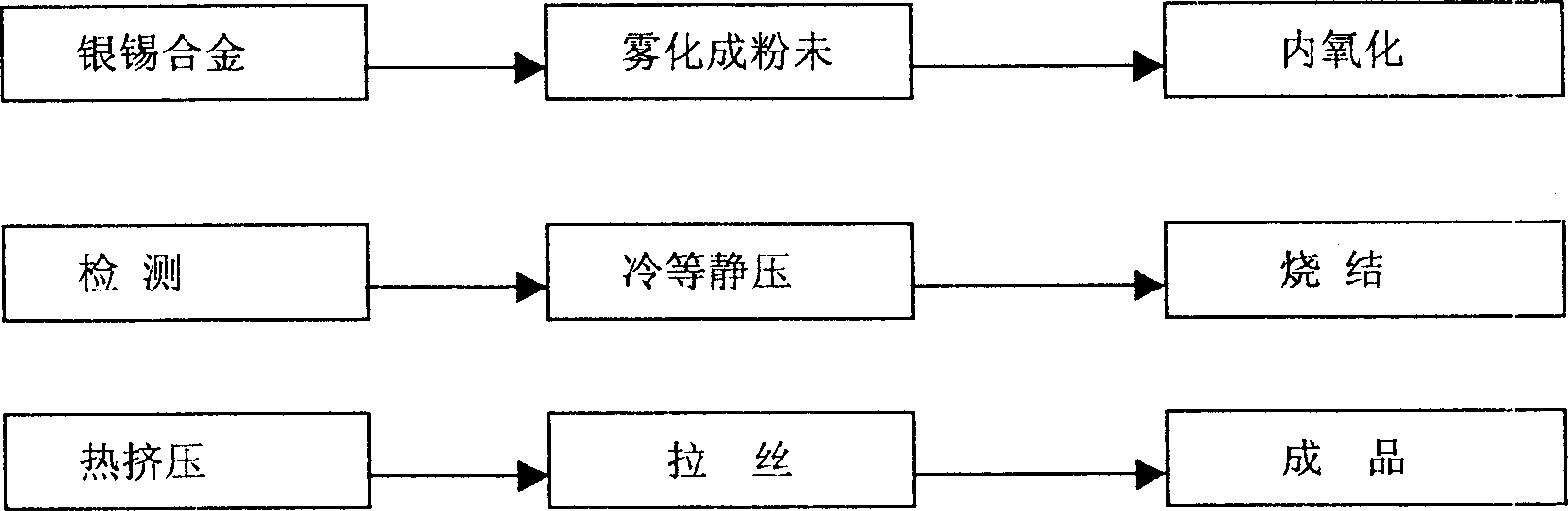

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Take 8.9 kg of silver and 1 kg of tin, place them in an intermediate frequency furnace and smelt them into a liquid state, then use high-pressure water atomization equipment to atomize the alloy, and the atomized liquid particles are dried into alloy powders, and after screening, Put the powder with a particle size of 150 mesh to 300 mesh into the internal oxidation furnace for oxidation. During oxidation, the temperature is controlled at 500 ° C, and the oxygen pressure of 0.8 is maintained. After oxidation for 2 hours, it is taken out. After the test meets the requirements, the cold isostatic pressing process is used. The pressure is set to 1800Kg / cm 3 . It is processed into a billet in a special pressure equipment, and then sintered in the equipment at a temperature of 750 ° C for 5 hours, taken out and extruded into wire, and then drawn to obtain the finished product.

Embodiment 2

[0013] Example 2: Take 14 kg of silver and 1.1 kg of tin, place them in an intermediate frequency furnace and smelt them into a liquid state, then use high-pressure water atomization equipment to atomize the alloy, and the atomized particle liquid is dried into alloy powder, and after screening, the Put the powder with a particle size of 150 mesh to 300 mesh into the internal oxidation furnace for oxidation. During oxidation, the temperature is controlled at 700 ° C, and the oxygen pressure of 1.2 is maintained. After oxidation for 2.2 hours, it is taken out. After testing and meeting the requirements, the cold isostatic pressing process is used. The pressure is set to 2500Kg / cm 3 . It is processed into a billet in the special pressure equipment, and then sintered in the equipment at a temperature of 800°C for 6 hours, taken out and extruded into wire, and then drawn to obtain the finished product.

Embodiment 3

[0014] Example 3: Take 12 kg of silver and 1.1 kg of tin, place them in an intermediate frequency furnace and smelt them into a liquid state, then use high-pressure water atomization equipment to atomize the alloy, and the atomized liquid particles are dried into alloy powder, and after screening, Put the powder with a particle size of 150 mesh to 300 mesh into the internal oxidation furnace for oxidation. During oxidation, the temperature is controlled at 800 ° C, and the oxygen pressure of 1.4 is maintained. After 3 hours of oxidation, it is taken out. After testing and meeting the requirements, the cold isostatic pressing process is used. The pressure is set to 2800Kg / cm 3 . It is processed into a billet in the special pressure equipment, and then sintered in the equipment at a temperature of 850 ° C for 6.5 hours, taken out and extruded into wire, and then drawn to obtain the finished product.

[0015] The performance indicators of the finished product made by the present...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com